Used AMAT / APPLIED MATERIALS / AKT 3500 SC PECVD #9011154 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9011154

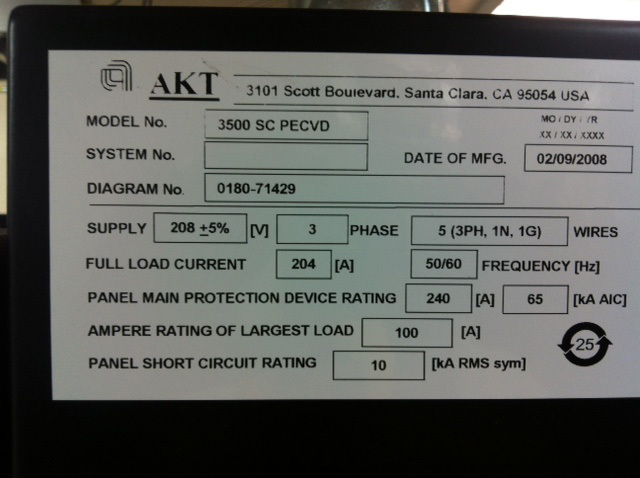

Vintage: 2008

PECVD system

Supply: 208 ± 5%, 3 phase, 5 wire

Full load current: 204 A, 50/60 Hz

Panel main protection device rating: 240 A, 65 kA AIC

Ampere rating of largest load: 100 A

Panel short circuit rating: 10 kA RMS sym

2008 vintage.

AMAT / APPLIED MATERIALS / AKT 3500 SC PECVD is a next-generation production reactor designed to produce very thin films of dielectric and other materials. This reactor utilizes a process called Plasma Enhanced Chemical Vapor Deposition (PECVD) to create a high-quality, low-cost film on substrates such as glass, plastic, and metal. The reactor is equipped with a low-pressure plasma chamber, and is divided into four distinct chambers for vacuum and chemical reactions. It also contains deposition sources for phosphorous and nitrogen, allowing users to deposit films such as silicon oxide. The plasma chamber is equipped with a Freon RF source, enabling a low deposition temperature to ensure excellent film properties and substrate compatibility. The total chamber volume also reduces voids in the film, meaning that even when thin films are deposited, the film can provide excellent electrical properties for optimal performance. The reactor features an innovative, integrated, fully-controlled source gas delivery equipment, allowing users to customize the film precursors for varying applications. This system is also designed to maximize gas utilization and lower process costs. In addition, the reactor includes an automated cleaning sequence to remove organic material, providing clean, dry process chambers for repeatable process runs with uniform films. AKT 3500 SC PECVD is capable of producing thin films with a minimum thickness of 0.2 microns. The reactor is also equipped with a reactive gas injection unit that allows for precise control of deposition parameters, including film optical density and composition. This machine maximizes film quality and improves film uniformity across the substrate. Overall, AMAT 3500 SC PECVD is an advanced production reactor that is designed to create high-quality thin film deposition with improved uniformity, thickness, and electrical properties. This reactor utilizes advanced technologies to reduce emissions and costs, allowing for wider production capabilities. Thanks to its automated systems and precise source control, the reactor offers a reliable, efficient, and cost-effective solution for thin film deposition processes.

There are no reviews yet