Used AMAT / APPLIED MATERIALS Centura 5200 #9188519 for sale

URL successfully copied!

Tap to zoom

ID: 9188519

Wafer Size: 8"

Vintage: 2003

HDP CVD System, 8"

Ultima TE process chamber

Wafer shape: SNNF

EMO Type: Turn to release

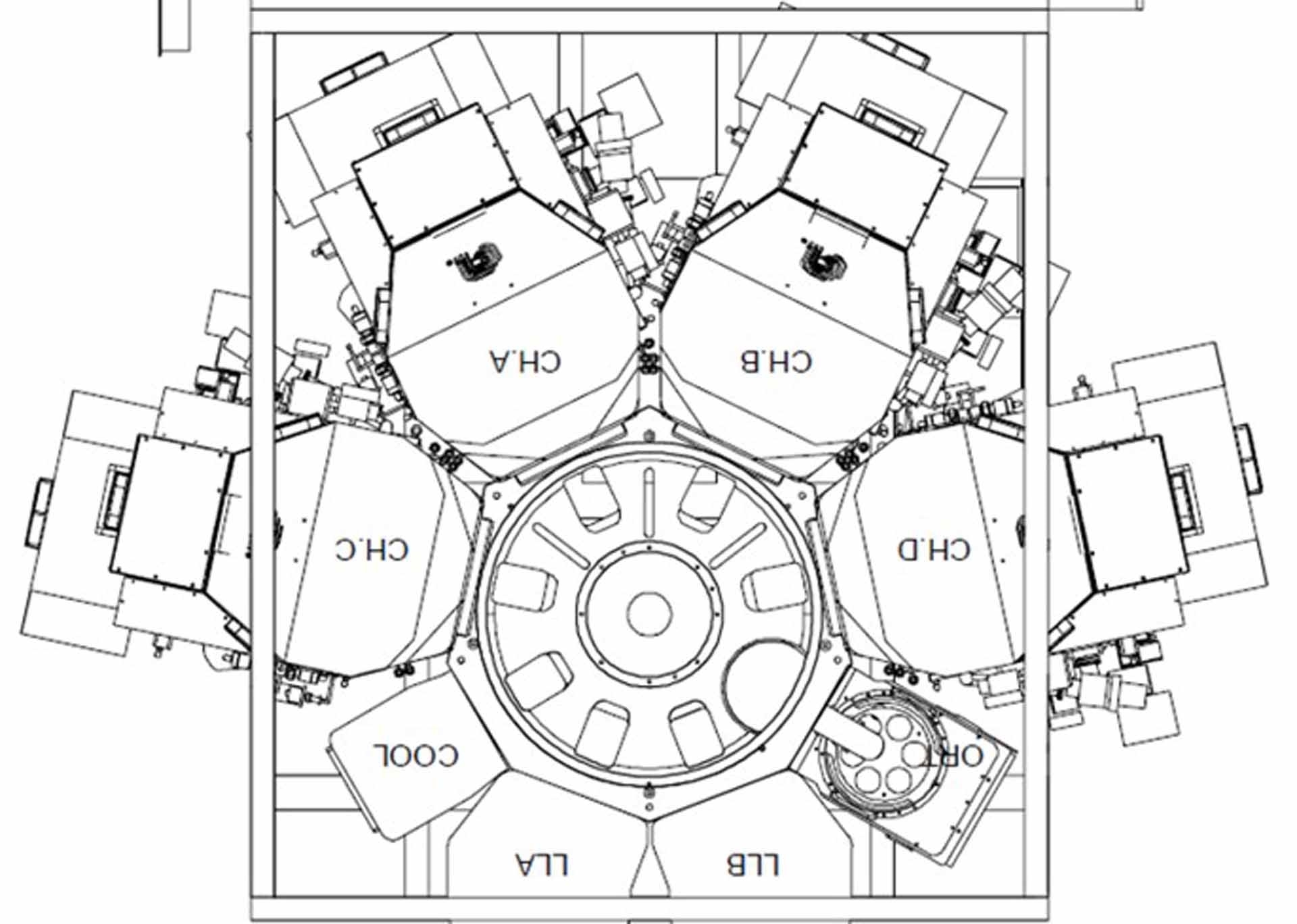

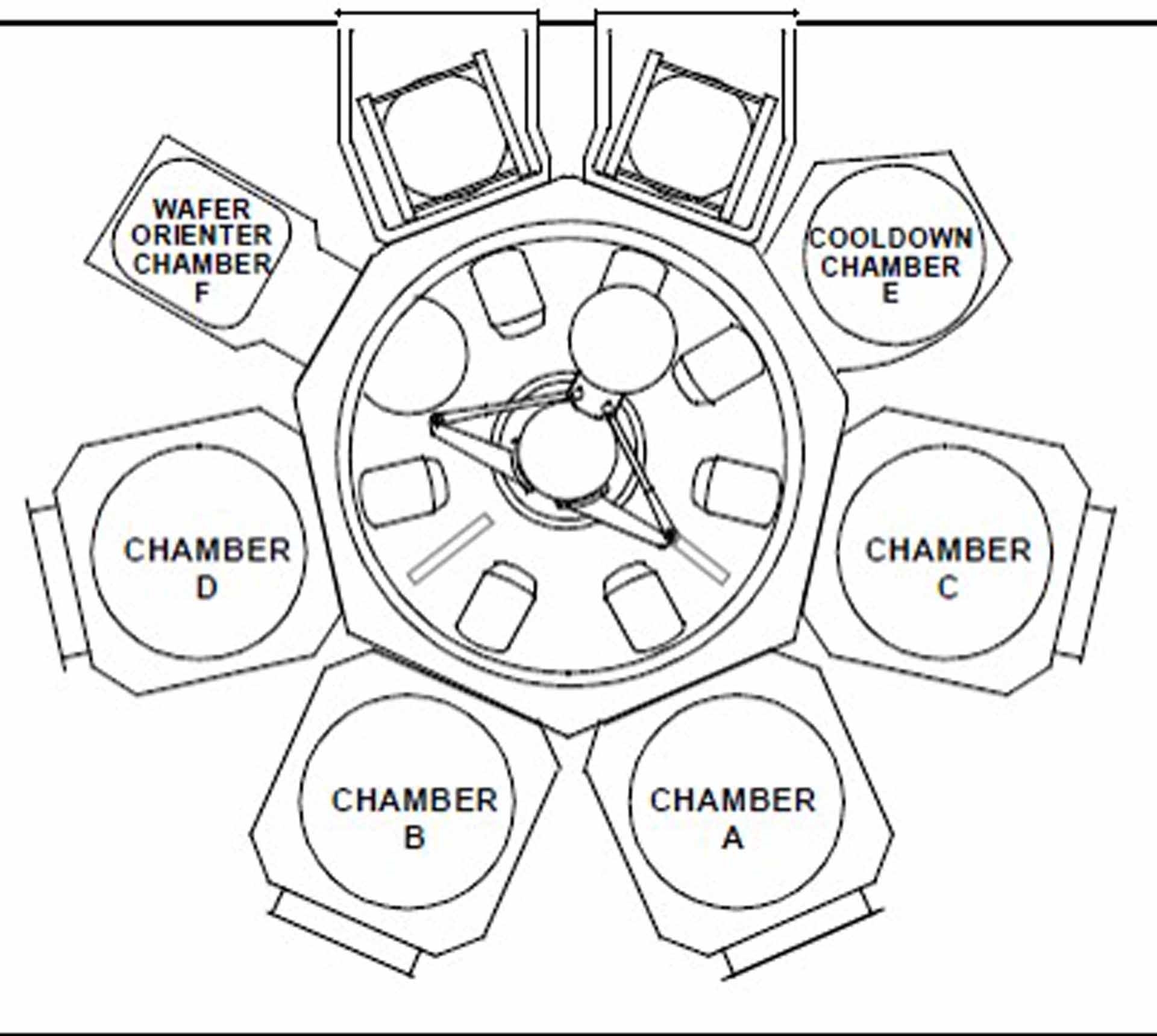

Chamber configuration:

Chamber A: HDP Ultima TE process chamber

Chamber B: HDP Ultima TE process chamber

Chamber C: HDP Ultima TE process chamber

Chamber E: Multi cooldown chamber

Chamber F: Orient chamber

Loadlock configuration:

Loadlock type: Wide body

Auto rotation

Cassette type: 200mm

Mapping function: FWM

Vent type: Variable speed

Fast vent option

Mainframe configuration:

Buffer robot type: HP+

Buffer robot blade: Ceramic blade

Remote monitor: Table mount

Clean system: RPS ( Remote plasma) clean

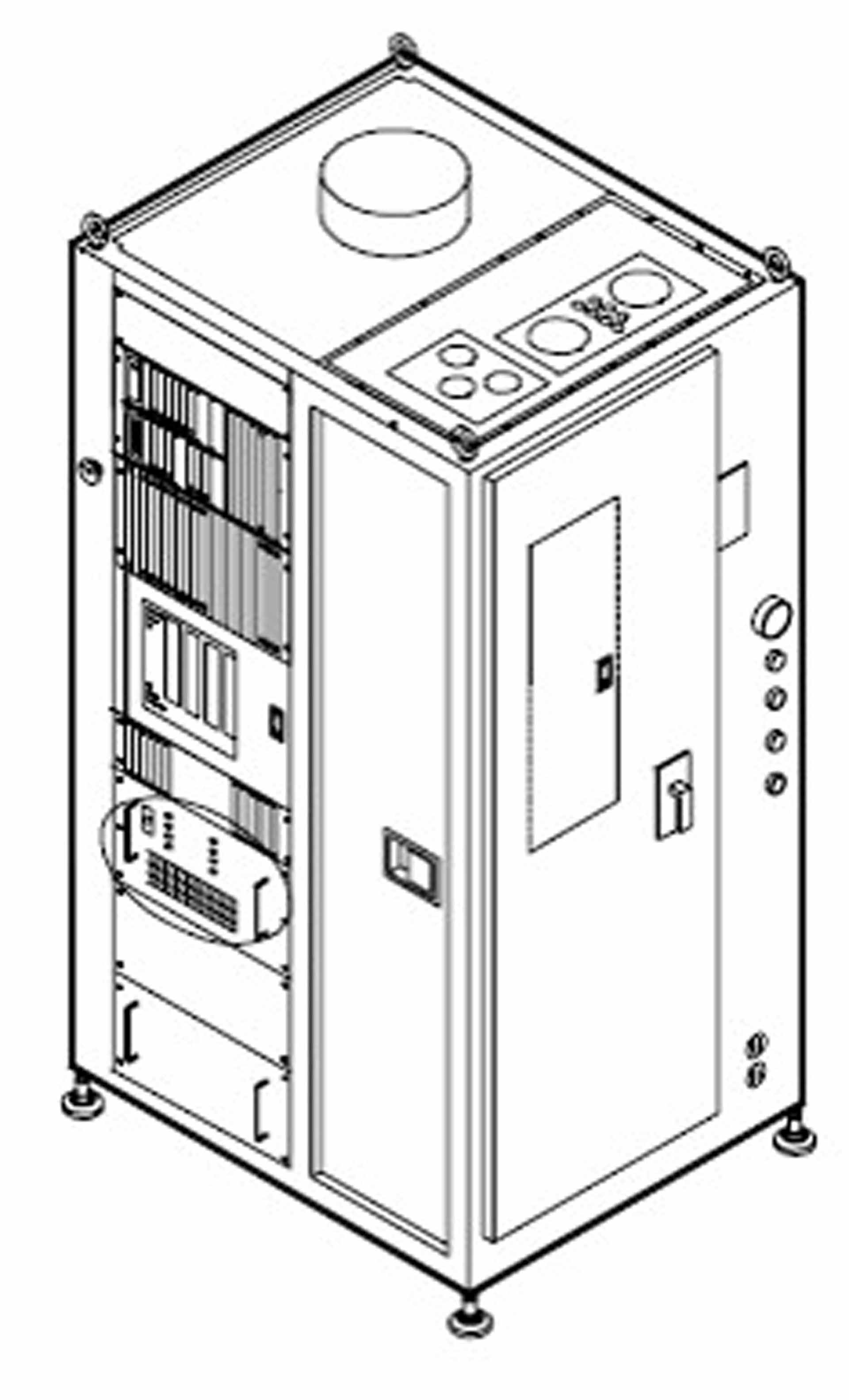

Sub-system configuration:

Chiller

RF Generator type: ETO

Gas panel configuration: Normal gas panel

Turbo pump: ADIXE ATH2300M

Gate valve: NC

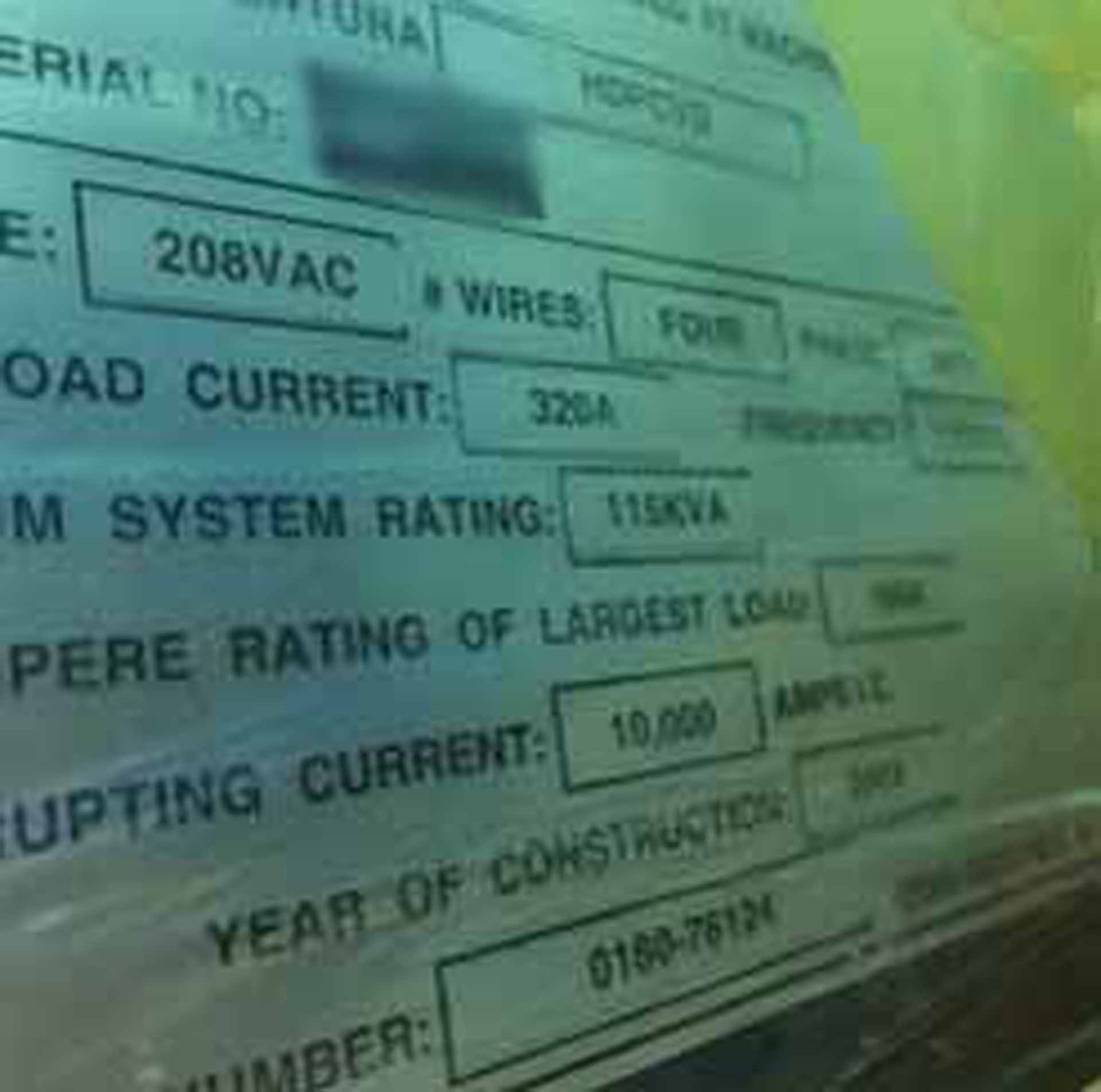

Electrical configuration:

Line voltage: 208V

Full load current: 320 A

Frequency: 50/60Hz

CE Safety mark: English

2003 vintage.

AMAT / APPLIED MATERIALS Centura 5200 reactor is a single-wafer thermal processing equipment that enables the fabrication of advanced semiconductor integrated circuits (ICs). It is a tool used by semiconductor manufacturers for etching, cleaning, and other operations associated with device fabrication. The system has a six-level process chamber configuration which permits the introduction of a variety of corrosive, aggressive, and other chemical species for a wide range of treatments. AMAT Centura 5200 reactor supports a variety of processes including wet and dry etching, deposition, cleaning, passivation and metal sputtering. It is engineered with patented zone-level control technology and a unique dual-gas wafer rotation unit which allows for the precise control of process conditions within various levels of the tool. The combination of these technologies enable the laser accurate control of thermal processes to enable the fabrication of higher levels of integration and performance. The tool is designed to be used in high-volume production environments and it is capable of processing up to 500 wafers per hour. Access to machine operations is provided via an intuitive Graphical User Interface (GUI) with a touchscreen display which permits optimized control of parameters and quick access to process data. The tool is features a suite of automated utilities which provide a range of features to facilitate the operation of the reactor. These include personnel security, wafer tracking, wafer lot quality control, and automatic wafer setup which enables the monitoring of process history to ensure repeatable performance. APPLIED MATERIALS Centura 5200 reactor is equipped to minimize environmental and safety concerns associated with chip making. It is designed to minimize chemical exposure and other hazardous conditions associated with the production of advanced ICs. The asset is compliant with a variety of regulations and standards including SEMI S2 and S8. In conclusion, Centura 5200 reactor is a highly advanced thermal processing model designed to meet the requirements of the next-generation of semiconductor manufacturing. Its suite of features provide a range of automated utilities to facilitate operation and reduce potential safety and environmental risks. It is a tool capable of meeting the highest levels of performance and repeatability for advanced IC fabrication.

There are no reviews yet