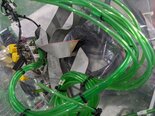

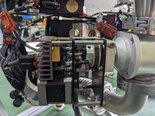

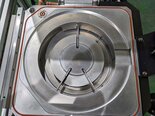

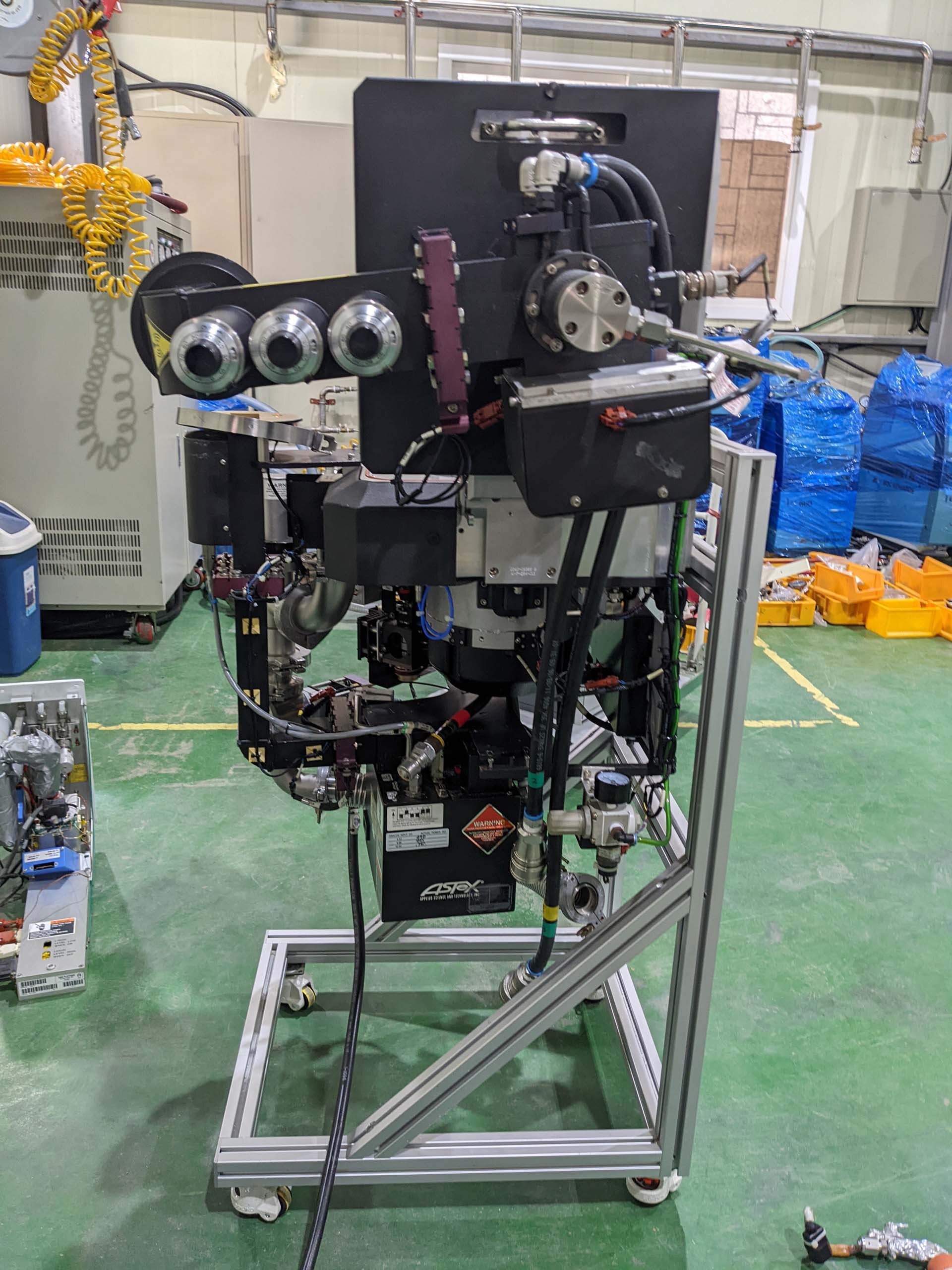

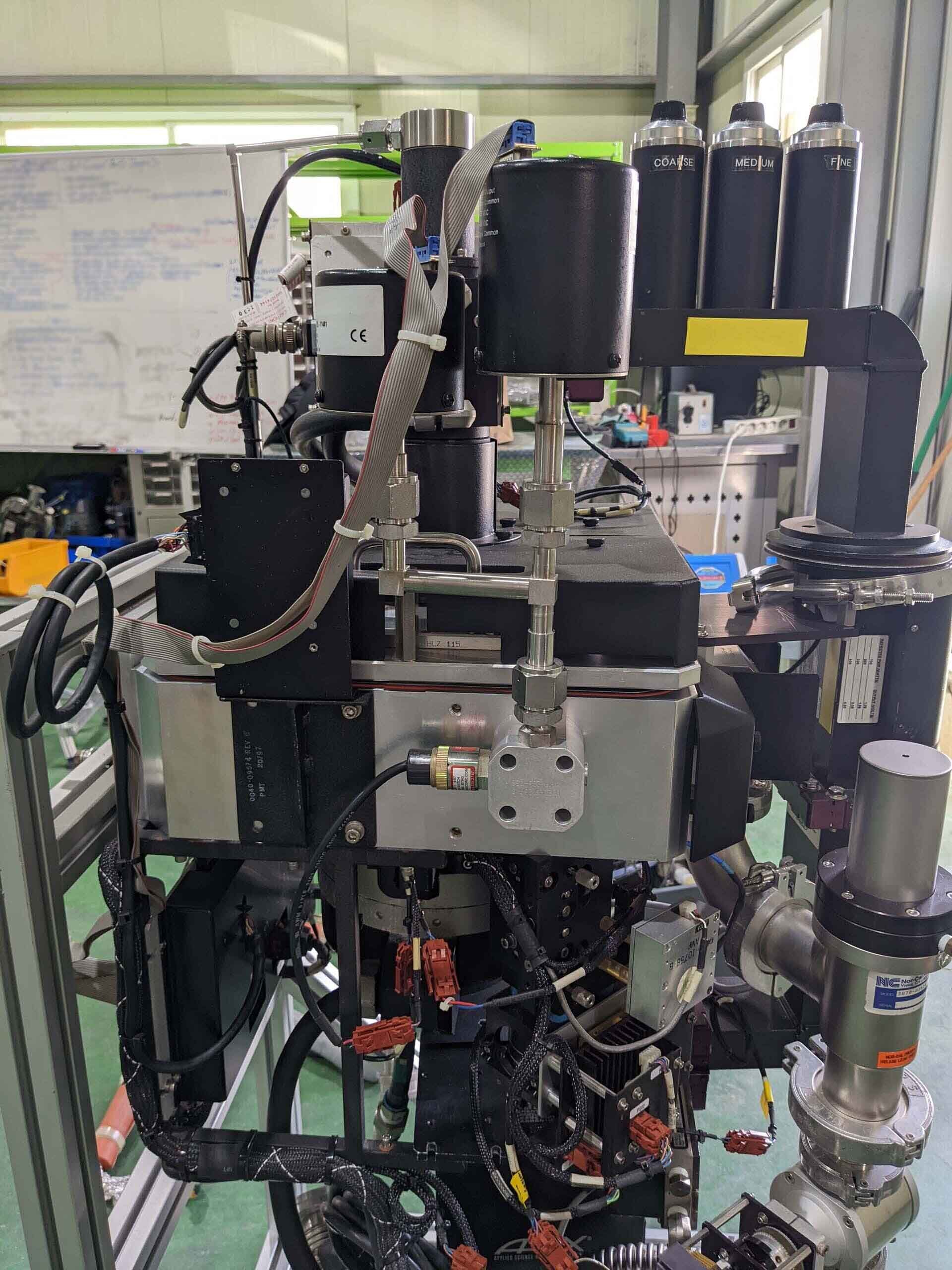

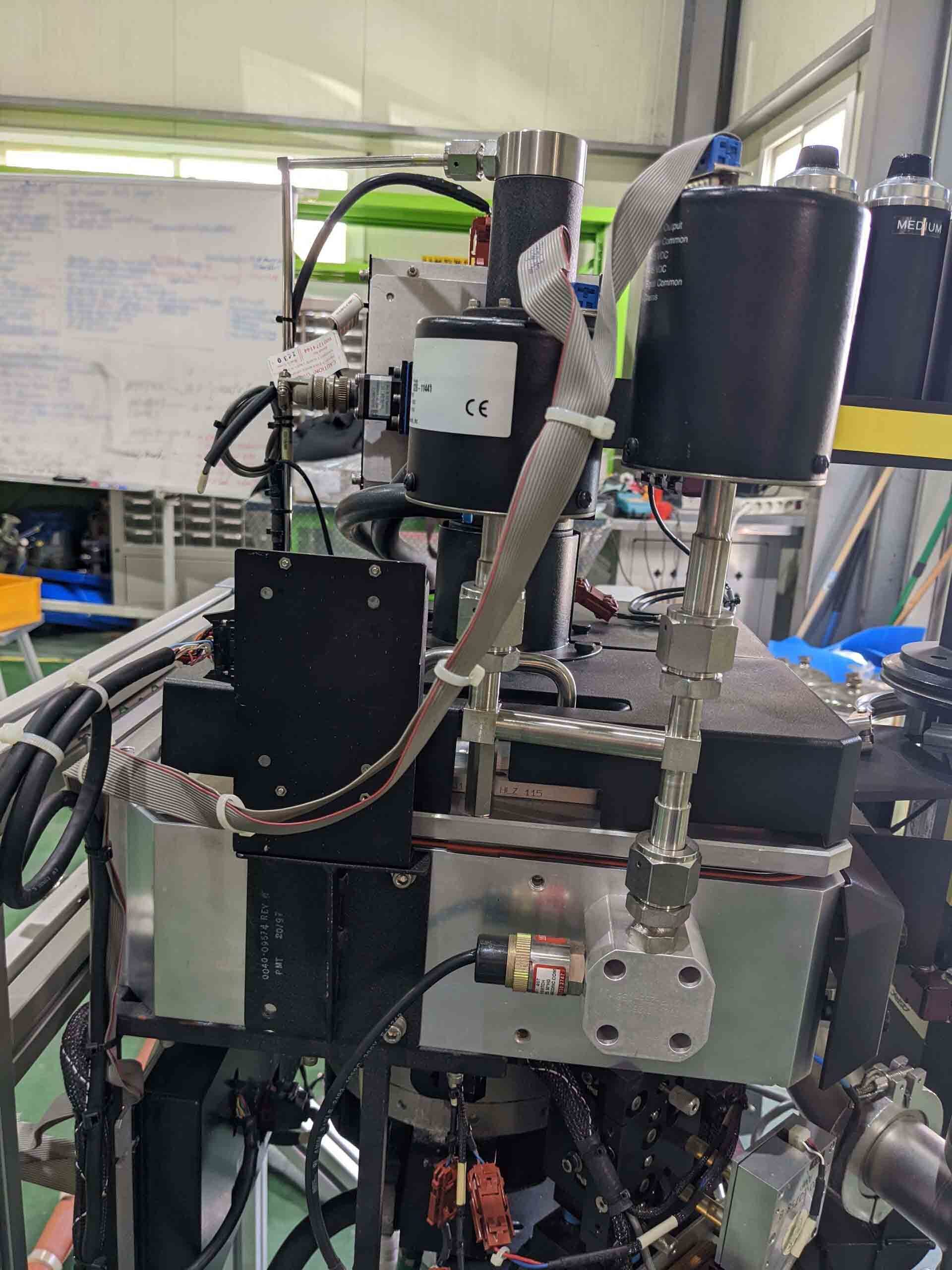

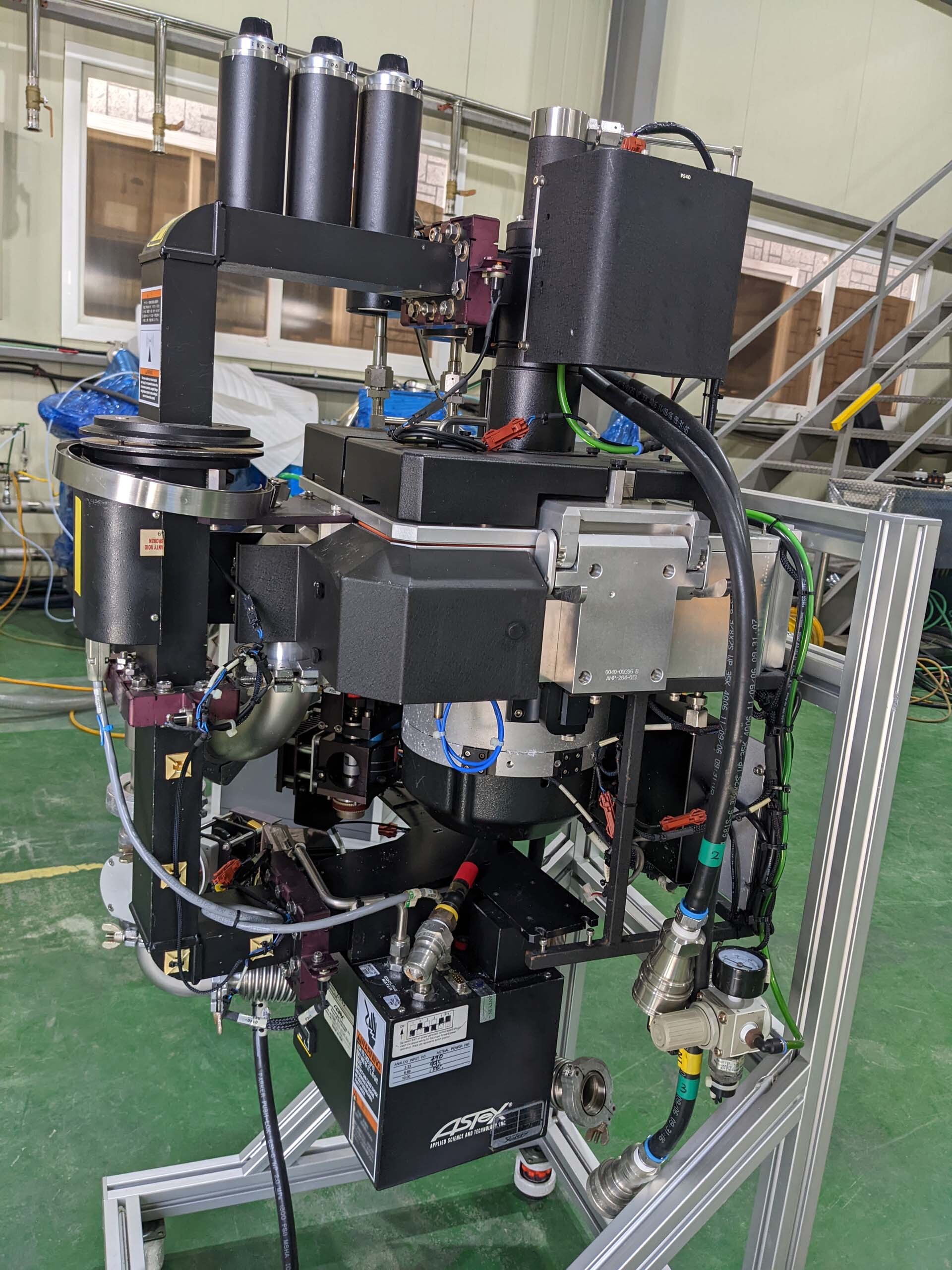

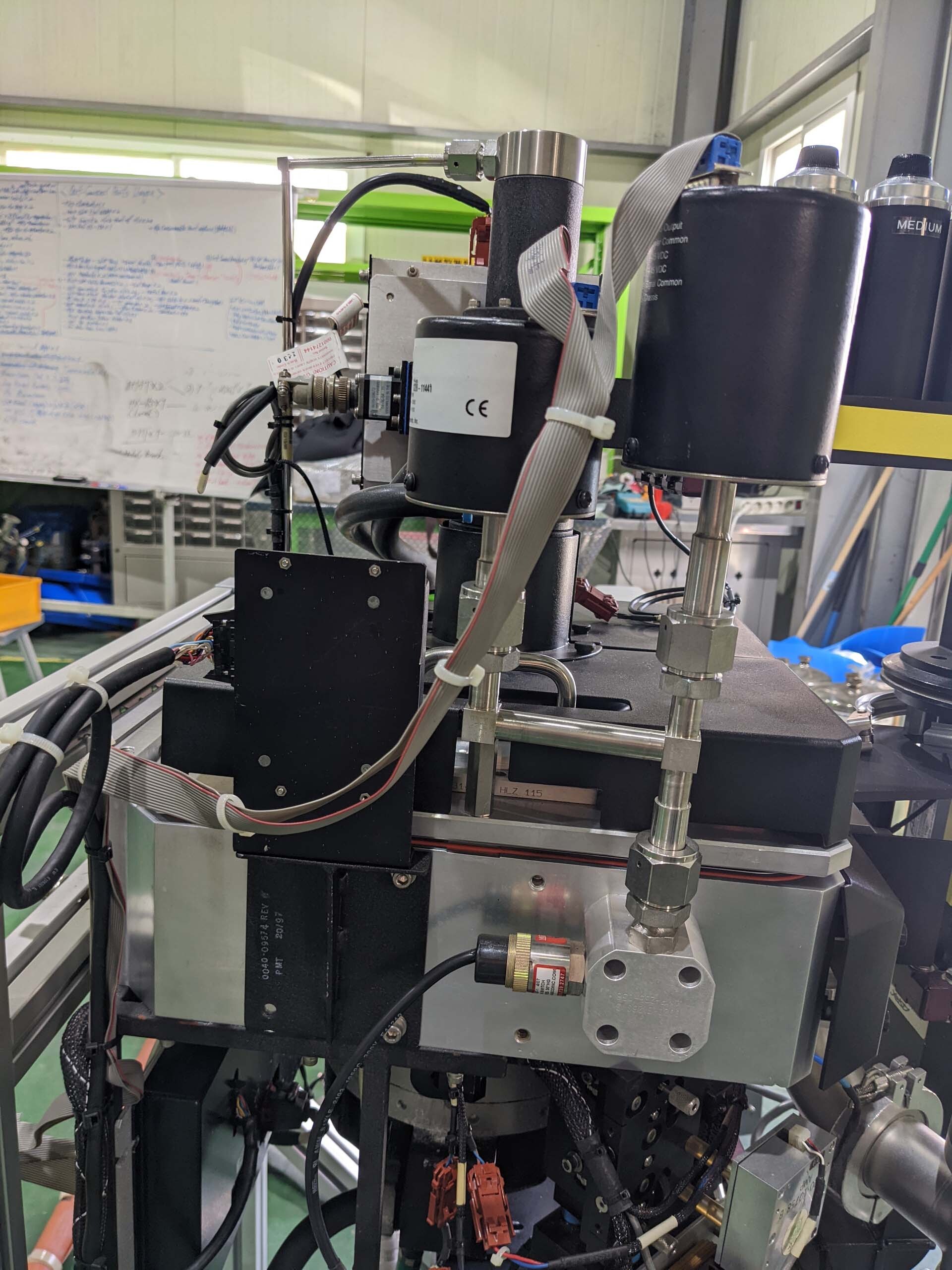

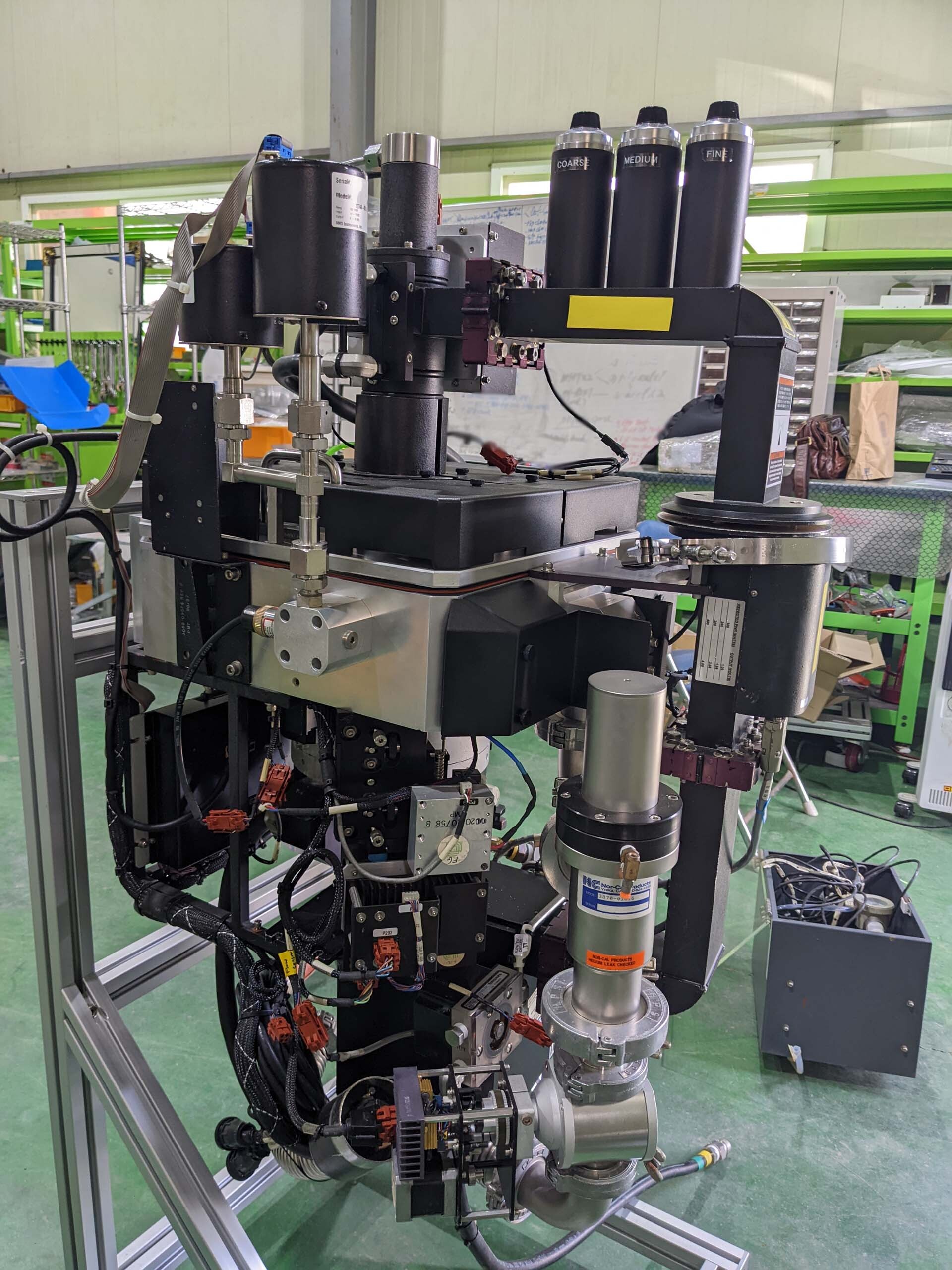

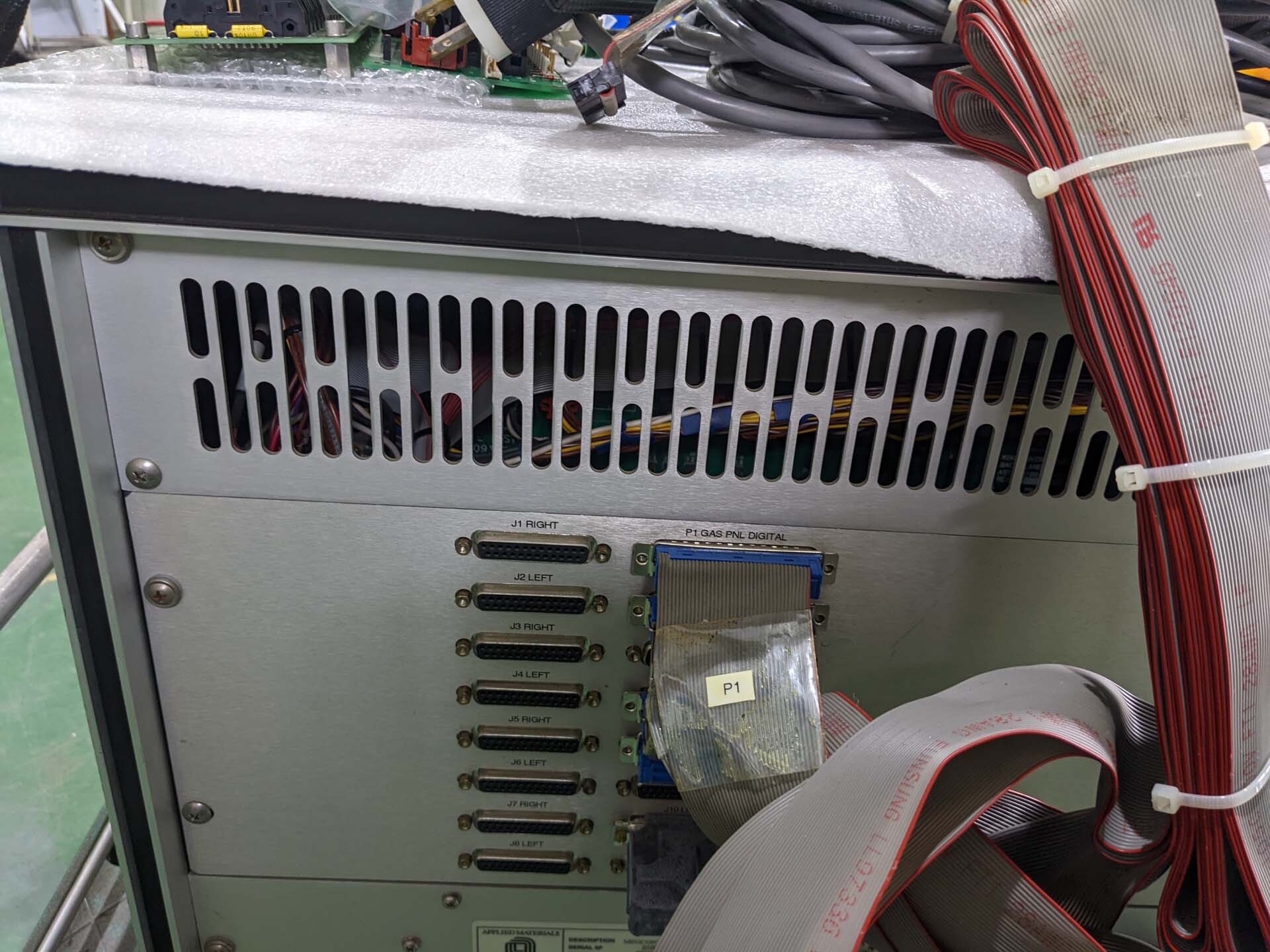

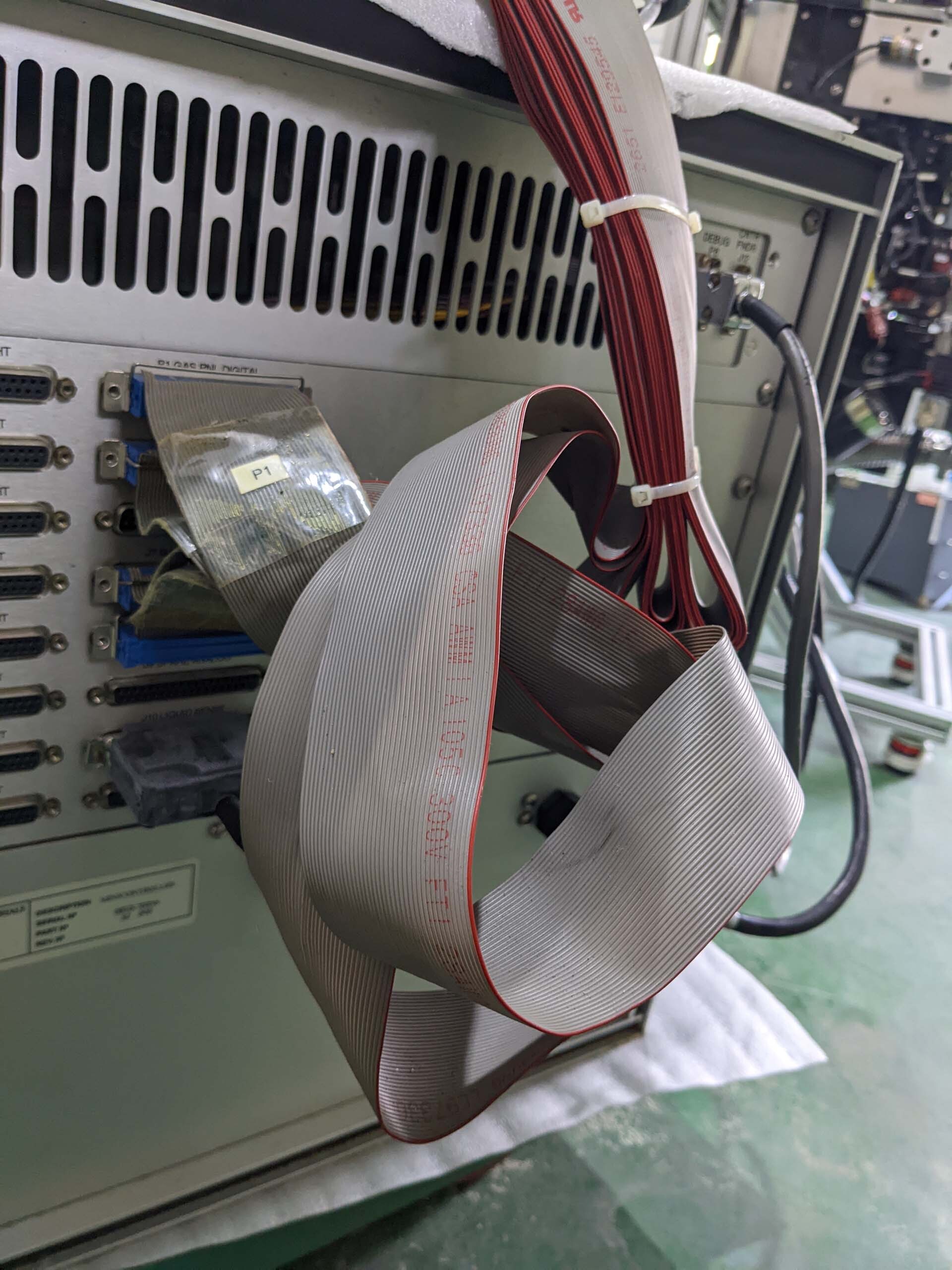

