Used AMAT / APPLIED MATERIALS AMP-3300 #9201707 for sale

URL successfully copied!

Tap to zoom

ID: 9201707

PECVD System

Silicon nitride / silicon dioxide dielectric films: Plasma-enhanced chemical vapor deposition system

Low-temperature

Four controlled process

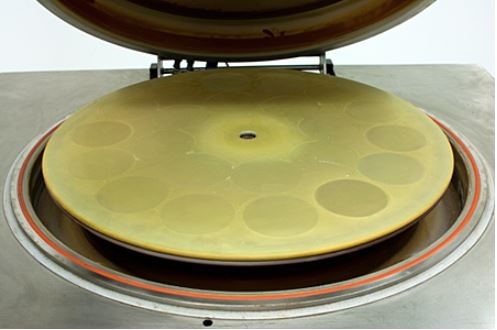

With reactor process chamber:

Radio frequency (RF) power

Chamber pressure

Chamber temperature / Gas flows

Plasma energy field is generated by RF power in the process chamber

Evacuated with a vacuum roughing pump / Motor-driven roots blower

Screwless electrode

Dual gas manifold

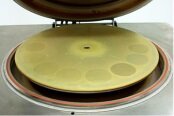

42 Pieces of 3-inch wafers

22 Pieces of 4-inch wafers

16 Pieces of 5-inch wafers

Deposition Rate: 300 A/Min

Temperature capability: Up to 300°C

RF Power: Up to 1500 W

Process Gases:

Oxide deposition: N2O & SiH4

Nitride deposition: SiH4, NH3, N2

Controller with real time process data collection / Control

User access: Password control

Complete system / Process parameters: Customer programming recipe

Process parameters recorded on system computer

Power Supply: Closed-loop RF

Water Pressure: 30-80 psig

Standard flow at 3 gpm (11.4 liters/minute) filtered to 100 to 125 microns.

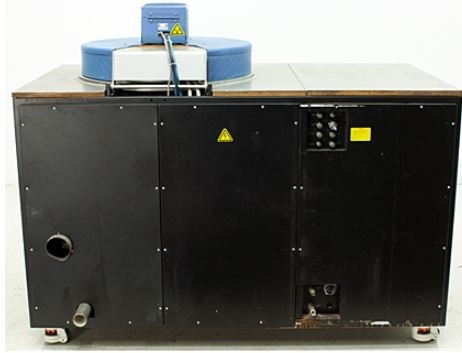

AMP-3300, 68″

Dimensions:

Width: 173 cm x 37″

Depth: 93 cm x 51″

Height: 129 cm

Water temperature:

Maximum inlet temperature: 77 F (25°C)

Minimum: 68 F (20°C).

Water resistivity: >20,000 ohms cm

Ambient air relative humidity: 40% or less

Process gases:

N2 at 30 psig

Delivered at 20-30 psig

N2 Pump purge: 30 Liters / Minute at psig to dilute residual reactant gases

Pneumatic air: 80-100 psig

Exhaust: 2-1/8-inch (54 mm) O.D.

Mechanical pump with proper purging to dilute residual reactant gases

Power:

208 VAC +/-5%, 3 Ph, 80 Amps, 60 Hz, 5-wire wye

380 VAC +/-5%, 3 Ph, 50 Amps, 50 Hz, 5-wire wye.

AMAT / APPLIED MATERIALS AMP-3300 reactor is a equipment designed to perform thermal and physical vapor deposition (PVD) processes. It has a unique combination of a large-area, rapid thermal processing (RTP) chamber, a vacuum transfer chamber, and a wafer carrier system. The RTP chamber is used to rapidly heat and cool wafers during deposition. It operates in the range of up to 600°C and has a temperature set-point accuracy of +/- 0.5°C. The vacuum transfer chamber enables wafers to be transferred into and out of the RTP chamber in a vacuum. The wafer carrier systems provide precise control of the wafer loading and unloading process. AMAT AMP-3300 also has an advanced control unit. This ensures predictable and repeatable process results. It has a plasma-treatment module, which can be added to the standard package to further improve the fabrication process. This module has the capability to clean hard surfaces, etch and/or activate them. It allows for higher deposition rate and improved wafer uniformity. When depositing materials onto wafers, APPLIED MATERIALS AMP 3300 is capable of delivering uniform layers across the entire wafer. It also has a low-VOC emission machine, which reduces the off-gasses released by the process. Using AMP 3300 for processes in the semiconductor fabrication industry is easy. Its powerful control tool allows the user to customize the settings for each process. Furthermore, its high-quality optical components allow the user to monitor the process in real-time. In conclusion, AMAT AMP 3300 is an efficient and reliable tool that is a great solution for PVD processes in the semiconductor fabrication industry. It has a high-precision positioner, allowing for accurate deposition sequences across the entire area of the wafer. Its plasma-treatment module increases the process speed and reduces wafer uniformity of the results. In addition, the powerful control asset ensures that each process is precisely tuned for the desired results.

There are no reviews yet