Used AMAT / APPLIED MATERIALS Centura 5200 Epi #9034366 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9034366

System, 8"

(3) Selective Epi chambers RP

Process: SEG (Selective Epitaxial Growth)

Software version: B6.40

Wafer shape: SNNF (Semi Notch No Flat)

Wafer cassette: 8" PEEK Miraial

Wafer transfer: Robot: HP+ENP, Wafer centering: On the fly

SMIF Interface: No

System configuration:

Chamber A; SEG

Chamber B: SEG

Chamber C: N/A

Chamber D: N/A

Chamber F: Single cool down

Chamber A, B, and C:

Manometer: MKS (1 Torr, 100 Torr, 1000 Torr)

Clean type: HCI Clean

RGA Port: Yes (connection port to the foreline)

(2) Pyrometers (upper/lower): Iron: MR-T399-99C, K118 (AMAT: 0090-35052)

Gas Pallet Configuration:

Gas name: MFC size

H2/N2 (H2 Main): H2: 100 L

H2/N2 (H2 Slit): H2: 20 L

HCl: HCl: 300 cc

SiH4: SiH4: 1 L

GeH4: H2: 500 cc

Direct-Dopant 1: H2: 300 cc

Mixed-Dopant: H2: 300 cc

SiH2Cl2: SiH2Cl2: 1 L

Direct-dopant 2: H2: 300 cc

Gas Delivery:

MFC: Type: Unit (C8100AF, C3101AF)

Valves: Veriflo

Rim pressure compressor: Pump CPRSR air with RSVR 1 MPA

Filters: Pall Teflon filter

Transducers: Measurement: MKS 852861PCH2GD, Display: MKS LDM-14793

Regulators: Veriflo Parker

Coating: SUS316EP

Single line drop (SLD): No

System cabinet exhaust: Top and side

(3) H2 Leak detector: Control Inst: SNT476-1000 ppm-H2 (AMAT: 0820-01021

(1)System controller: Remote AC Controller

Transformer: N/A (480 V Direct connection)

Chamber process kit: Quartz, carbon parts

QTY | AMAT P/N | Parts Name

(1) 0200-36727 SUSCEPTOR, 200MM EPI W/O CENTER TOSHIB

(1) 0200-35081 RING, PREHEAT GRAPHITE BETA COATING

(4) 0200-36642 PIN, 200MM EPI WAFER LIFT (LIFT+LINER LOCK PIN)

(3) 0200-00207 TIP, SUSCEPTOR SHAFT OUTSIDE

(1) 0200-35007 DOME, UPPER RP

(1) 0200-35042 DOME, LOWER QTZ W/BALL

(1) 0200-35162 LINER, CHMBR UPPER BRKT/CEN (25x)

(1) 0200-35161 LINER, CHMBR LOWER BRKT/CEN (25x)

(2) 0200-35916 INSERT, INJECT 3 ZONE QTZ (25x)

(2) 0021-00571 INSERT,EXHAUST SST

(1) 0200-35159 BAFFLE, INJECT 3 ZONE (25x)

(1) 0200-00412 SHAFT, SUSCEPTOR W/RMVBL PINS NO CEN EPI

(1) 0200-35424 LIFT, WAFER 8" POLY QUARTZ

Foreline heater: Heater jacket from tool to pump 4", temp controller (not included in scope)

Dry pumps: Stored inside of Helios Zenith (not included in scope)

Load lock: iL70N New Look

Transfer: iL70N New Look

Chamber A: iH-35SE

Chamber B: iH1000

Chamber C: iH1000

Gas abatement: (not included in scope)

(1) Boc Edwards Helios Zenith

(1) Kurita water circulation unit

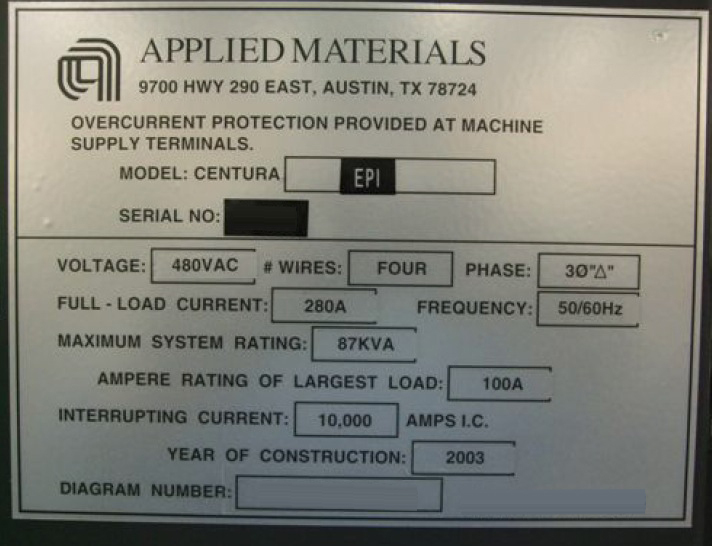

Full load current: 280 A

Maximum system rating: 87 KVA

Ampere rating of largest load: 100 A

Interrupting current: 10,000 Amps I.C.

480 VAC, 3-Ph, 50/60 Hz, 4-Wires

2003 vintage.

AMAT / APPLIED MATERIALS Centura 5200 Epi is a modern semiconductor processing tool used for depositing thin layers of polycrystalline materials onto substrates. This reactor is suitable for a variety of epi-processing applications, such as epitaxy, strained layer heterostructures, high-mobility buffer layers, dislocation mitigation, and low defect device layers. AMAT Centura 5200 Epi utilizes an atmosphere chamber and pressure control equipment to induce high-temperature in situ epitaxial growth. This reactor provides a high-precision system to safely control reaction environment and process conditions. It features low-pressure quartz dual-chamber designs equipped with a zone-by-zone temperature control for the substrate. This ensures reproducible and uniform epitaxial growth. APPLIED MATERIALS Centura 5200 Epi comes with a fuel delivery unit designed for precise and stable control of the reactant gasses introduced into the chamber. It is equipped with integrated remote-sensing mass-flow controllers that continually adjust pressure to maintain precise gas flow and composition over a range of pressures. This machine prevents contaminants and impurities from entering the reactor chamber. Centura 5200 Epi also includes an interlocked bypass valve and pressure monitoring tool. This eliminates the need for frequent maintenance to the asset. Additionally, its advanced purge panel has a two-stage heating model. This provides an efficient on-board plasticizer removal and particle control equipment. This allows for increased process gas stability and improved process uniformity. AMAT / APPLIED MATERIALS Centura 5200 Epi has also been designed with a robust fast-response heating and cooling system. This mechanism ensures precise temperature control from temperatures as low as 500°C and as high as 700°C. The high-temperature controllers provide precise temperature uniformity for accurate and repeatable process performance. AMAT Centura 5200 Epi is an advanced and sophisticated epi-processing tool designed to meet a variety of modern semiconductor manufacturing needs. It provides uniformity and reliability in a wide variety of epi-processing applications, making it an ideal tool for the modern semiconductor manufacturer.

There are no reviews yet