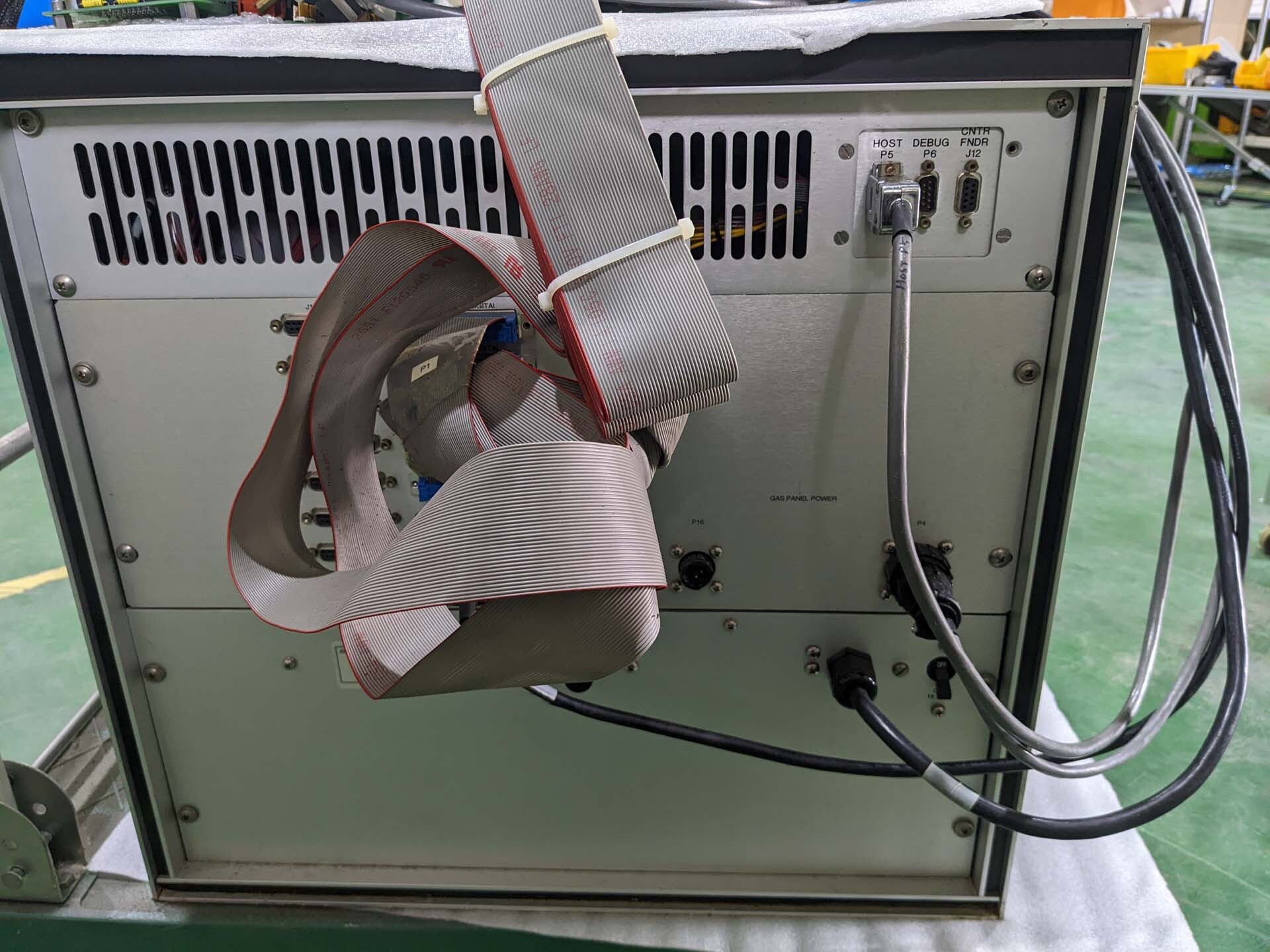

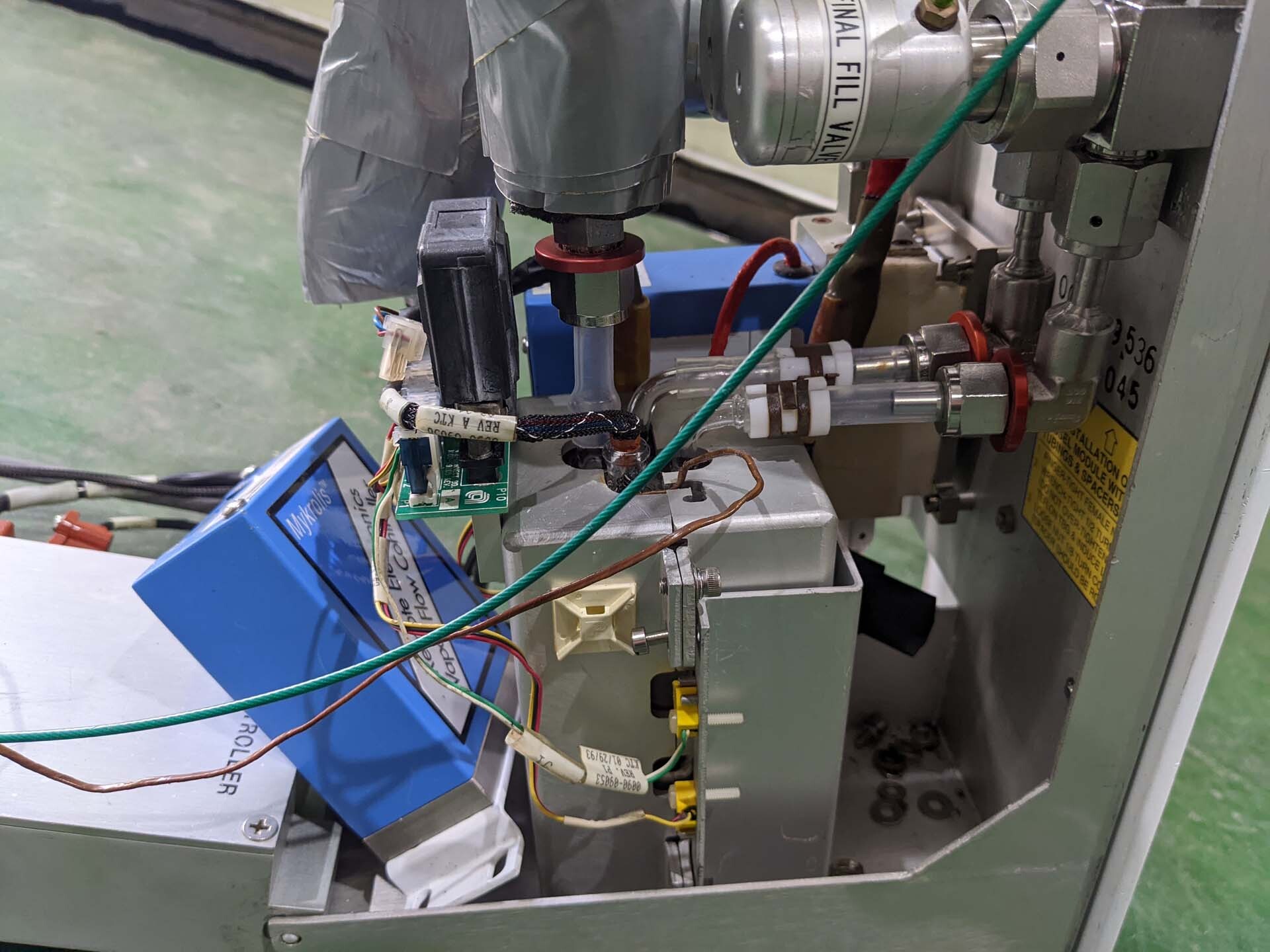

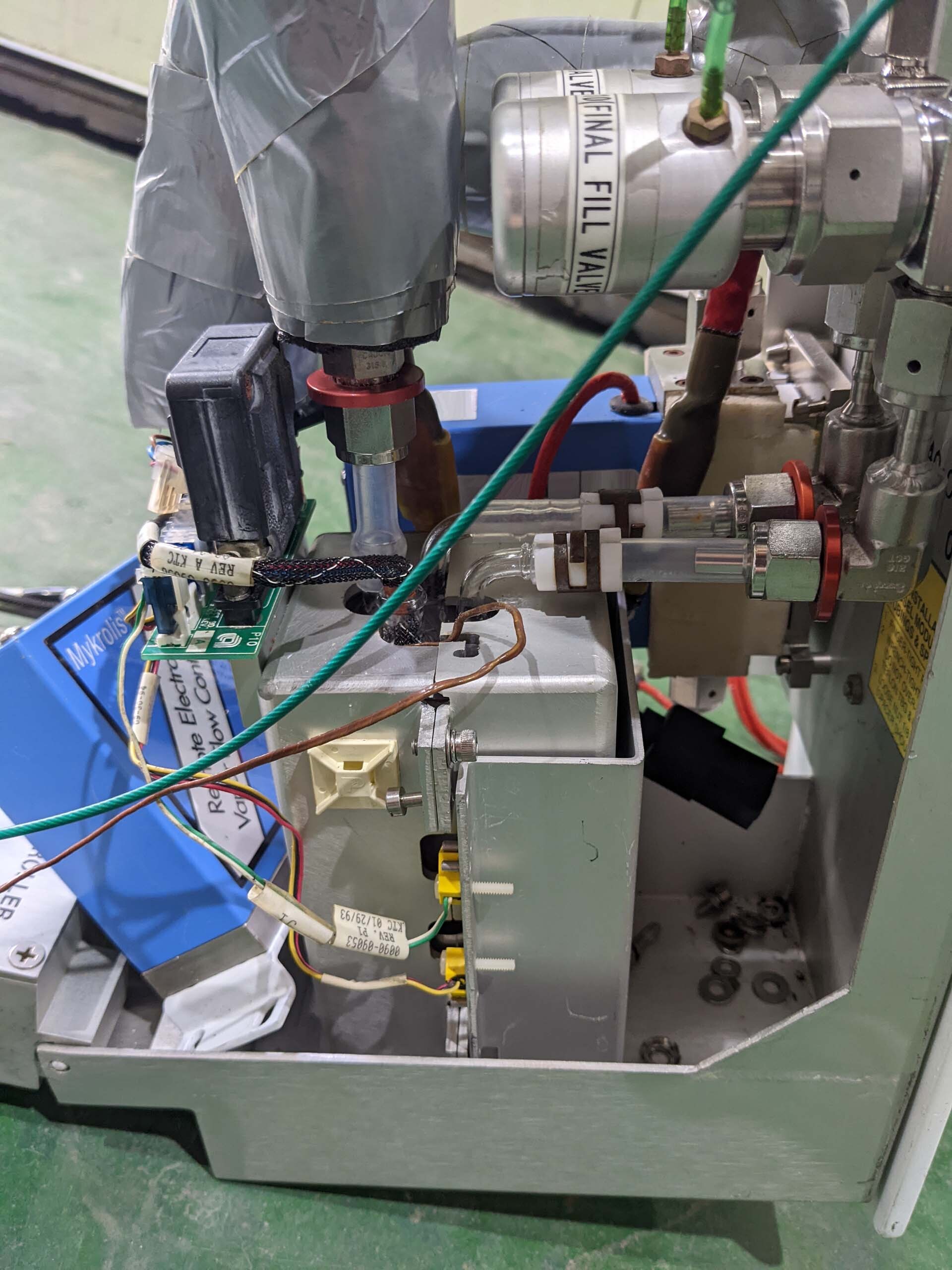

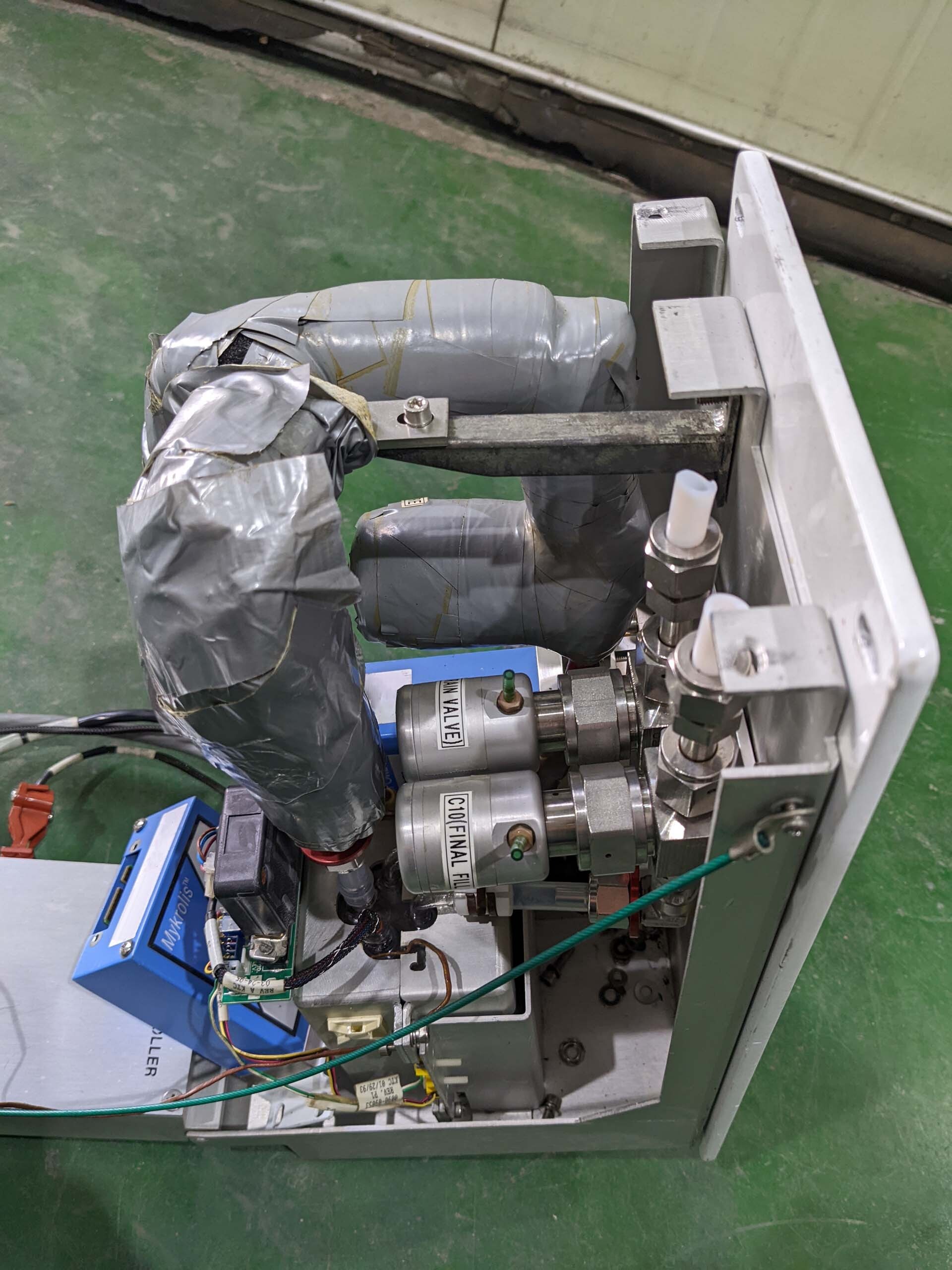

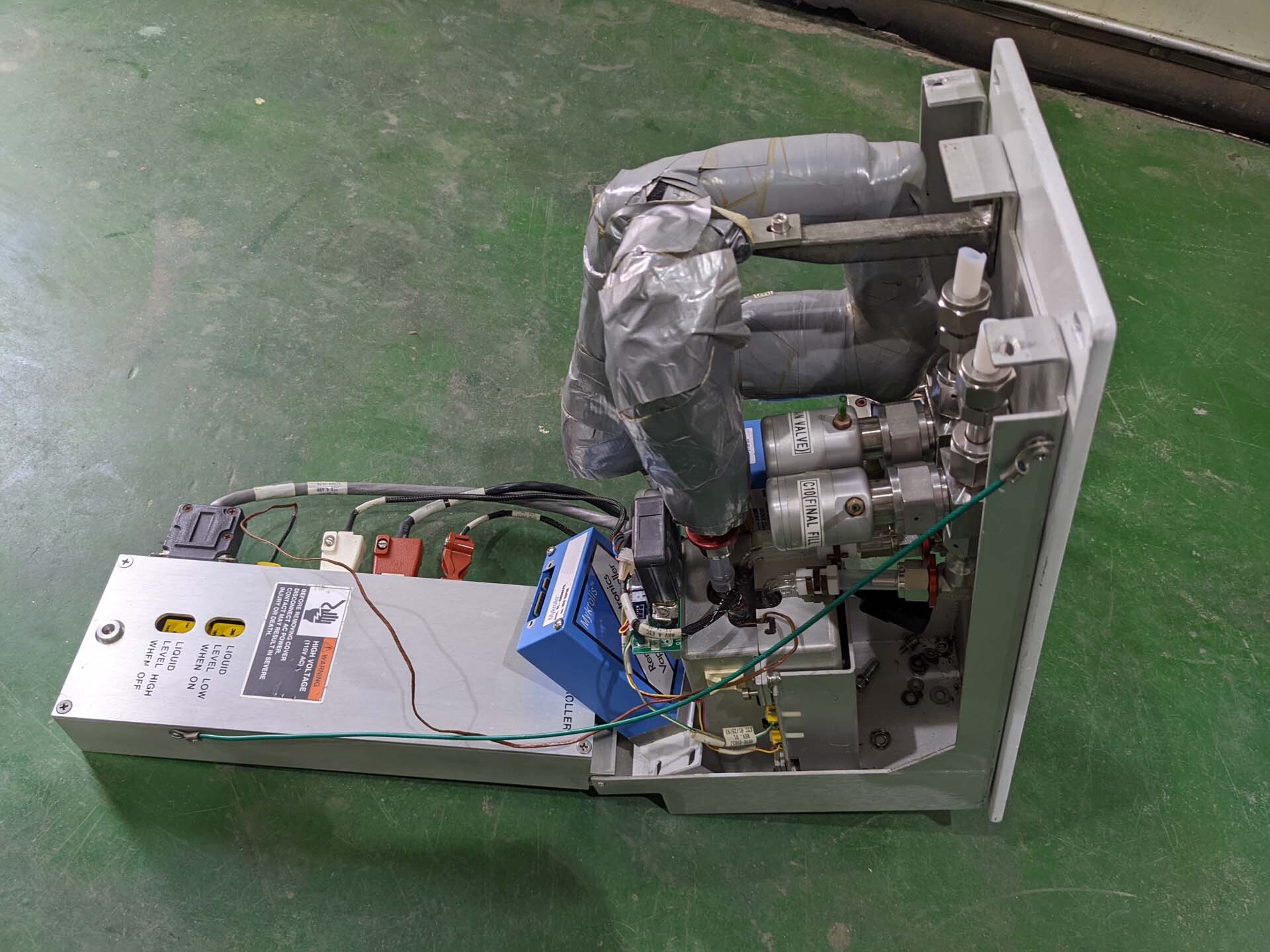

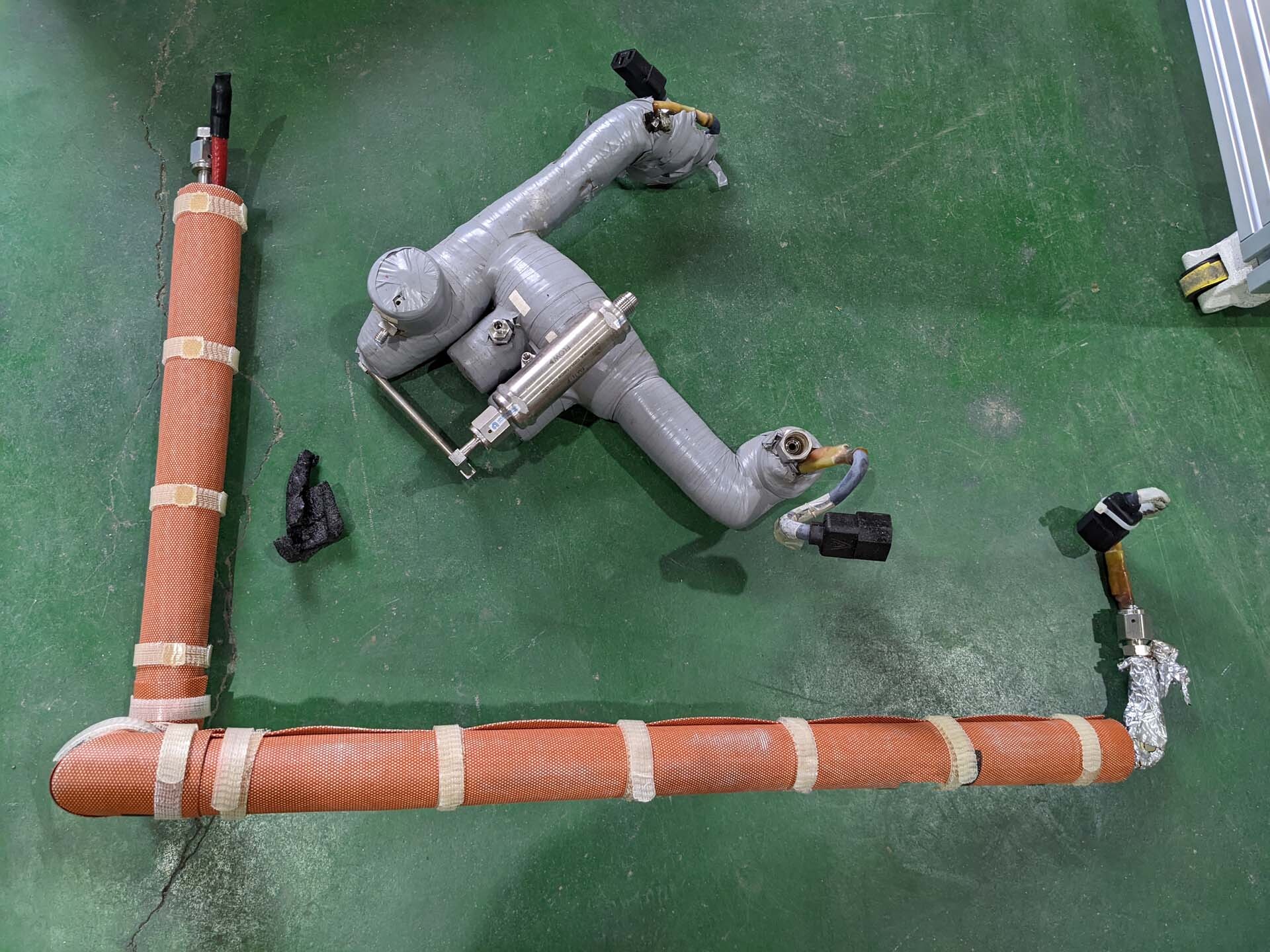

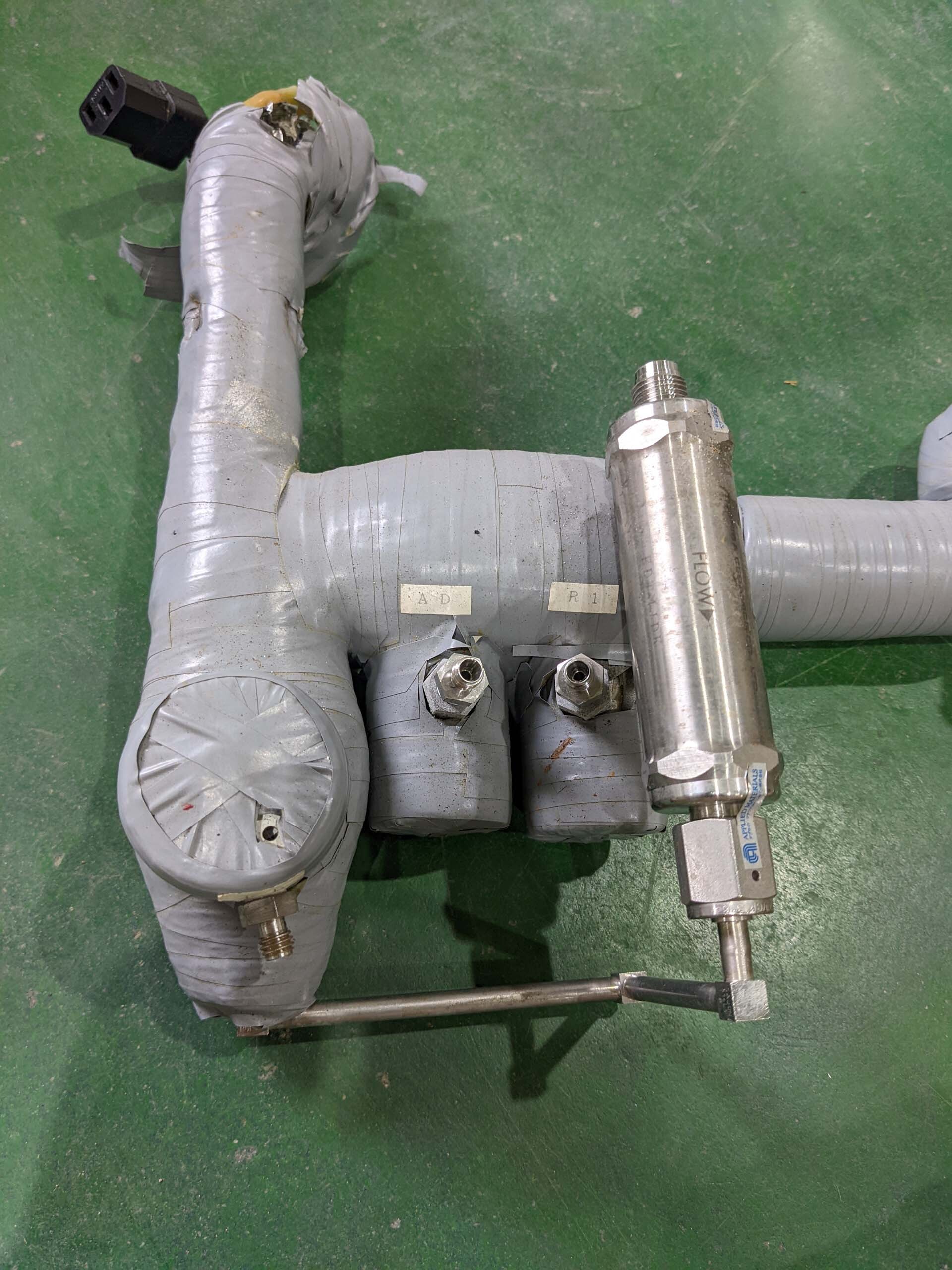

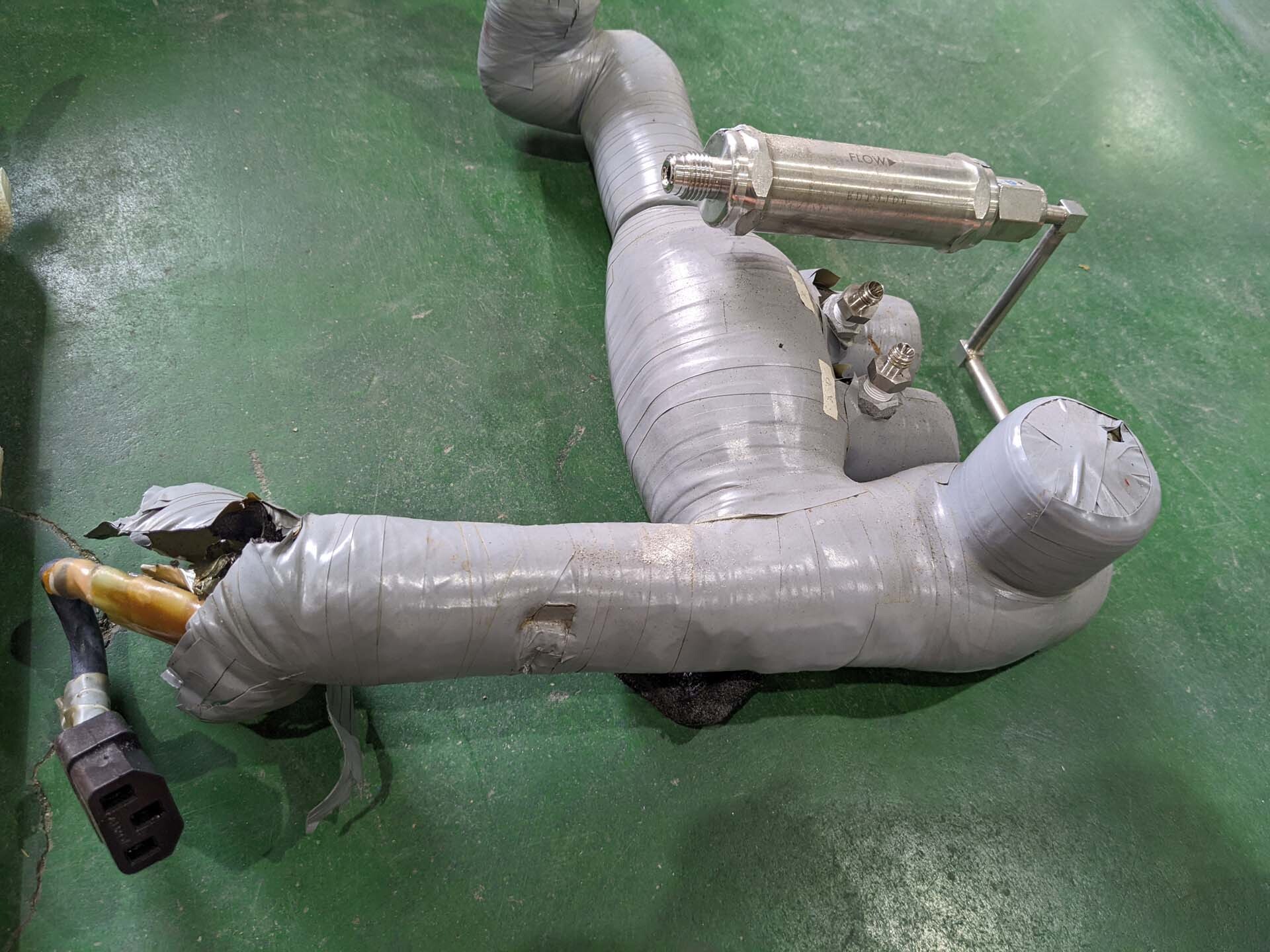

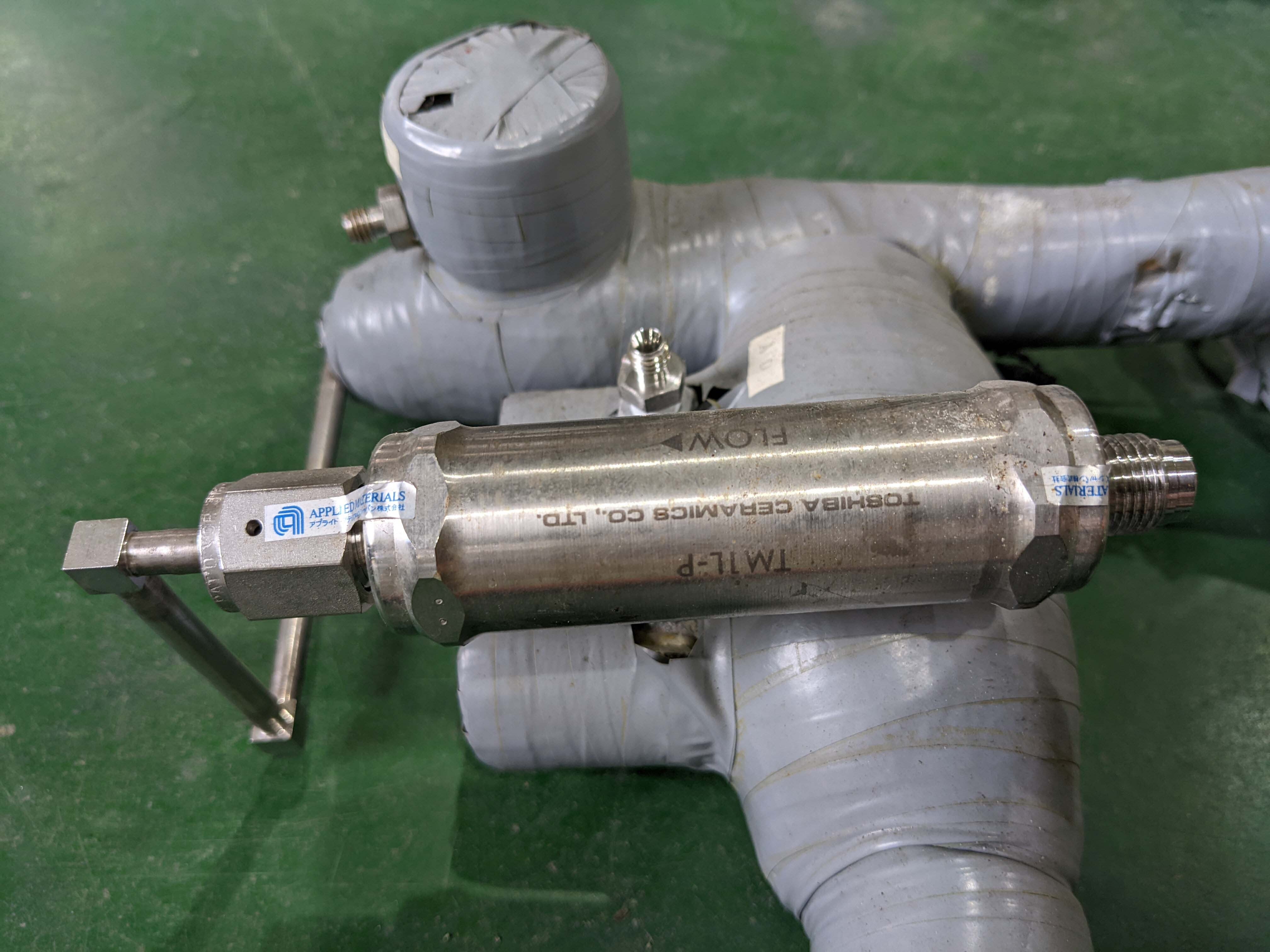

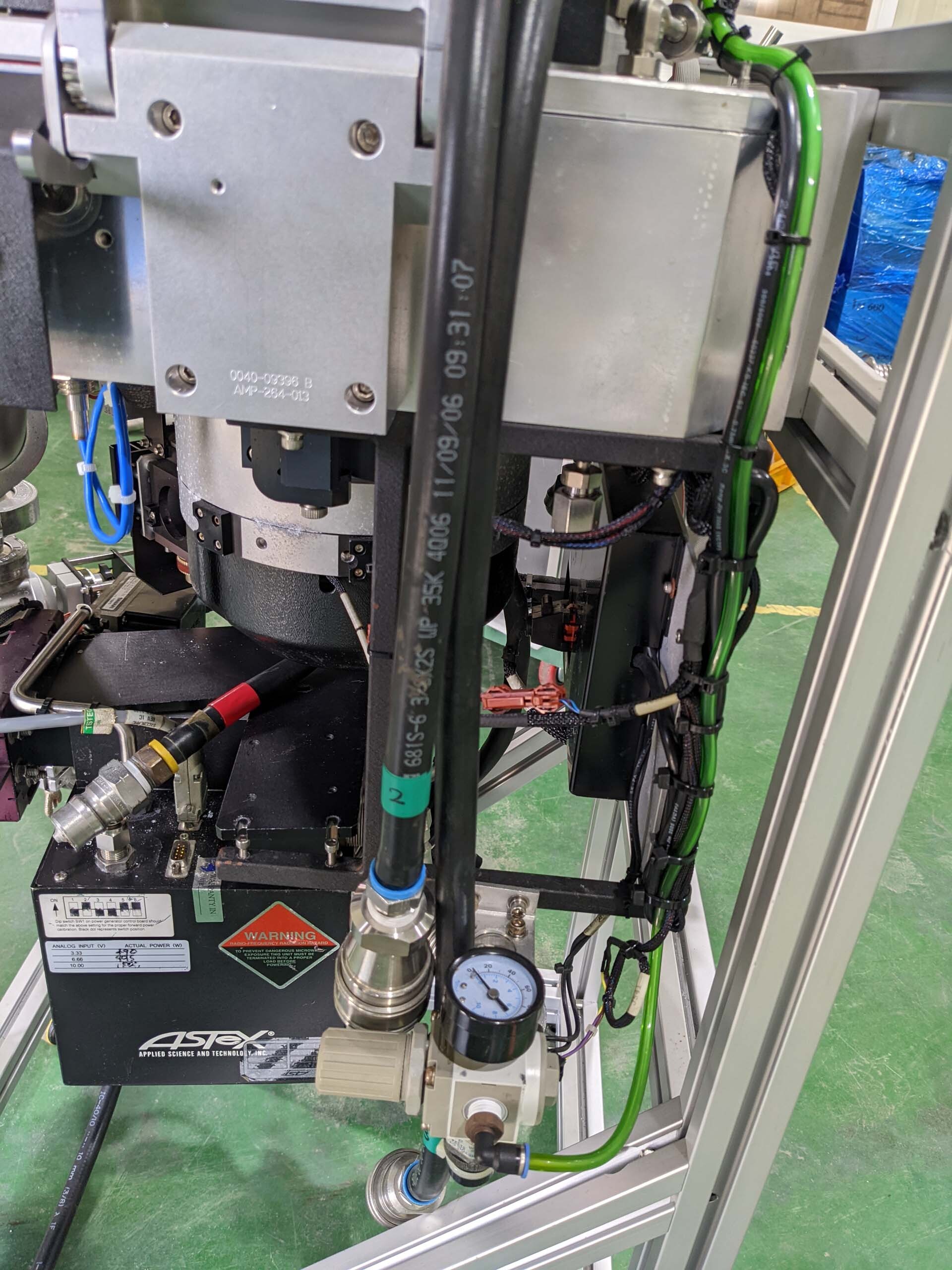

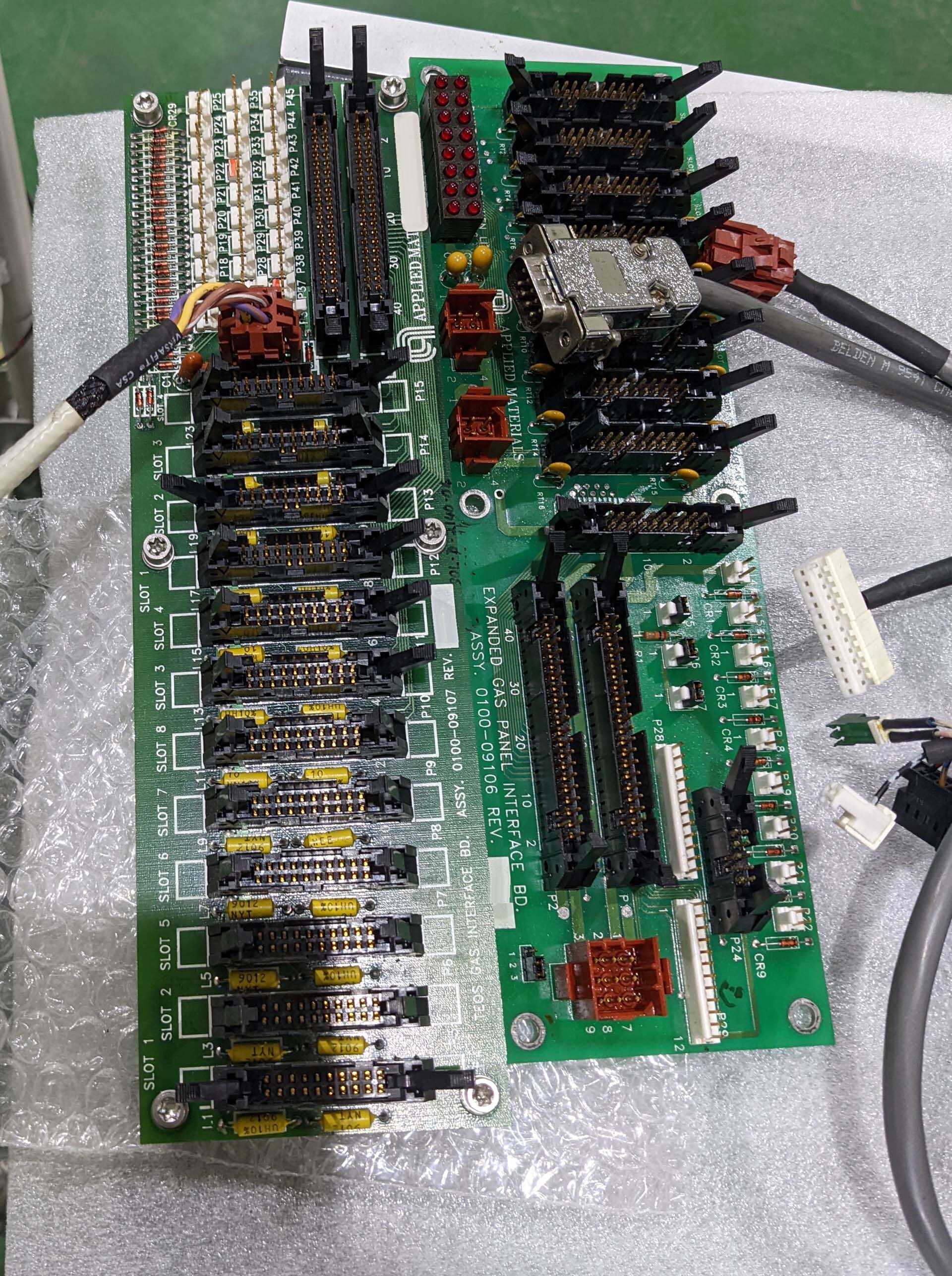

