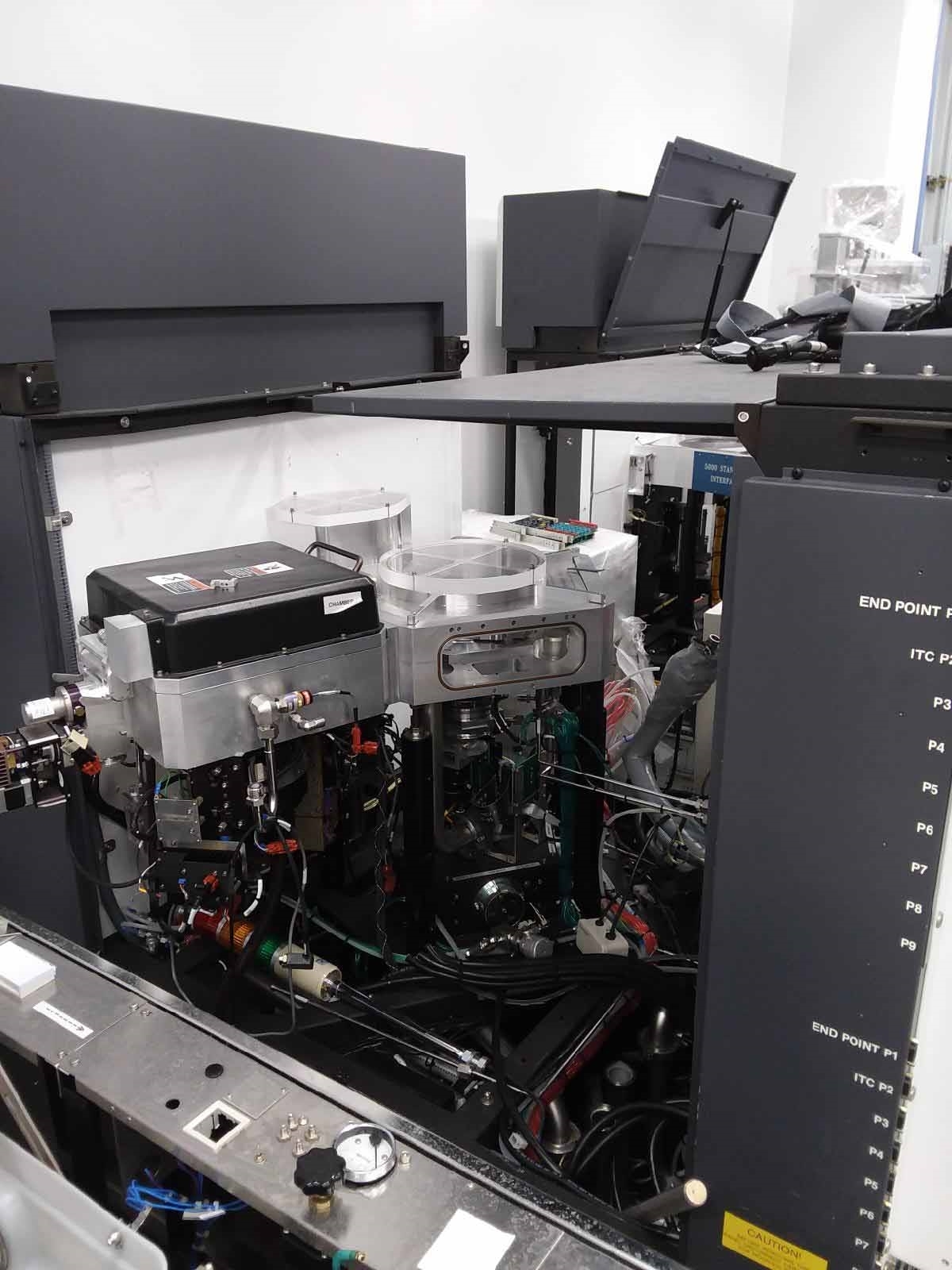

Used AMAT / APPLIED MATERIALS P5000 #9203417 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

AMAT / APPLIED MATERIALS P5000 reactor is a multi-purpose, production-scale etcher and deposition tool. It is an advanced vacuum processing system ideal for creating state-of-the-art thin-film components and devices. AMAT P-5000 is constructed with a tubular-shaped, single-walled stainless steel chamber, providing robust reliability and ease of installation. It stands at 156.5 cm in height and is located inside a double-walled stainless steel enclosure with a 20-inch closing diameter and a pressure capability of up to 6 torr. The chamber itself has a standard pumping speed of 106 l/s and a volume of 187 liters. APPLIED MATERIALS P 5000 is composed of polysilicon, titanium silicide, and silicon nitride materials. APPLIED MATERIALS P-5000 utilizes two primary imaging configurations; the circular-view image processor and the plan-view image processor. The circular-view processor is designed for wafer etching and other patterning processes, while the plan-view processor allows for the complete substrate deposition process. Both processors rely on dual-source illumination, allowing for a detailed imaging of the entire chamber. P-5000 is powered by two FM-300 electronic power supplies, with a range of up to 800 watts and a precision regulation of 1%. High-end capacitors and rotameters allow for precise control of the etching and deposition rates. AMAT / APPLIED MATERIALS P-5000 utilizes an all-around vacuum sealing system, comprising a combination of gas baffles, heated slides, heaters and resistors, and special cryo-coolers. This seals all process components, eliminating potential leakage points, and allows for reliable pulsed etching up to 800W. The system is installed in a modern cleanroom and offers excellent contamination control, with potential minimum flow rates of 3ppb of particles at a rating of 0.5 microns. An independent load-lock chamber provides excellent wafer processing, while the easy-to-use graphical user interface allows for quick and efficient operation. P 5000 is designed to meet the highest standards for quality assurance and production efficiency, offering much better yields and reduced defects for large-scale production. Its advanced reactor design provides excellent control, reliability and performance, making it one of the most reliable tool sets in its class.

There are no reviews yet