Used AMAT / APPLIED MATERIALS 7800 #9095974 for sale

URL successfully copied!

Tap to zoom

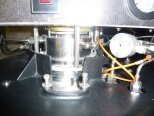

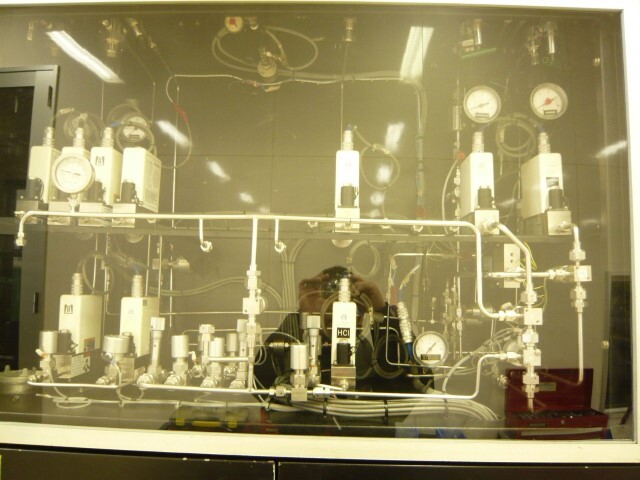

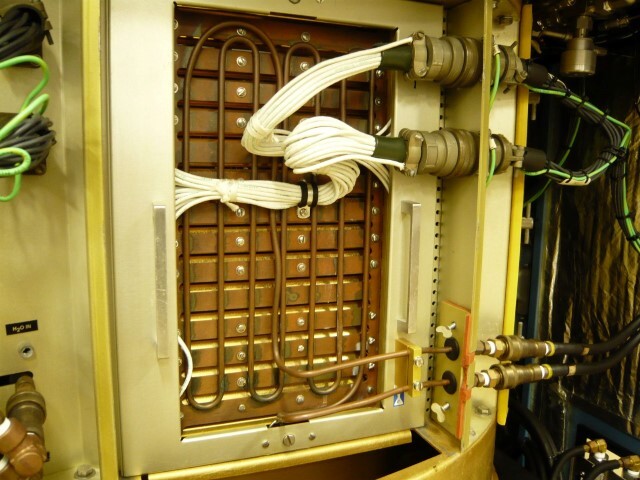

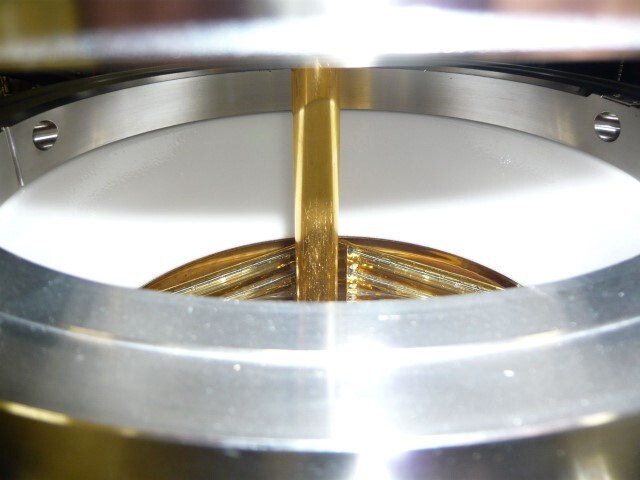

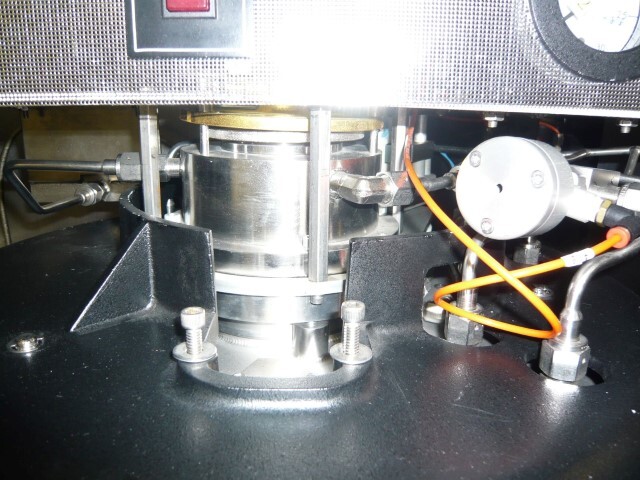

AMAT / APPLIED MATERIALS 7800 is a multi-purpose deposition equipment used in a variety of thin film processes. It is built with a wide range of features designed to support a large array of film growth requirements. AMAT 7800 is a reactive-ion plasmachemical-vacuum deposition tool. It is designed to deposit high-quality films and structures, as well as the etching of features. APPLIED MATERIALS 7800 serves a number of industries such as the disk drive, graphic display, IC packaging, display, and photovoltaic applications. 7800 includes a DC magnetron sputtering source, capable of producing a high power single-frequency sputtering discharge for thin film deposition. It has a wide range of process gas options which can be introduced into the chamber in order to help produce an array of films, including oxides and other high dielectric materials. The Applied Material AMAT / APPLIED MATERIALS 7800 features a low-pressure plasma source and a quadra-arm quartz antenna system that produces ions and accelerates them across the chamber, providing uniformity across substrates or film thickness and etching of features. It is also equipped with a high-voltage 'Pulse RIE' source capable of producing high-paramagnetic layers for magnetic media applications. The deposition unit is equipped with two arm-mounted electrostatic wafer chucks, allowing uniform coverage across the wafers. In addition to the uniform deposition, this tool supports edge beveling, oxide dip coat processing, patterned etching, and other unique features in order to provide superior process uniformity. AMAT 7800 offers outstanding process control and repeatability through its software and programming feature. The machine is capable of controlling of up to 40 process parameters across substrates and target materials for maximal film deposition, deposition uniformity, and process performance. In sum, APPLIED MATERIALS 7800 provides the most reliable and effective process control available in the market and is designed to be used for a variety of thin film growth applications. It is a great choice for those looking to deposit high-quality films and structures with repeatable precision and dependable performance.

There are no reviews yet