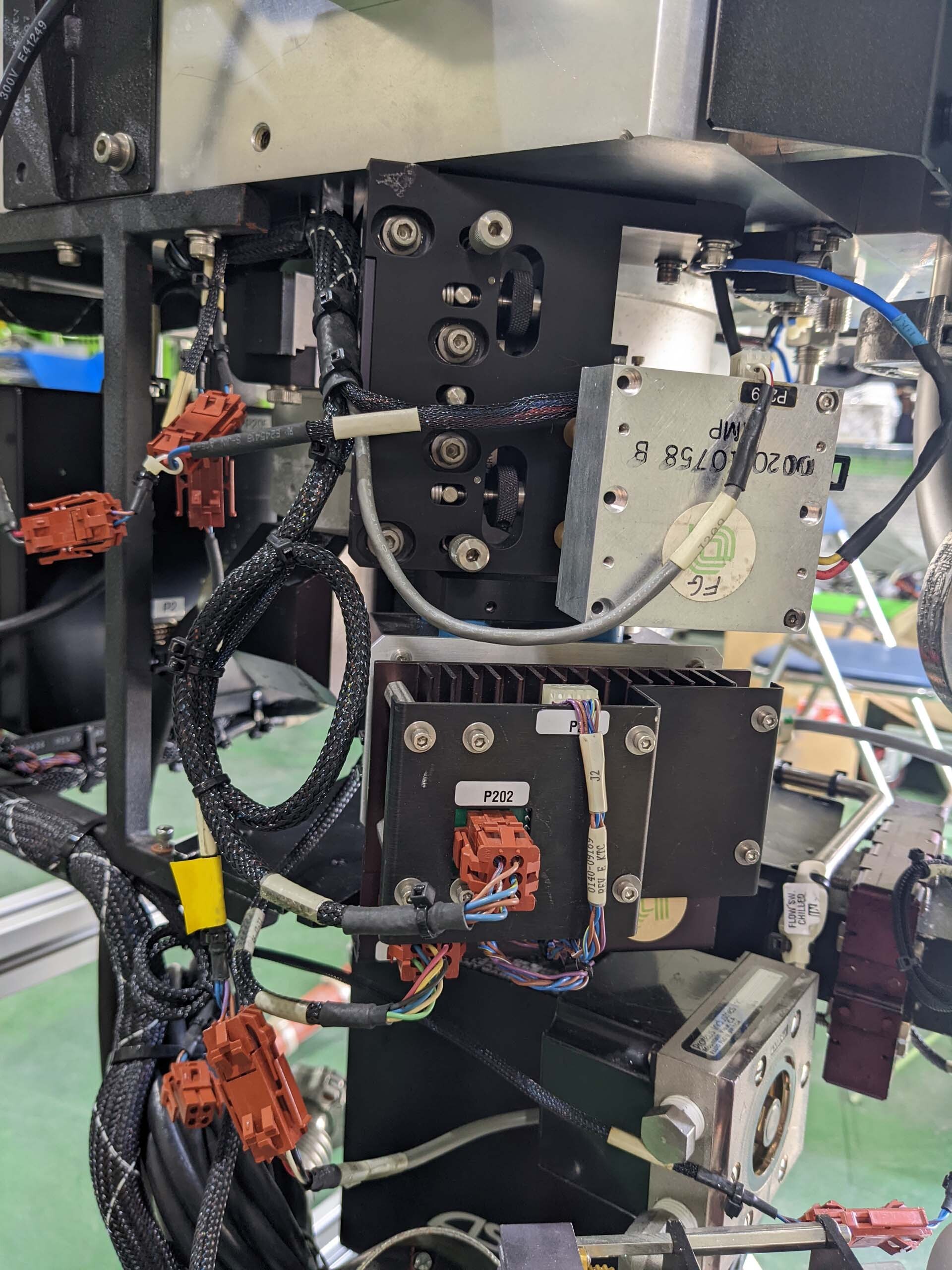

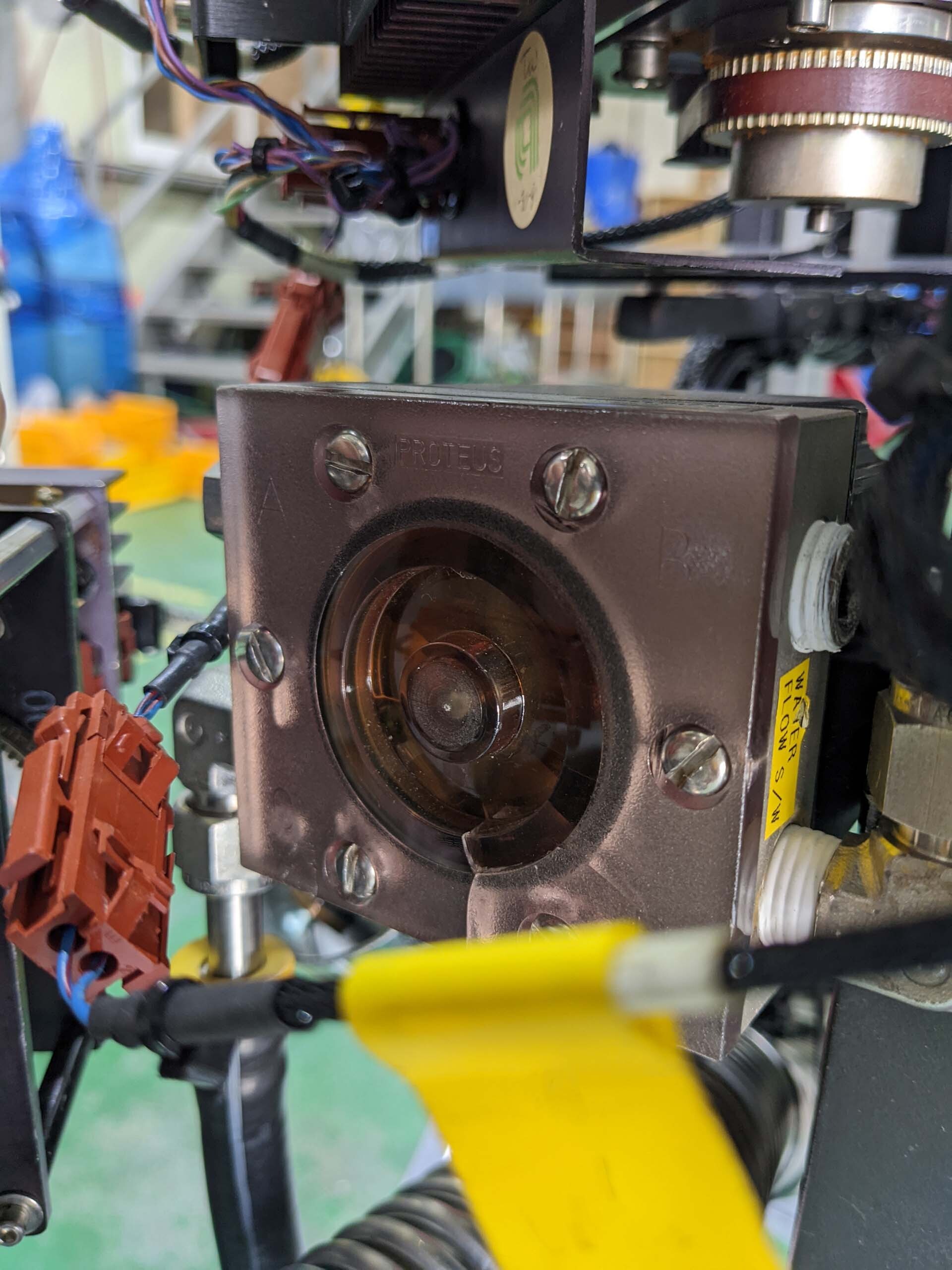

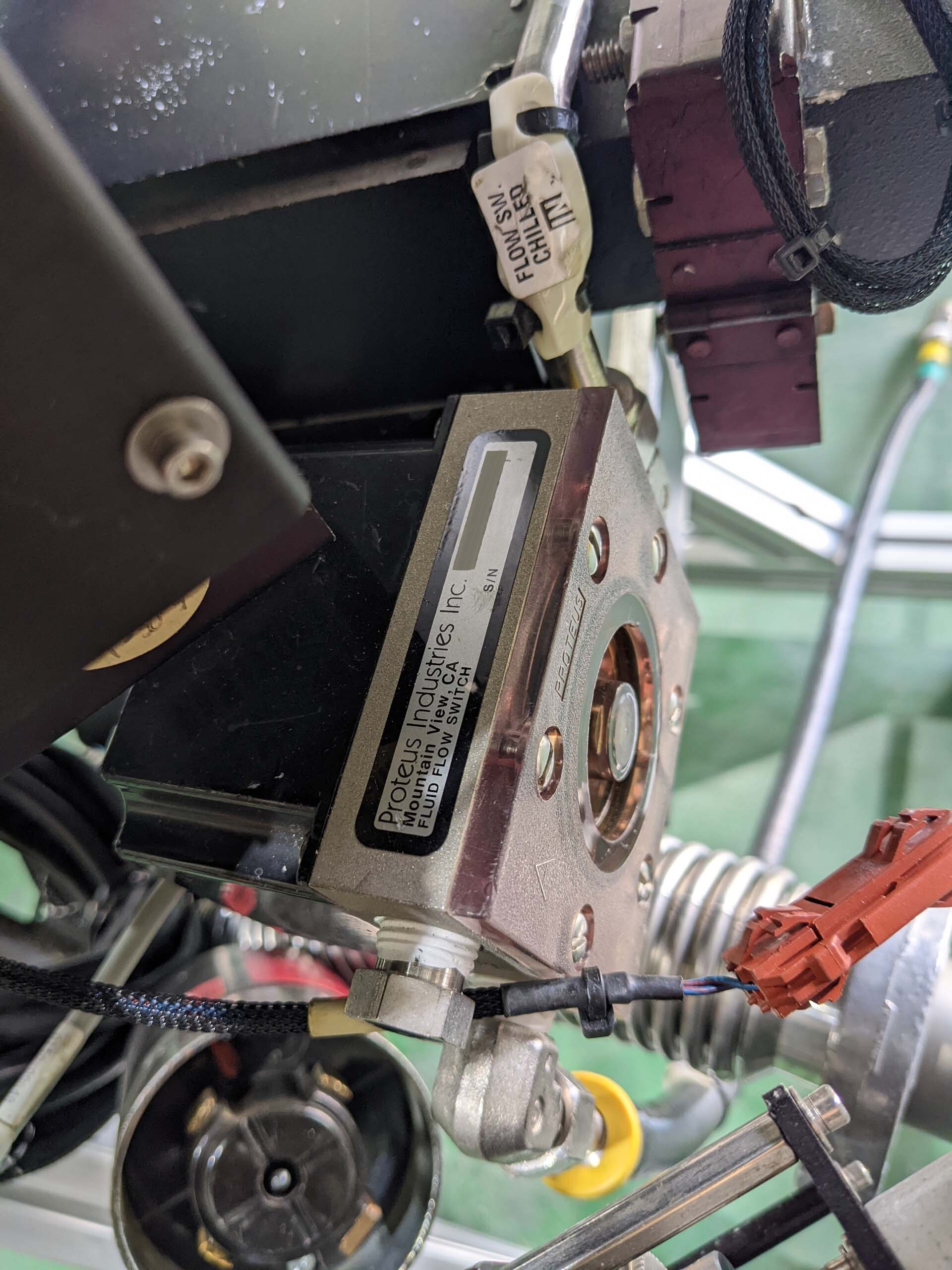

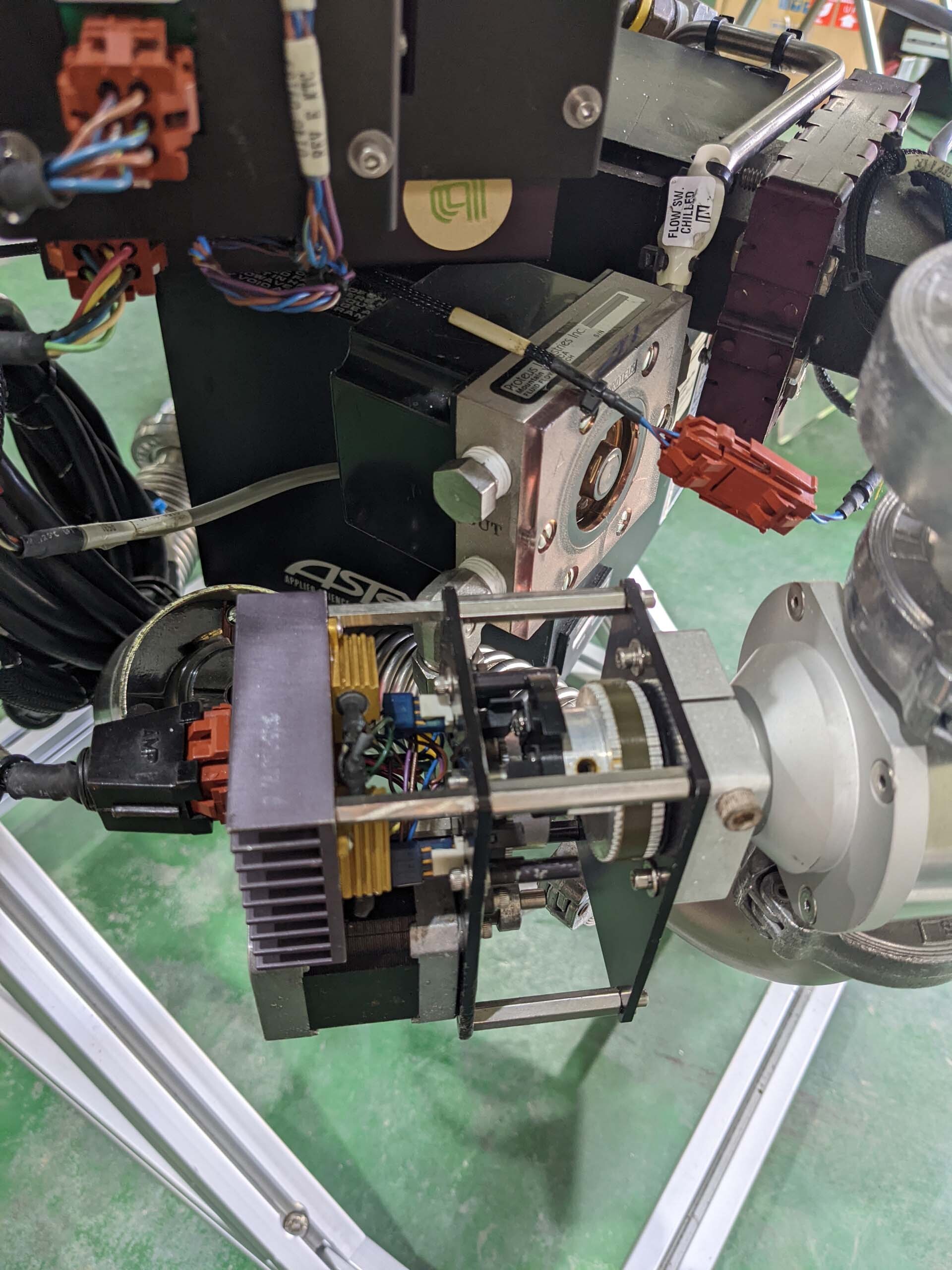

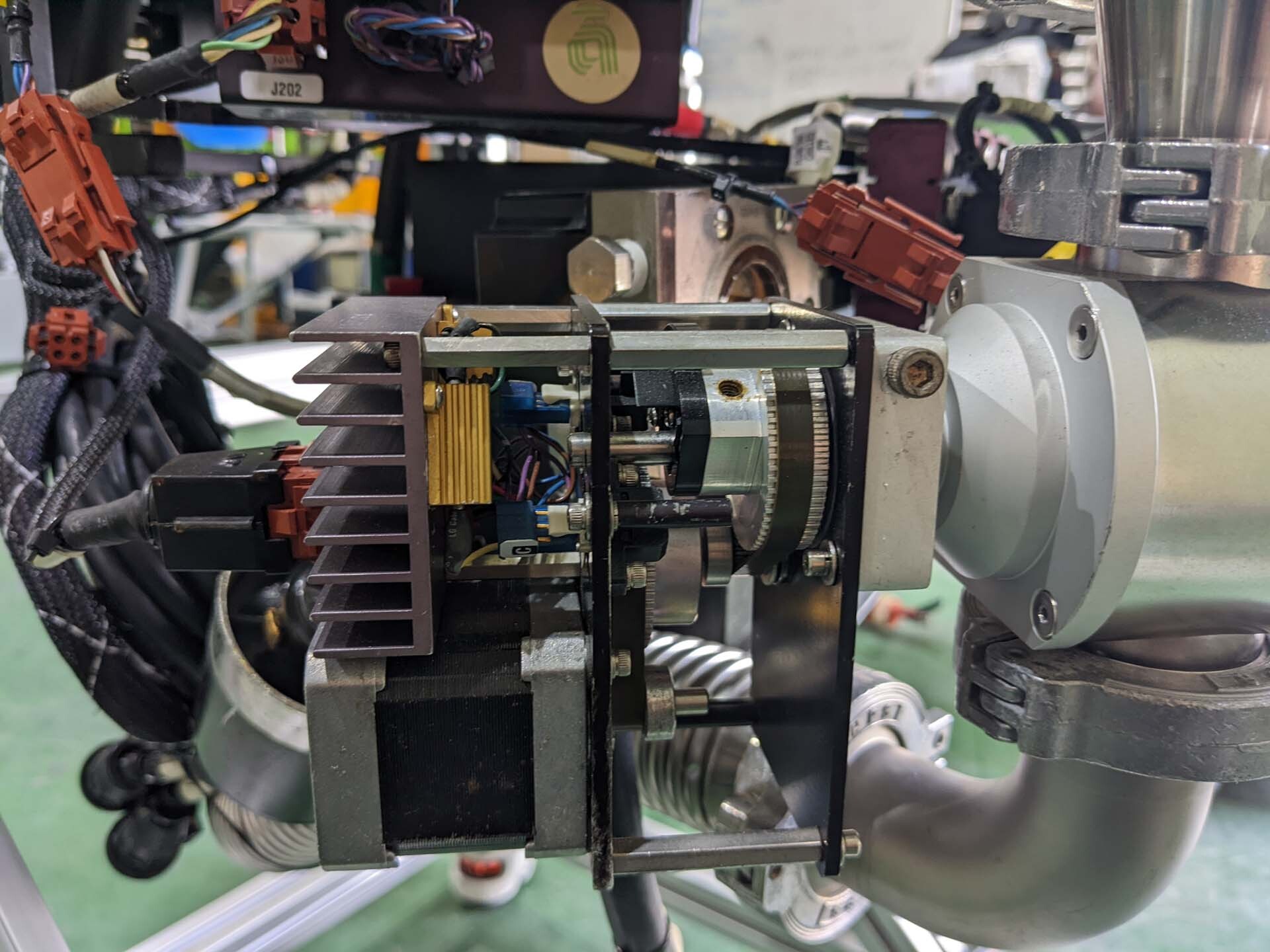

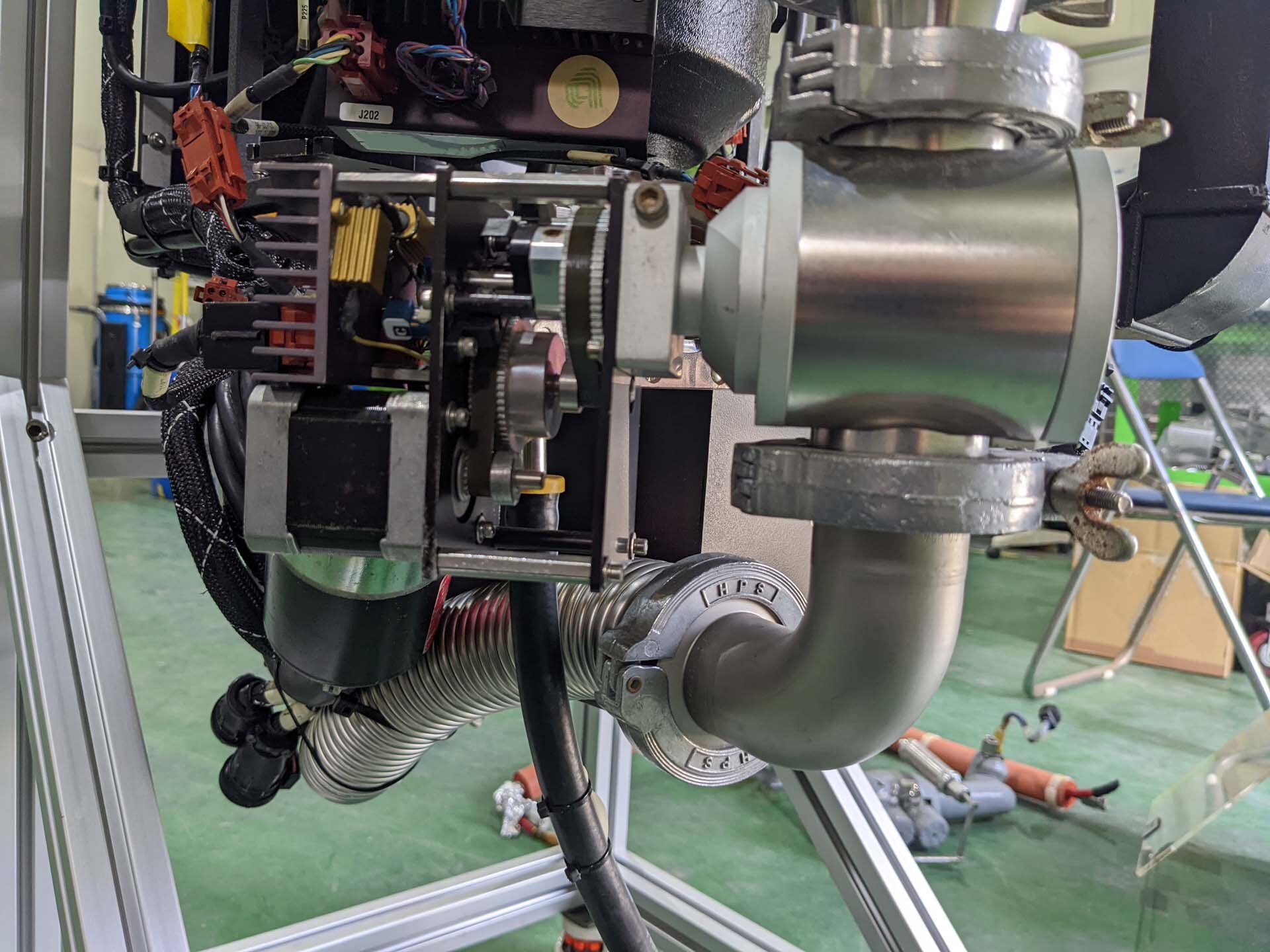

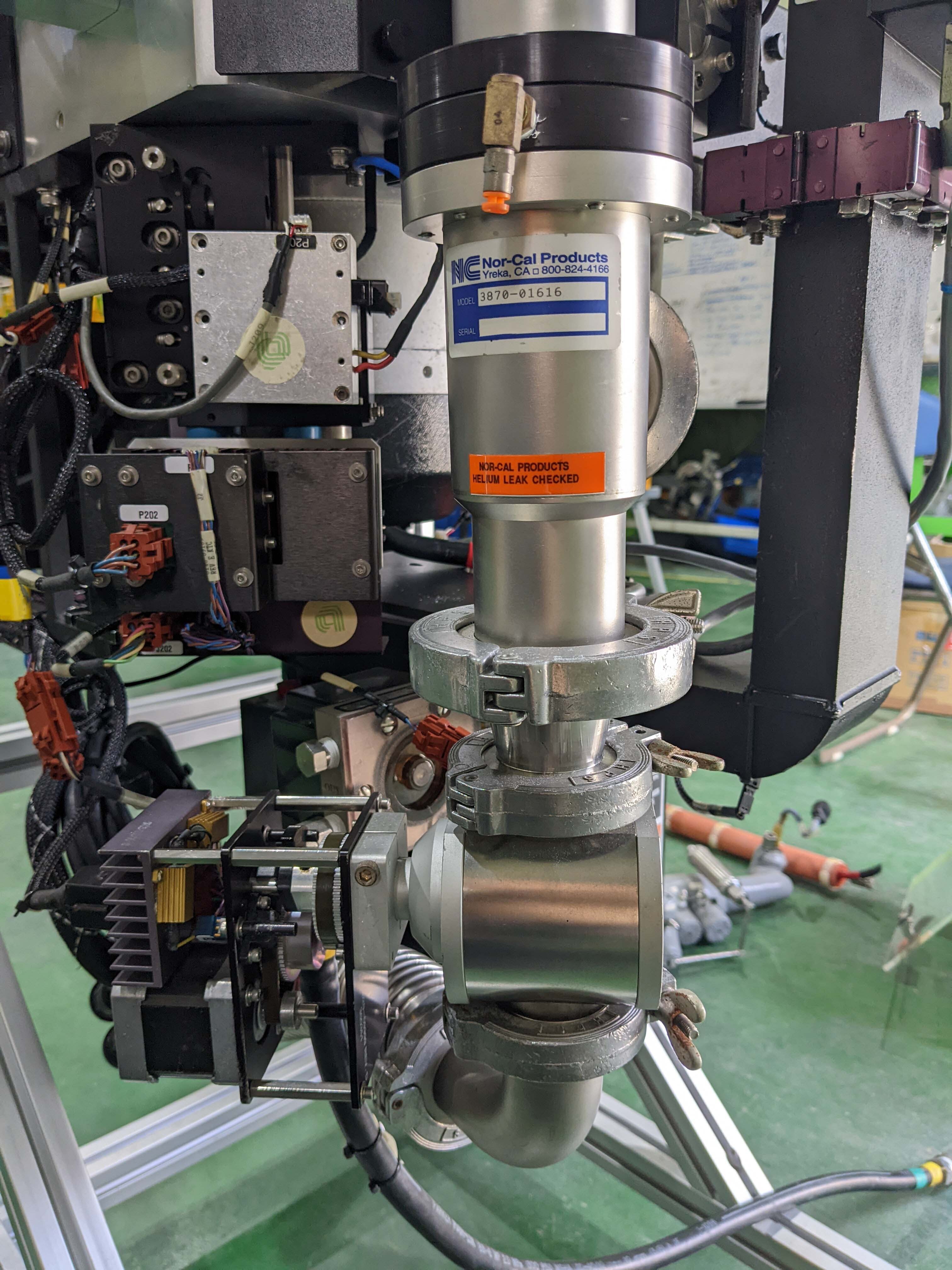

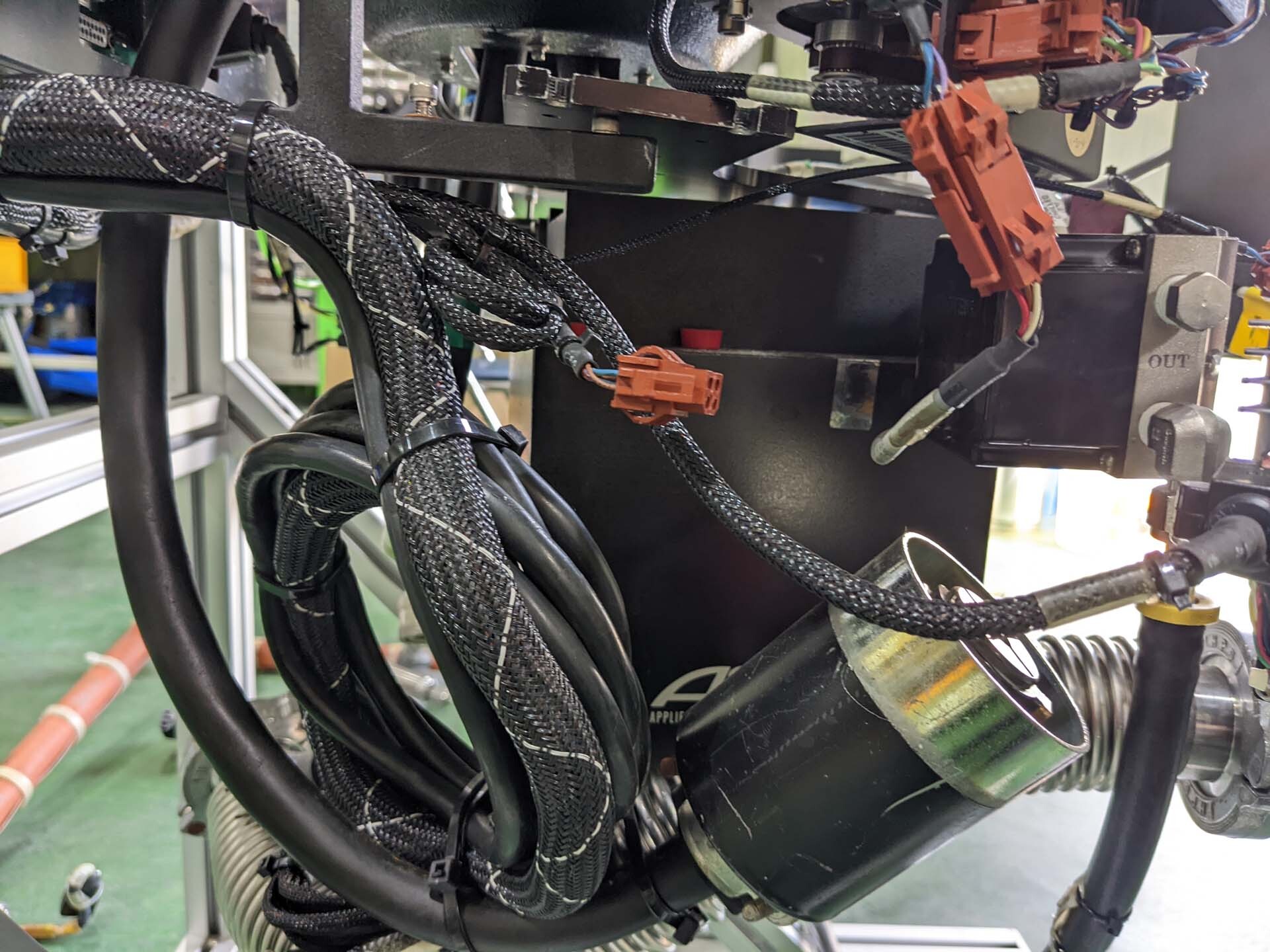

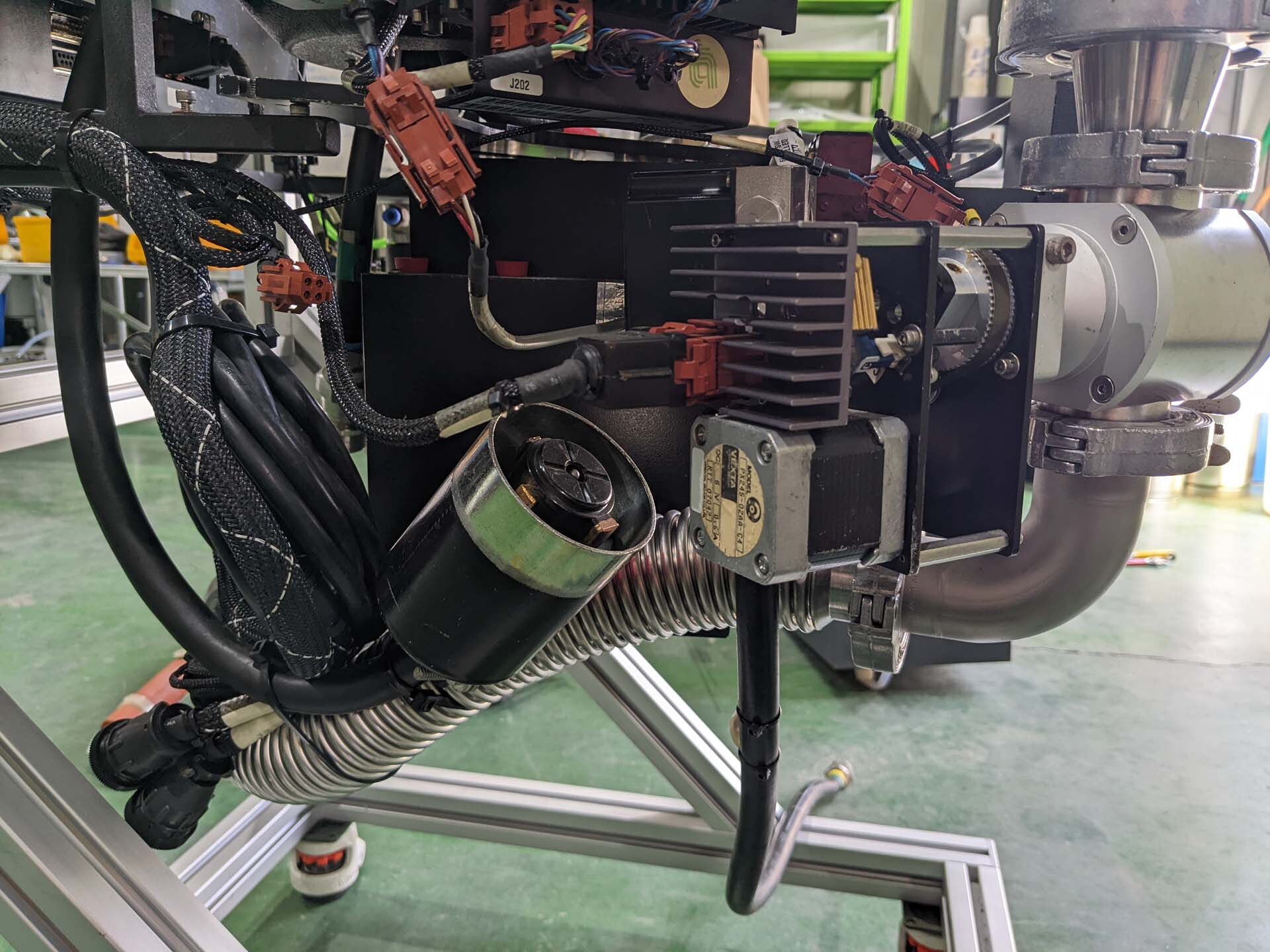

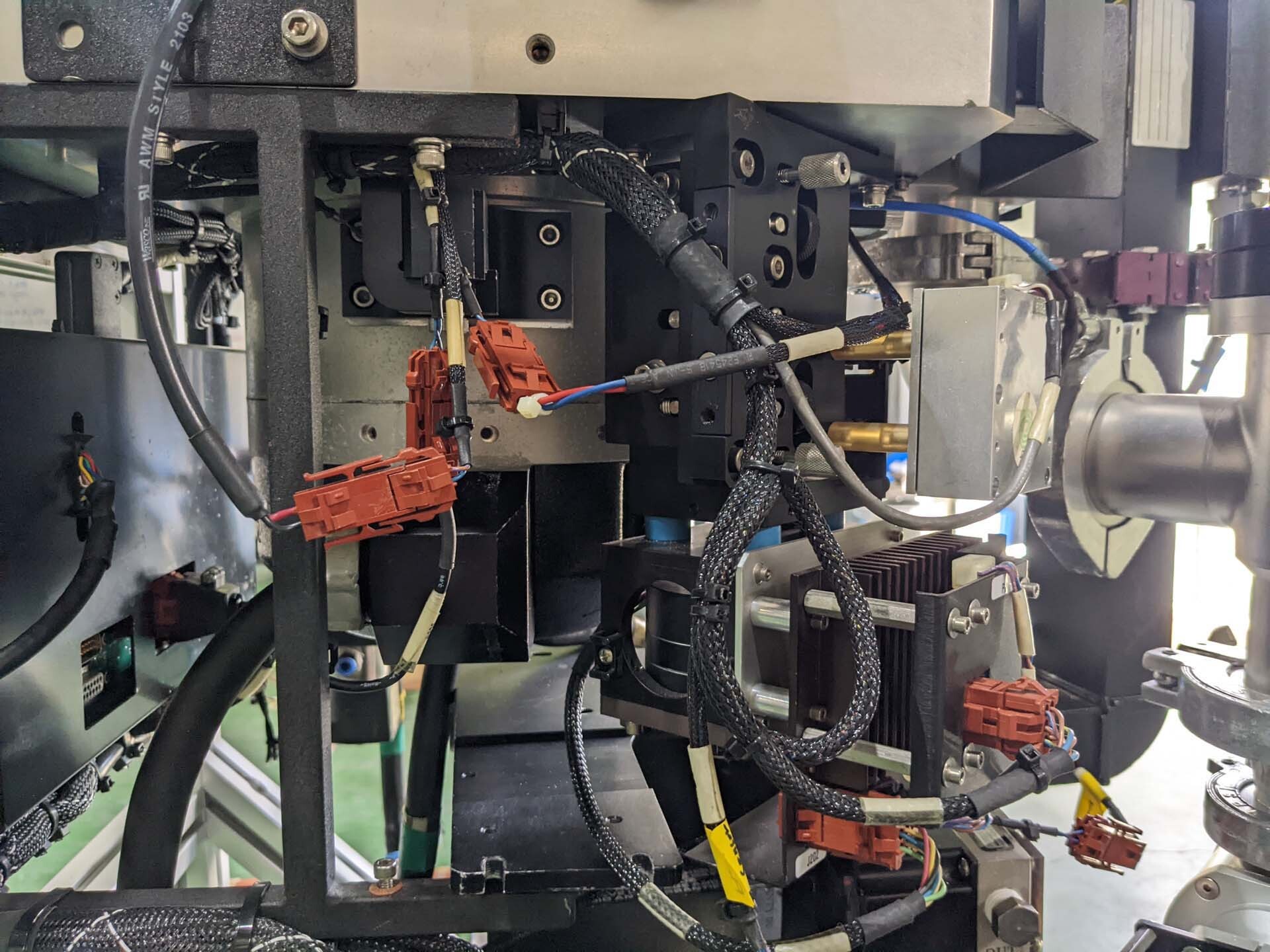

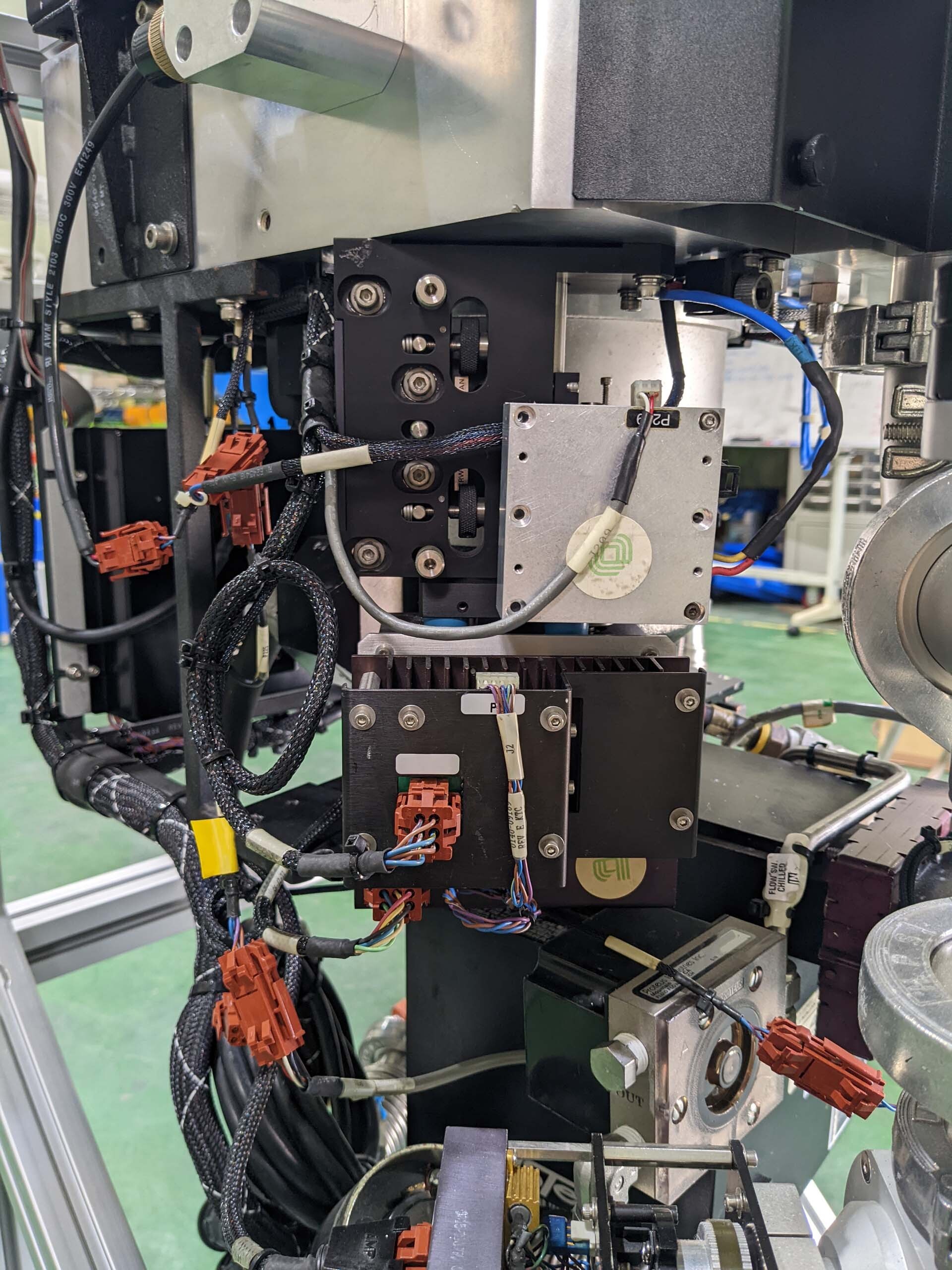

