Used AMAT / APPLIED MATERIALS Centura 4.0 Radiance #9072172 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9072172

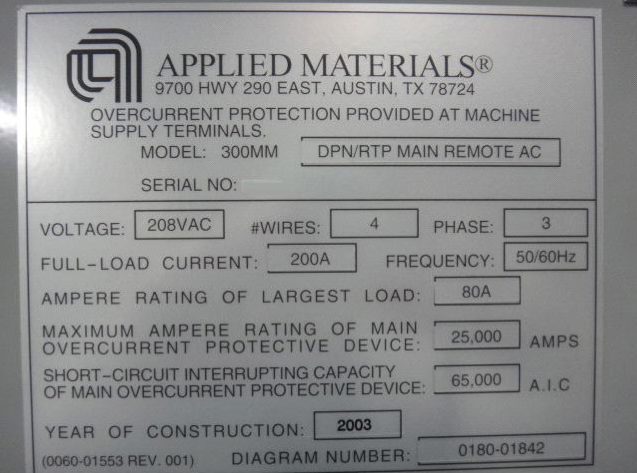

Wafer Size: 12"

Vintage: 2003

Platform RTP system, 12"

Chambers: A, B, D:

Chamber type: Radiance RTP

Lamp HTR

N2; PRCS/BTM/MAGLEV: 50/50/100slm

O2; PRCS 50/10slm, He: 50slm

Modifications:

CH-A.B.D Oximeter additional, Oxygen concentration monitoring

CH-A.B.D OLT additional functions, Remodeling the lamp annealing specification

Missing parts:

Slit Assy(Ch-A), 0010-03057

Slit Assy(Ch-B), 0010-03057

VHP Robot(Buffer), 0242-30245

Lamp head cooling water IN side hose (Ch-D)

Wafer suppor cylinder buttons (Ch-A)

FI Robot(FI), 0190-10300

APC (Ch-A), 0500-01147

Bu robot driver (Buffer), 0190-08277

RTC CPU Board (Ch-A,B,D), 0190-28454

FI Robot (FI), 0190-10300

ipump (LLK), 0190-27340

Maglev Controller (Ch-D), 0190-24282

Currently in storage

2003 vintage.

AMAT Centura 4.0 Radiance Reactor is a semiconductor processing equipment that harnesses high throughput capability to deliver optimal performance. It is a 4-chamber CVD system capable of processing substrates up to 200mm in diameter. With its high levels of stability, reliability, and scalability, the Centura 4.0 Radiance Reactor is designed to meet the needs of the semiconductor industry's most demanding challenges. The Centura 4.0 Radiance Reactor's four chambers are optimized for various applications, including diffusion, etch, and chemical vapor deposition. Each chamber is capable of pumping large volumes of gas, up to 4.2 std L/min, allowing for highly efficient processing with uniform flow and constant pressure. It also features an advanced temperature control unit that can maintain temperatures as low as 150°C or as high as 1000°C, providing a wide range of process requirements. Additionally, the use of improved gas-handling components and remote monitoring provide uniform process control across all chambers. The chamber walls are made of quartz, and the interior surfaces are treated with nickel to ensure long-term stability and prevent contamination. The machine also features a contactless drive tool that eliminates the need for replacement parts such as brushes and bearings, which further increases asset reliability. Furthermore, the high throughput capability, resulting from the combination of four chambers and a high-efficiency process gas delivery model, provides maximum throughput performance while minimizing overall process costs. The Centura 4.0 Radiance Reactor offers a number of safety features, such as an automated ignition equipment, a mechanical chamber interlock for enhanced safety, and a well-designed ventilation system that is capable of evacuating large volumes of exhaust successfully and quickly. In addition, the unit is designed to meet industry safety standards, including SEMI S94 and NFPA and ATEX requirements. The Centura 4.0 Radiance Reactor is the perfect choice for a broad range of advanced semiconductor applications. Its combination of reliable high throughput capability, scalability, and excellent process control makes it an ideal choice for manufacturers in this rapidly growing industry.

There are no reviews yet