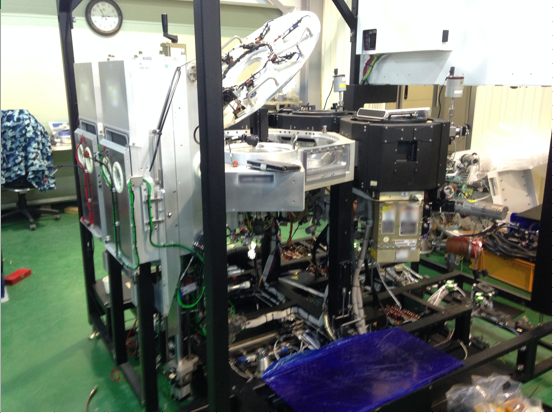

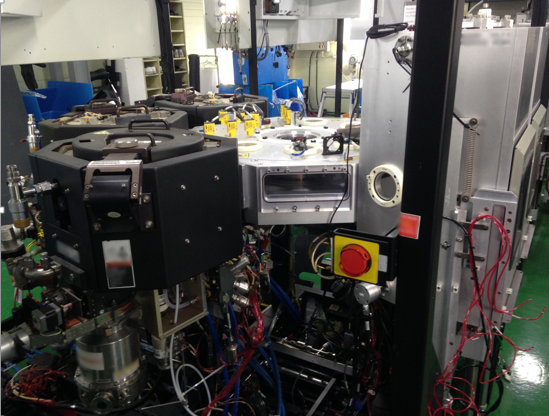

Used AMAT / APPLIED MATERIALS Centura 5200 Phase I #9133089 for sale

URL successfully copied!

Tap to zoom

ID: 9133089

Poly etcher, 8"

Wafer shape: JMF

Chamber Type/ Location

System Configuration BASE

Position A Poly Main Etch

Position B Poly Main Etch

Position C Poly Main Etch

Position F ORIENTER

System Safety Equipment

EMO Switch Type TURN TO RELEASE EMO ETI COMPLIANT

EMO Guard Ring INCLUDED

Smoke Detector At MF No Skin YES

Smoke Detector At Gen Rack YES

Smoke Detector At AC Rack YES

Pallet Corrosive Gas Line Qty 3

Pallet Inert Gas Line Qty 5

Filter Qty 8

Gas Panel Pallet B Gas Panel Pallet B

Gas Line Requirement

Pallet Pallet

Gas Line Configuration

Line 1 Gas

MFC Size

Line 2 Gas

MFC Size

Line 3 Gas

MFC Size

Line 4 Gas

MFC Size

Line 5 Gas

MFC Size

Line 6 Gas

MFC Size

Line 7 Gas

MFC Size

Line 8 Gas

MFC Size

Pallet Corrosive Gas Line Qty 3

Pallet Inert Gas Line Qty 5

Filter Qty 8

Gas Panel Pallet C Gas Panel Pallet C

Gas Line Requirement

Pallet Pallet

Gas Line Configuration

Pallet Corrosive Gas Line Qty 3

Pallet Inert Gas Line Qty 5

Filter Qty 8

Gas Panel Features Gas Panel Features

Gas Panel Features

Gas Panel Facilities Hook Up

Gas Panel Exhaust

Gas Panel Controller VME I

Mainframe

General Mainframe Options

Facilities Type REGULATED

Facilities Orientation MAINFRAME FACILITIES BACK CONNECTION

Loadlock/Cassette Options

Loadlock Type NBLL W/ AUTO-ROTATION

Loadlock Cover Finish ANTI-STATIC PAINTED

Loadlock Slit Valve Oring Type VITON

Wafer Mapping STD

Wafer Out of Cassette Sensor YES

Cassette Present Sensor YES

Transfer Chamber Options

Transfer Ch Manual Lid Hoist YES

Robot Type CENTURA HP ROBOT

Wafer On Blade Detector BASIC

Loadlock Vent BOTTOM VENT

Front Panel

Front Panel ANTI-STATIC PAINTED

Signal Light Tower 4 COLOR SIGNAL LIGHT TOWER INCLUDING RED LIGHT

4 Color Signal Light Tower Configuration

Top Light Color RED

Second Light Color YELLOW

Third Light Color GREEN

Fourth Light Color BLUE

Signal Light Tower Buzzer ENABLED

Second Signal Light Tower YES

Remote

System Controller

Controller Type 86 INCH COMMON CONTROLLER

Cntrlr Electrical Interface BOTTOM FEED

Controller Exhaust TOP EXHAUST

Controller Cover Option YES

System Monitors

System Monitor 2 TTW / different cable lengths

Monitor Cursor 2 BLINKING CURSOR

AC Rack

GFI 30mAMP

AC Rack Types 84 INCH SLIM AC GEN RACK

Exhaust Collar 84 INCH SLIM RACK EXHAUST COLLAR

Umbilical

Ctrlr to Mainframe Umbilical 25Ft

HX Control Cable Length 50Ft

Heat Exchanger Hose Length 65Ft

Pump Cable Length 65Ft

RF Generator Cable 65Ft

Signal Light Tower Ext Cable

Pump Interface Only

Pump Interface Qty Interface Only.

AMAT / APPLIED MATERIALS Centura 5200 Phase I is a high-throughput chemical vapor deposition (CVD) reactor designed for use in semiconductor fabrication. The equipment consists of ten chambers for wafer processing, as well as various tool management capabilities. It is designed for low-temperature processing of silicon-based materials such as silicon nitride, silicon oxide, and silicon oxynitride. Using capacitively coupled plasma (CCP) technology, AMAT Centura 5200 Phase I provides highly uniform and precise deposition processes. It features an advanced digital chamber volume (DV) capability designed for precise control over the deposition rate of the wafer. The system can also be used in multiple process recipes due to its dual process controller design. APPLIED MATERIALS Centura 5200 Phase I offers a uniquely scalable processing architecture, allowing for increased deposition rates and higher throughput. This unit can process wafers up to 200 mm in diameter, with a maximum process temperature of up to 1200°C. Wafers can be pre-cleaned and pre-cooled in the machine, and post-cooled to prevent oxidation of the deposited material. Centura 5200 Phase I offers an advanced industry-standard safety feature, and is compliant with all government safety regulations. The tool is designed for minimal contact with the wafers, ensuring no subsequent contamination. For a clean room setting, the tool is equipped with an air-flow control package, as well as a pass-through buffer chamber for wafer handling. By providing a combination of features, the asset can optimize the CVD process to provide uniformity and uniform gain in thickness. This allows for the preservation of surface quality while providing the desired coverage and film thickness. The unmatched accuracy and precision of this model provides for one of the most advanced manufacturing solutions available.

There are no reviews yet