Used AMAT / APPLIED MATERIALS Centura 5200 #9198786 for sale

URL successfully copied!

Tap to zoom

ID: 9198786

Wafer Size: 8"

Vintage: 2003

HDP CVD System, 8"

Wafer shape: SNNF

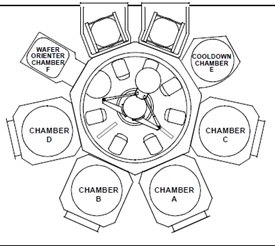

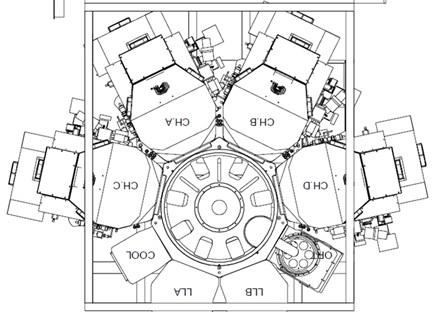

Chamber configuration:

Chamber A: HDP Ultima TE process chamber

Chamber B: HDP Ultima TE process chamber

Chamber C: HDP Ultima TE process chamber

Chamber E: Multi cooldown chamber

Chamber F: Orient chamber

Loadlock configuration:

Loadlock type: Y body

Auto rotation

Cassette type: 200mm

Mapping function: FWM

Vent type: Variable speed

Fast vent option: Yes

Mainframe configuration:

Buffer robot type: HP+

Buffer robot blade: Ceramic blade

Remote monitor: Table mount

Clean system: RPS ( Remote Plasma) clean

Includes:

Normal TE gas panel

LEYBOLD MAG2000 Turbo pump

Gate valve: NC

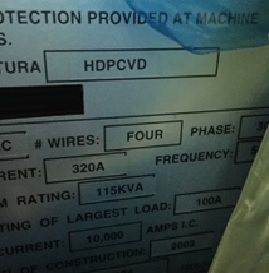

Electrical configuration:

Line voltage: 208V

Full load current: 320 A

Frequency: 50/60Hz

Missing parts:

Chiller

RF Rack

2003 vintage.

AMAT / APPLIED MATERIALS Centura 5200 is a chemical vapor deposition (CVD) reactor designed for the industrial fabrication of semiconductors. This multi-chamber reactor supports the deposition of up to three materials simultaneously for applications such as copper dual damascene structures, high-aspect-ratio contact and MIM capacitor structures, and advanced metal interconnects. With its patented Tamarac Amox Etch Single-wafer module and its dual-downward-load process capability, AMAT Centura 5200 provides for the reliable production of high-quality, high-performing semiconductor devices. At the heart of APPLIED MATERIALS Centura 5200 are its five system components that ensure optimized process performance and excellent process control. Centura 5200 is equipped with an Onsite Complex Module (OCM) that takes advantage of advanced model-based control technology to enable rapid and precise process tuning under varying operating conditions. This module provides near real-time feedback on wafer quality, deposition rate, and process uniformity. Additionally, the On-Wafer Electrical Test (OWET) module supports the rapid testing of wafer electrical characteristics, while the Single-Wafer Etcher Module (SWEM) ensures fast and accurate etching processes. AMAT / APPLIED MATERIALS Centura 5200 is also equipped with a dual-downward load capability for improved throughput, along with rotatable tweezers for improved handling of large substrates. AMAT Centura 5200 also features a user-friendly graphical interface that allows users to easily access process recipes, examine deposition profiles, or adjust process parameters. Through the OCM, three integrated chambers enable multi-layer deposition to produce high-quality Copper dual damascene structures and enable MIM capacitor and contact structures with sub-75nm aspect-ratio features. Its integrated thermal isolation feature helps minimize beam contamination and minimize wafer misalignment. The mainframe has also been designed for expandability with the capability to integrate up to six chambers for testing multiple materials or processes simultaneously. Through integration with tool kits from major IC manufacturers, APPLIED MATERIALS Centura 5200 helps manufacturers develop yield improvements and get devices to market faster. It is designed for ease of maintenance and supports up to one million-hour mean time between failures (MTBF). This enables manufacturers to benefit from both increased device performance and reduced downtime. Overall, Centura 5200 is designed for high-performance, high-throughput industrial applications and offers advanced deposition capabilities that can help bring new devices to market faster. With its combination of robust materials deposition, process control and expandability features, AMAT / APPLIED MATERIALS Centura 5200 is the ideal choice for the fabrication of advanced semiconductor devices.

There are no reviews yet