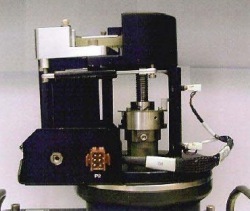

Used AMAT / APPLIED MATERIALS Centura 5200 #200226 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 200226

DPS metal etch throttle valve rebuild kit

Replaces OEM screw and nut on DPS throttle valve.

AMAT / APPLIED MATERIALS Centura 5200 is a next-generation PECVD reactor suitable for producing advanced semiconductor products like FinFETs, gate dielectrics, MEMS, thin-film bulk materials, and diffusion barriers in a highly efficient and cost-effective manner. AMAT Centura 5200 has a modular design, which allows for various combinations of source gases and the flexibility to easily integrate additional process modules. It has been designed with a variety of features designed to maximize material quality and uniformity including a patented gas delivery equipment, high efficiency gas transport system, low pressure remote plasma source, and high resolution uniformity control. Furthermore, its design has been optimized to enable safe, reliable, and reproducible performance over time. APPLIED MATERIALS Centura 5200 features a large chamber design that allows users to process up to 4" wafers in one uniform process. It features an automated wafer transport unit that reduces the likelihood of human errors due to the contactless nature of the operation. This prevents any mechanical damages to the wafer surface during transfer. Additionally, the automated gas handling machine ensures accurate gas inlet rate control and repeatability over time. Centura 5200's process capabilities are also extremely versatile. It comes with a selectable power range from 0-300 watts and can be used for a wide range of process recipes. These recipes can be tailored to individual requirements, depending on the application and process conditions. This allows users to maximize the performance of AMAT / APPLIED MATERIALS Centura 5200 and produce the highest quality product. In terms of process uniformity, AMAT Centura 5200 achieves excellent results with near-perfect wafer-to-wafer uniformity across the entire wafer surface, exceeding the industry standard. The entire process is automated and requires minimal manual intervention. This ensures consistency, time and cost savings, while delivering the highest quality products. All in all, APPLIED MATERIALS Centura 5200 is an excellent choice for processing semiconductor materials and components with superior results and cost savings. Its robust design, versatile process capabilities, and high-precision uniformity control make Centura 5200 an ideal choice for the modern semiconductor production.

There are no reviews yet