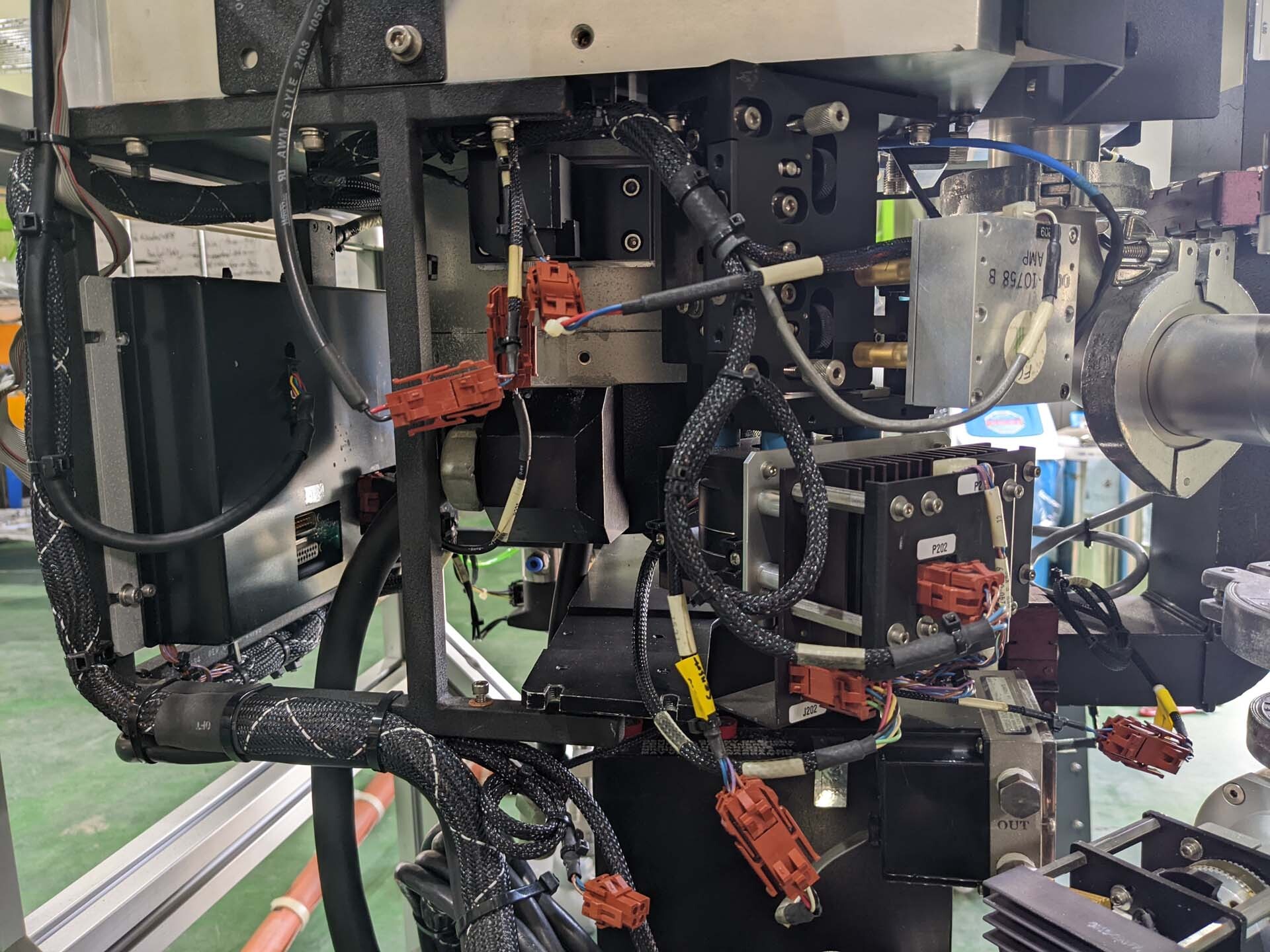

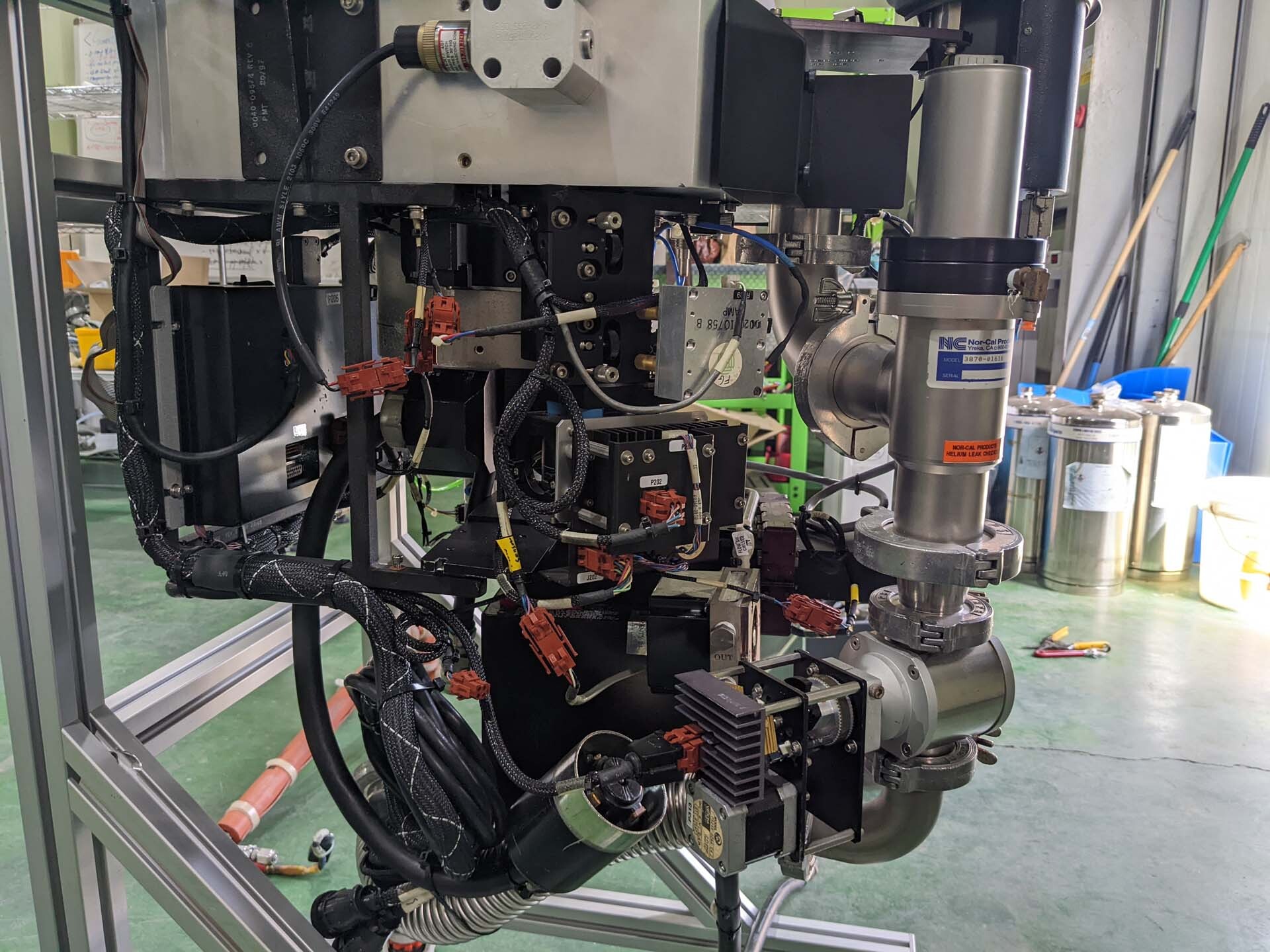

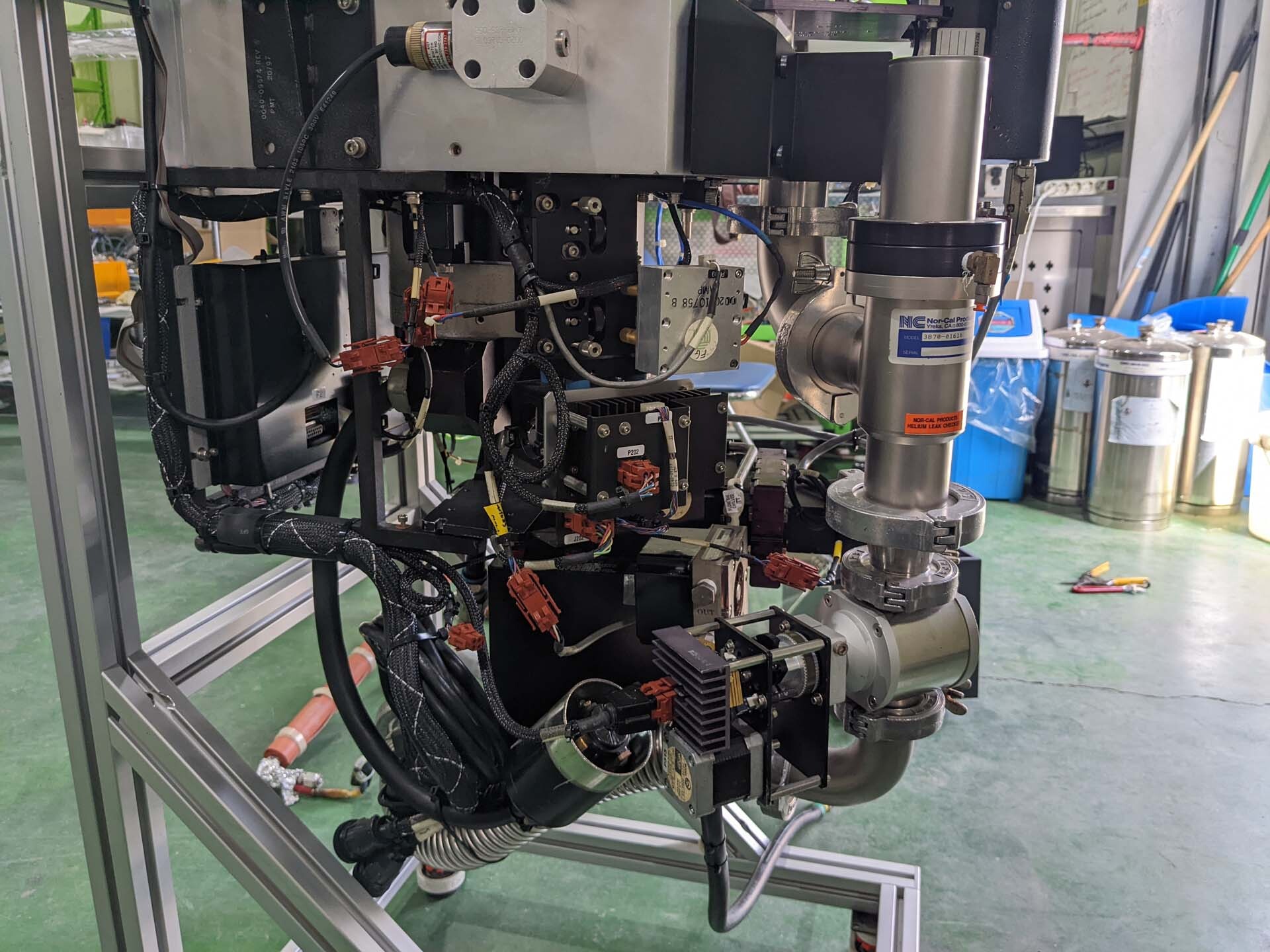

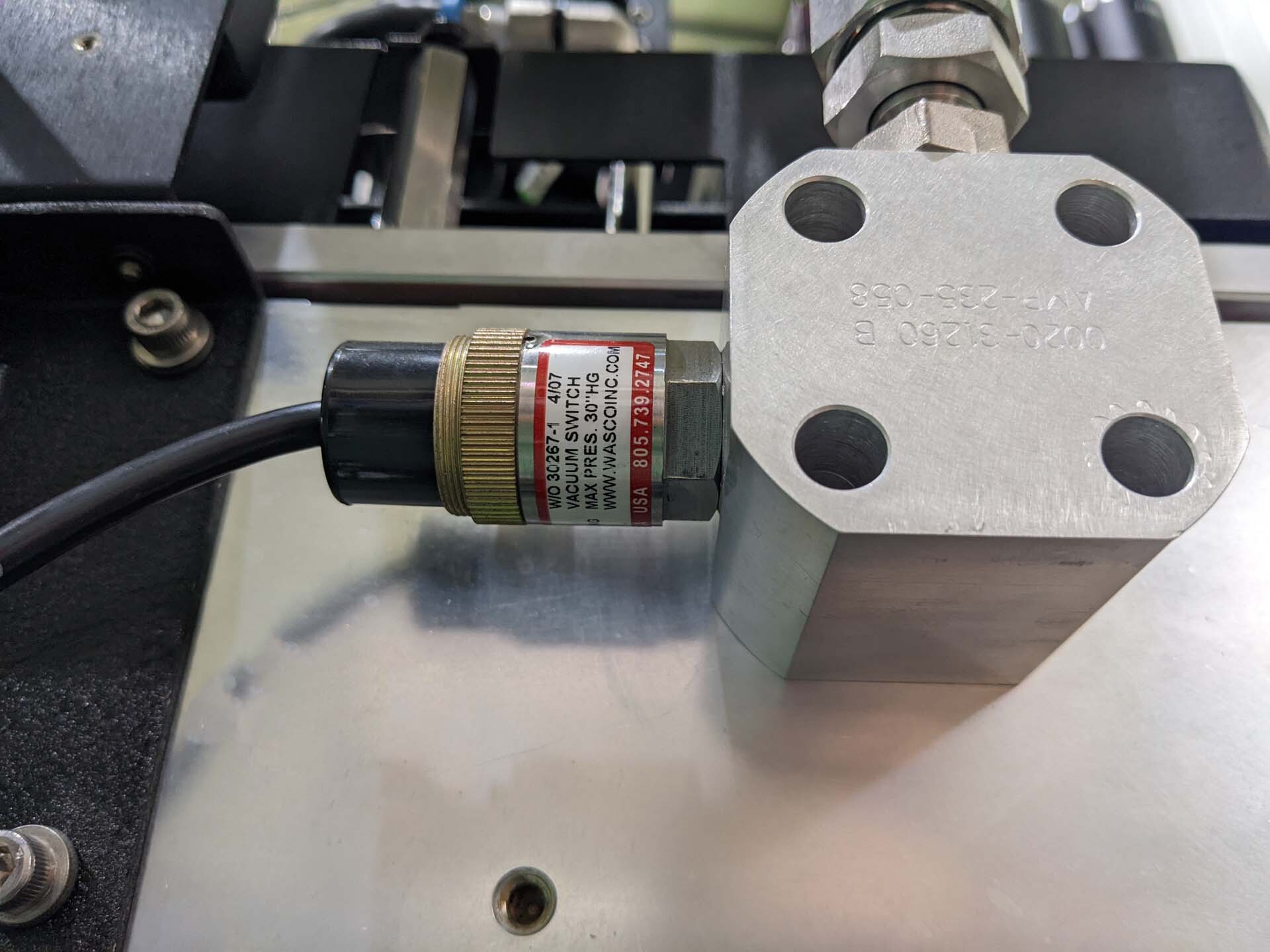

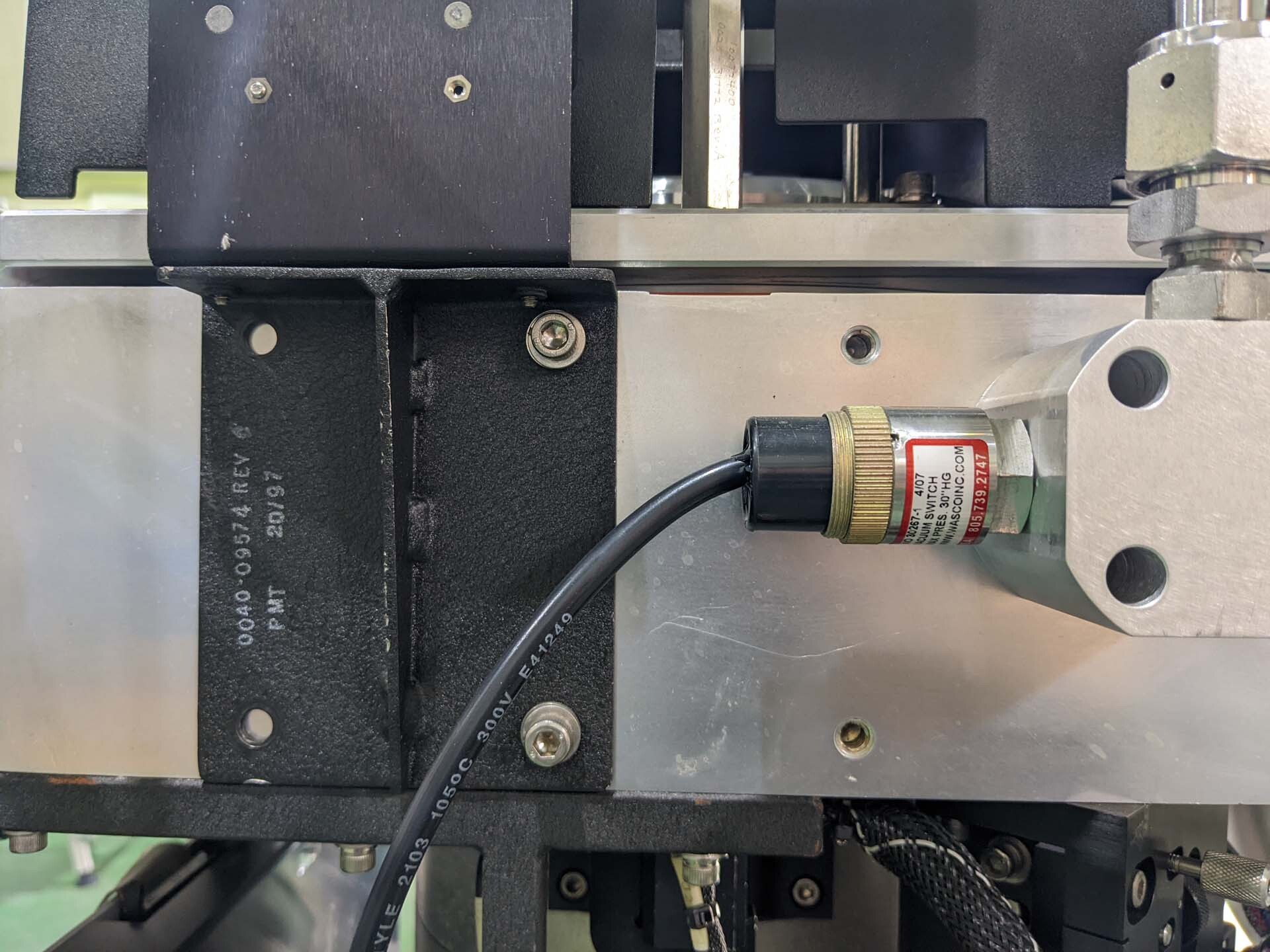

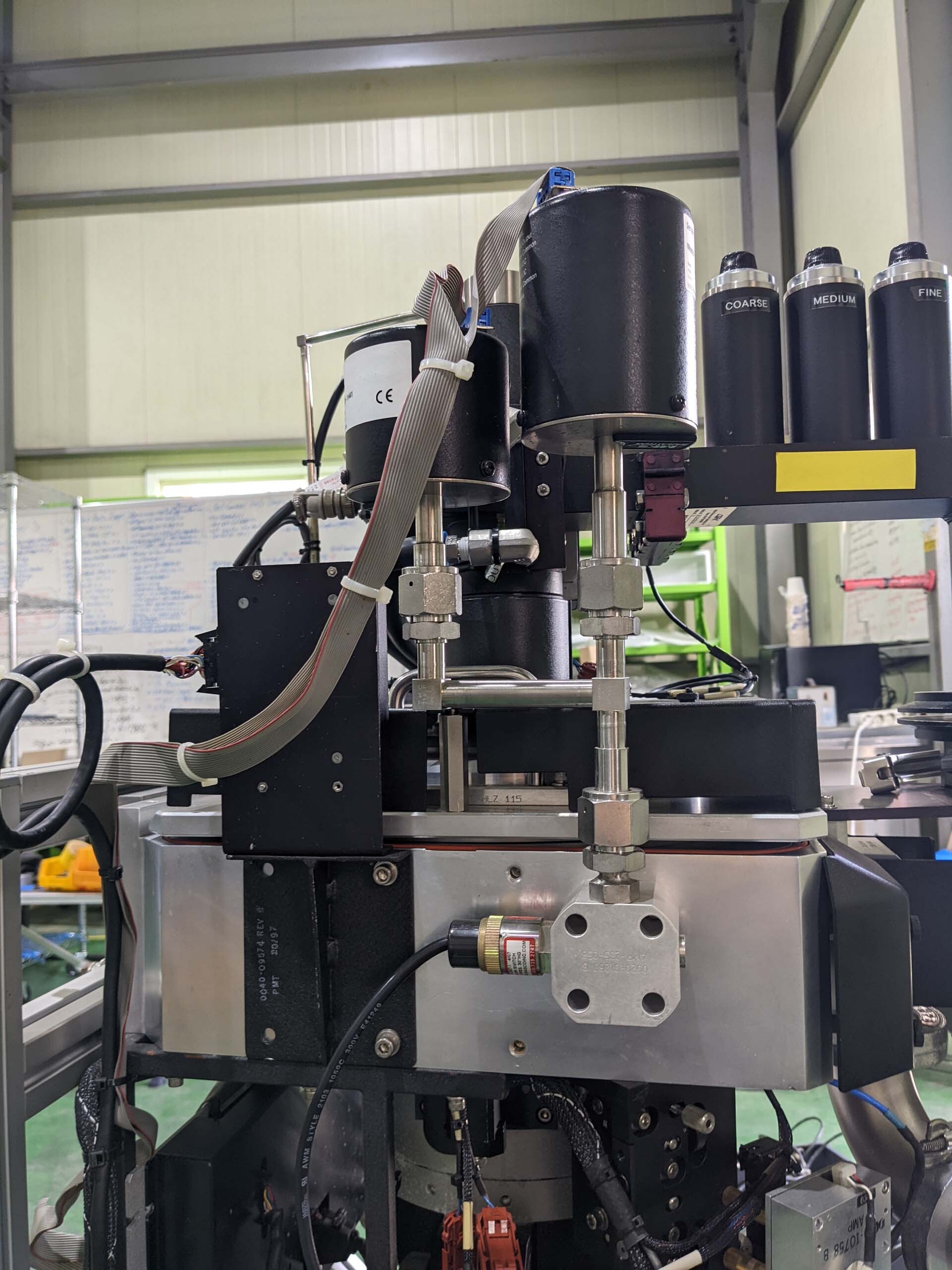

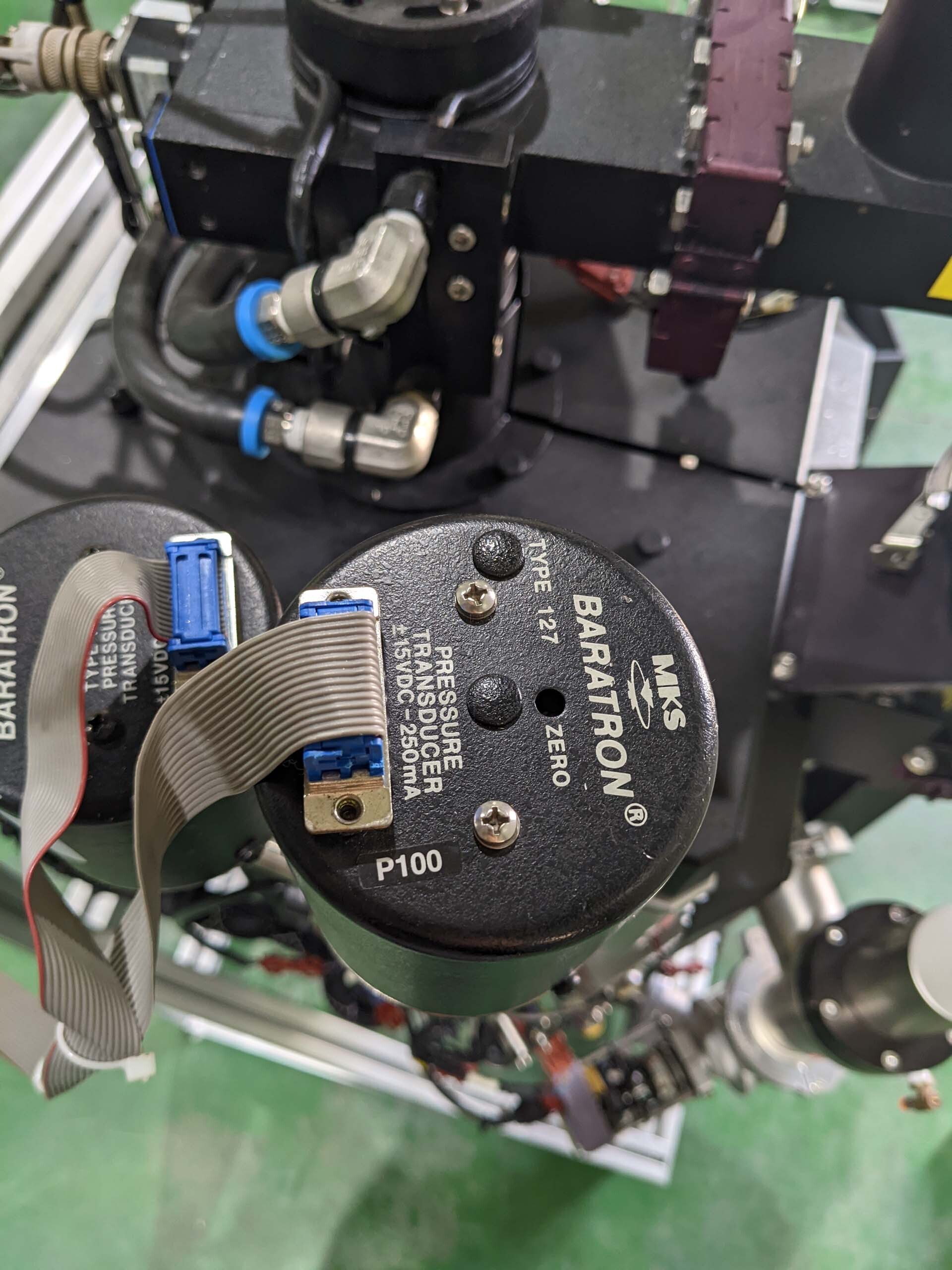

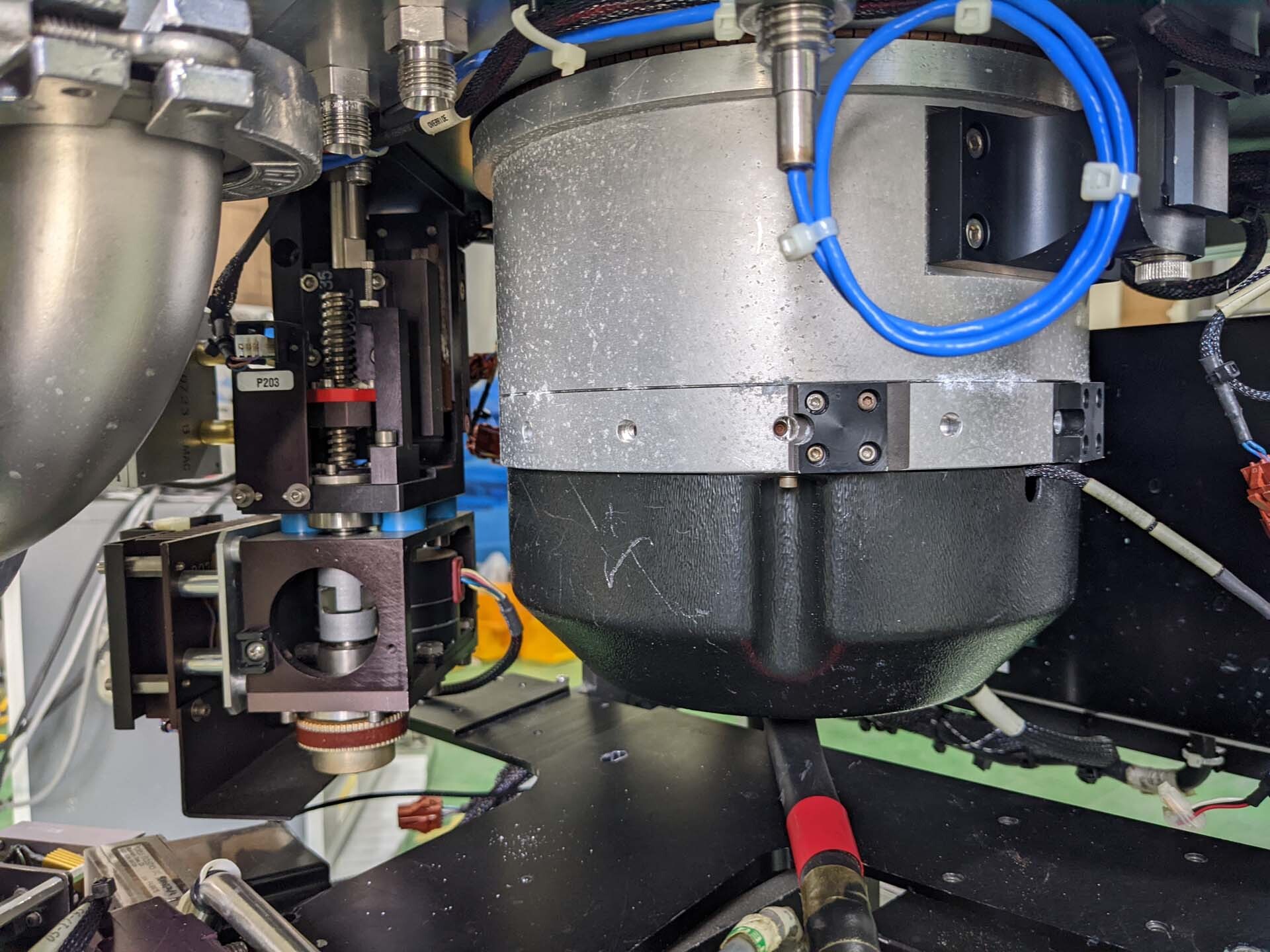

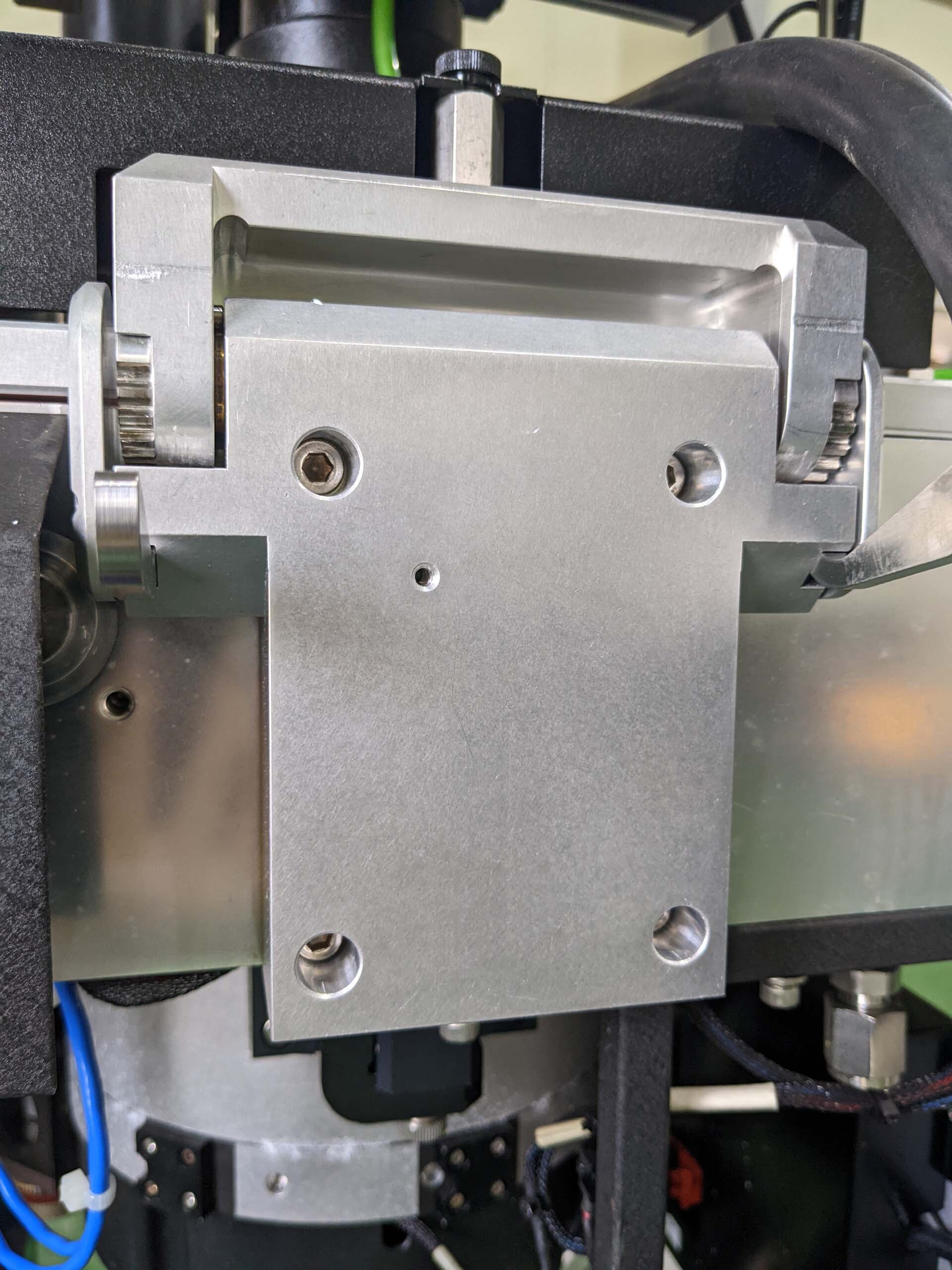

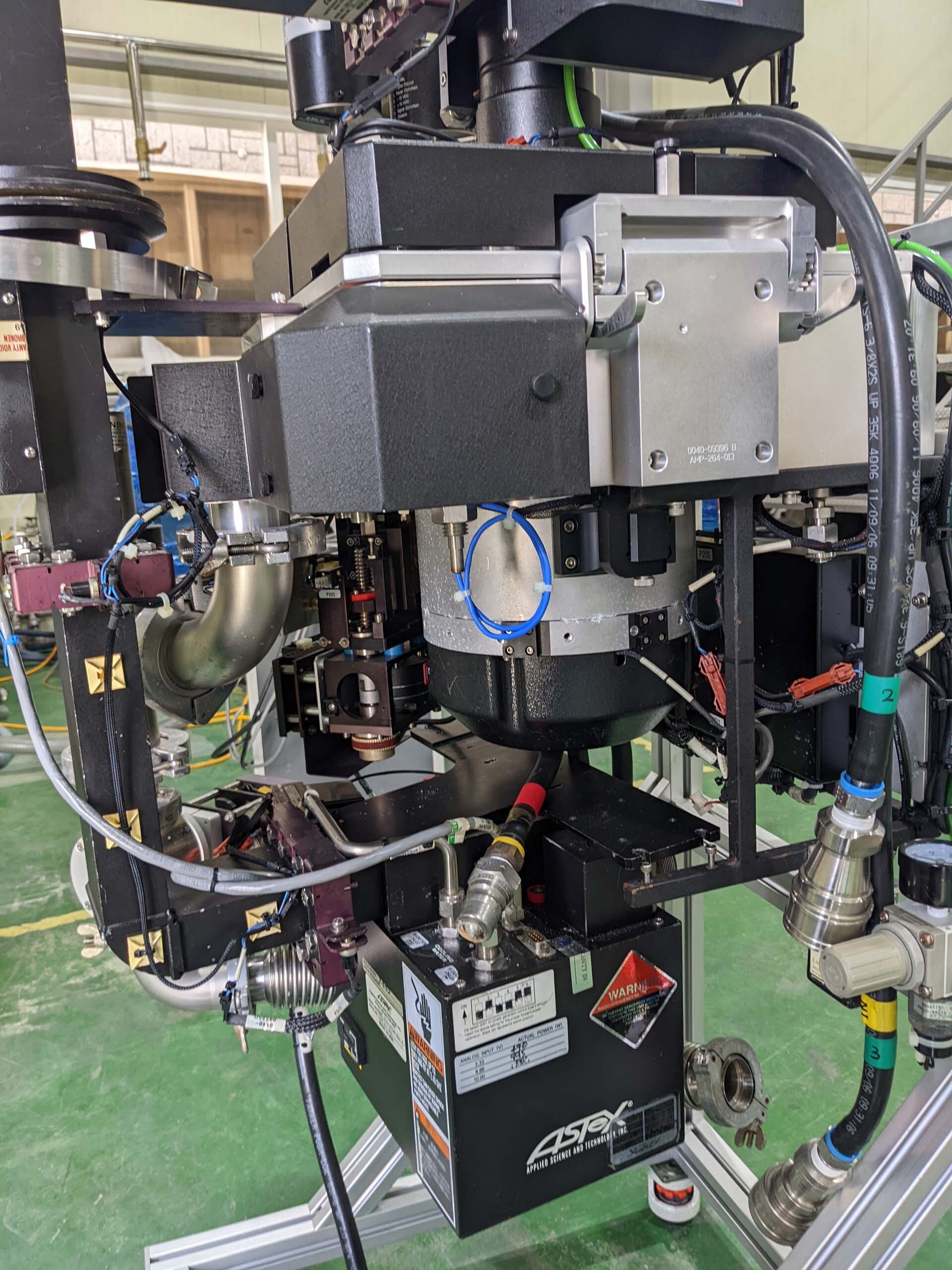

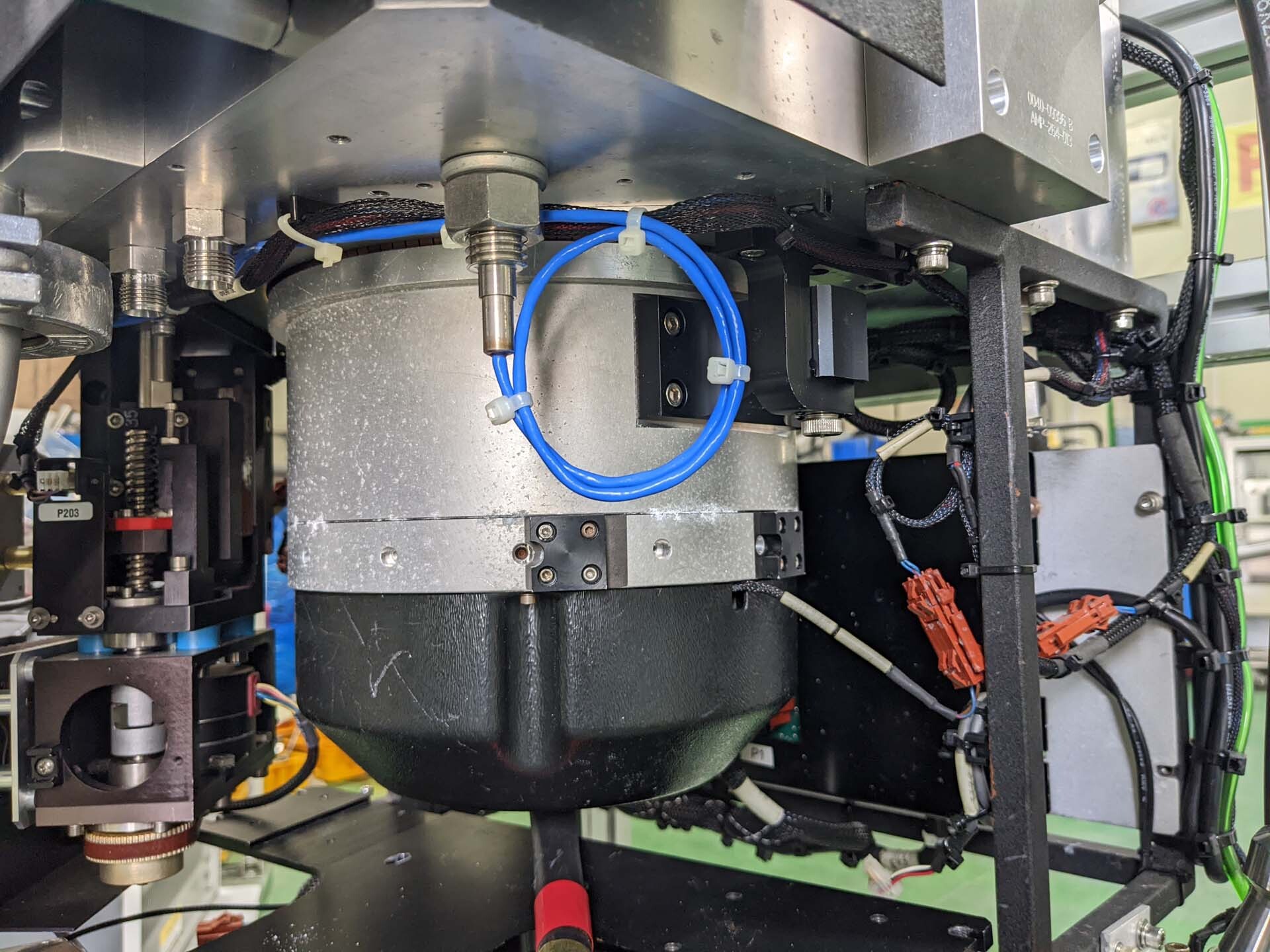

