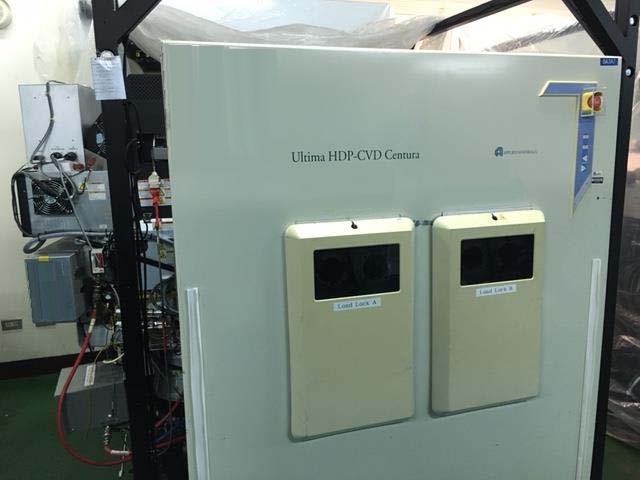

Used AMAT / APPLIED MATERIALS Centura 5200 #9198283 for sale

URL successfully copied!

Tap to zoom

ID: 9198283

Wafer Size: 8"

Vintage: 2000

HDP CVD System, 8"

Wafer shape: SNNF

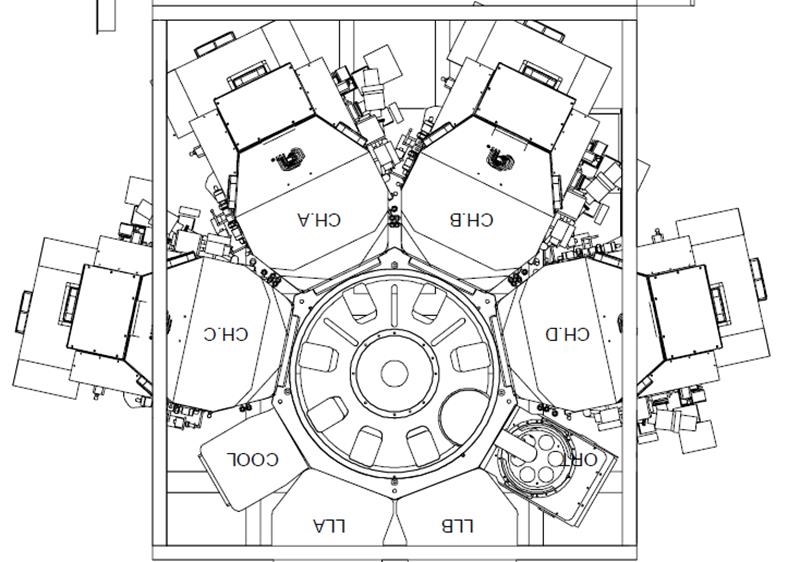

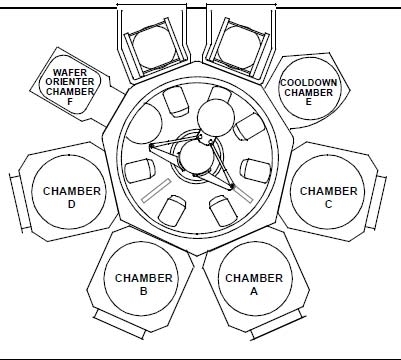

Chamber configuration:

Chamber A: HDP Ultima TE process chamber

Chamber B: HDP Ultima TE process chamber

Chamber C: HDP Ultima TE process chamber

Chamber E: Multi cooldown chamber

Chamber F: Orient chamber

Loadlock configuration:

Loadlock type: Narrow body

Auto rotation

Cassette type: 200mm

Mapping function: FWM

Vent type: Variable speed

Fast vent option

Mainframe configuration:

Buffer robot type: HP+

Buffer robot blade: Ceramic blade

Status light tower: RYG

Remote monitor: Table mount

Includes:

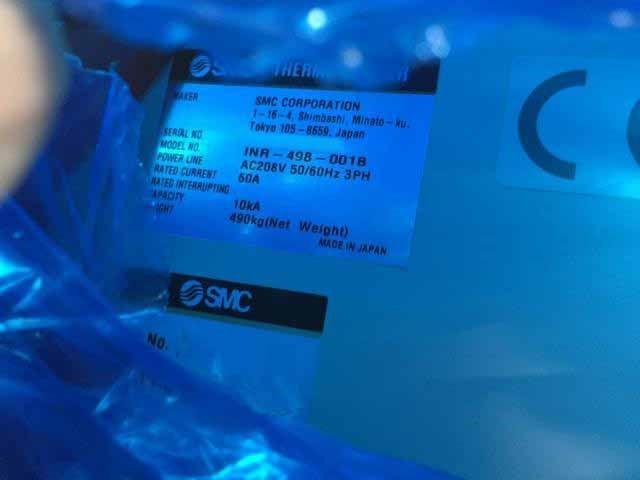

SMC Thermo chiller INR-498-001B

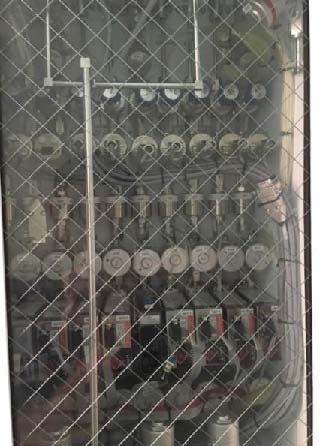

RF Generator type: ETO RF System

Standard gas panel

With (3) sets gas pallet

LEYBOLD MAG2000 Turbo pump

Gate valve: NC

Electrical configuration:

Line voltage: 208V

Full load current: 320 A

Frequency: 50/60Hz

2000 vintage.

AMAT / APPLIED MATERIALS Centura 5200 is an advanced plasma-based reactor designed for the production of electronic micro-devices. As a plasma-enhanced chemical vapor deposition (PECVD) reactor, AMAT Centura 5200 has a number of advantages over other deposition mechanisms, such as chemical vapor deposition (CVD) or thermal CVD. APPLIED MATERIALS Centura 5200 system's main components are the plasma chamber, power supplies, vacuum pump, glassware, computer controlled process chamber, and support hardware. The plasma chamber is a vacuum chamber that contains a process gas, such as nitrogen or argon, along with a small amount of a precursor gas, such as silane. This combination of gases is what creates the plasma inside the chamber. The power supplies provide the energy necessary to create the plasma. The glassware in Centura 5200 includes a deposition plate, a substrate stage, an exit pipe, and various other components that help to regulate the size and temperature of the process zone. The substrate stage is necessary for the deposition process and holds the substrate, either a wafer or a transfer substrate, in place. The deposition plate is necessary for directing the gas to the desired location on the substrate. The exit pipe transports the exhaust gases from the plasma chamber. The process chamber is an enclosed container with a computer-controlled temperature sensor and a preconditioning gas flow controller. The gas flow controller regulates the flow of gases necessary for the deposition process and maintains a constant temperature in the chamber. AMAT / APPLIED MATERIALS Centura 5200 uses an air-to-gas based mechanism to generate plasma that results in high deposition rates and excellent uniformity of the deposits on the substrate. The vacuum pump within AMAT Centura 5200 is used to maintain the pressure within the plasma chamber and also to evacuate any byproducts of the deposition process. This ensures that the process gas within the chamber is not affected by any stray atoms or particles from the reaction. Finally, the support hardware of APPLIED MATERIALS Centura 5200 is designed to provide integral support for the operation of the reactor. This includes components such as air valves, pressure sensors, temperature sensors, and shut-off devices. These components serve to both monitor and control the operation of the reactor by allowing adjustment of the gas flows, gas pressures and temperatures, and other parameters. Overall, Centura 5200 PECVD reactor is a reliable and efficient system for the fabrication of a multitude of micro-devices and products. Its combination of advanced components and computer-controlled process chamber ensure that the highest quality of depositions is achieved in the most efficient manner possible.

There are no reviews yet