Used AMAT / APPLIED MATERIALS AKT-55k #9237806 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9237806

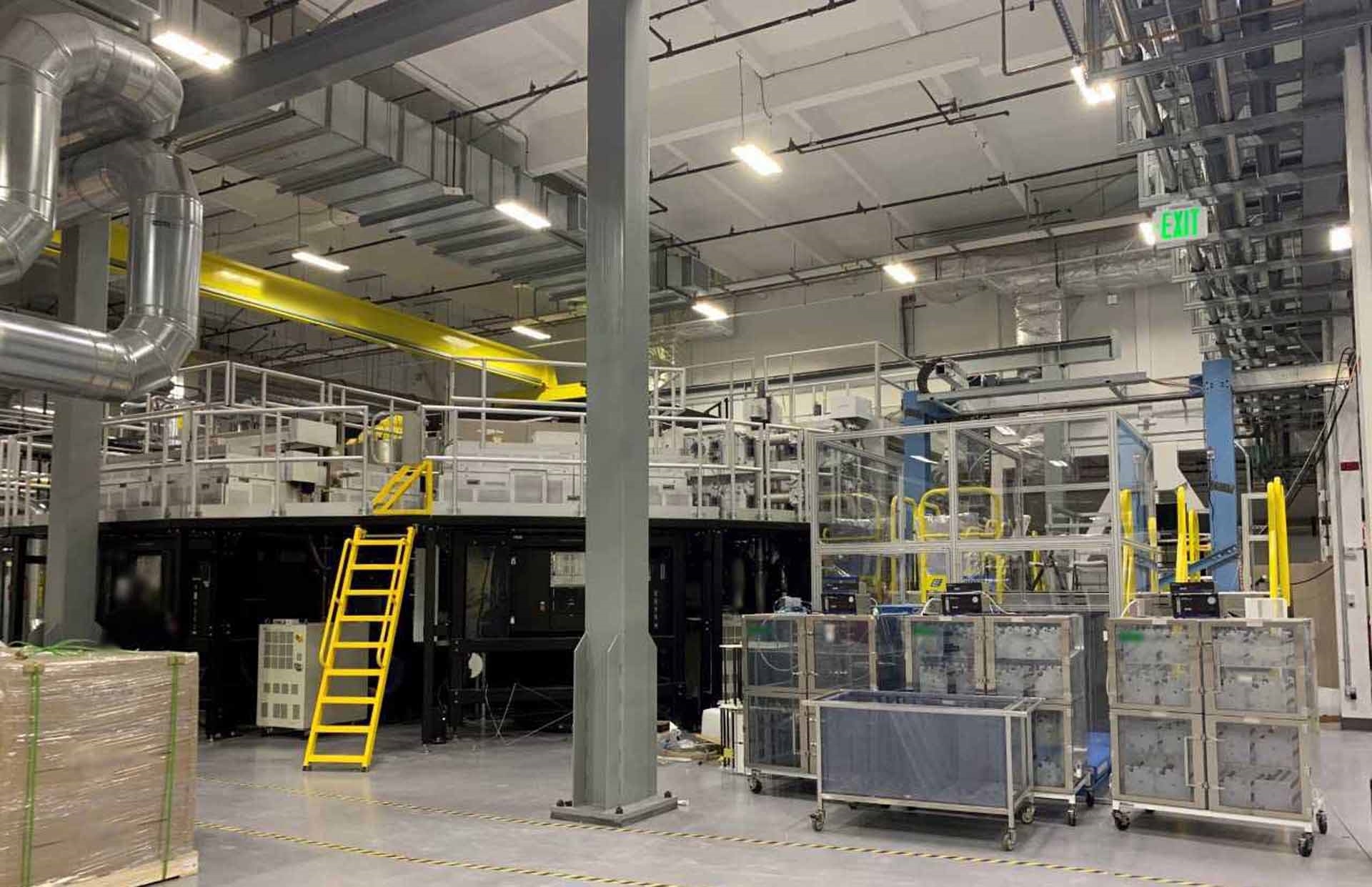

PECVD System

Generation: 8.5

Dual single slot loadlock (Loading, cooling, unloading)

Transfer chamber

(3) Process chamber

Master cluster controller

Remote support system:

RF Generator

Pump

Abatement

Heat exchanger

Remote plasma

Substrate size: 2200 mm x 2600 mm

(3) Susceptor: Temperature<230°C

(2) Loadlock: DSSL

Vacuum robot: Dual arm

(3) RPSC: MKS

(3) Abatement

EDWARDS Pumps:

(7) iH1800

(3) iF30K

RF Generator:

(3) 13-14MHz (15kW)

(4) 40MHz (4kW)

(3) Gas panels: NF3, Ar, SiH4, H2, PH3, B2H6

Loader: Manual loader.

AMAT / APPLIED MATERIALS AKT-55k reactor is an industrial grade reactant chamber designed to facilitate the synthesis of various compounds in controlled reactor settings. It is a sealed vessel in which various reaction conctants are mixed and reacted to form new chemical compounds, and is capable of sustaining temperatures up to 1,000°C. The chamber consists of several modularized components, including a cold outer wall, reaction chamber, and active parts. The cold outer wall is a double-walled shell made from stainless steel that serves as the non-reactive enclosure for the entire unit. Within the outer shell is the reaction chamber, where the reaction process takes place. The chamber is refractory lined and designed to hold up to 55 kilograms (kg) of material. The active parts of the reactor consist of a gas handling equipment, temperature control system, pressure control unit, and fluid transfer machine. The gas handling tool uses natural gas as a fuel source to generate the required temperatures, while the temperature control asset optimizes temperatures to meet the desired reaction conditions. Similarly, the pressure control model manages the pressure levels inside the reactor, and the fluid transfer equipment manages the material that is fed into the reactor. The system is also fitted with a series of safety features to ensure optimal performance and safety of personnel and equipment. An explosion-proof Flame Arrestor prevents explosions from occurring inside the vessel. A pressure relief valve is also included in the unit to vent off excess pressure in the event of a reaction runaway. An inert gas supply line is also included to prevent reactive materials from causing hazardous reactions. The reactor is ideal for a range of different applications including chemical synthesis, metallurgical or chemical plant operations, petrochemical refining, and the testing and characterization of new materials. This affordably priced device provides efficient and controlled performance and can be integrated into a variety of industrial operations.

There are no reviews yet