Used AMAT / APPLIED MATERIALS Centura 5200 #9071275 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9071275

Wafer Size: 8"

Epi Reactor, 8"

Application: Sige Bipolar/BICMOS

Chamber type | Selected option:

Chamber A: (RH) Reduced pressure EPI

Chamber B: (RH) Reduced pressure EPI

Chamber C: (RH) Reduced pressure EPI

Chamber D: Empty

Chamber E: Empty

Chamber F: (CA) Single slot cooldown

EMO Guard ring

Chamber A/B/C:

Thickness control options: Accusett 2

Recipe control software: No

Third manometer: P/N 0220-35949, 200 Torr

Gas line isolation: Yes

Leak check port: None

RGA port and valve: None

Gas delivery options:

ATM Capability in GP Only: No

Gas panel type: Configurable

Gas panel exhaust: Chamber B side

MFC: P/N: 0221-18389, Unit 8561 MFC's

Filter: Millipore

Pump purge: Yes

Chamber A/B/C Gas Option:

SiHCl3: Not applicable

SiH2Cl2: Yes

SiH4: Yes

GEH4: Yes

Direct inject dopant: 2

Mixed dopant 1: Yes

Mixed dopant 2: Yes

Mainframe:

Loadlock type: P/N: 0220-35948 Narrow body load locks with tilt-out

WBLL Equalization: No

Cassette platform type: Universal

Common chamber options:

Variable speed blower: Yes

SW Monitor quartz pyrometer kit: 3

Lamps type: Ushio log life

Susceptors: Tabbed susceptor

Brands: Toshiba

Lift pin type: Hollow silicon carbide

Susceptor support shaft: NCP Susceptor support shaft

Tips: Silicon carbide removable tips

Exhaust inserts: Stainless steel

Lower liners: Non-vented

Pump isolation valve: No

Exhaust deposit reduction: N/A

Transfer chamber:

Wafer sensing: On the fly cneterfinding

Transfer chamber lid hoist: Yes

Robot: HP + ENP

Transfer chamber purge, 15 SLM: Yes

Diagnostics and control:

SECSTrace: Yes

Vacuum pumps:

Pump brand: Edwards

Loadlock chamber pump: Edwards iQDP40

Transfer chamber pump: Edwards iQDP40

Proces chamber pump: Edwards iH1000

Monitors: (1) Through the wall and (1) Table mount

Manual Set

Tools and kits:

Centura HT Temp profiling kit

Upper dome centering ring kit

HT Level 1 Consumable kit

(2) Additional Level 1 consumable kit

Additional Epi quartz and graphite spares:

(2) Reduced pressure upper dome

(2) Lower dome

(4) Spare susceptors

(4) Preheat rings

Manually input spare:

P/N: 3920-01120, 10-120 lb-in torque wrench

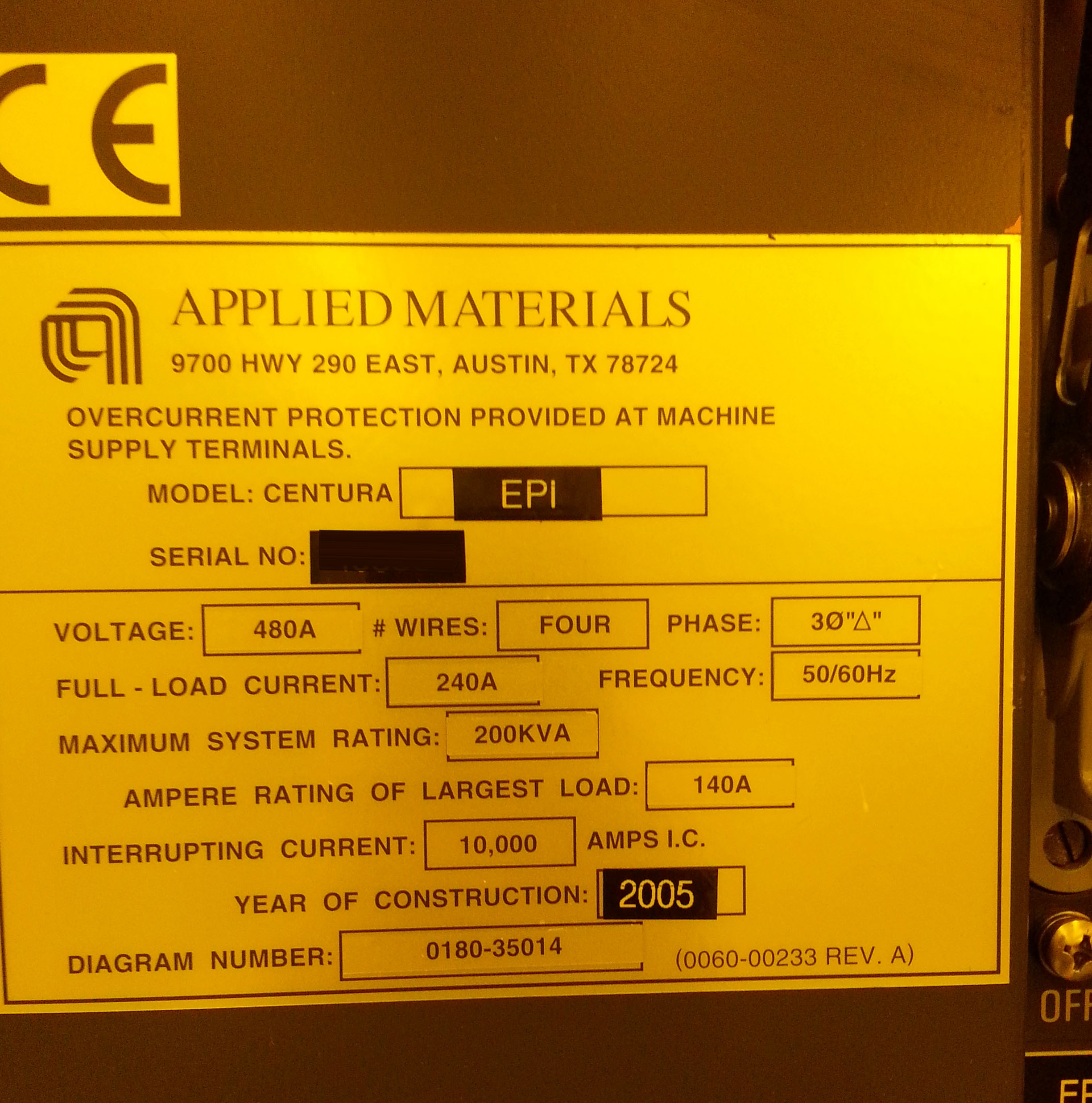

480 V with transformer, 60 Hz, 600 A

Currently installed

2005 vintage.

AMAT / APPLIED MATERIALS Centura 5200 is a reactor equipment designed for use in advanced electroplating, etching and dielectric processing applications. It is equipped with high precision photolithographic masks for patterned processing. The system is designed to apply physical and chemical treatments over large areas of substrates quickly and efficiently. AMAT Centura 5200 is constructed with a thick stainless steel outer shell, which provides reliable and durable protection against corrosion and other environmental conditions. Inside the shell, state-of-the-art control modules and a robotic transport unit is employed to ensure accuracy and repeatability in the machine's processes. The tool also features an automated array of pumps, valves and other motion control components to ensure reliable and accurate delivery of materials. The asset can accommodate several types of bath configurations as well as a variety of substrate materials, making it suitable for various applications. Additionally, the user can select the appropriate batch duration and process parameters according to the material being processed. The model also supports embedded programmable logic, enabling it to monitor and control all the necessary parameters for the specific process, allowing for more control of the process conditions. The reactor offers a wide range of operating temperature from RT (room temperature) to 350°C, and the maximum flow rate of 175 l/min.; making it suitable for high speed, high accuracy plating processes. The user can also specify custom parameters such as the desired rate of evaporation, and the equipment is able to detect and store any process results for future reference. APPLIED MATERIALS Centura 5200 is a reliable reactor that is equipped with advanced technology to provide accurate, repeatable and efficient plating, etching, and dielectric processes. It can easily be configured to handle many different types of substrates and bath configurations, making it a reliable and versatile reactor.

There are no reviews yet