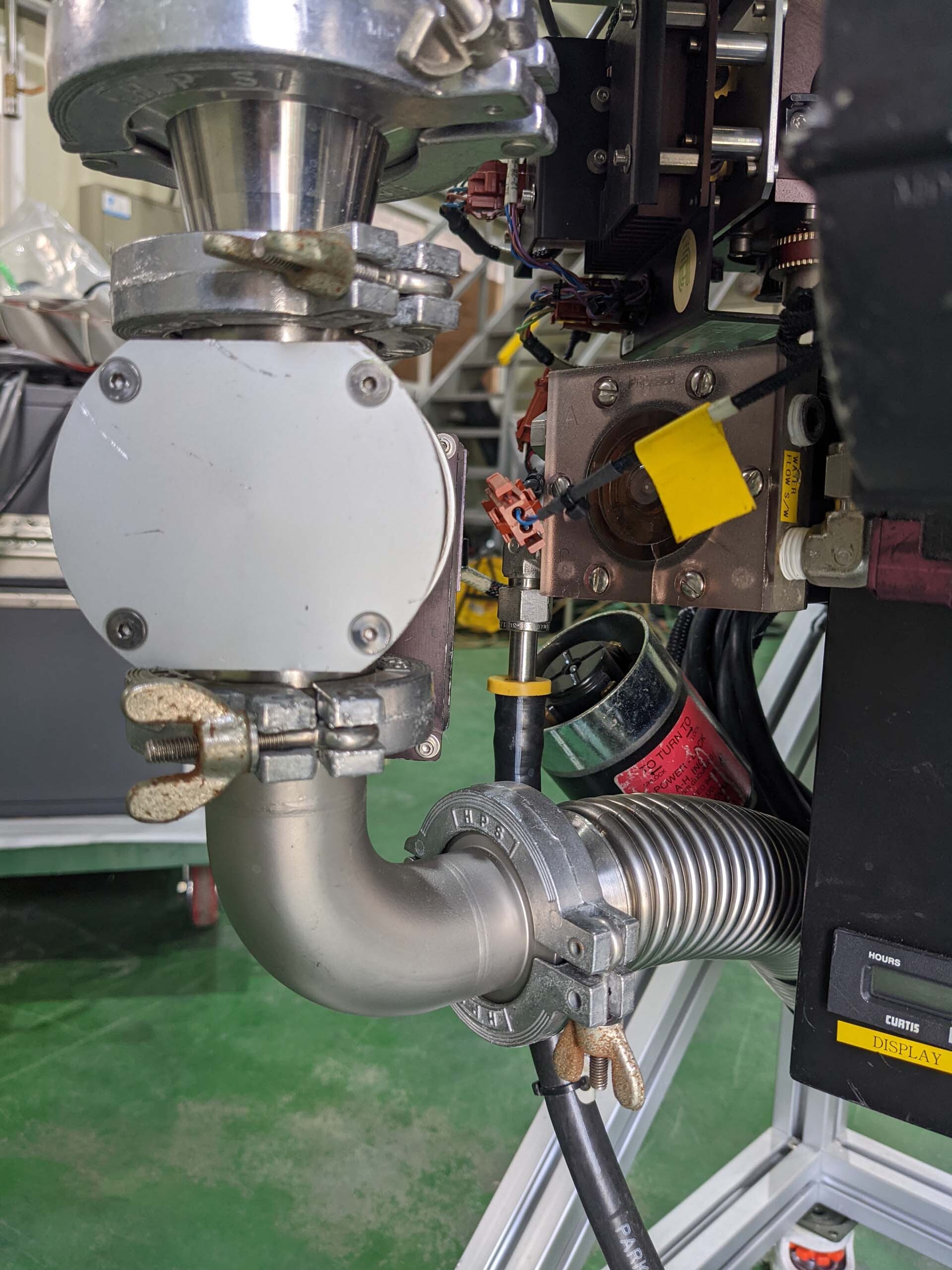

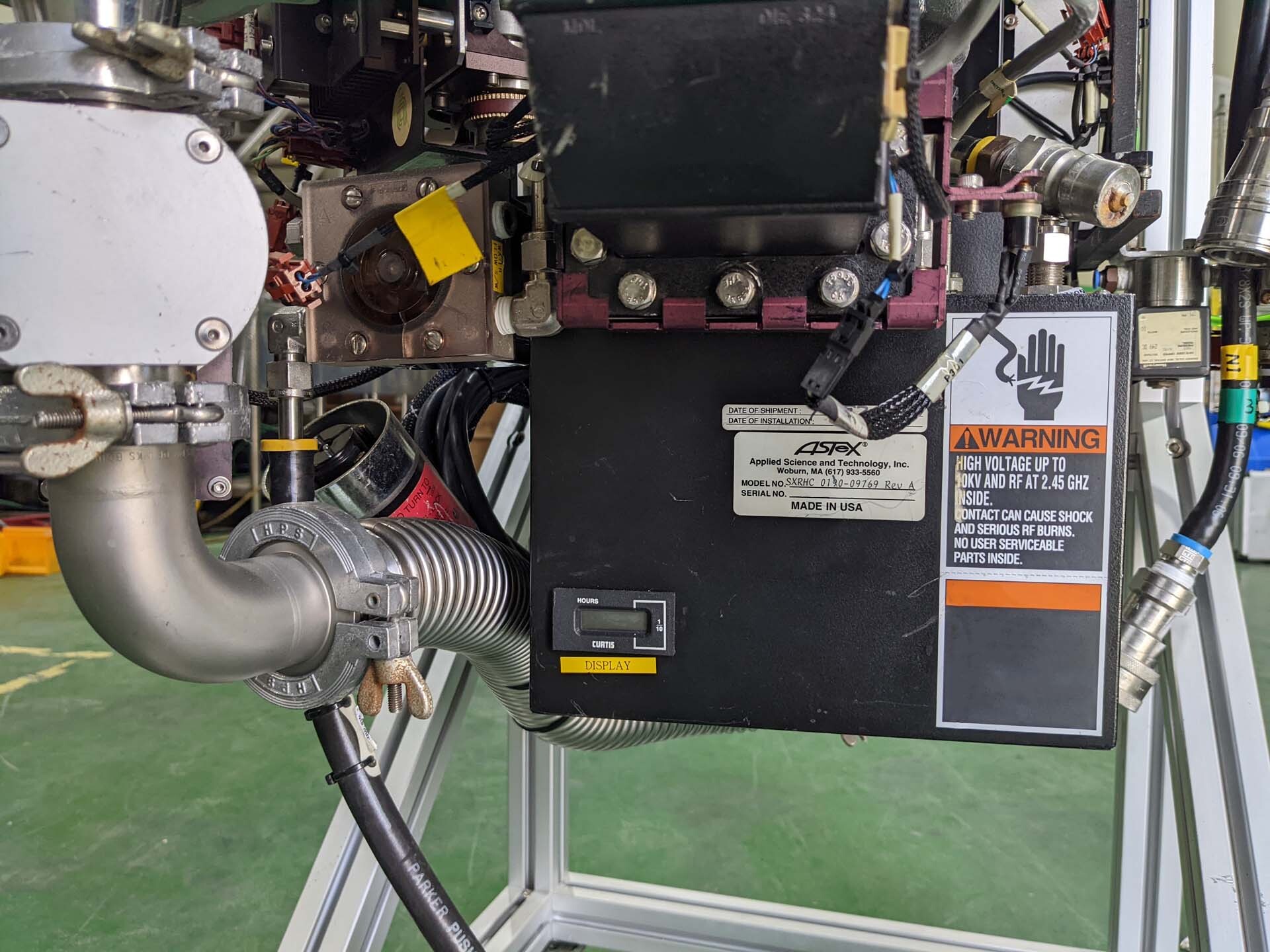

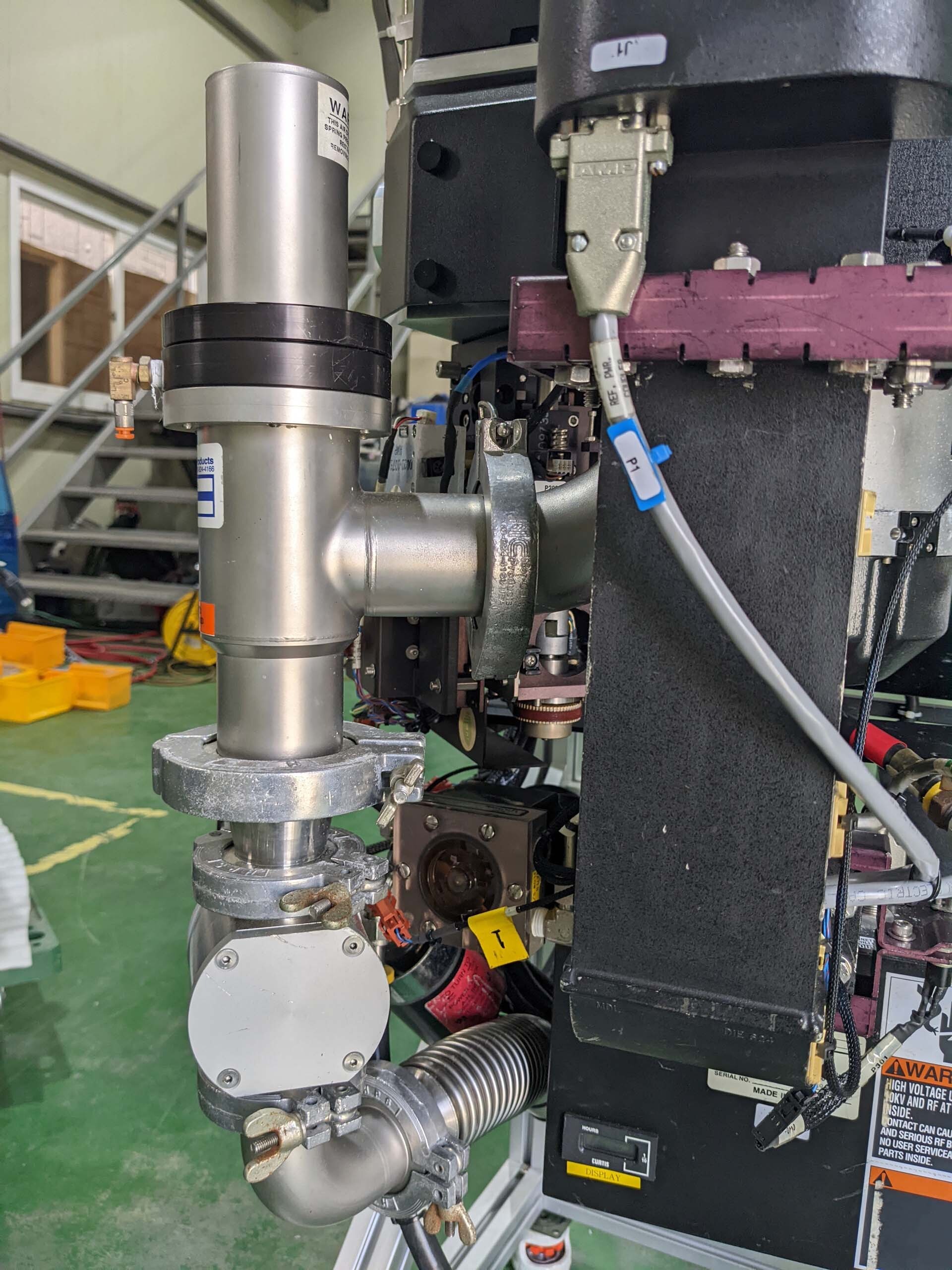

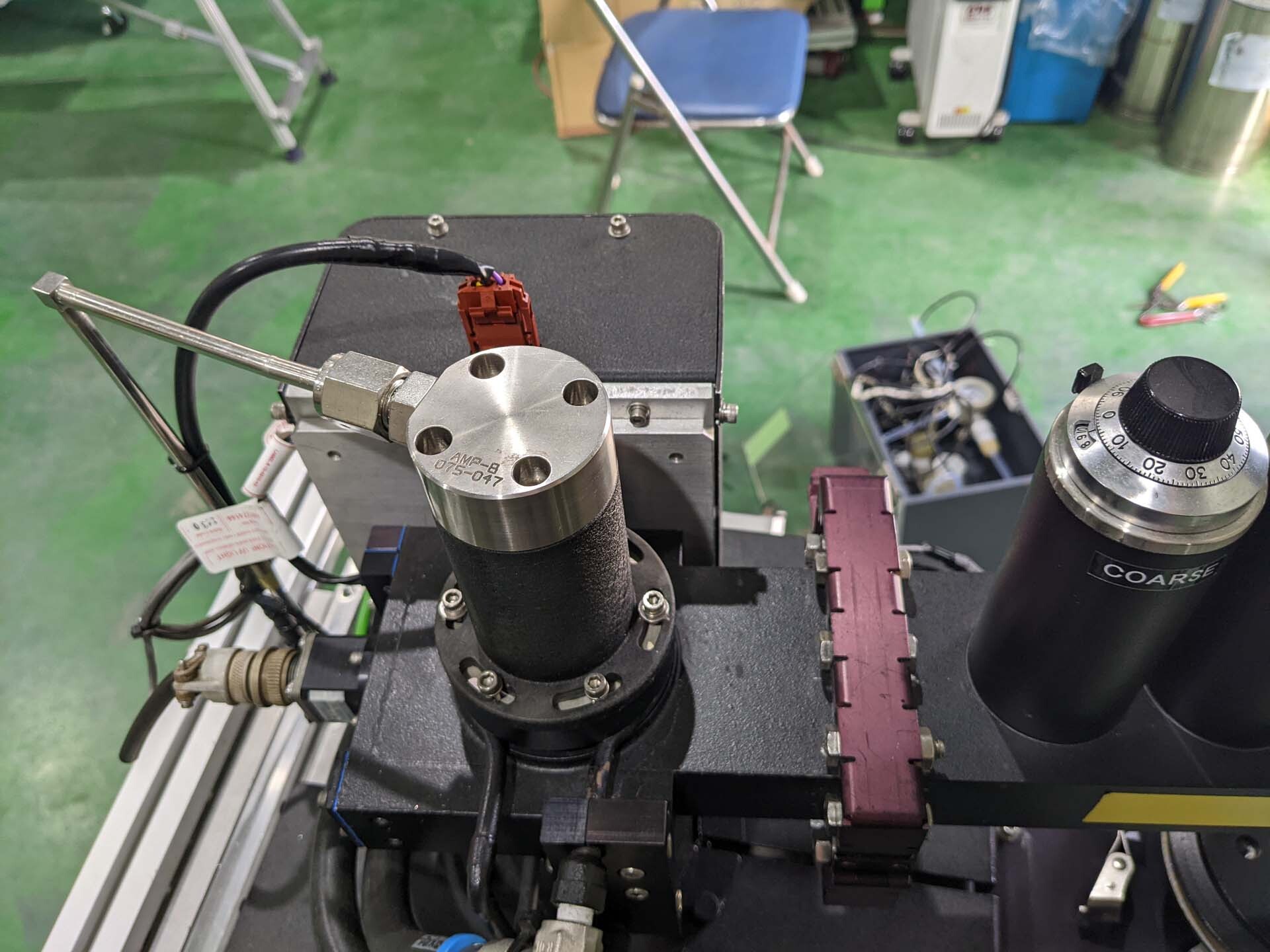

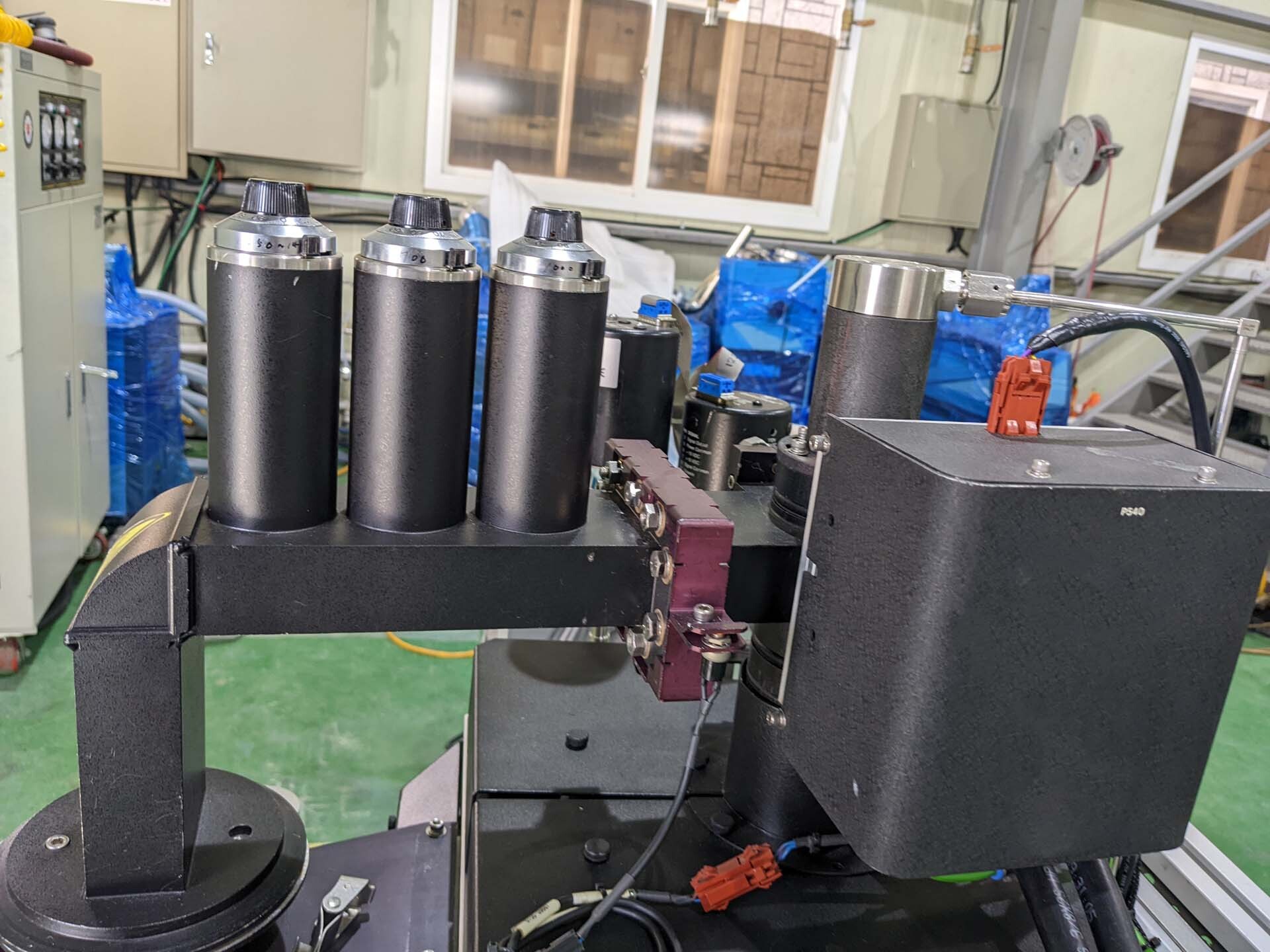

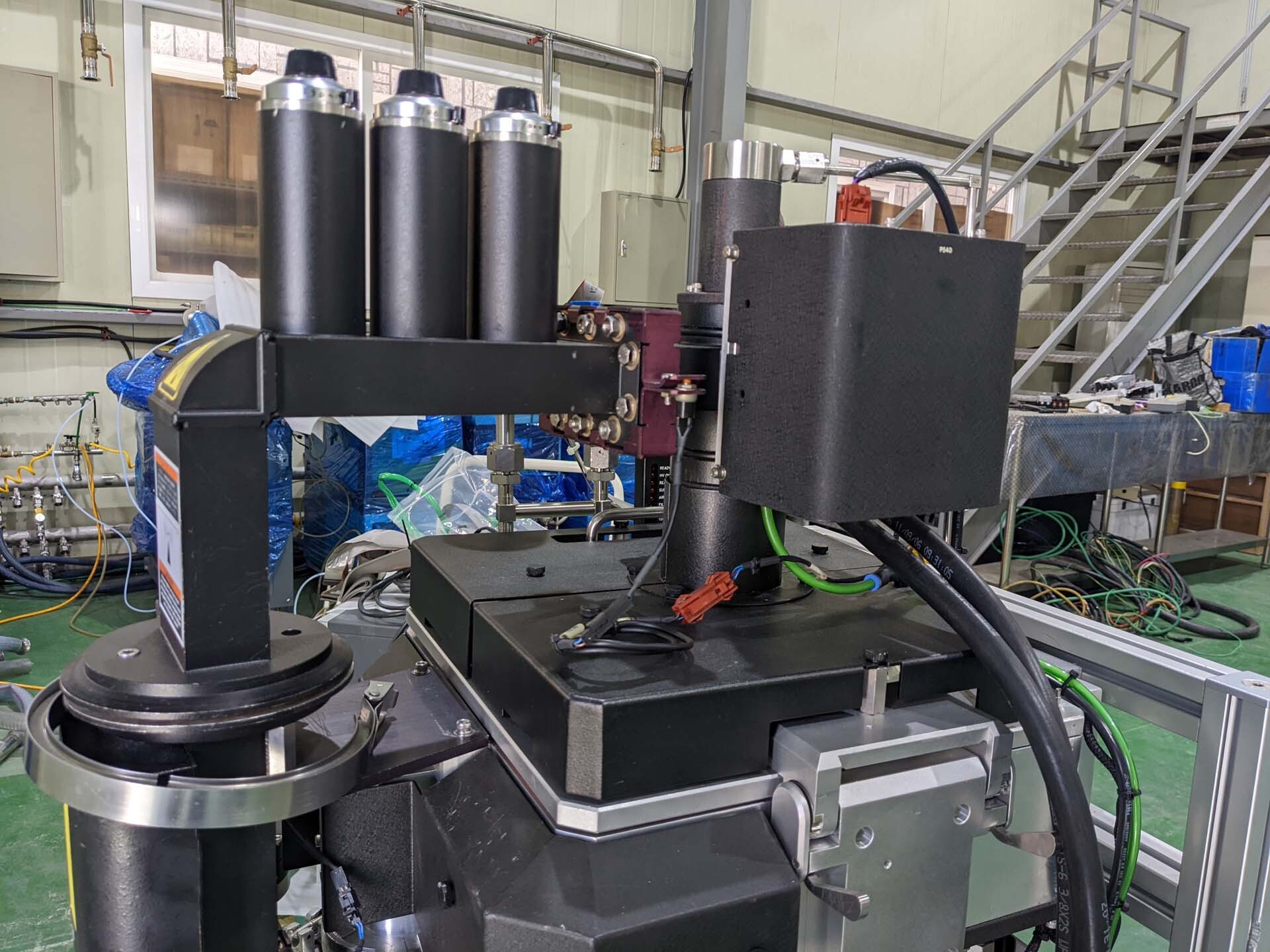

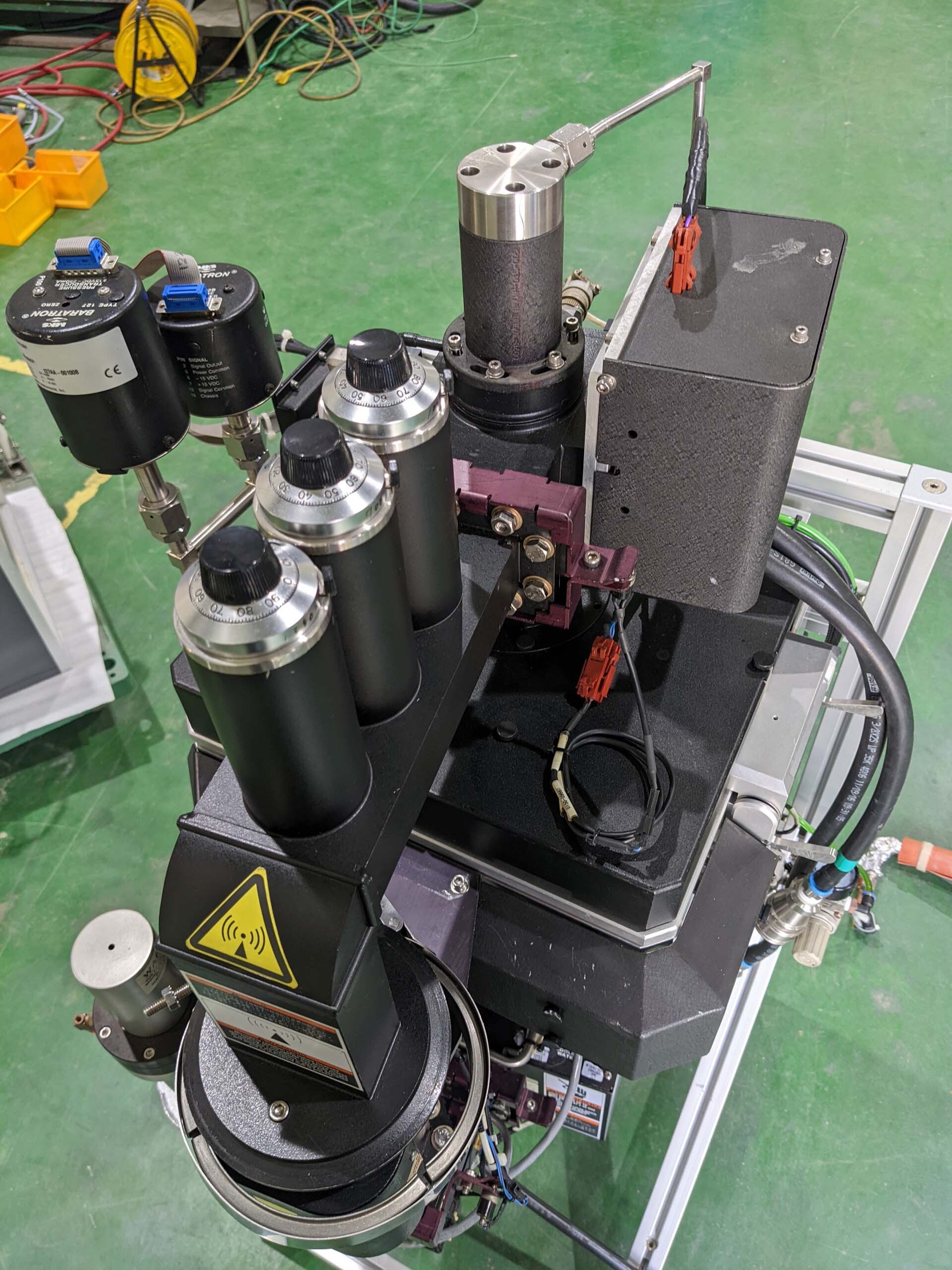

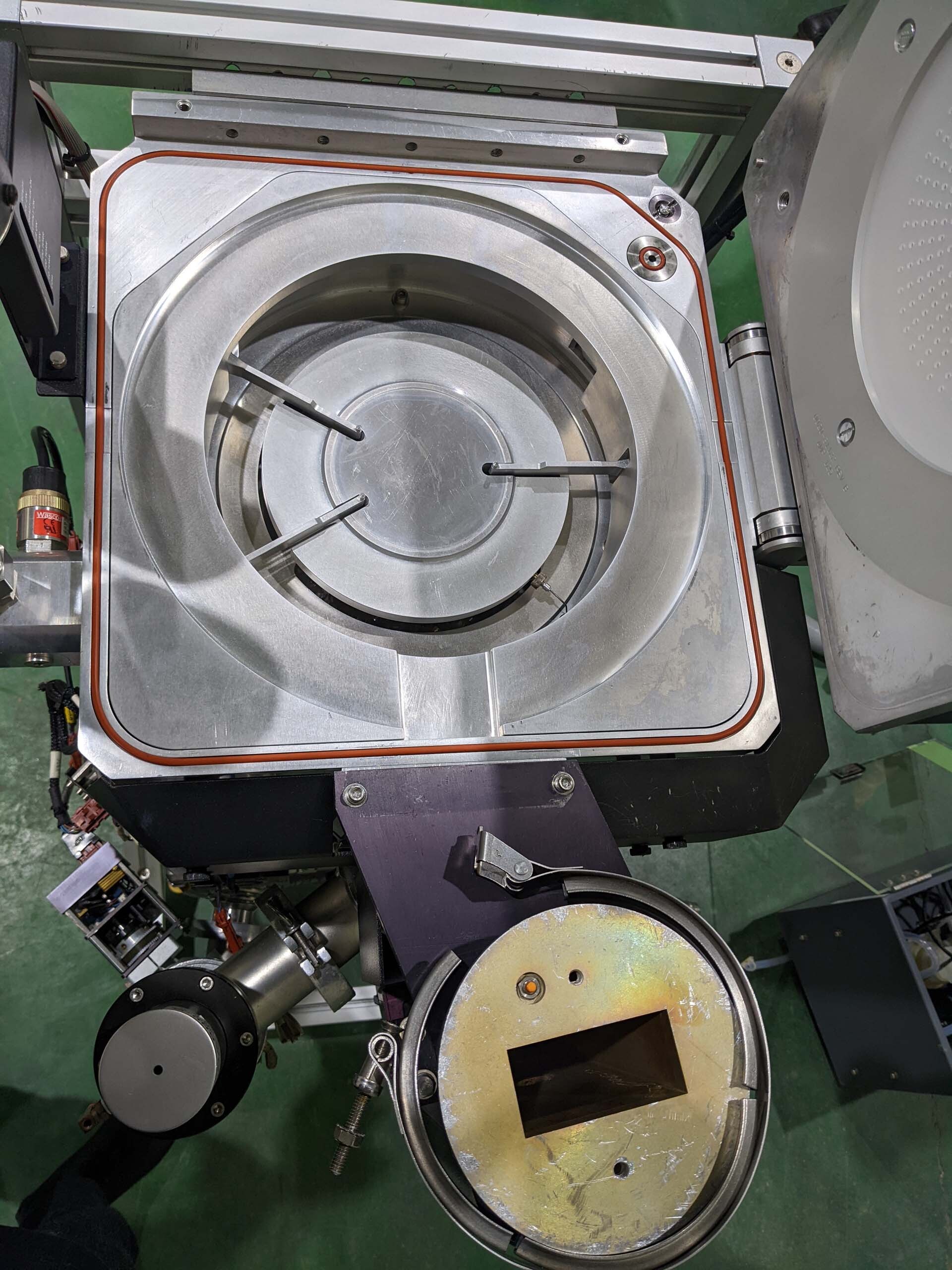

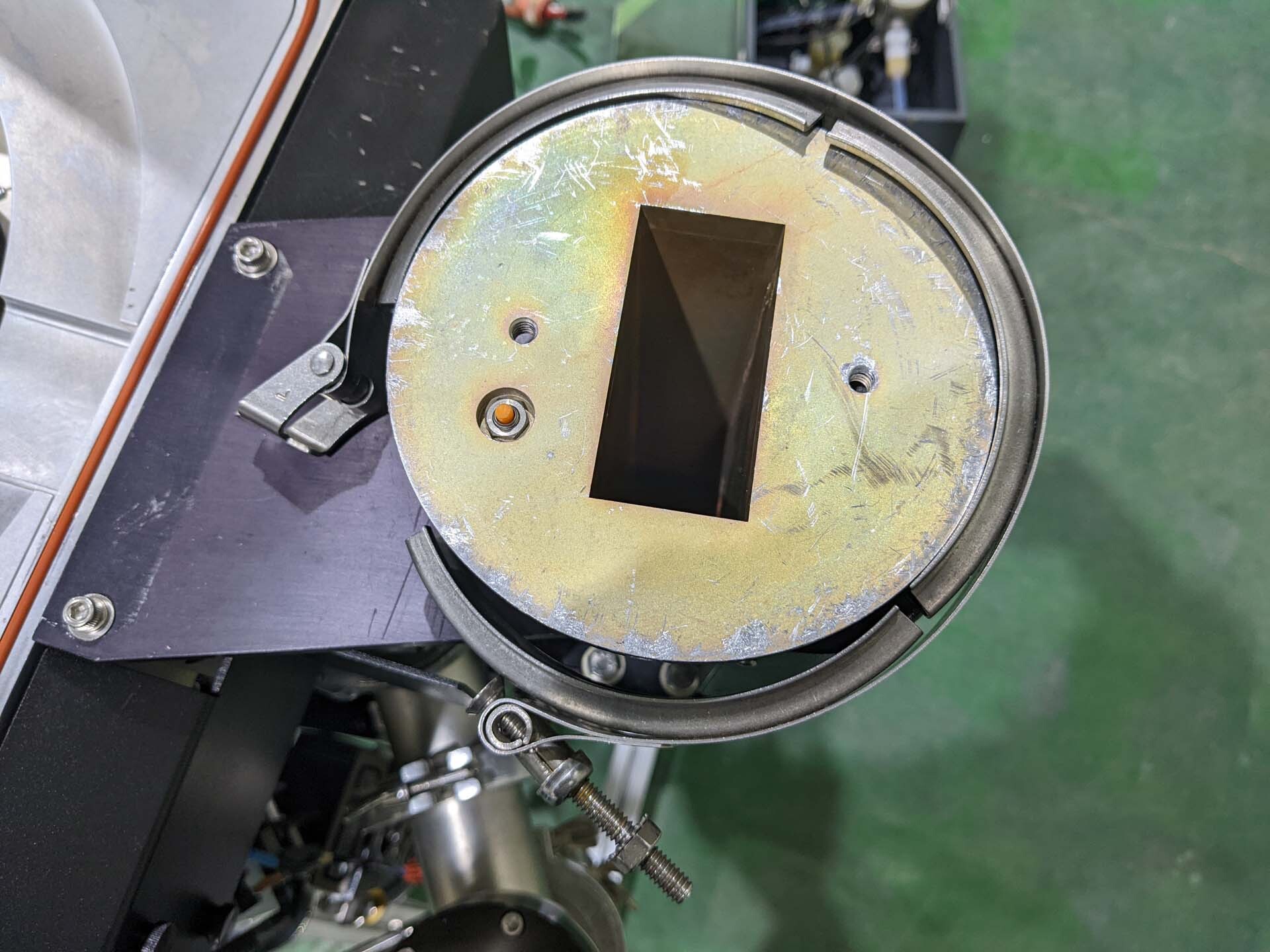

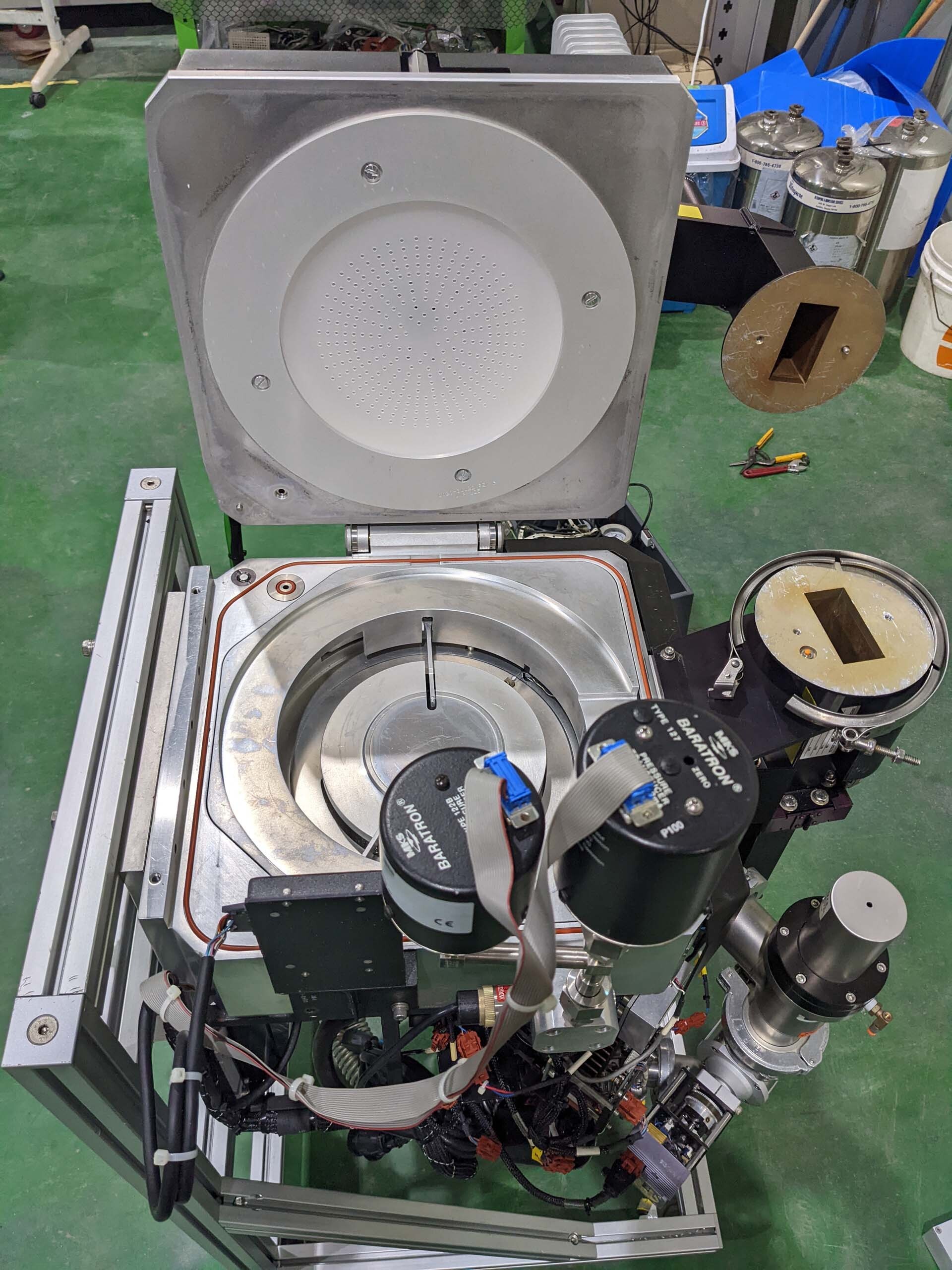

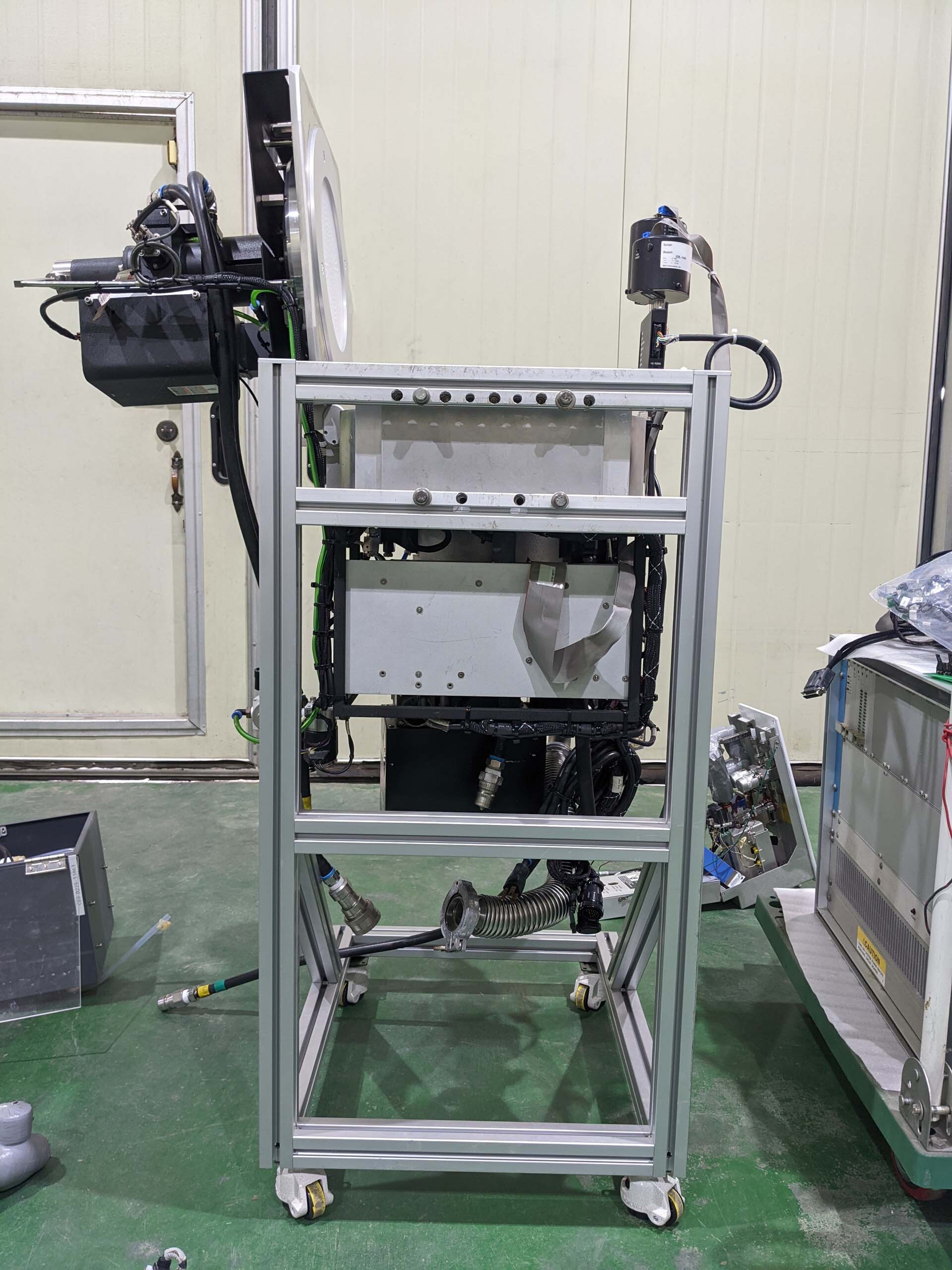

