Used AMAT / APPLIED MATERIALS Centura 5200 #146830 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 146830

Wafer Size: 8"

Vintage: 1996

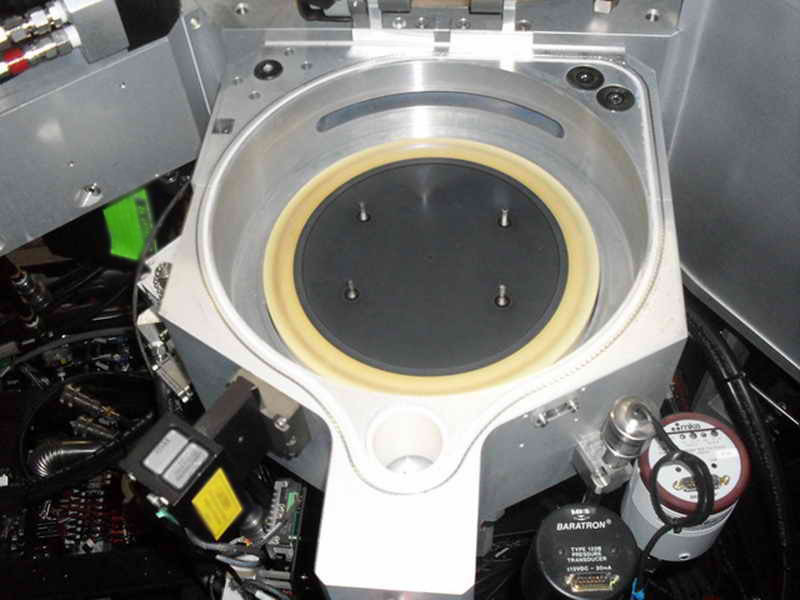

DxZ System with 3 Chambers, 8"

RF cleaning type

Application: CVD

Platform Type CENTURA I BODY

SBC Board V452

Chamber Type

Position A DxZ Nitride

Position B DxZ Nitride

Position C DxZ Nitride

Position D Blank

Position E MULTI COOLDOWN

Position F

CHA - DxZ CHAMBER

Chamber Options

Process Kit Customer Option

Baratron Guage 10Torr / 1Torr

Match AE 3155094-003A

Heater Lift 0010-38426

RF Generator RFG 2000-2V

EPD 0500-01047

Heater Driver 0190-09419

CHB - DxZ CHAMBER

Chamber Options Selected Option

Process Kit Customer Option

Baratron Guage 10Torr / 1Torr

Match AE 3155094-003A

Heater Lift 0010-38426

RF Generator RFG 2000-2V

EPD 0500-01047

Heater Driver 0190-09419

CHC - DxZ CHAMBER

Chamber Options Selected Option

Process Kit Customer Option

Baratron Guage 10Torr / 1Torr

Match AE 3155094-003A

Heater Lift 0010-38426

RF Generator RFG 2000-2V

EPD

Heater Driver 0190-09419

CHE - COOLDOWN CHAMBER

Type Multi cooldown

CHF - (OA) ORIENTER

Orienter Standard

Gas Delivery Options

Pallet Options

Component Selection STANDARD

Valve Veriflo

Transducer MKS

Regulator

Filter

Transducer Displays

MFC Type STEC 4400

Gas Panel Pallet A

Gas Line Requirement

Gas Line Configuration

Line 1 Gas NH3

MFC Size 2 SLM

Line 2 Gas N2

MFC Size 5SLM

Line 3 Gas SiH4

MFC Size 200 SCCM

Line 4 Gas NF3

MFC Size 1 SLM

Line 5 Gas N2O

MFC Size 1 SLM

Line 6 Gas CF4

MFC Size 3 SLM

Line 7 Gas N20

MFC Size 4V 239.7 SCCM / 2V 119.8SCCM

Line 8 Gas N2

MFC Size 5 SLM

Line 9 Gas HE

MFC Size 5SLM

Gas Panel Pallet B

Gas Line Requirement

Gas Line Configuration

Line 1 Gas NH3

MFC Size 2 SLM

Line 2 Gas N2

MFC Size 5SLM

Line 3 Gas SiH4

MFC Size 200 SCCM

Line 4 Gas NF3

MFC Size 1 SLM

Line 5 Gas N2O

MFC Size 1 SLM

Line 6 Gas CF4

MFC Size 3 SLM

Line 7 Gas N20

MFC Size 4V 239.7 SCCM / 2V 119.8SCCM

Line 8 Gas N2

MFC Size 5 SLM

Line 9 Gas HE

MFC Size 5SLM

Gas Panel Pallet C

Gas Line Requirement

Gas Line Configuration

Line 1 Gas NH3

MFC Size 2 SLM

Line 2 Gas N2

MFC Size 5SLM

Line 3 Gas SiH4

MFC Size 200 SCCM

Line 4 Gas NF3

MFC Size 1 SLM

Line 5 Gas N2O

MFC Size 1 SLM

Line 6 Gas CF4

MFC Size 3 SLM

Line 7 Gas N20

MFC Size 4V 239.7 SCCM / 2V 119.8SCCM

Line 8 Gas N2

MFC Size 5 SLM

Line 9 Gas HE

MFC Size 5SLM

Transfer Chamber

Transfer Ch Manual Lid Hoist YES

Robot Type CENTURA HP ROBOT

Robot Blade Option Ceramic Blade

Remotes

Heat Exchanger AMAT 0

Currently stored in a cleanroom

1996 vintage.

AMAT / APPLIED MATERIALS Centura 5200 reactor is an advanced plasma-enhanced chemical vapor deposition (PE-CVD) system that provides a clean, low-temperature process environment for semiconductor device fabrication. It is an ultra-high-vacuum, horizontally operated reactor and offers ultimate flexibility with a wide range of CVD process recipes and materials. AMAT Centura 5200 utilizes microwave frequencies, ion plating, and plasma-enhanced reaction sources to achieve more controllable and reproducible processes to lay down the thin-film layers on the substrate, enhancing the device performance and reliability. The instrument can accurately and precisely control the source gas temperatures and flow rates for required process parameters, as well as the temperature of the substrate itself. APPLIED MATERIALS Centura 5200 features a multi-zone exothermal heating furnace system to maximize productivity, as well as a group of end-point sensors carefully placed in each reaction zone to guarantee homogeneous processes for the consistent formation of high-quality thin-film layers. Ultimately, the uniform film thickness, accompanied by advanced deep profile analysis (DPA), process monitoring and feedback loops guarantee the repeatability of even extremely complex processes. The addition of a large-area substrate holder provides the flexibility of running two different processes at the same time with a minimal footprint. Additionally, the advanced automatic RF/DC power generator of Centura 5200 provides a precise power control with a faster ramp-up time than traditional systems. Finally, AMAT / APPLIED MATERIALS Centura 5200 includes user-friendly software that enables faster process setup, analysis of results, recipe formation, and more. It has been extensively tested and certified in key laboratories worldwide and is considered one of the most advanced and efficient PE-CVD systems available.

There are no reviews yet