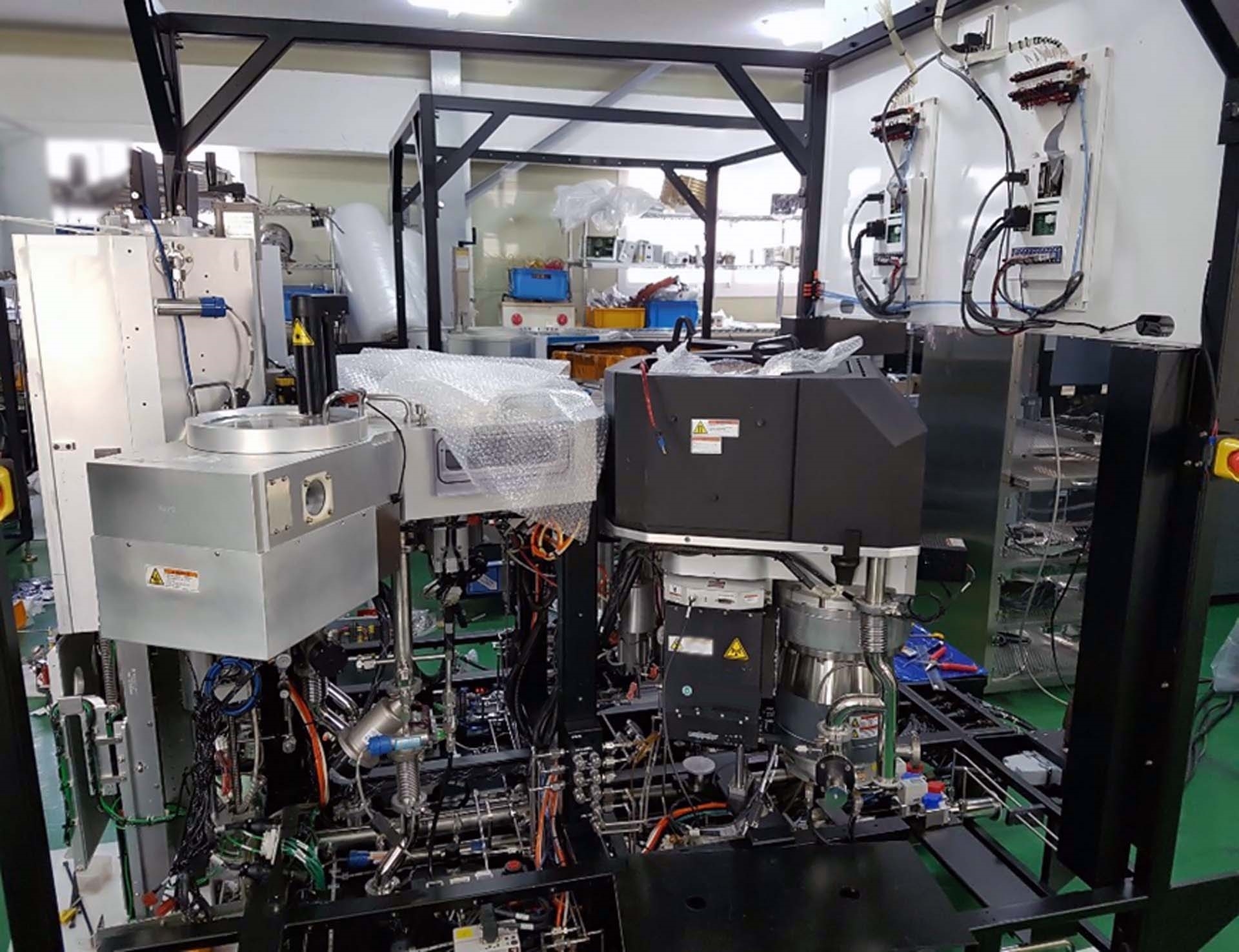

Used AMAT / APPLIED MATERIALS Centura 5200 eMax #9244054 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9244054

Wafer Size: 8"

Oxide etcher, 8"

Loadlock type: Narrow body

(2) eMax Chambers

Controller

AC Rack

Generator rack

Buffer robot: VHP+

Turbo pump: ALCATEL 1603

ENI 28B RF Generator

RF Rack

MFC Type: AERA 770FC-770AC.

AMAT / APPLIED MATERIALS Centura 5200 eMax is a semi-conductor enable wafer etching, deposition, stripping, and cleaning reactor. The equipment is capable of processing substrates in a variety of configurations and with a range of throughput capabilities. The Centura 5200 allows for precise control of process parameters, maximizing die yield and profitability. The Centura 5200 is equipped with a number of innovative components designed to optimize the production process. It features a flexible Endura Process Chamber that can be configured to suit individual process needs. This chamber utilizes a Slant Wall PECVD (Plasma Enhanced Chemical Vapor Deposition) process that increases throughput by consolidating all of the processes into a single system. This chamber has a high-precision platform that ensures perfect wafer alignment, allowing for precision etching and deposition. Additionally, the Zero Compression Edge Isolation (ZCEI) technique is implemented in the chamber, which further increases control of the process parameters and improves the overall worflow. The Centura 5200Further ensures process control with Throughput Safeguard Mechanisms that continuously monitor the process conditions. This is a key component of AMAT Trusted Integration architecture which provides certified process control and guarantees quality. The unit also employs advanced Vacuum Design technologies that allow for clean process chambers and faster cycle times. The reactor comes with a variety of specialized deposition/etching processes designed to meet the needs of unique applications. It is equipped with Silicon Nitride deposition technology, offering increased conformality and superior dielectric properties. Metal Gates deposition technology enables production of dense hardmask layers that protect underlying features during etching phases. Additionally, the machine utilizes the Smooth Surface wet cleaning and etching process to optimize cleanliness and uniformity across the wafer during production, significantly improving post-processing performance. The Centura 5200 is supported by an integrated tool platform designed to facilitate efficient tool monitoring and management. It is equipped with a Smart Alarm Manager that enables efficient automation of process monitoring and helps prevent costly reticles from production. The Performance Analytics Platform allows users to identify potential problems and manage the production process in real-time. Finally, the asset is equipped with a unified cloud API (Application Programming Interface) that provides seamless integration and unified control across Device Interoperability and Tool-to-Tool Connectivity. AMAT Centura 5200 eMax is a powerful semi-conductor wafer etching, deposition, stripping, and cleaning reactor. With comprehensive process control, advanced deposition/etching processes, and an integrated model platform, the equipment is ideal for production of advanced semiconductor devices.

There are no reviews yet