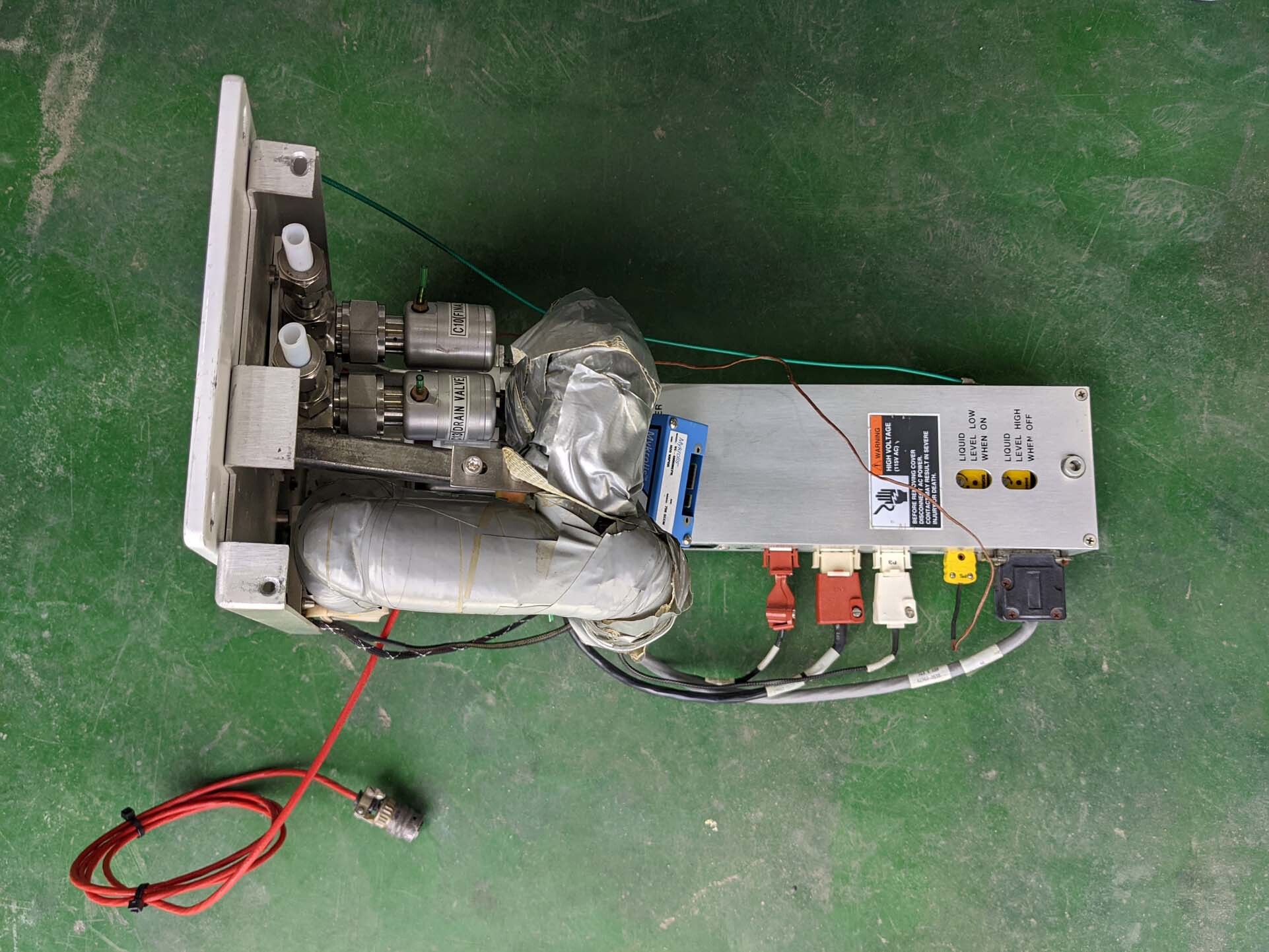

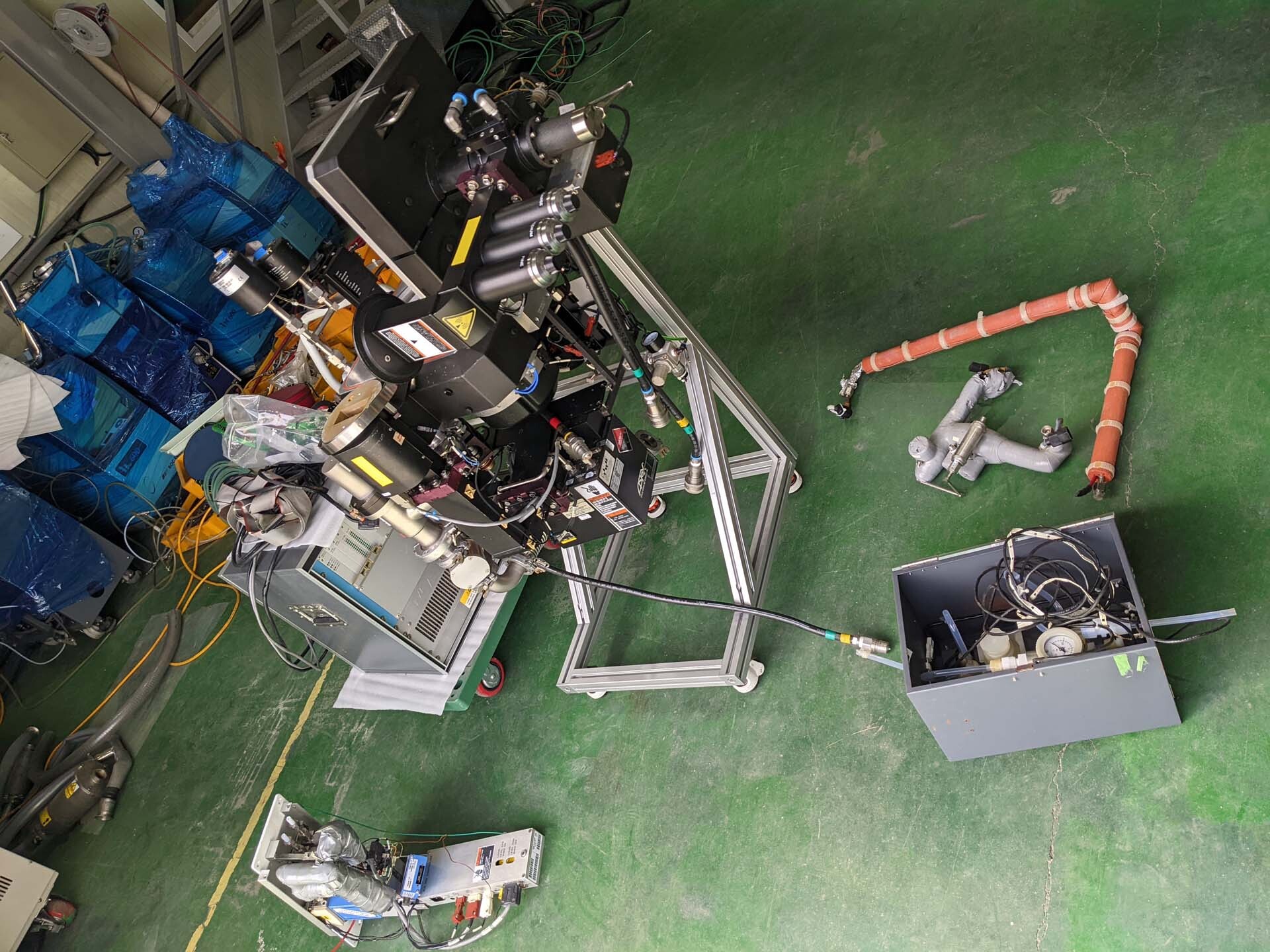

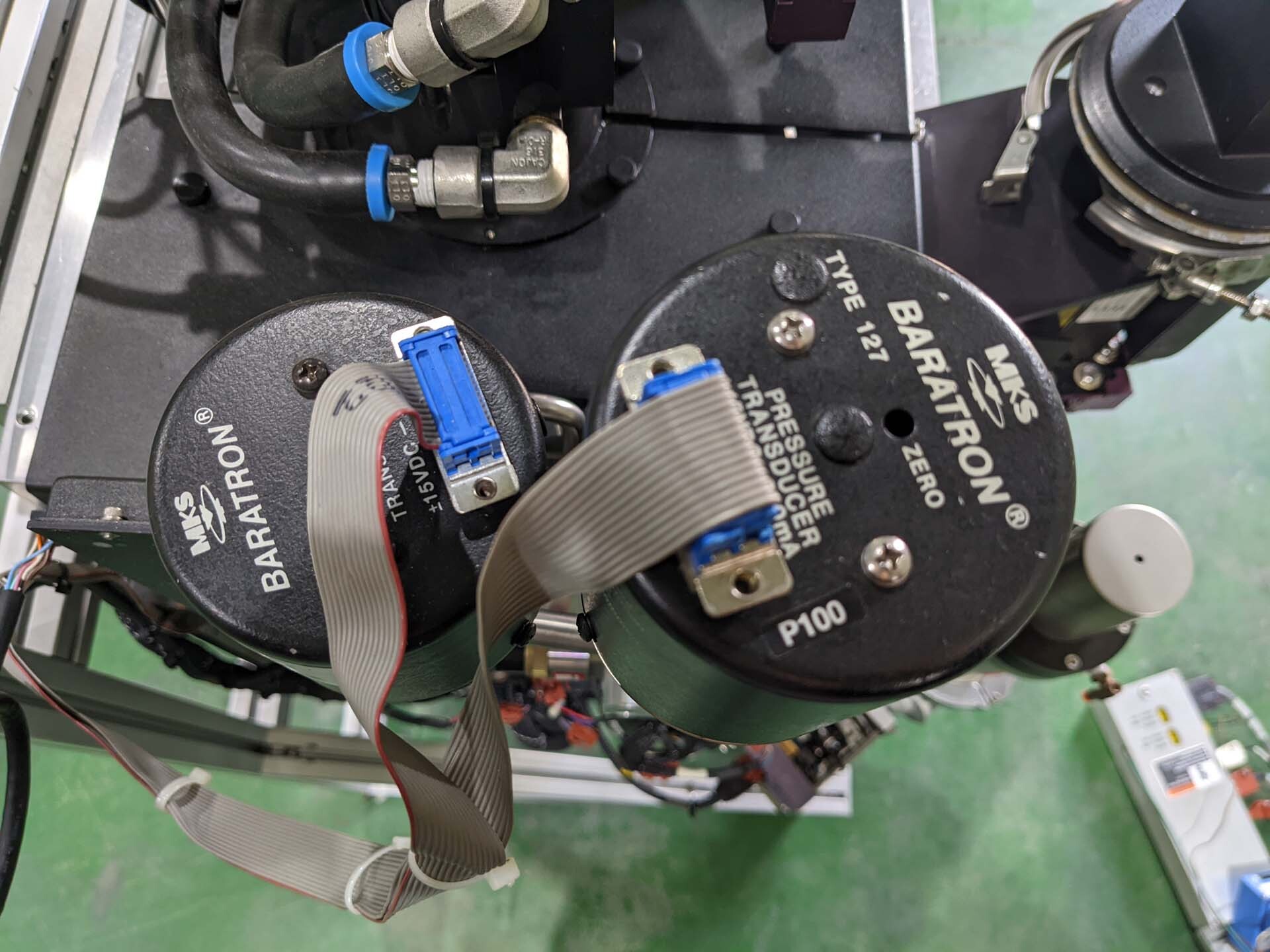

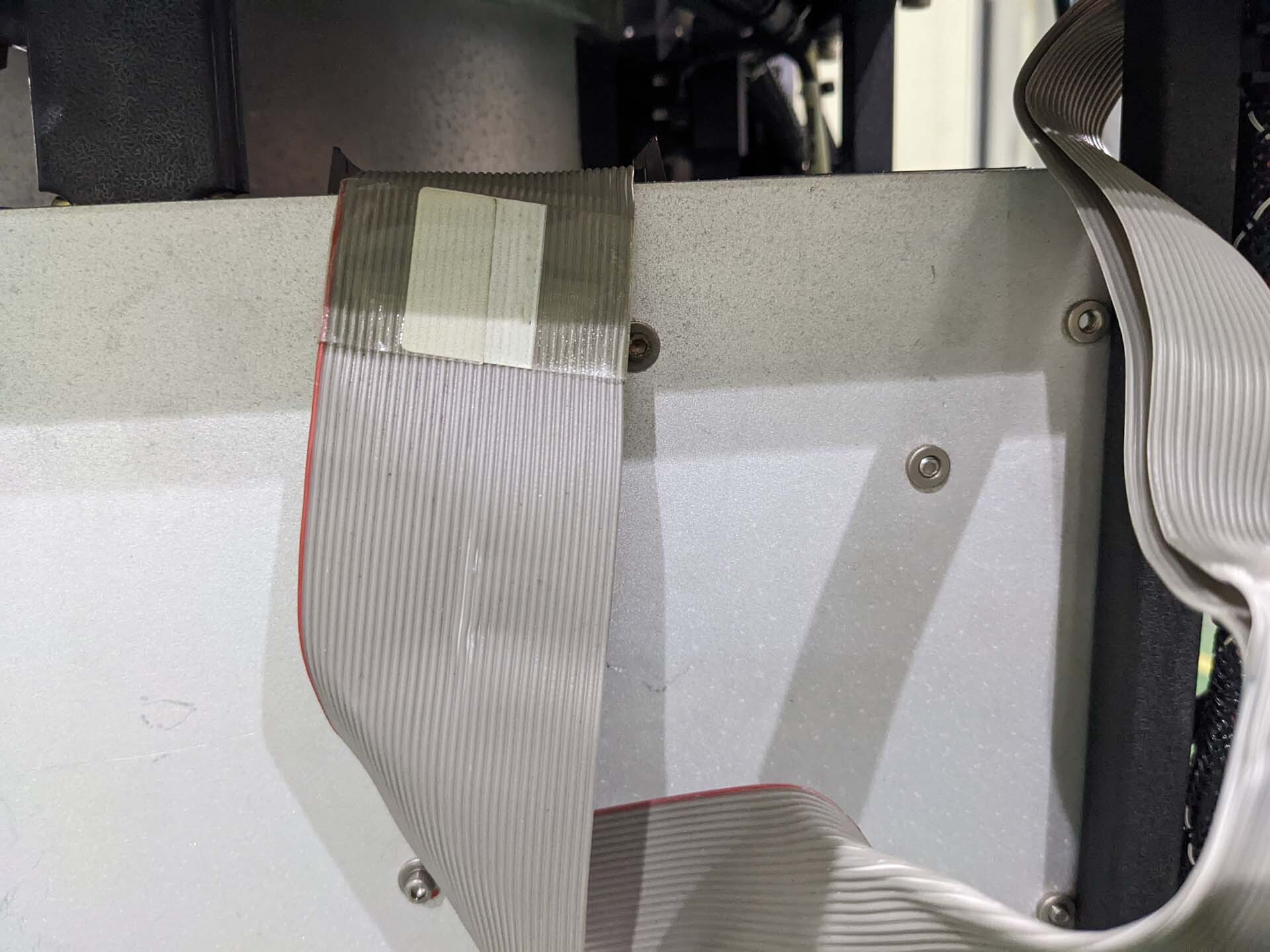

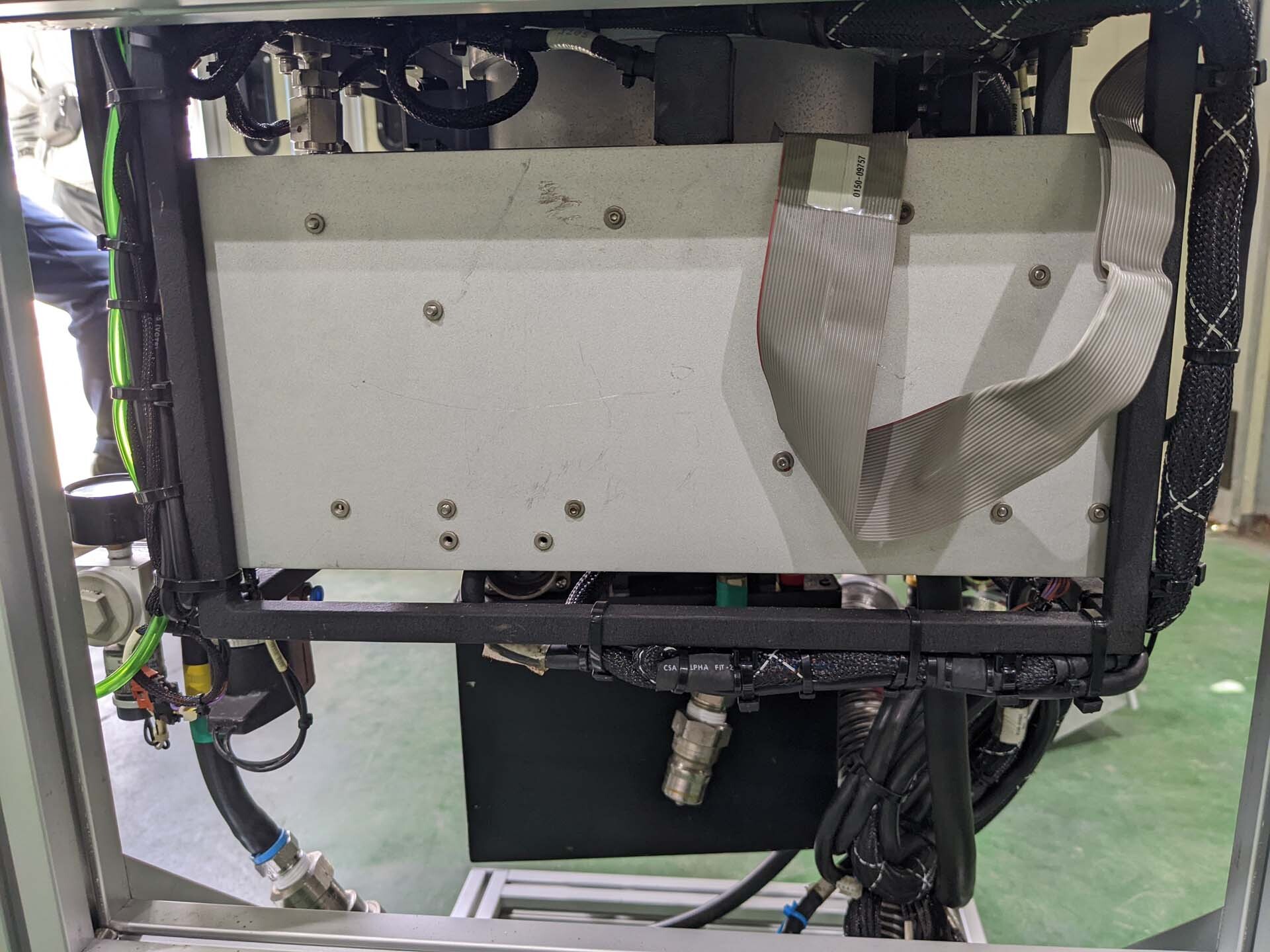

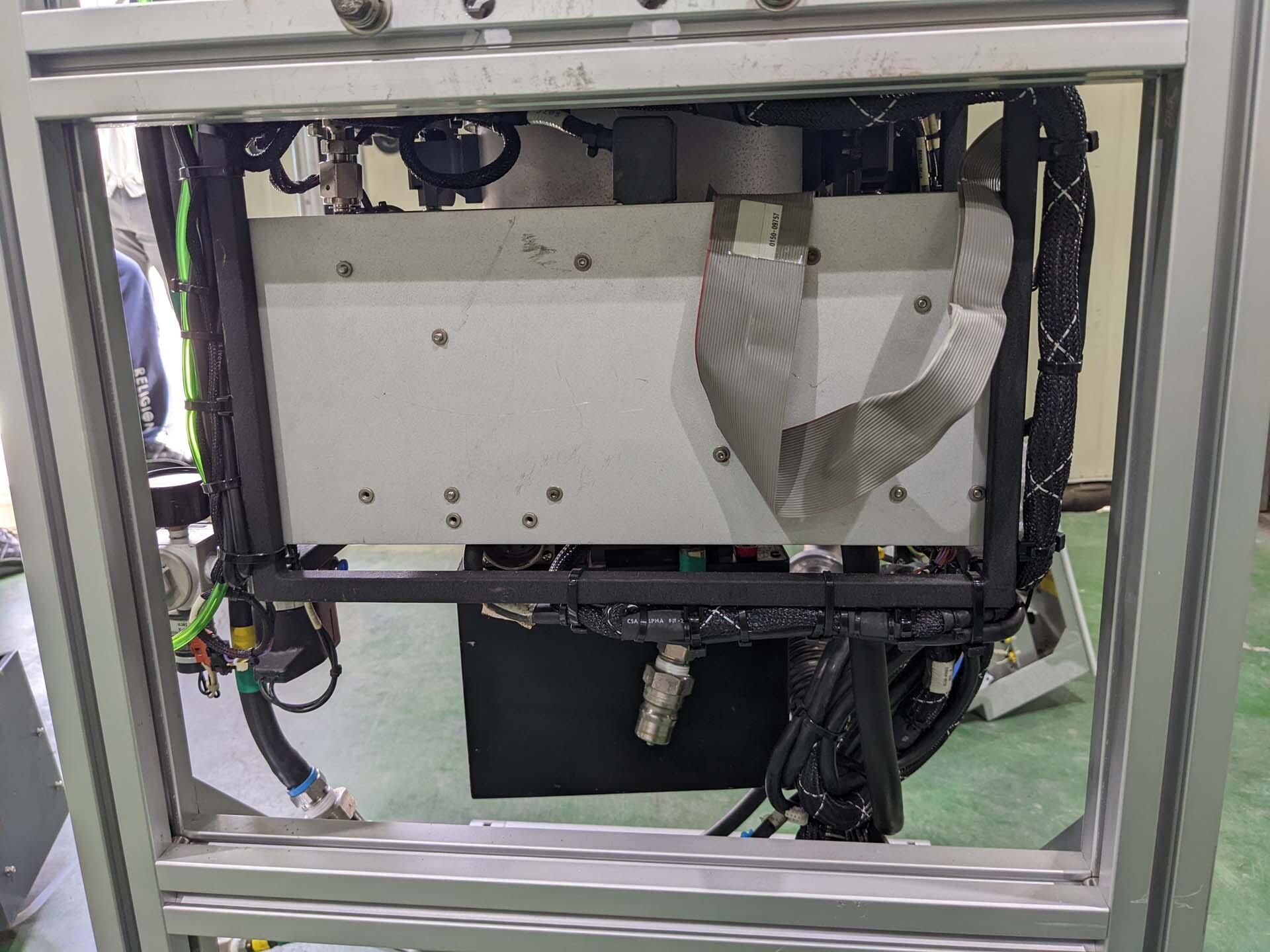

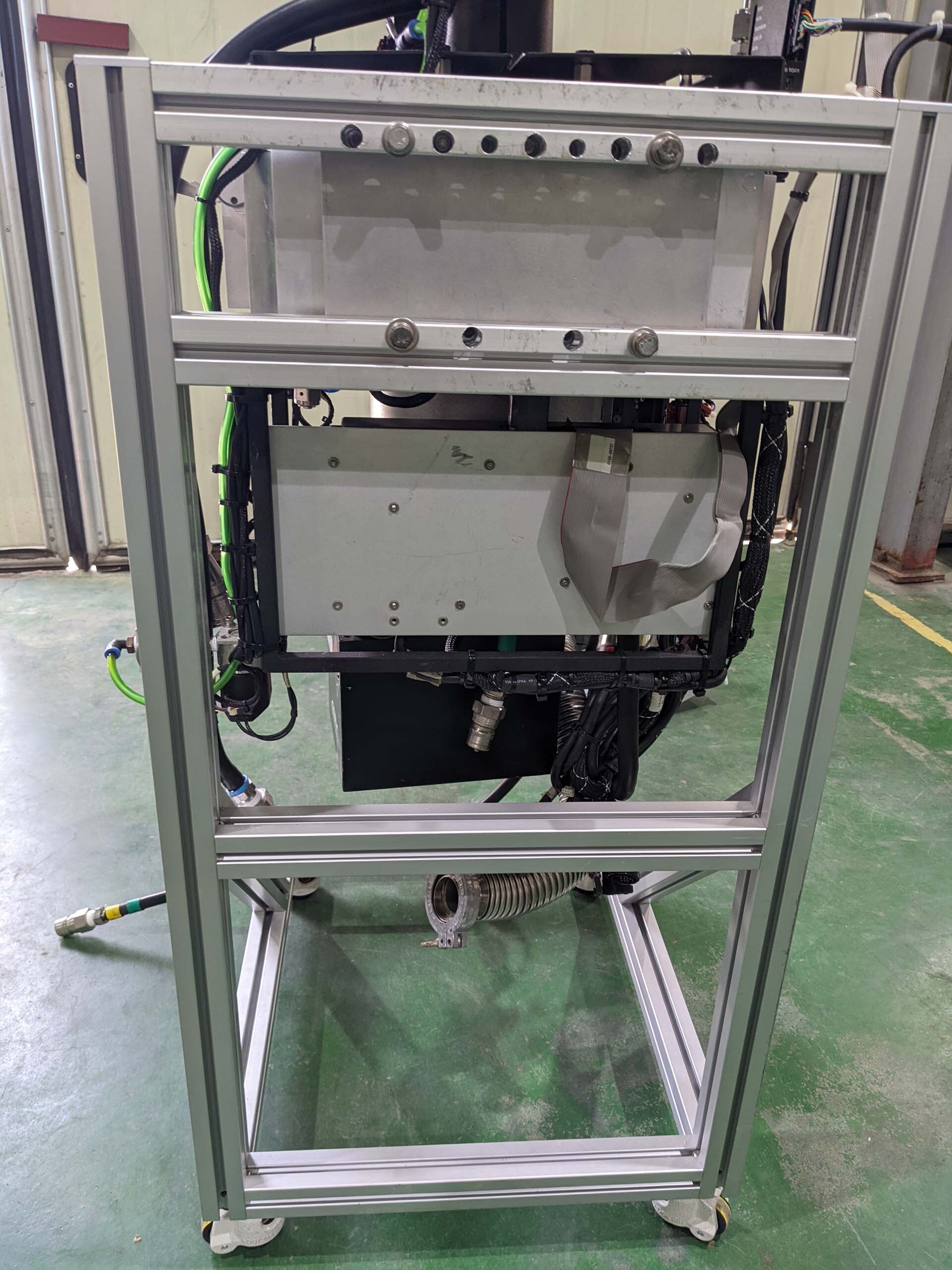

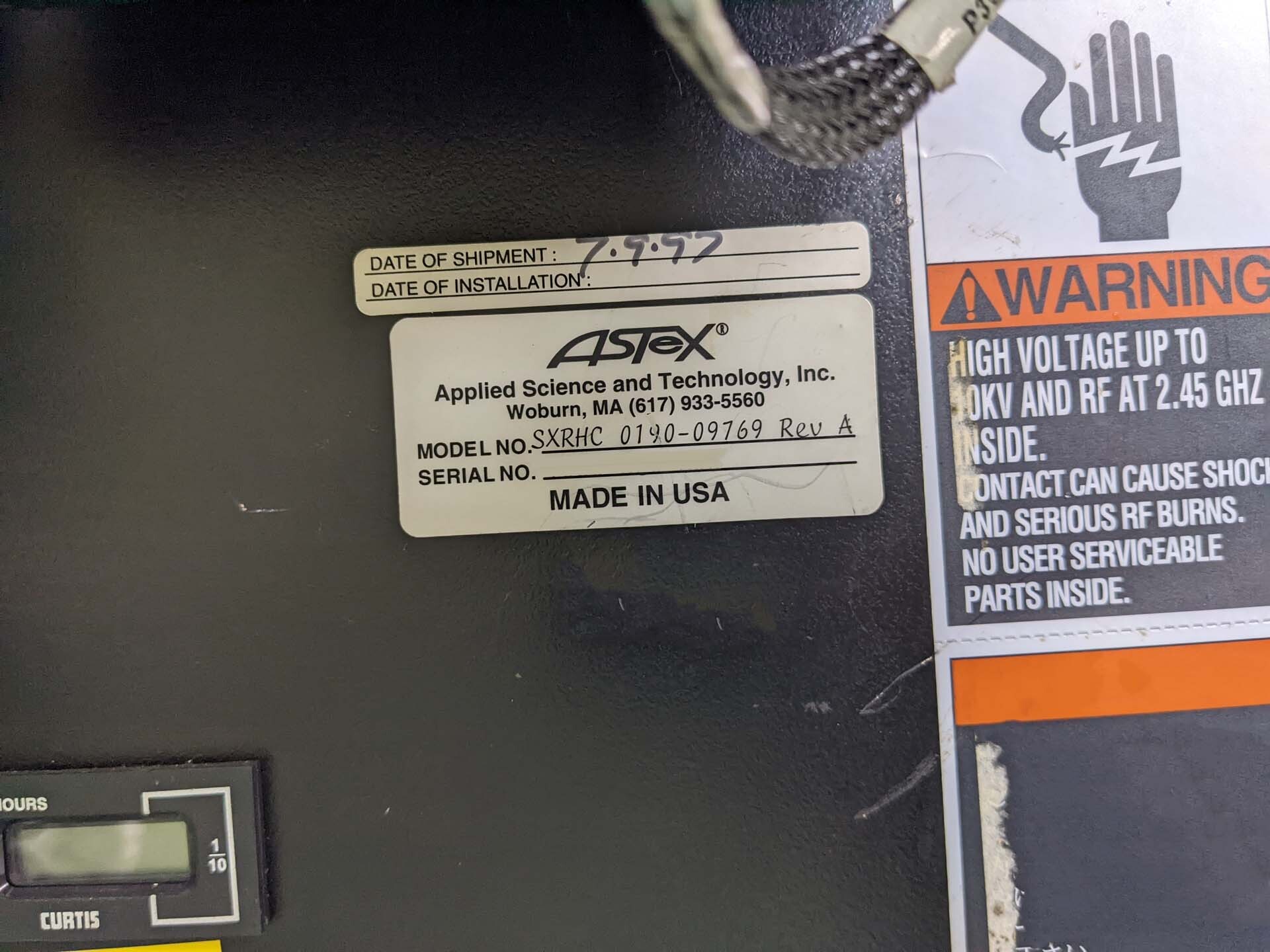

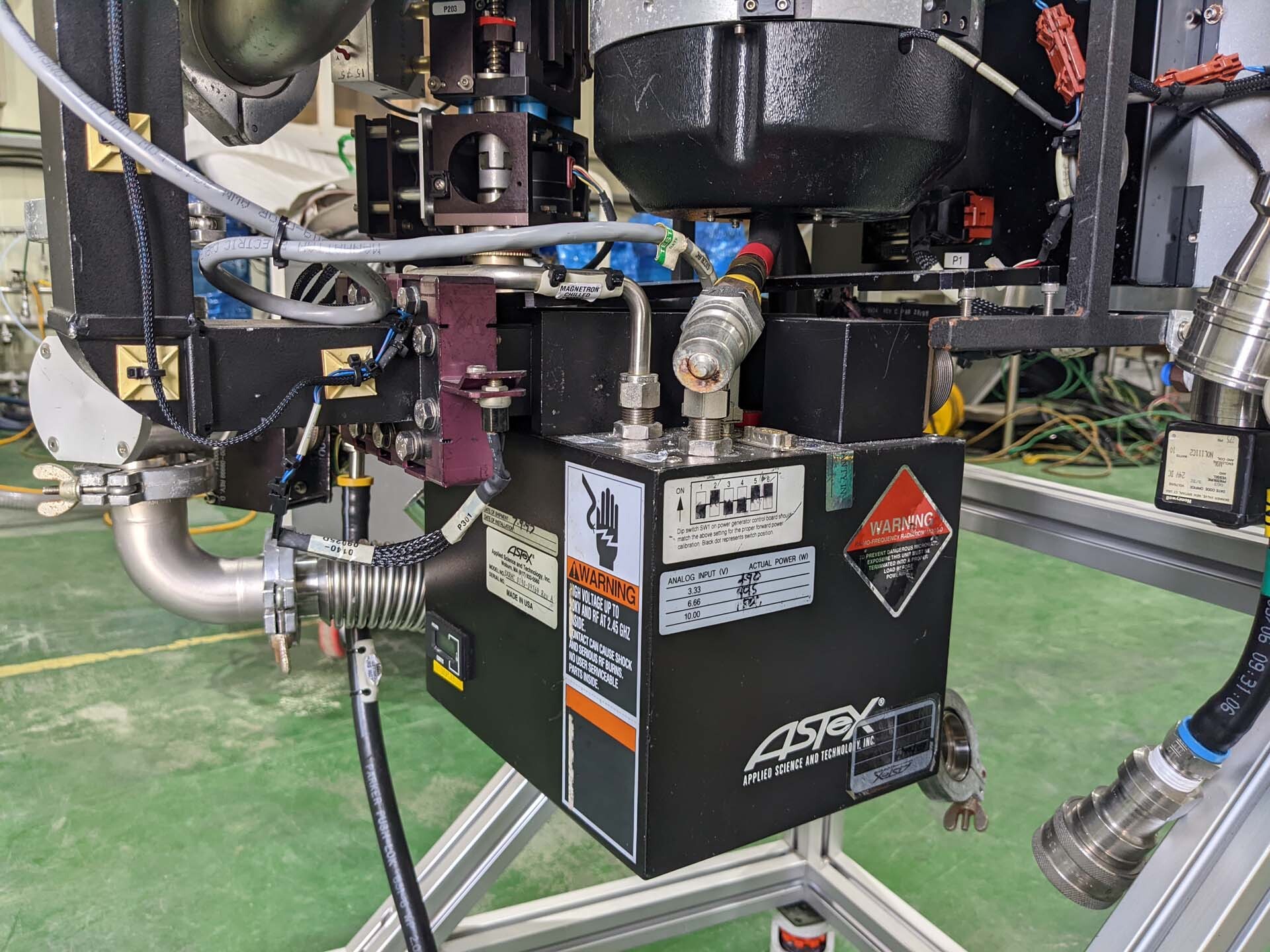

Used AMAT / APPLIED MATERIALS ASP Chamber for P5000 #293642390 for sale

URL successfully copied!

