Used AMAT / APPLIED MATERIALS Centura 4.0 #189613 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 189613

Wafer Size: 12"

Rev 4 HART mainframe only, 12"

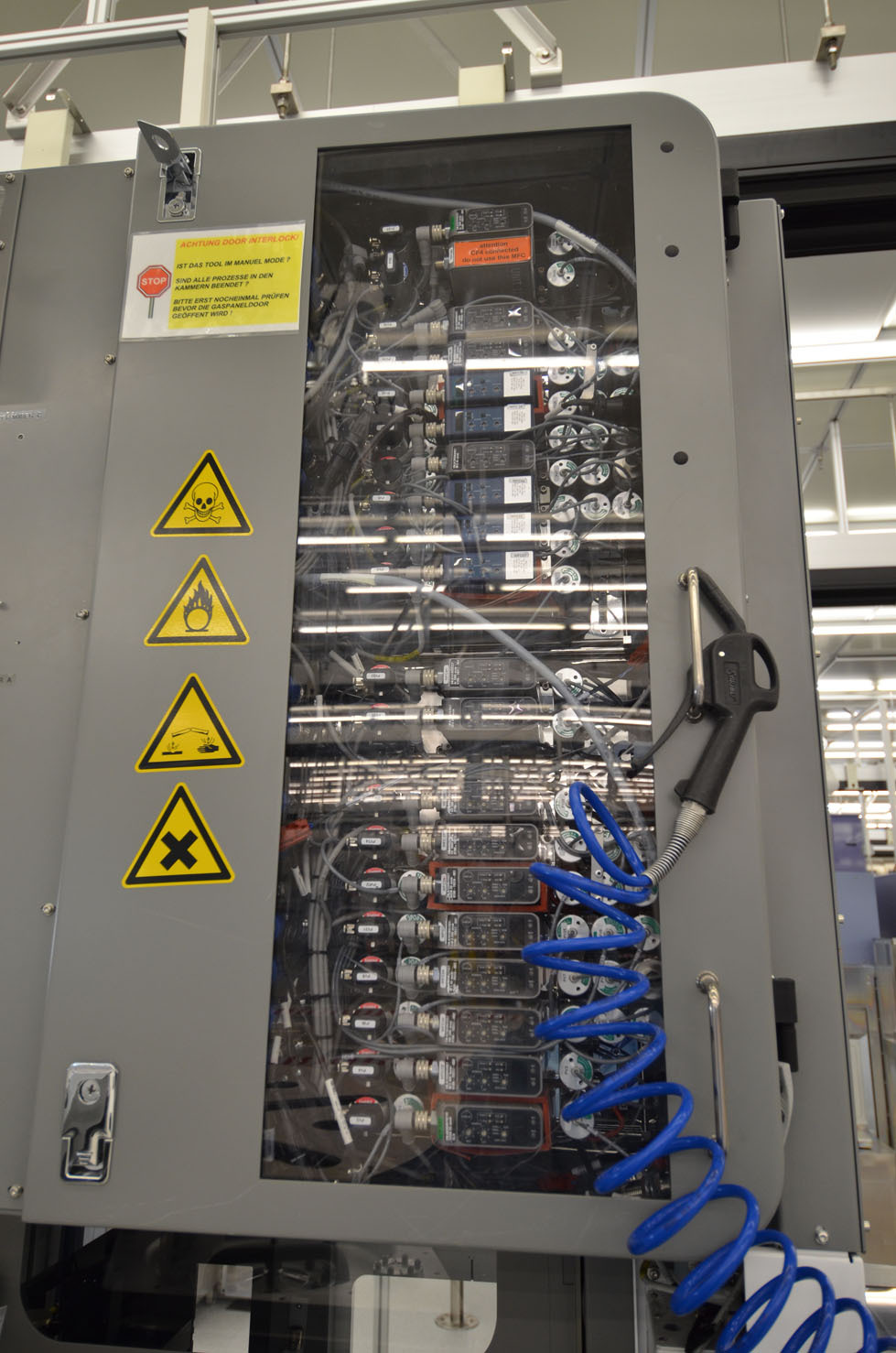

Amat centura rev 4 mainframe & gas box

Previously fitted with with dual deep trench chambers

Top source

Chiller upgrade

With 2 load locks

2 load ports

MKS frca 26349 delta flow ratio controller

Main frame only

12" mainframe controller configuration:

A1- industry pack i/o

A2- industry pack i/o

A3- motion vacuum robot

A4- dnet 2-ch. Scanner

A5- dnet 2-ch. Scanner

A6- dnet 2-ch. Scanner

A7- serial

A8- processor

A9- (spare non-cpci slot)

A10- cpci power

B1- dnet i/o (dio. Combo)

B2- (empty)

B3- dnet i/o (dio. Combo)

B4- motion signal conditioner with otf

B5/B6- front end loadlocks

B7/B8- interlocks

B9- interlocks

B10- interlocks (test connector empty)

SMC ex180 sdn1 serial interface

2001 vintage.

AMAT Centura 4.0 is an advanced chemical reaction equipment developed for advanced process development and production. It is a cluster tool platform and a full system integration platform, offering a robust set of capabilities. The unit provides a high throughput platform and scalability and is designed to be rapidly customized to accommodate new process developments. At the core of the platform is the dual-zone chamber, which provides an ideal environment for uniformly balanced and optimized focusing of both substrate and process energies. The precise control of the atmosphere within the dual-zone chamber produces superior process uniformity and repeatability, and is unique to the Centura 4.0. In addition to providing exceptional control over the process environment, the Centura 4.0 also offers a wide set of advanced features, including multiple programmable parameters, multi-stage pumping capabilities, and adaptive processes control (APC), all of which contribute to the machine's six-sigma process optimization capabilities. The Centura 4.0 also offers a comprehensive array of wet process capabilities, with an automated material handling tool (AMHS) that facilitates the loading and unloading of substrates and materials for processing. AMHS enables rapid sample loading and unloading, as well as the lower downtime associated with process optimization experiments. The Centura 4.0 also provides an adaptive process control (APC) module and a proprietary process replication scheme for maximum process utilization and optimization. The APC module analyzes the process results and allows for rapid adjustments of in situ process parameters in order to optimize process performance results. The process replication module ensures that caused by module relocation, changing environmental conditions, or the introduction of new processing chemistry are all timely corrected or minimized to ensure optimal process uniformity at all times. The Centura 4.0 also offers advanced visual feedback, real-time tracking, and a regulation asset to ensure that all process recipes are followed accurately and consistently. The combination of all of these features ensures that the Centura 4.0 is capable of providing superior process performance results. In conclusion, the Centura 4.0 is a sophisticated chemical reaction model that provides a high throughput platform, scalability, and rapid process tuning capabilities. It offers an automated material handling equipment with high precision process control, adaptive process control, process replication scheme, and visual feedback. All of these features come together in the Centura 4.0 to create a powerful and reliable chemical reaction system for advanced process development and production.

There are no reviews yet