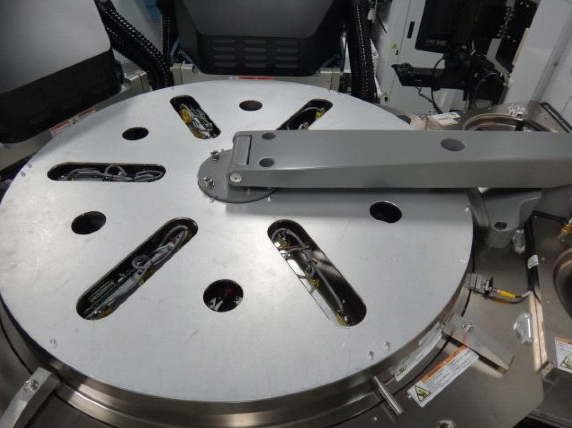

Used AMAT / APPLIED MATERIALS Centura 4.0 Radiance #9072014 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9072014

Wafer Size: 12"

Vintage: 2002

Platform RTP system, 12"

Chambers: A, B, D:

Chamber type: Radiance RTP with ISSG

Gas config. (sccm)=MFC full scale

N2 Frame(50000)/H2 Low(10000)/H2(20000)/O2 Low(1000)/O2(50000)/N2(50000)/N2 BP(50000)/HE BP(50000)/N2 MLV(100000)

Modifications:

Ch-D Expansion, Chamber added

Ch-D He Line additional remodeling, wafer cooling capacity improvement

Missing parts:

RTC CPU Board(Ch-A,B,D), 0190-28454

Electromagnetic valve unit(LLK-A), 0190-13033

Lamp Head Assy(Ch-A), 0040-88855

Lamp Head Assy(Ch-B), 0040-88855

Lamp Head Assy(Ch-D), 0040-88855

Lamp Power Face Board(Ch-A), 0100-01700

LFD Board(Ch-A), 0100-01973

Lamp Head Supply Water Line

Pyrometer Set(Ch-A), 0010-18024

Pyrometer Set(Ch-B), 0010-18024

Pyrometer Set(Ch-D), 0010-18024

DC Power Supply(Ch-A), 1140-00187

ISO Valve(Ch-A)

Leak Port Manual Valve(Ch-A)

NSK Driver

Lamp Head Vac Line Valve(Ch-A,D)

Lift Pin (Ch-A,D), 0200-01942,

Lamp Head Hose (Ch-D)

Rotor Bottom

Chamber Over Temp Sensor (Ch-D)

Xfer OTF Sensor BANK4 (Buffer)

Currently in storage

2002 vintage.

AMAT Centura 4.0 Radiance tool is a high-performance deposition equipment designed for advanced semiconductor manufacturing applications. This reactor provides ultra-precise process control, maximum productivity, and outstanding flexibility for superior device and product quality, and maximum returns on investments. The Centura 4.0 Radiance is equipped with advanced process technologies, including a Floating Zone MOCVD source, multiple remote plasma sources, integrated etch, in situ, and out of chamber metrology capability. The reactor also features low pressure cryogenics for high-precision deposition on substrate surfaces with distributed uniformity, and high throughput rates for greater productivity. The Floating Zone MOCVD source is designed for high-precision doping to a resolution of ±5 μm for high-quality device deposition, and for near-perfect device uniformity across a substrate. This oxide etch technology combines high flexibility, selectivity, and high-depth uniformity for a range of semiconductor device deposition applications. High quartz-processing temperatures ensure optimum silicon device profiles with fewer defects. The remote plasma sources feature an innovative, highly-configurable, single-module design to reduce cost and maintenance requirements. This design does not require an internal gas seal, reducing process complexity which leads to a reduction in downtime. The in situ chamber electrical characterization metrology system allows for faster measurements, reducing cycle times for excellent precision. This advanced spectroscopic metrology unit can characterize devices down to a 100nm feature size, and provide quantitative process data at lower biasing voltages. The SureCEM out-of-chamber metrology machine speeds the measurement time by up to 3x, and increases test accuracy up to 10x compared to traditional x-ray techniques. The Centura 4.0 Radiance is designed for ultra-high throughput processes for superior device production. A high speed lens tool coupled with digital control optimizes substrate scan speed for greater efficiency, while a compact design eliminates the need for a separate pre- and post-vacuum sequence resulting in faster cycle times. The reactor is also equipped with Core Control, an integrated wafer-by-wafer data management asset that provides real-time process monitoring and reporting.

There are no reviews yet