Tap to zoom

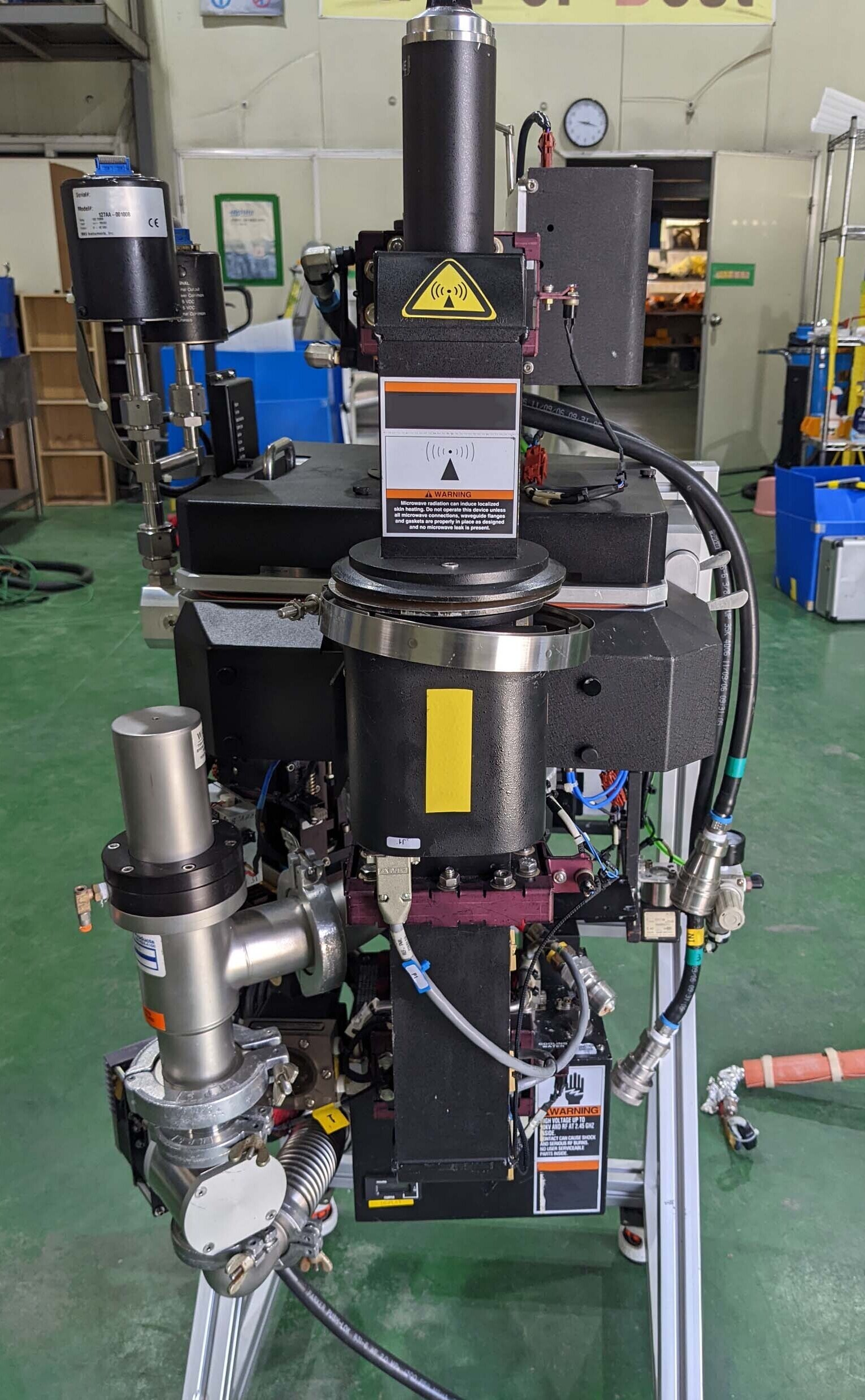

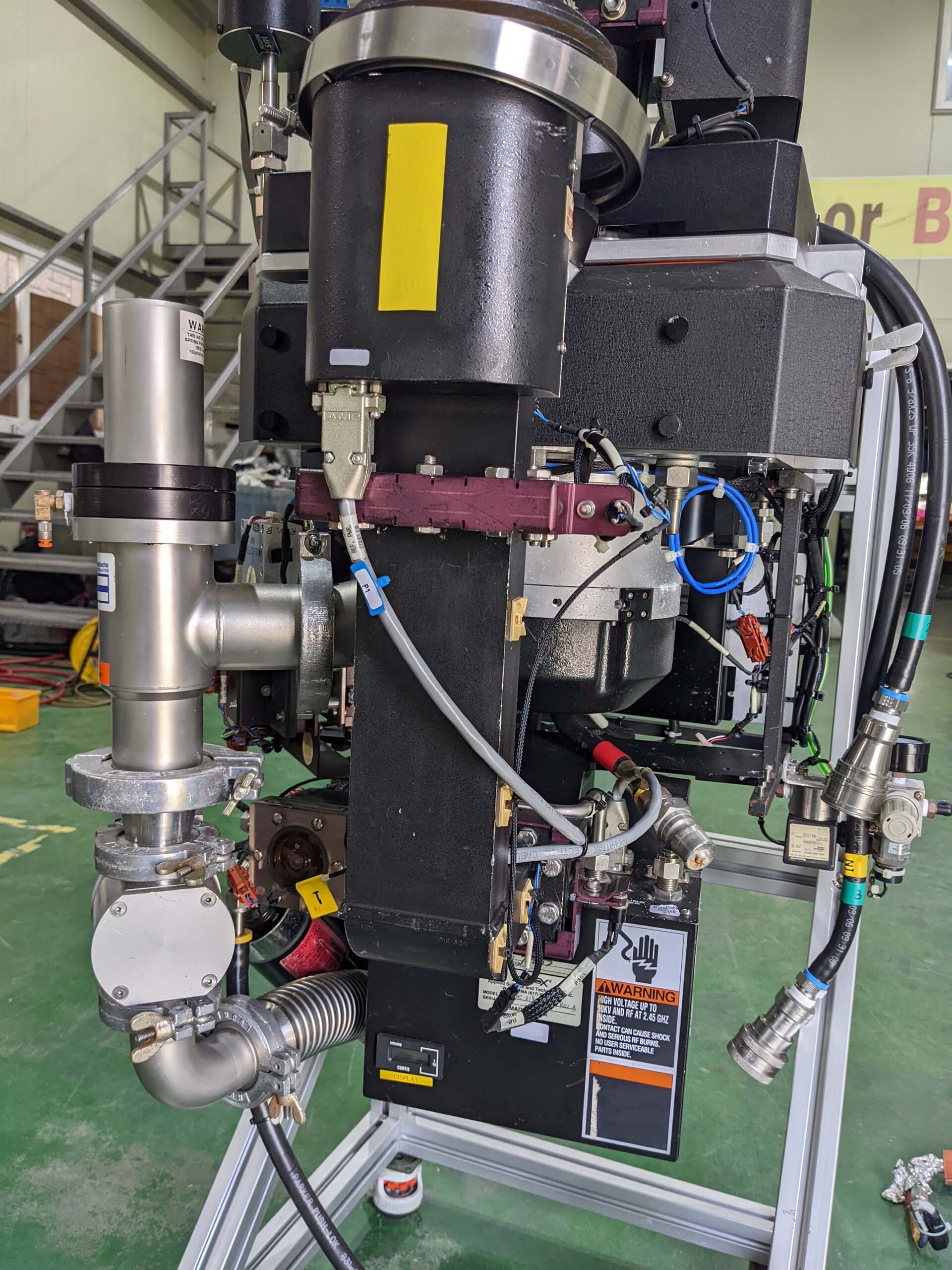

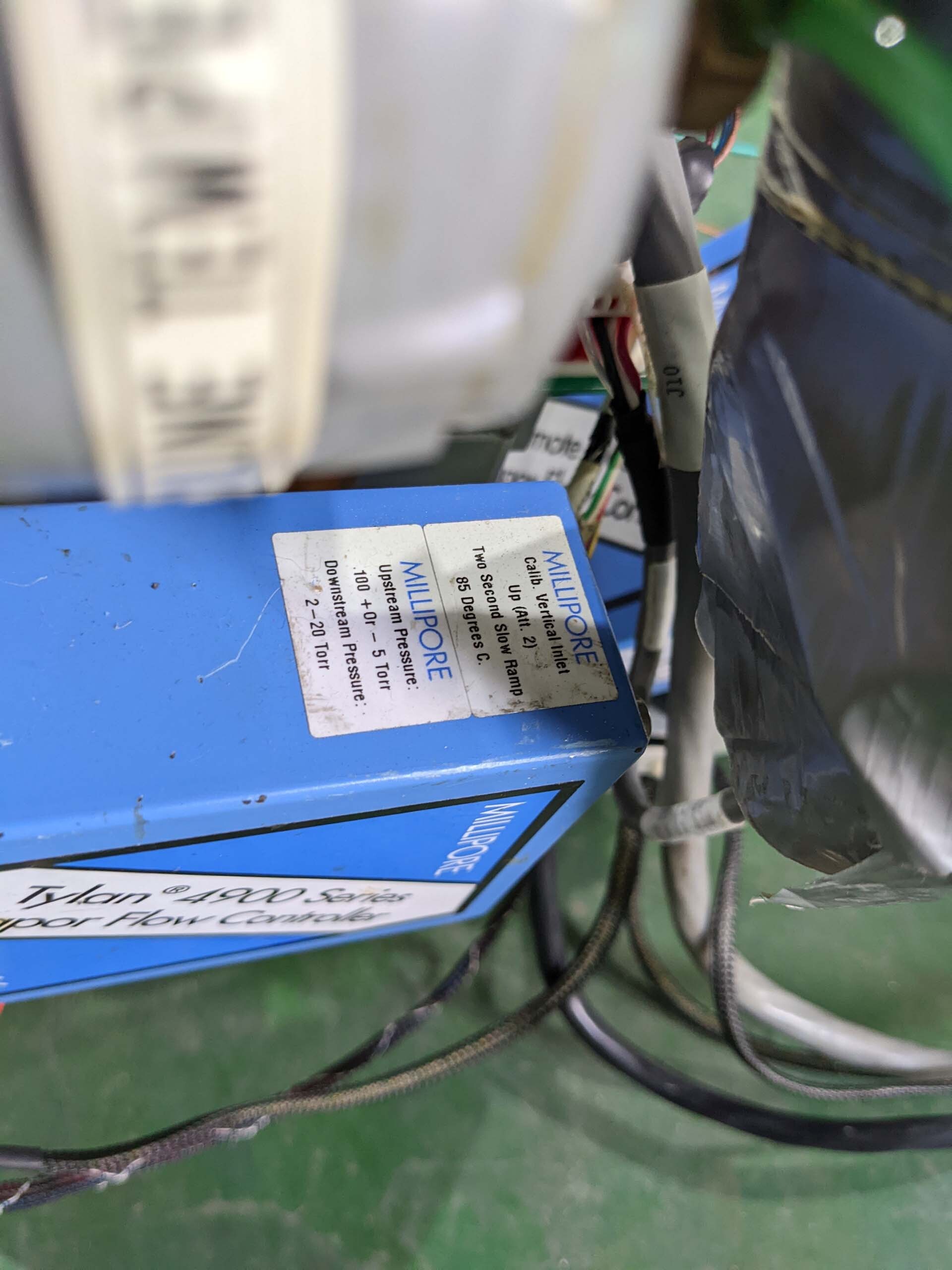

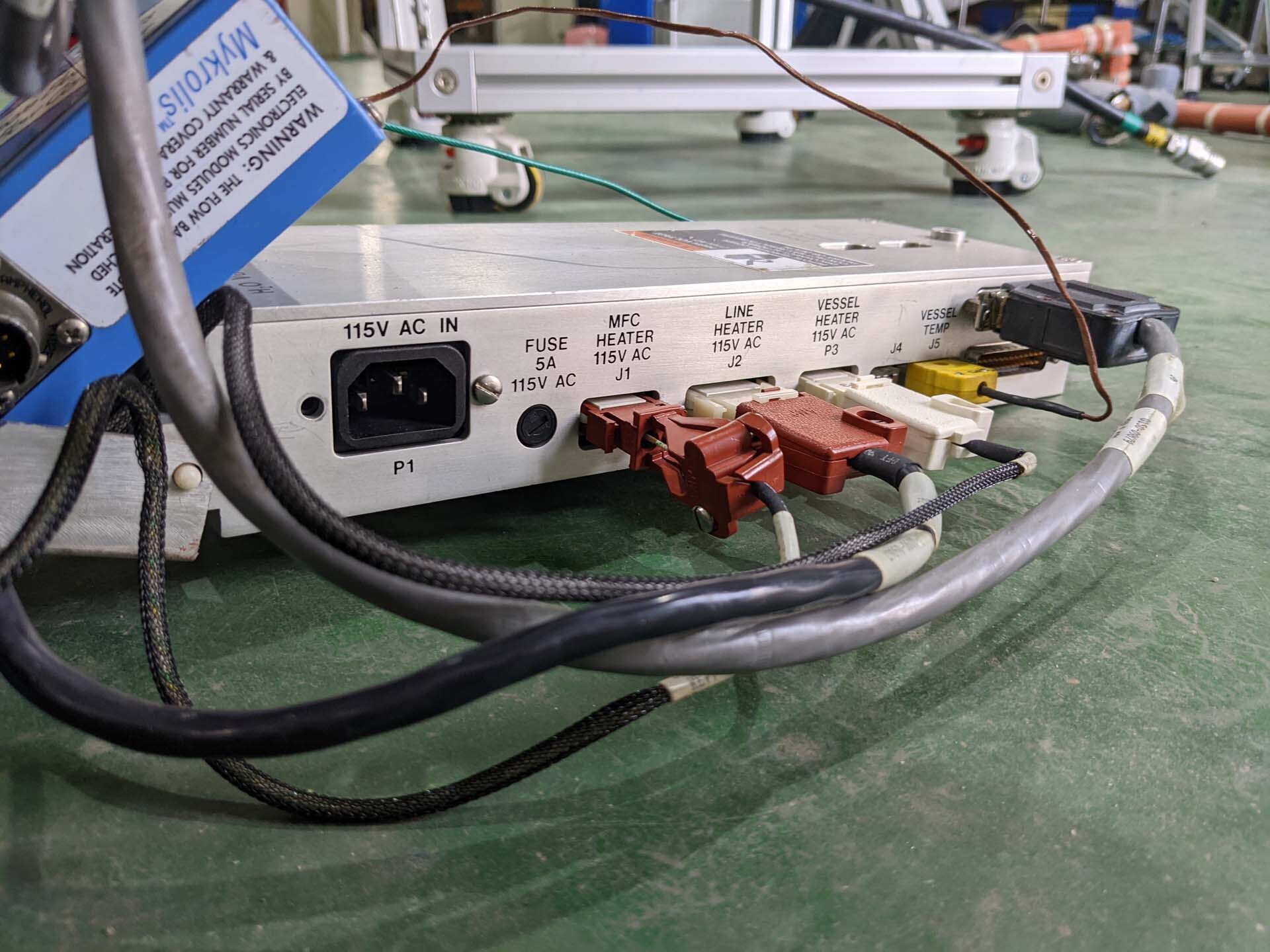

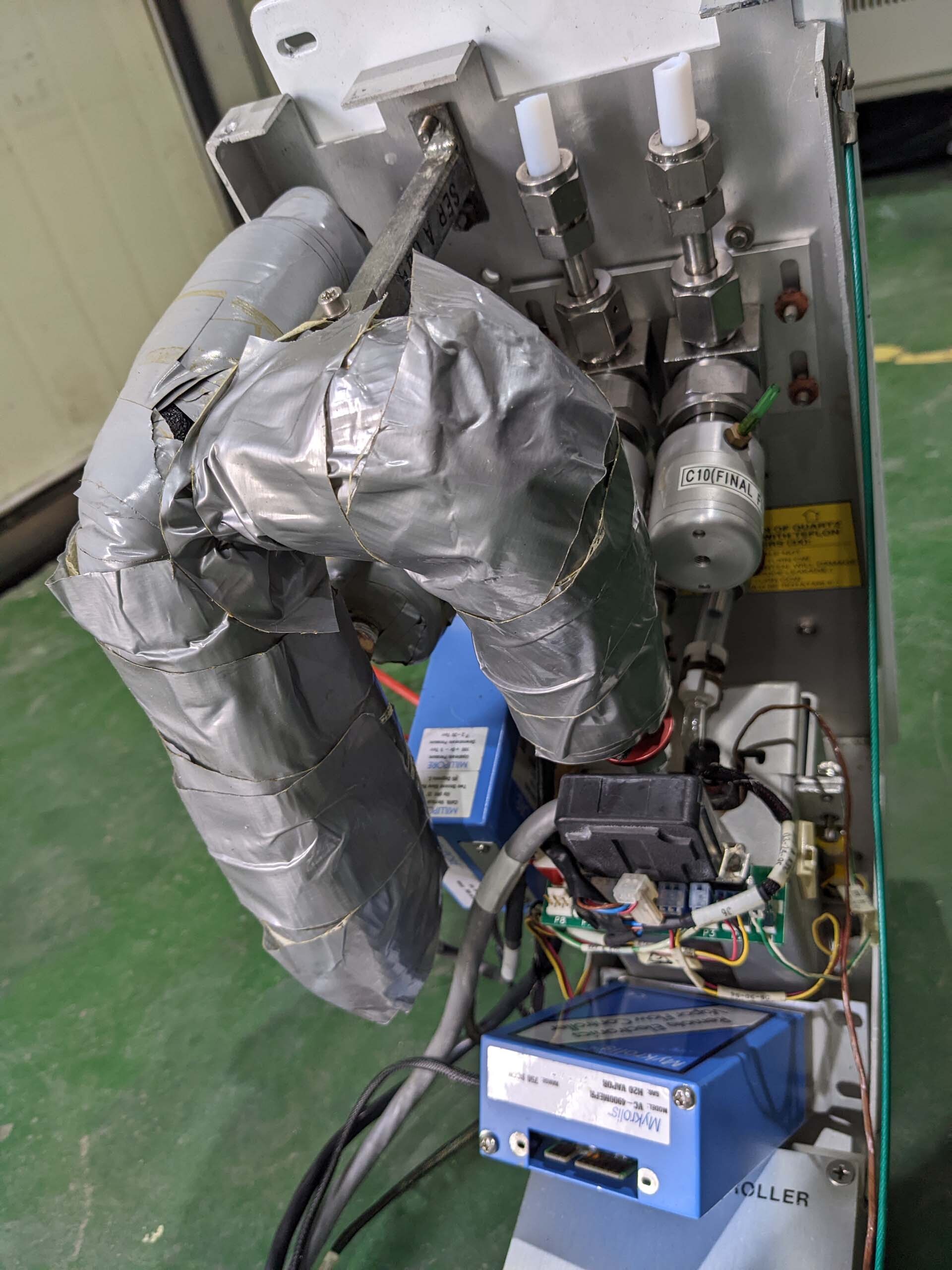

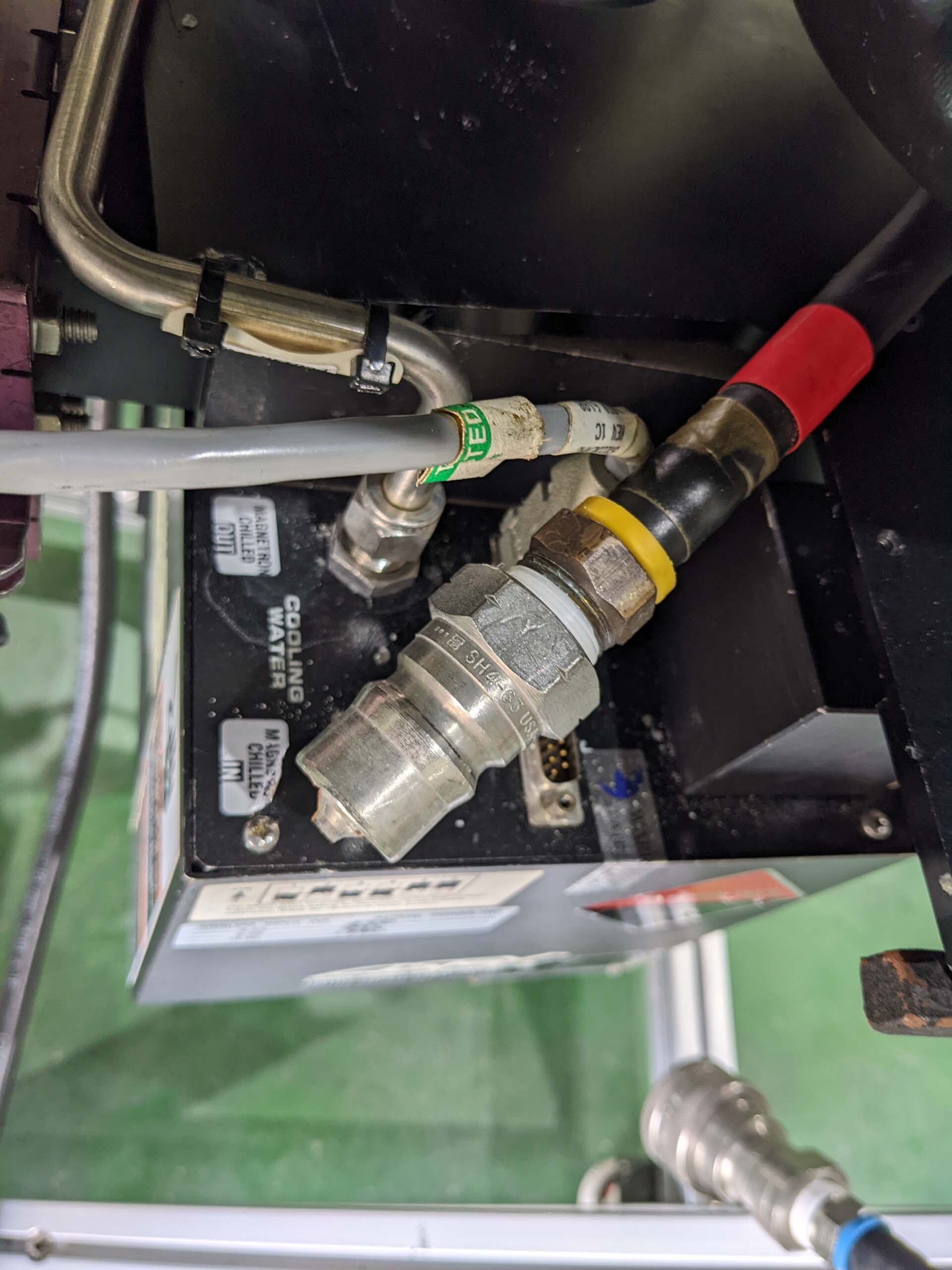

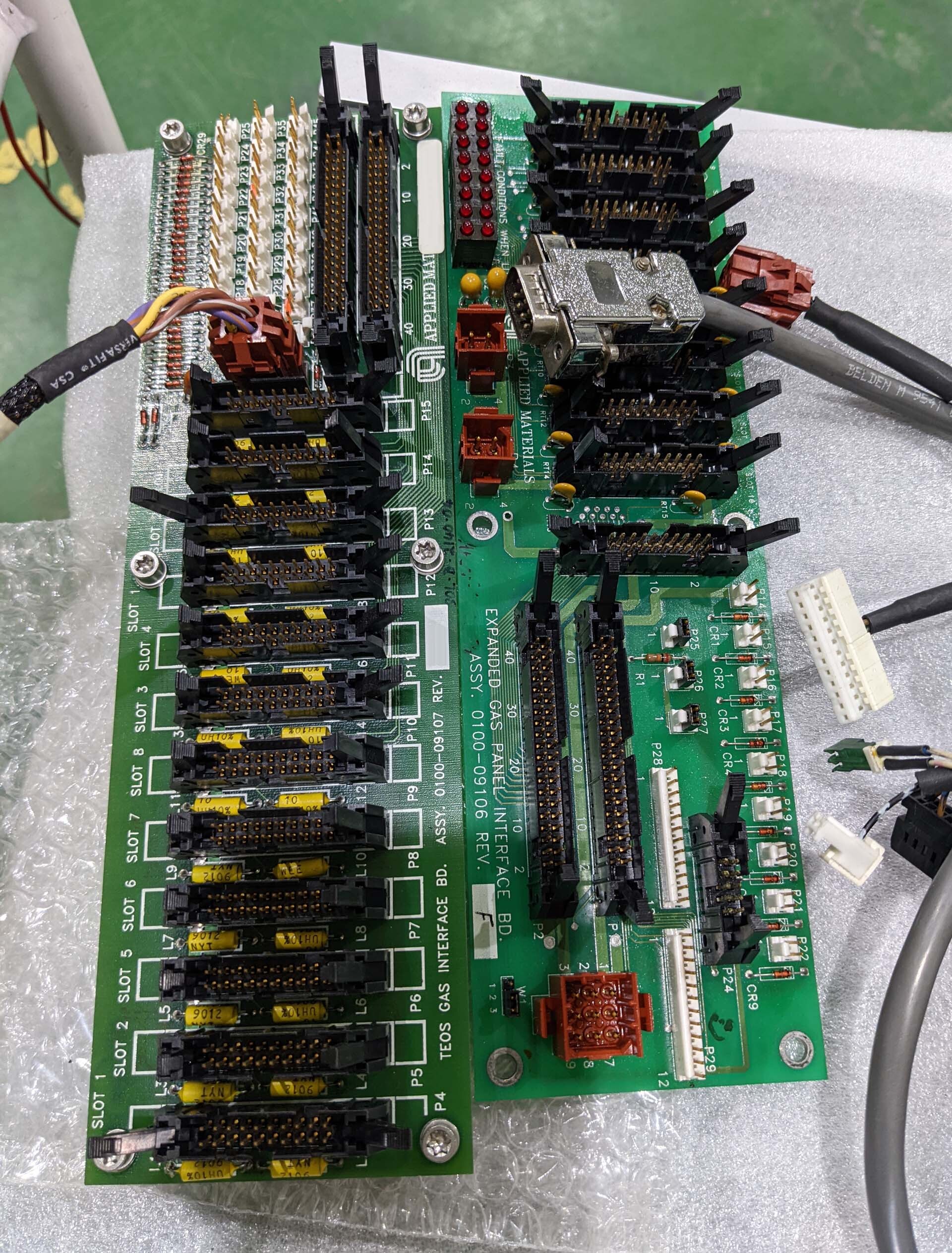

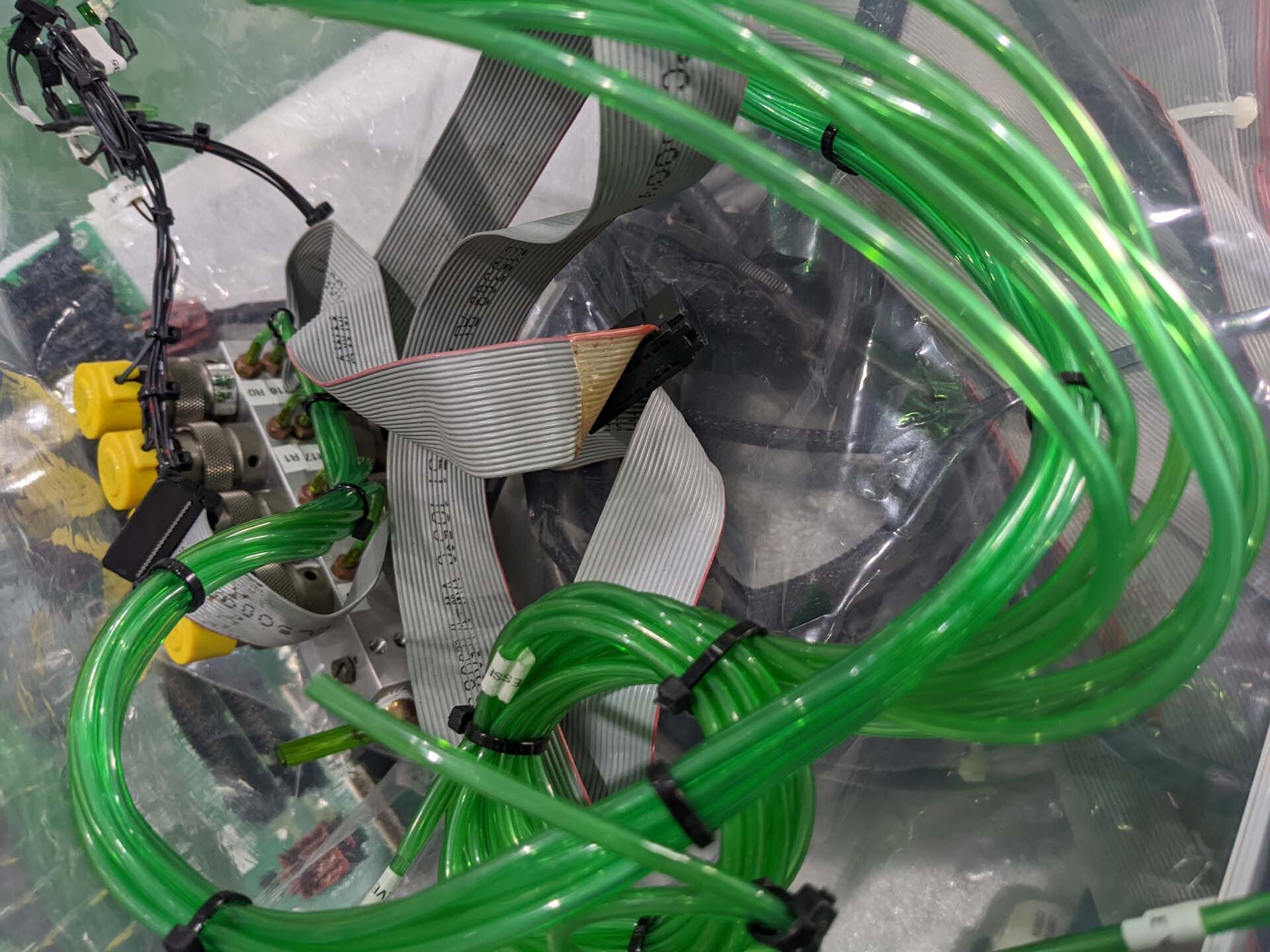

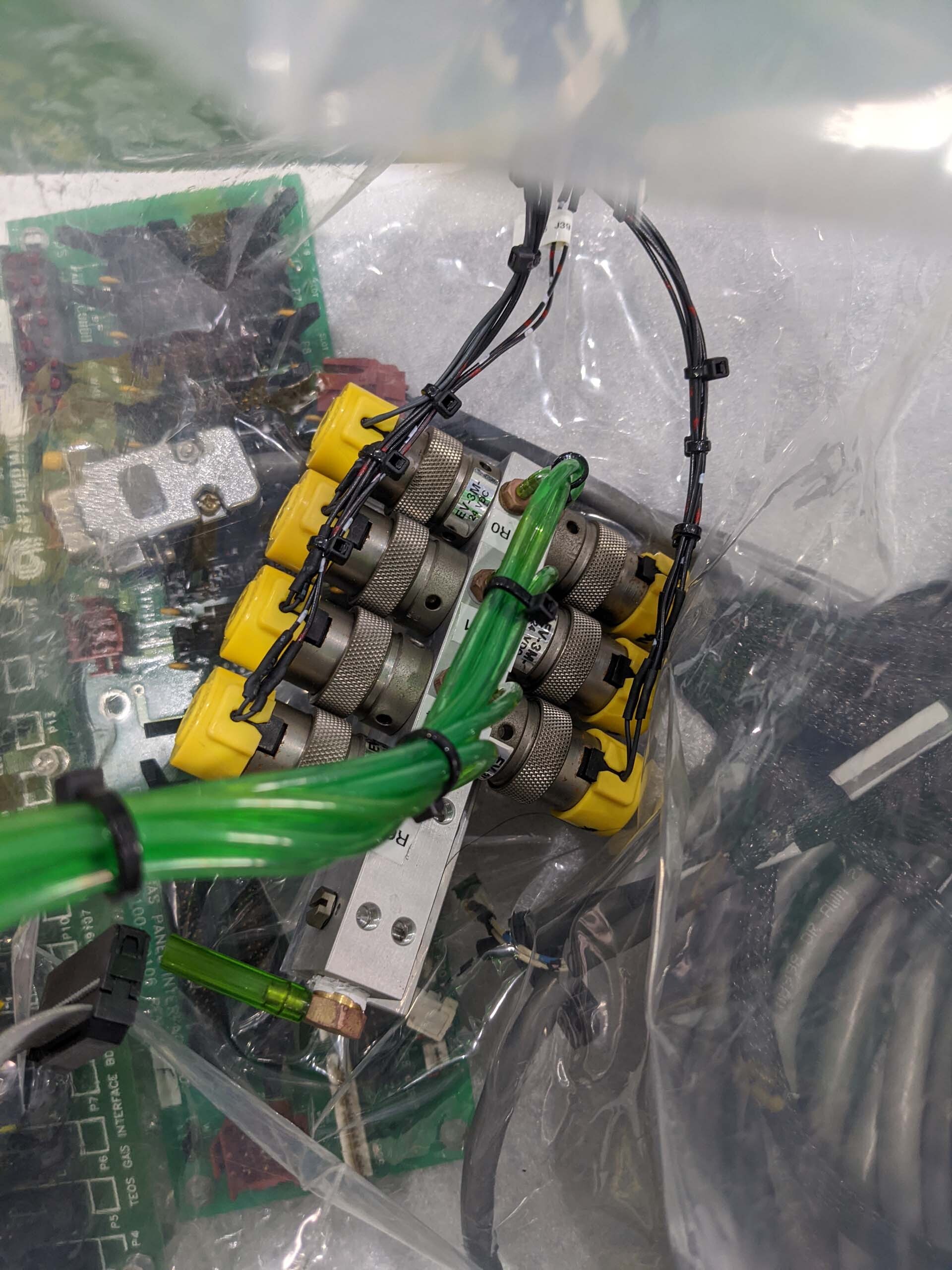

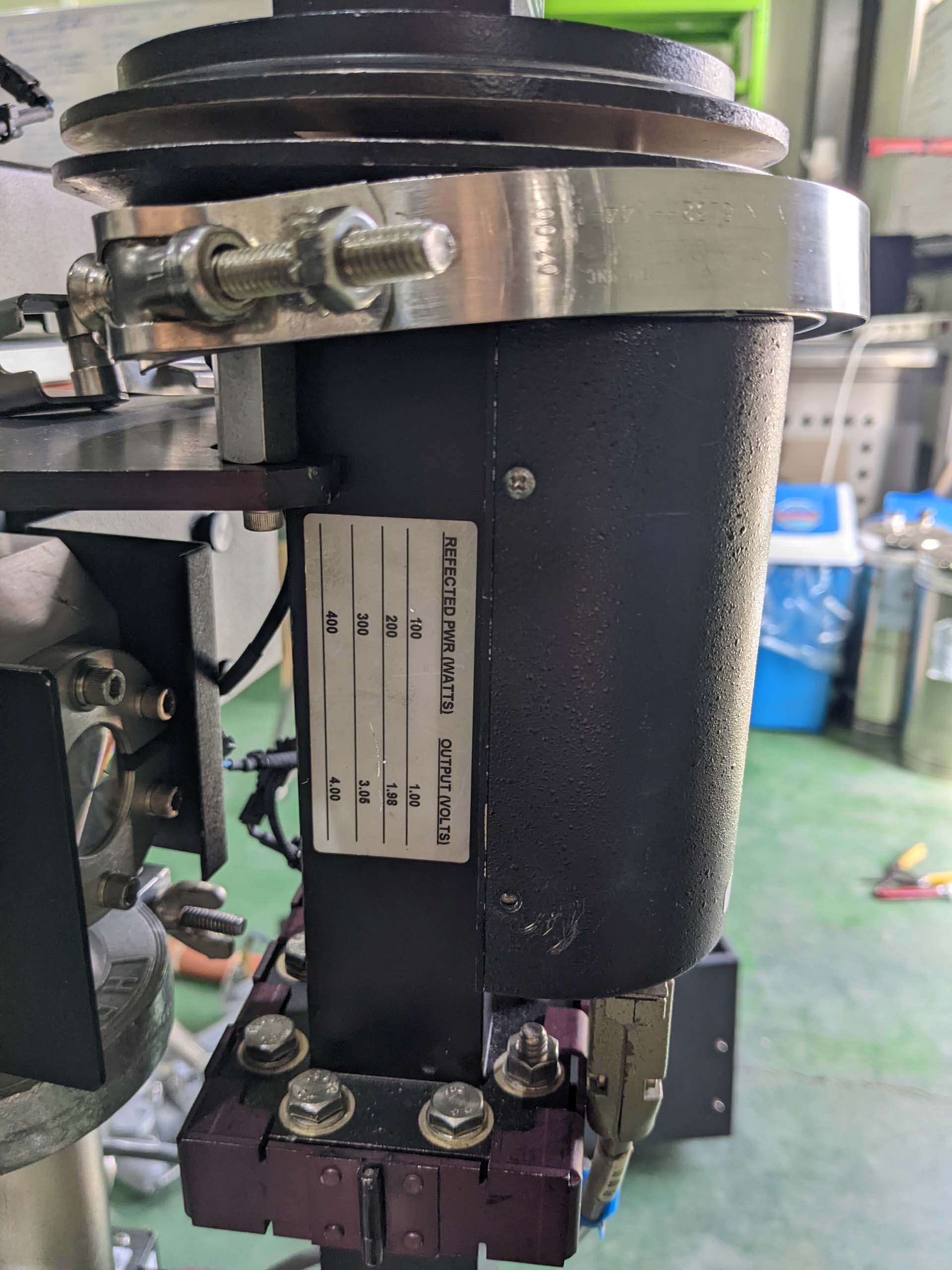

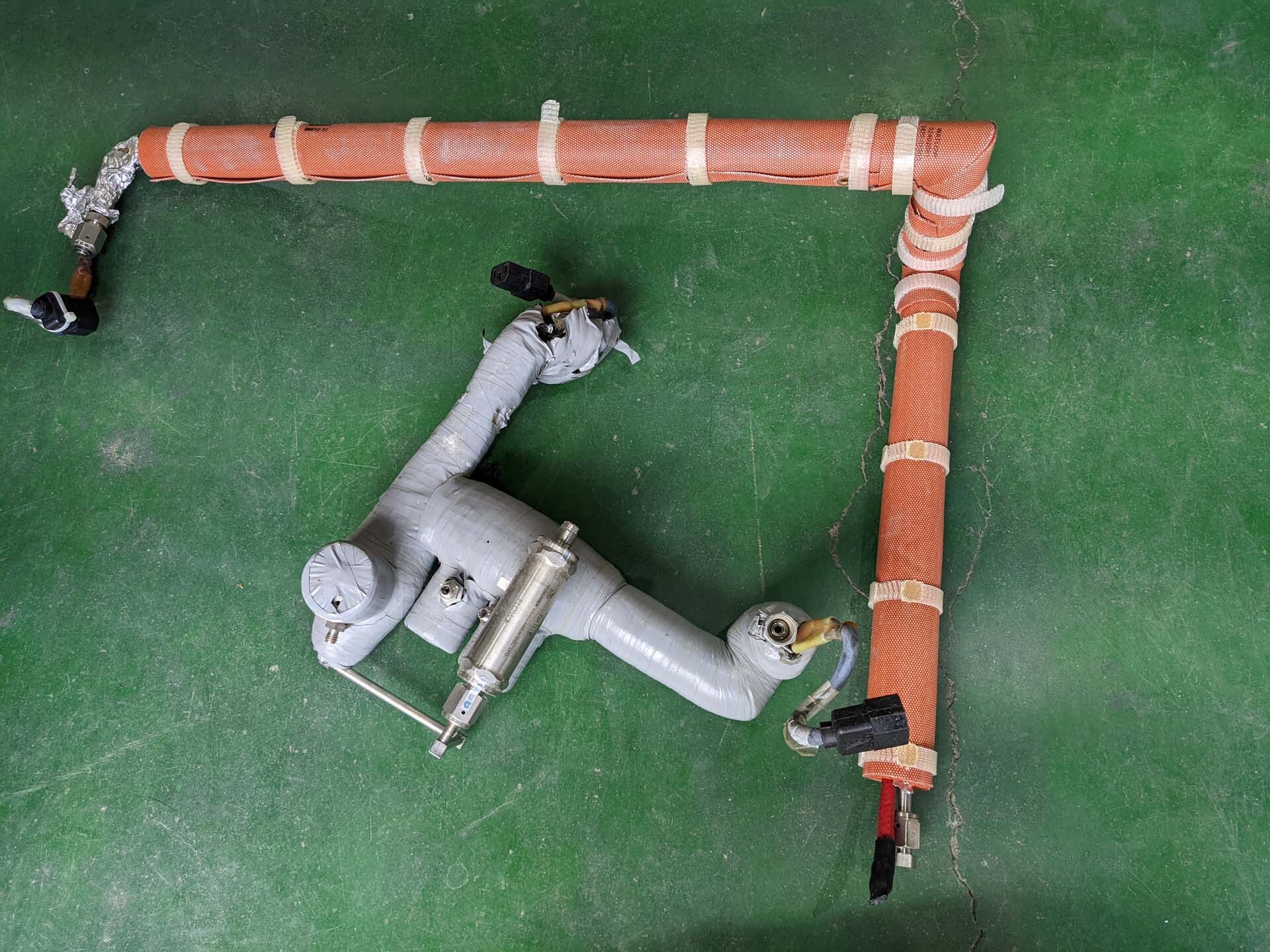

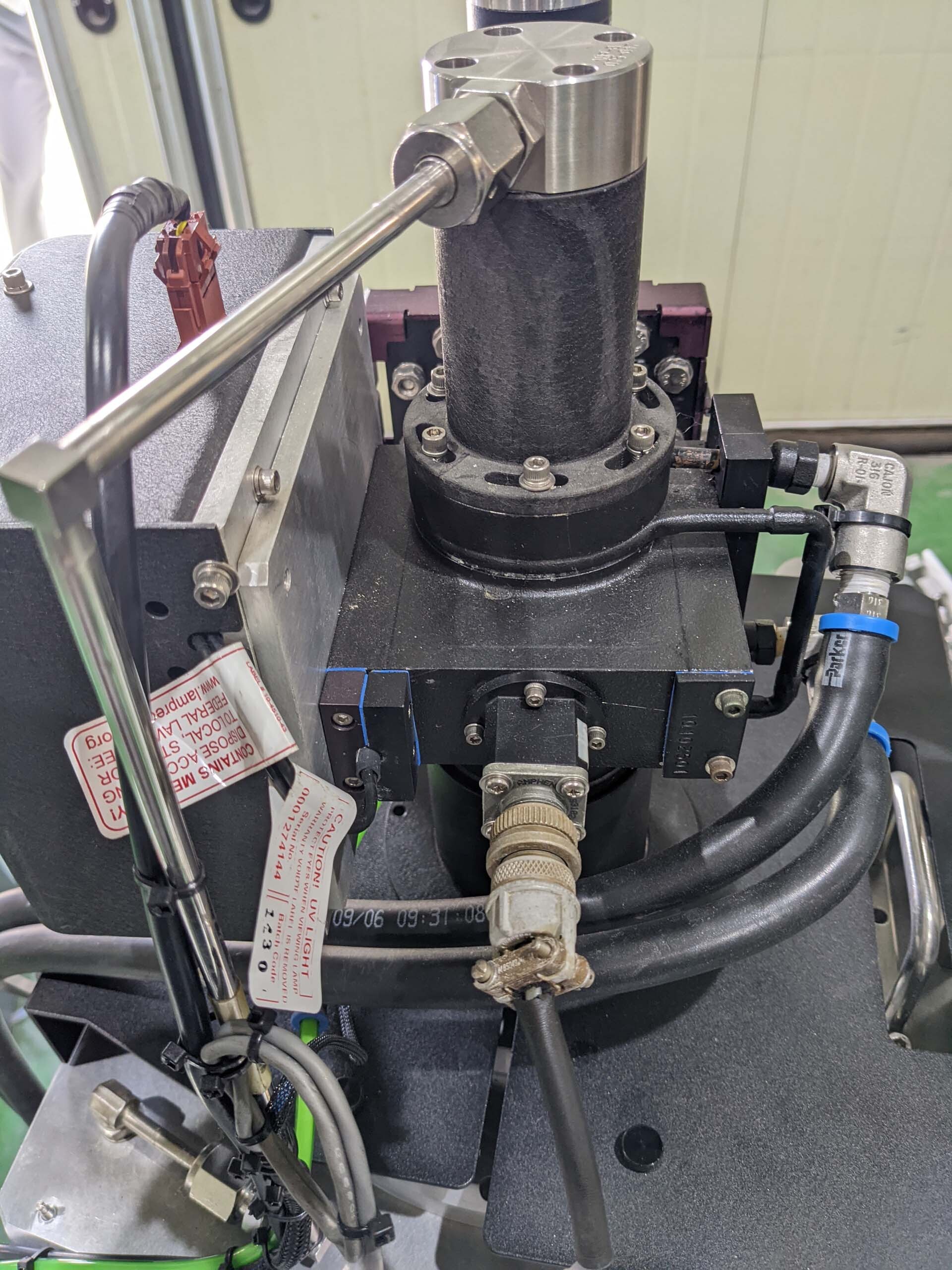

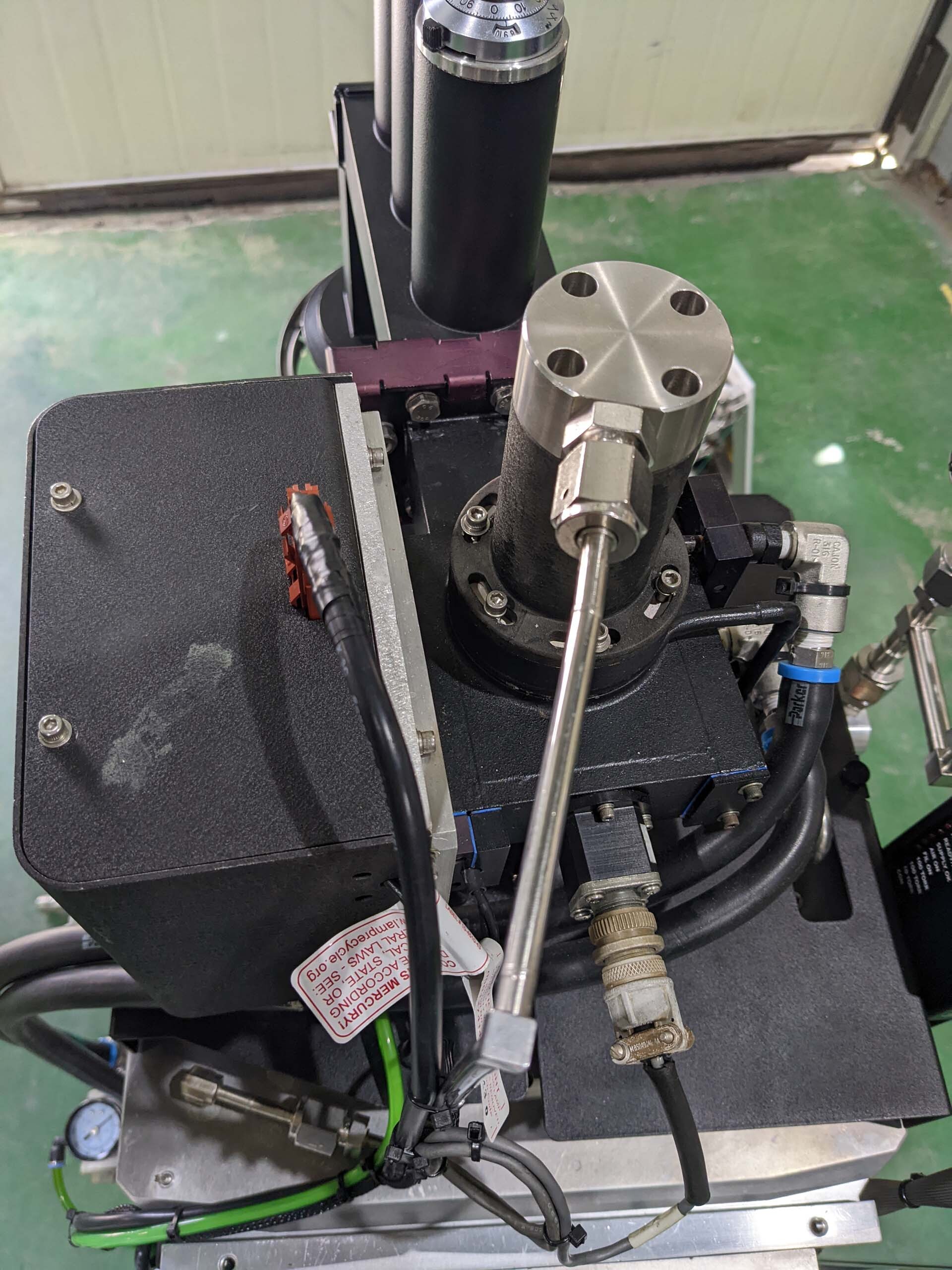

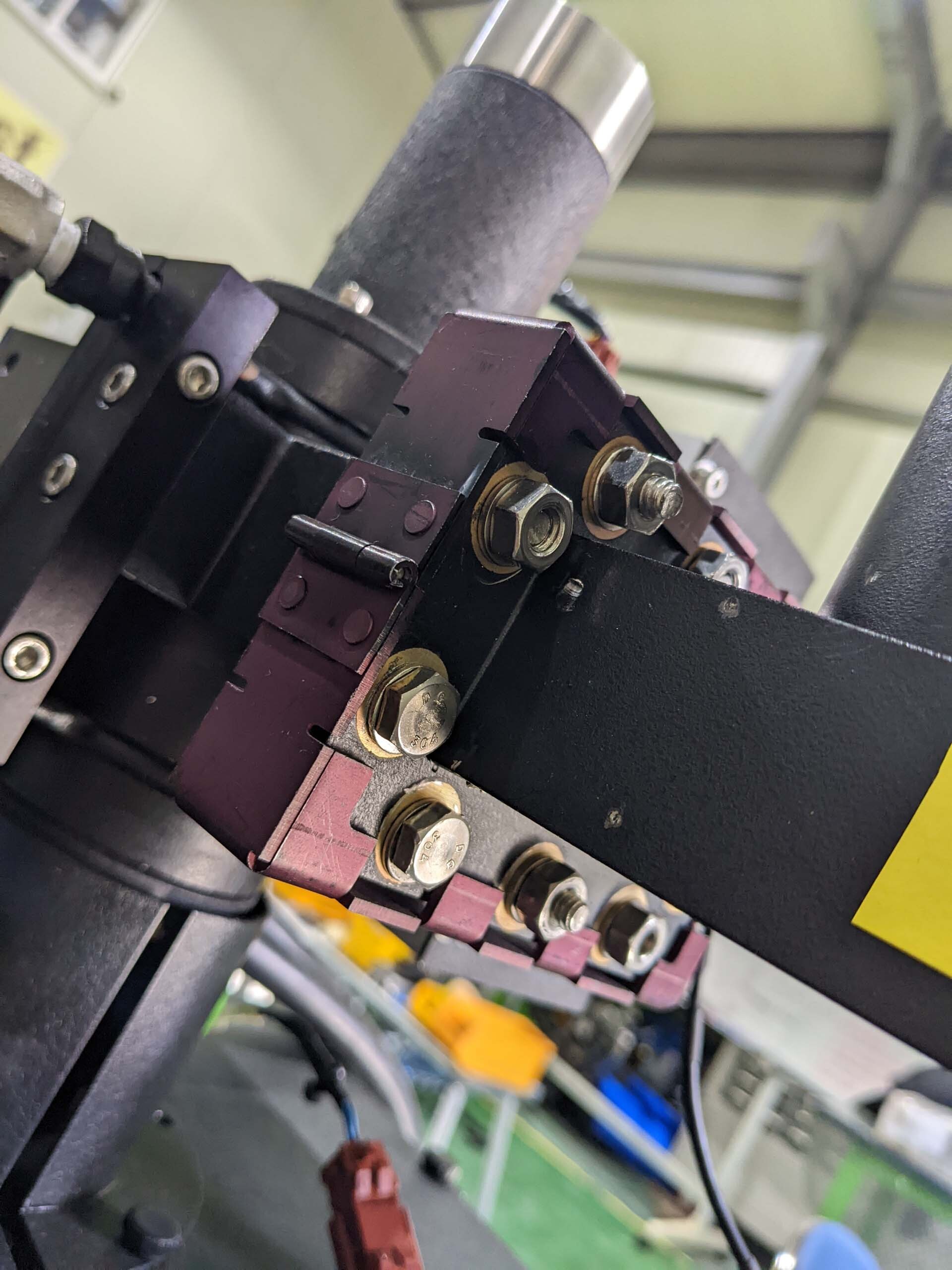

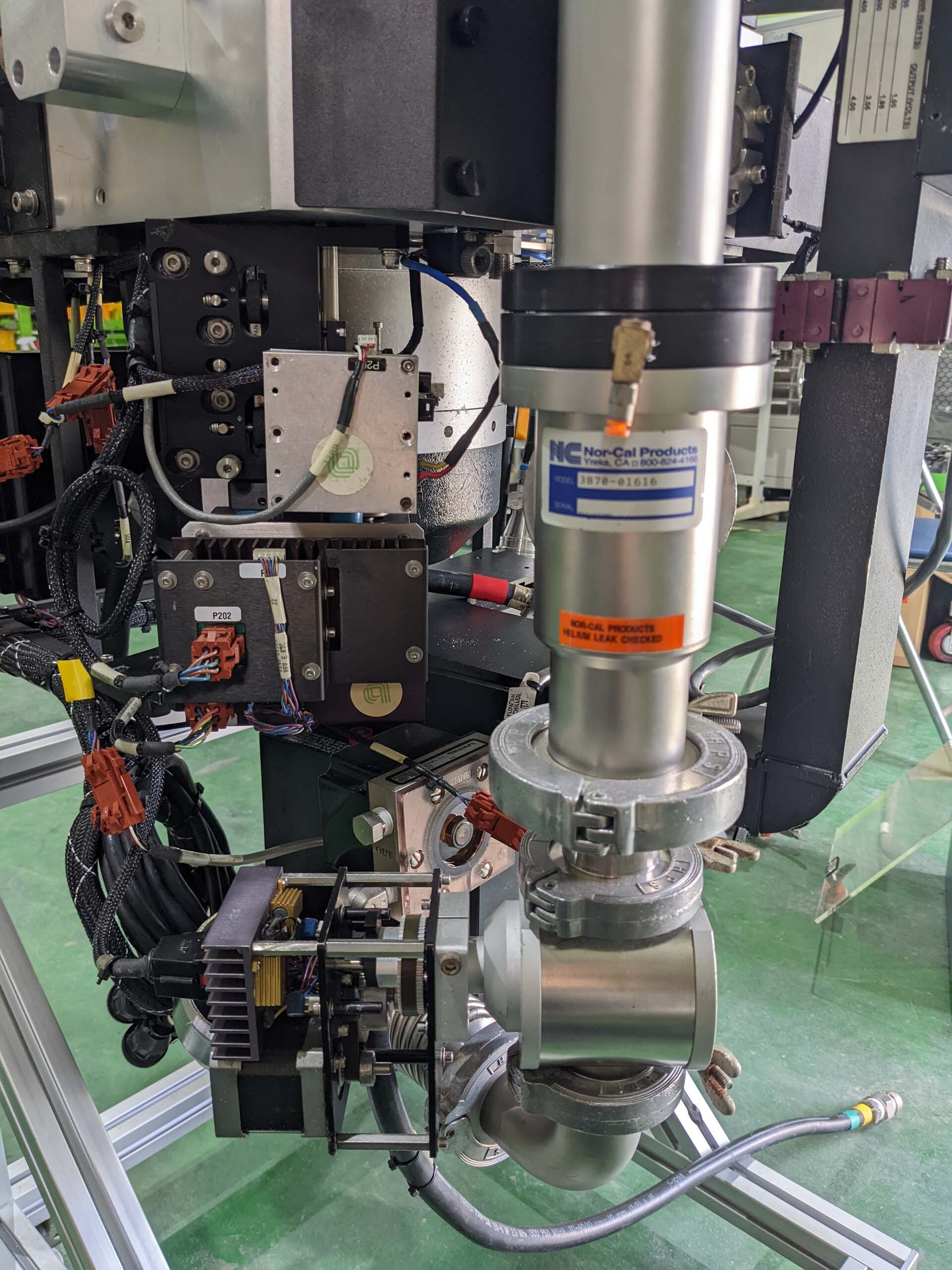

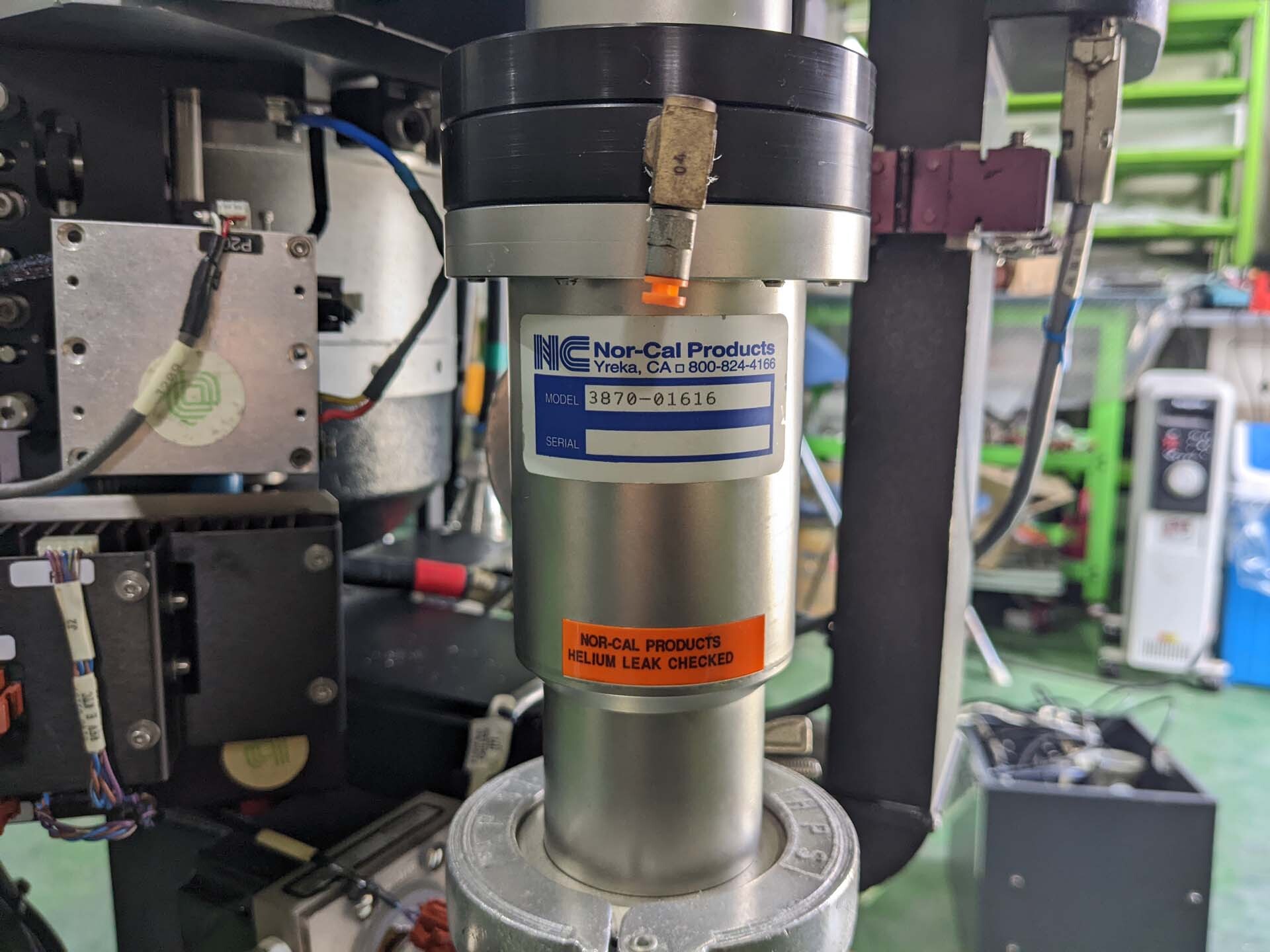

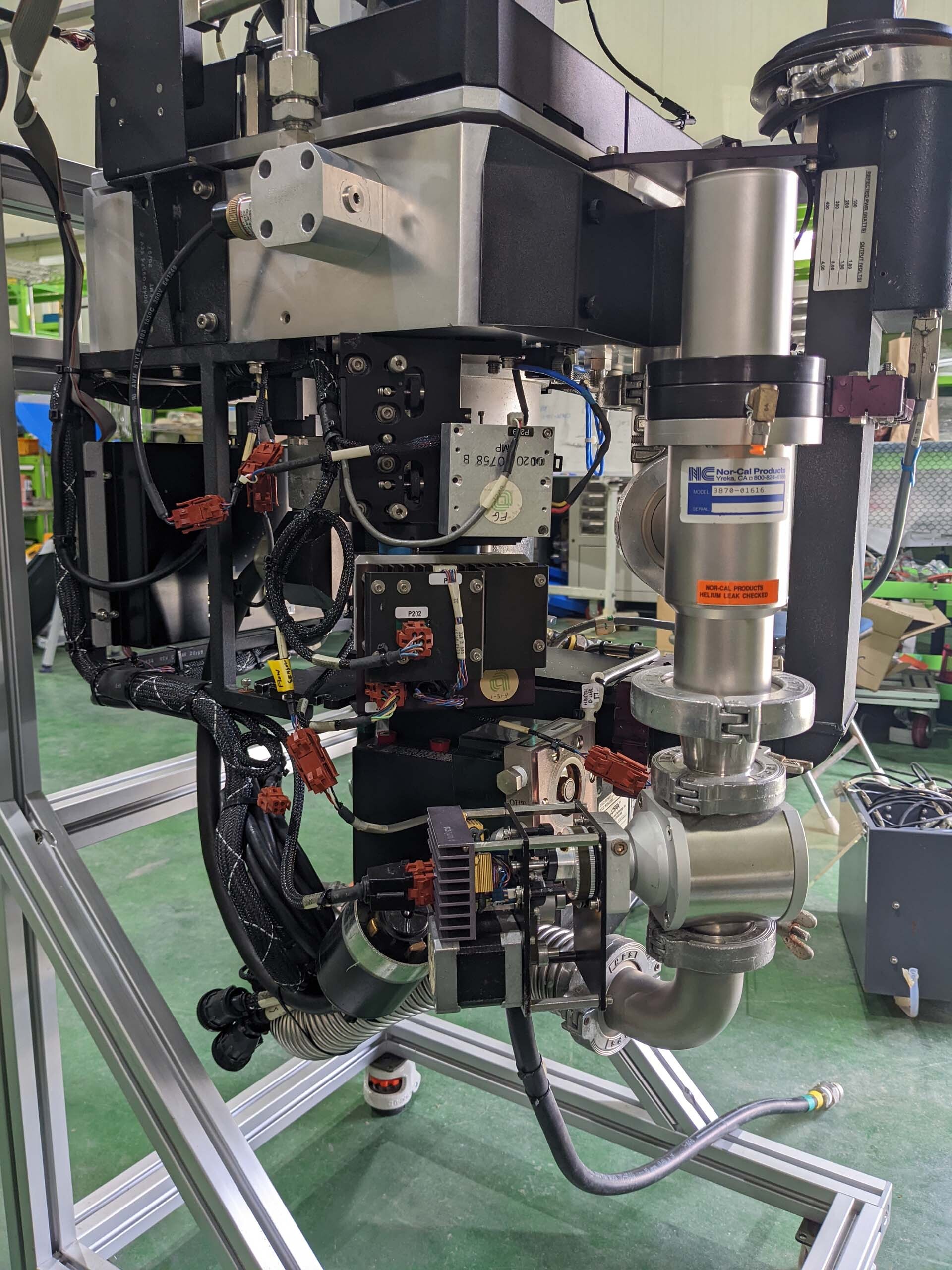

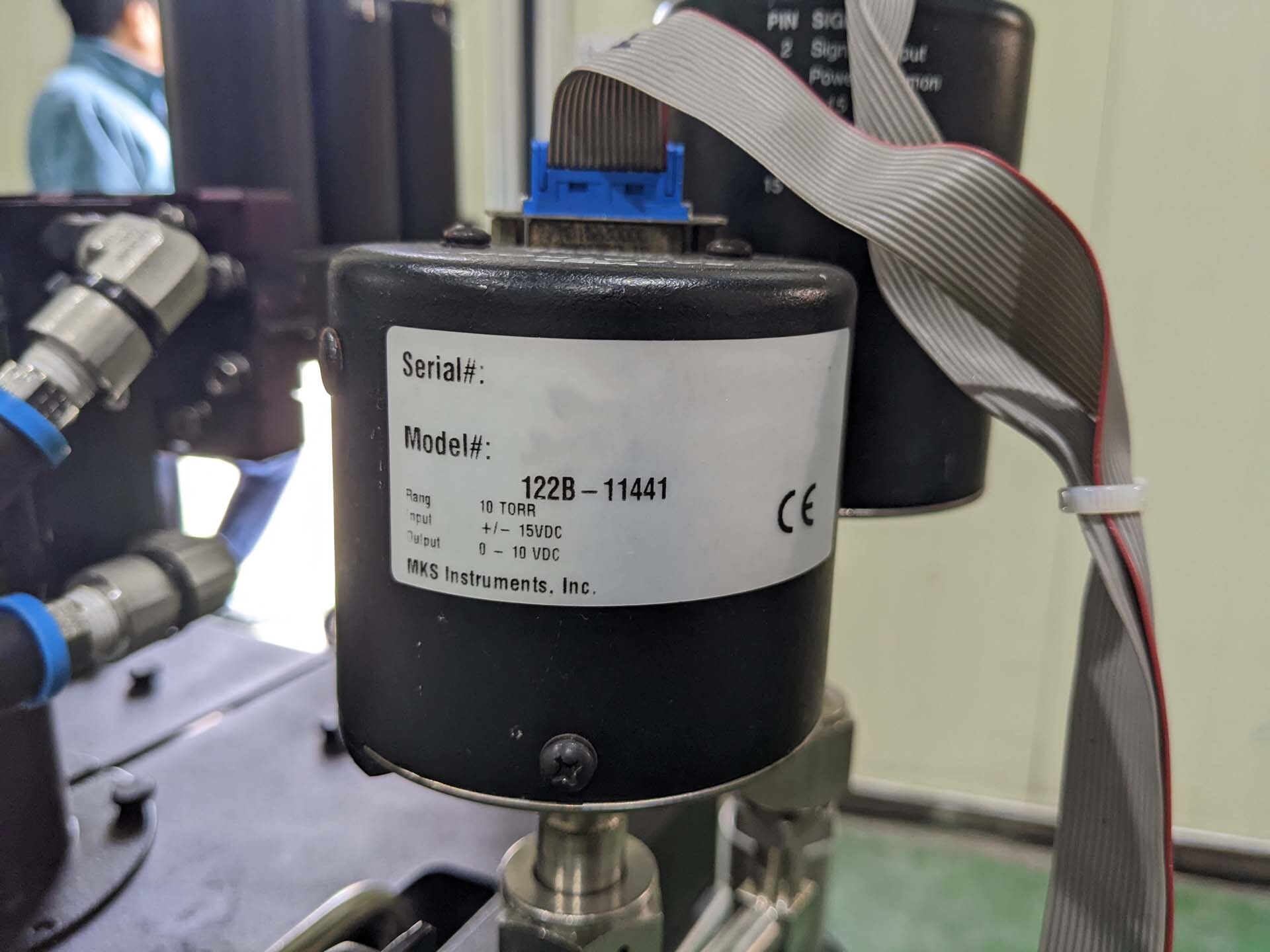

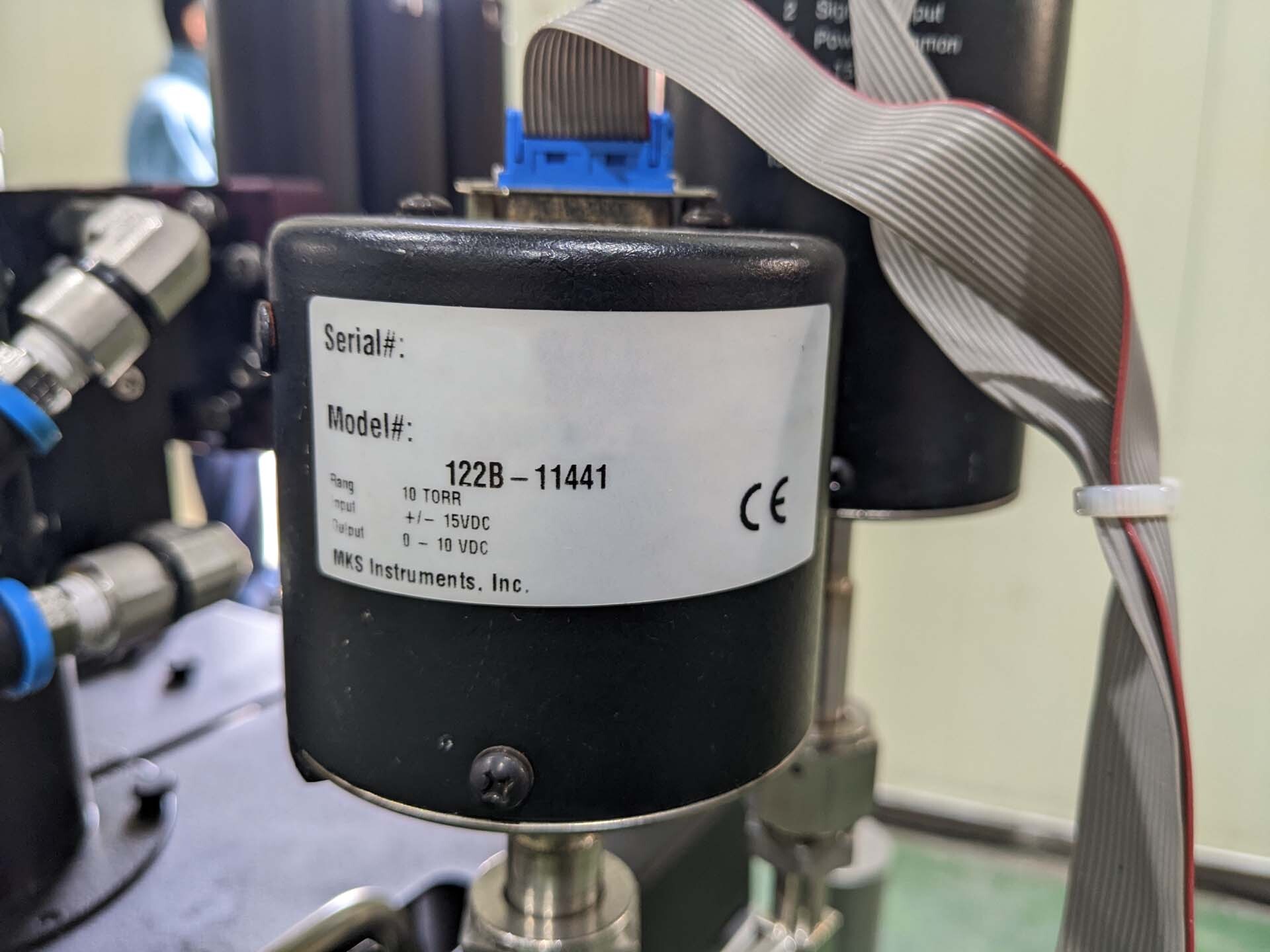

AMAT / APPLIED MATERIALS ASP Chamber is a state-of-the-art, reactor, used in processing materials at the nanometer scale. This reactor combines two main technologies: plasma-based etch and Advanced Substrate Processing (ASP). The plasma-based etch is used to clean, surface process, and etch materials at a nanometer scale. The plasma source for the etch is provided by a proprietary dual-frequency magnetron source that enables etching with high selectivity and anisotropy across a wide range of materials. This etching is also further enhanced with an inductively coupled plasma source, a remote HF generator, and a high-density source. Additionally, the etch capability is complemented by the in-situ substrate heating options which provides rapid and uniform temperature control, enabling uniform etch rates and excellent control. The second component of AMAT ASP Chamber is the Advanced Substrate Processing (ASP) technology. This technology provides a suite of unique capabilities, including chemical deposition and atomic layer deposition (ALD). The ASP provides chemical deposition with an advanced set of process gases, a proprietary Langmuir-Blodgett platform, and integrated mass spectrometry. This process gas allows precise control of film thickness and uniformity at nanometer scale levels. The ALD capabilities of APPLIED MATERIALS ASP Chamber are enabled by the Massively Parallel ALD Source (MPALS). This source provides the capability for highly accurate depositions, with excellent energy and flux control for uniform film deposition on a large substrate area. Additionally, the ALD process is further enabled by an integrated temperature cycle ramp, which provides precise compositional control, excellent thermal isolation, and uniform film density. In conclusion, ASP Chamber serves as a powerful tool for fabrication, processing, and deposition to meet the requirements of the most advanced nanoscale applications. This reactor provides precision control of etch parameters, as well as chemical and atomic layer deposition for unique nanoscale processing requirements.

There are no reviews yet