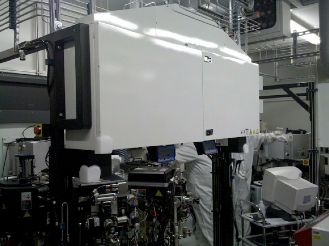

Used AMAT / APPLIED MATERIALS Centura 5200 MxP #137526 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 137526

Wafer Size: 6"

Tungsten WxZ / HeWEB system, 6"

(2) Deposition and (2) etch chambers

Process: CVD W

Standard Centura frame

SoGware Version: E3.0

System Power Rating: 208 VAC 3Phase

Loading Configura(on: Narrow Body Dual AutoIndexer Loader

Chm Positon A: HeWEB. Chamber: Gases/Chemicals Used: Customer specific

Chm Positon B: HeWEB. Chamber: Gases/Chemicals Used: Customer specific

Chm Positon C: WxZ. Chamber: Gases/Chemicals Used: Customer specific

Chm Positon D: WxZ. Chamber: Gases/Chemicals Used: Customer specific

Chm Positon E: Mul( Slot cooling Chamber: Gases/Chemicals Used: N2

Chm Positon F: Orient chamber

System Configuration:

AMAT CENTURA 5200 Standard Mainframe Body

AMAT CENTURA 5200 Mainframe Transfer Chamber

(2) Narrow Body Loadlock Chamber

(2) WxZ Process Chamber

System Controller/AC Power Box

CRT Monitor with Light Pen

RF Generator rack

Currently stored in a warehouse.

AMAT / APPLIED MATERIALS Centura 5200 MxP is a PECVD (Plasma Enhanced Chemical Vapor Deposition) reactor for the mass-production of semiconductor wafer substrates and other electronic components. It is a high-throughput, configurable desktop tool with a multi-pulse recipe for precise repeatability and unparalleled consistency in operating conditions. AMAT Centura 5200 MxP can provide multiple films from the same run, due to its flexible module design—including a special "multiplexer" module that is designed to support up to 9 independent films. This allows the end-user to achieve higher throughput and fewer production steps. The 5200 MxP is based on the MxP hardware architecture, which is designed to provide maximum flexibility and scalability by allowing for the integration of new tool components and processes. It contains a surface tracking system for precise control of substrate temperature during film deposition, a reactive ion equipment for metal-ion plasma etching, and an advanced reaction control system for adjusting the internal environment. The reactor is equipped with a diffusion shield that ensures consistent deposition across the entire substrate, reducing undesirable electrical and thermal effects. In addition, the 5200 MxP also has a recirculating convection cooling system which maintains a precise temperature profile across the substrate's surface, allowing for high-performance films. APPLIED MATERIALS Centura 5200 MxP has built-in Dynamic feedback control (DFC), which can respond to deposition conditions in real-time and make corrective adjustments. This feature helps to maintain uniform thickness across the entire substrate, while also reducing any undesirable effects such as electrical and thermal stress. The overall design of Centura 5200 MxP offers reliable and repeatable results at a fast speed, making it a good choice for large-scale high-volume manufacturing applications. Its integrated design, combined with the advanced reaction control and temperature control systems, ensures uniform and superior results for any kind of substrate.

There are no reviews yet