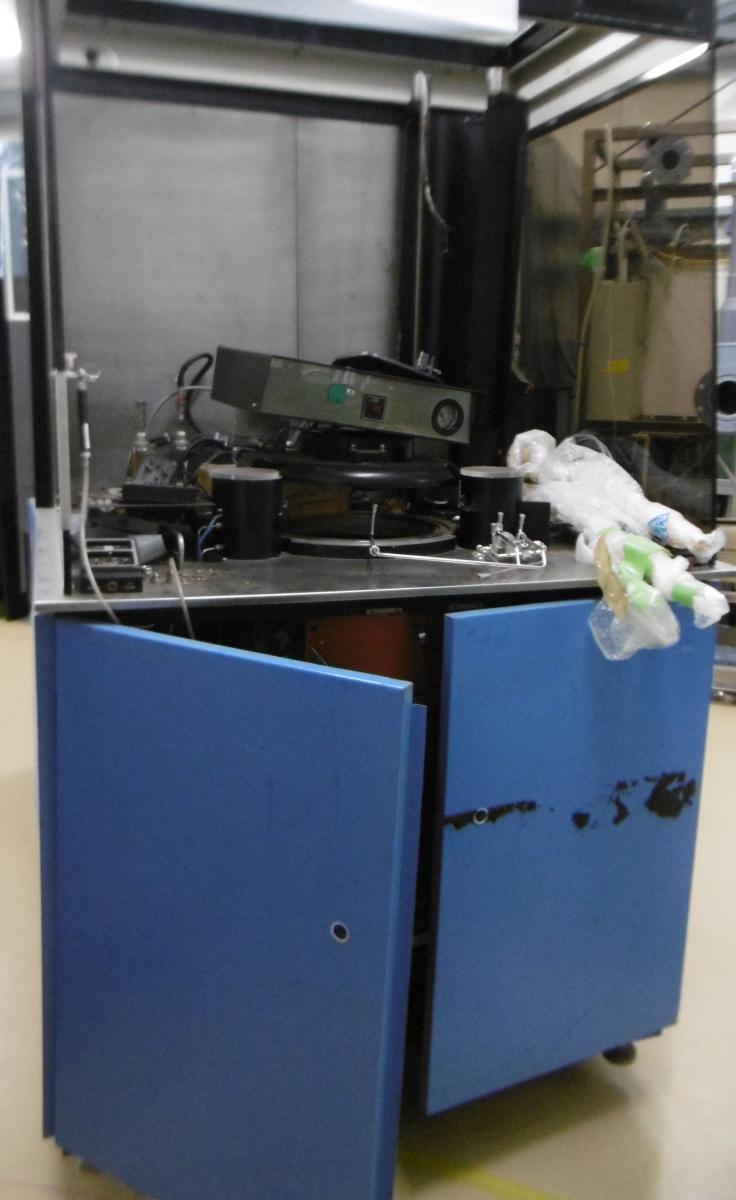

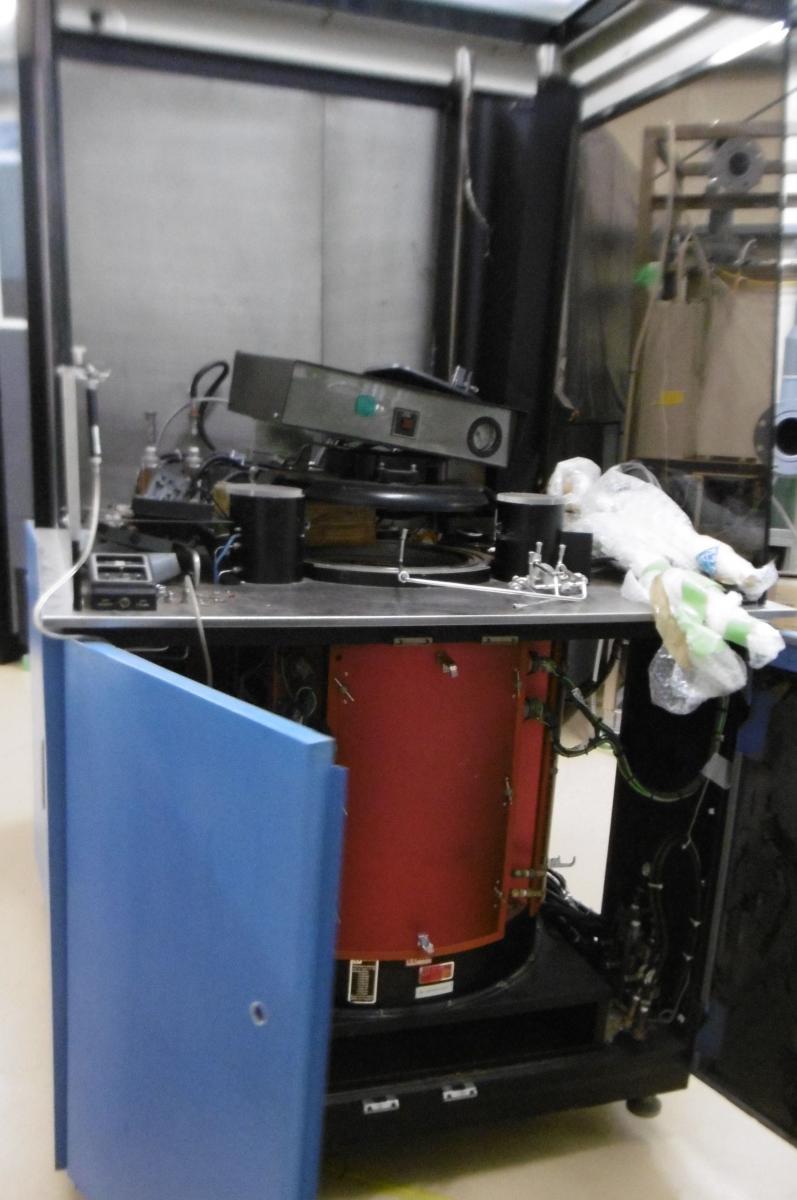

Used AMAT / APPLIED MATERIALS 7811 #9095878 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS 7811 is a multi-chamber, high-temperature vacuum furnace designed to perform various high-temperature thermal processing operations for semiconductor fabrication. The instrument is equipped with several heating elements to produce temperatures up to 1400 °C which can be accurately regulated over a range of ±2.5 °C by computer control. This advanced tool is composed of a main reaction chamber with an auxiliary lower chamber (the process tool) connected by a movable door to provide access to the wafers during substrate transfer and loading operations. The reaction chambers are kept under a constant atmosphere of nitrogen while the process tool is typically filled with argon. The furnace is also provided with a gas injection equipment which is capable of providing various precursor gas mixtures to the process chamber; enabling processes such as deposition, oxidation, annealing, and notching. AMAT 7811 includes an advanced heating system with several elements located both inside and outside the reaction chamber. This unit features an independent principal zone, as well as adjustable pre- and post-heaters, giving the instrument a total of three heating zones. This allows for precise temperature management and an even heating of wafers and processes. The tool is also fitted with a quartz viewport, which provides a direct view of the wafer's progress by allowing visual access to the heating chamber. The instrument is equipped with multiple alarms and safety devices to ensure the safety of the operator and the equipment. Among these safety devices is a lid cover and a backplane to prevent accidental exposure to high temperatures. APPLIED MATERIALS 7811 also includes two independent vacuum pumps, enabling both large scale and small scale processing operation. 7811 is a highly advanced tool for high-temperature thermal processing operations and is an integral part of most semiconductor fabrication processes. With its in-chamber and adjustable heating elements, well-designed gas injection machine, multiple alarms and safety devices, and its quartz viewport tool, the instrument provides reliable and repeatable results, making it an excellent choice for any semiconductor fabrication process.

There are no reviews yet