Used AMAT / APPLIED MATERIALS Centura 5200 #9247619 for sale

URL successfully copied!

Tap to zoom

ID: 9247619

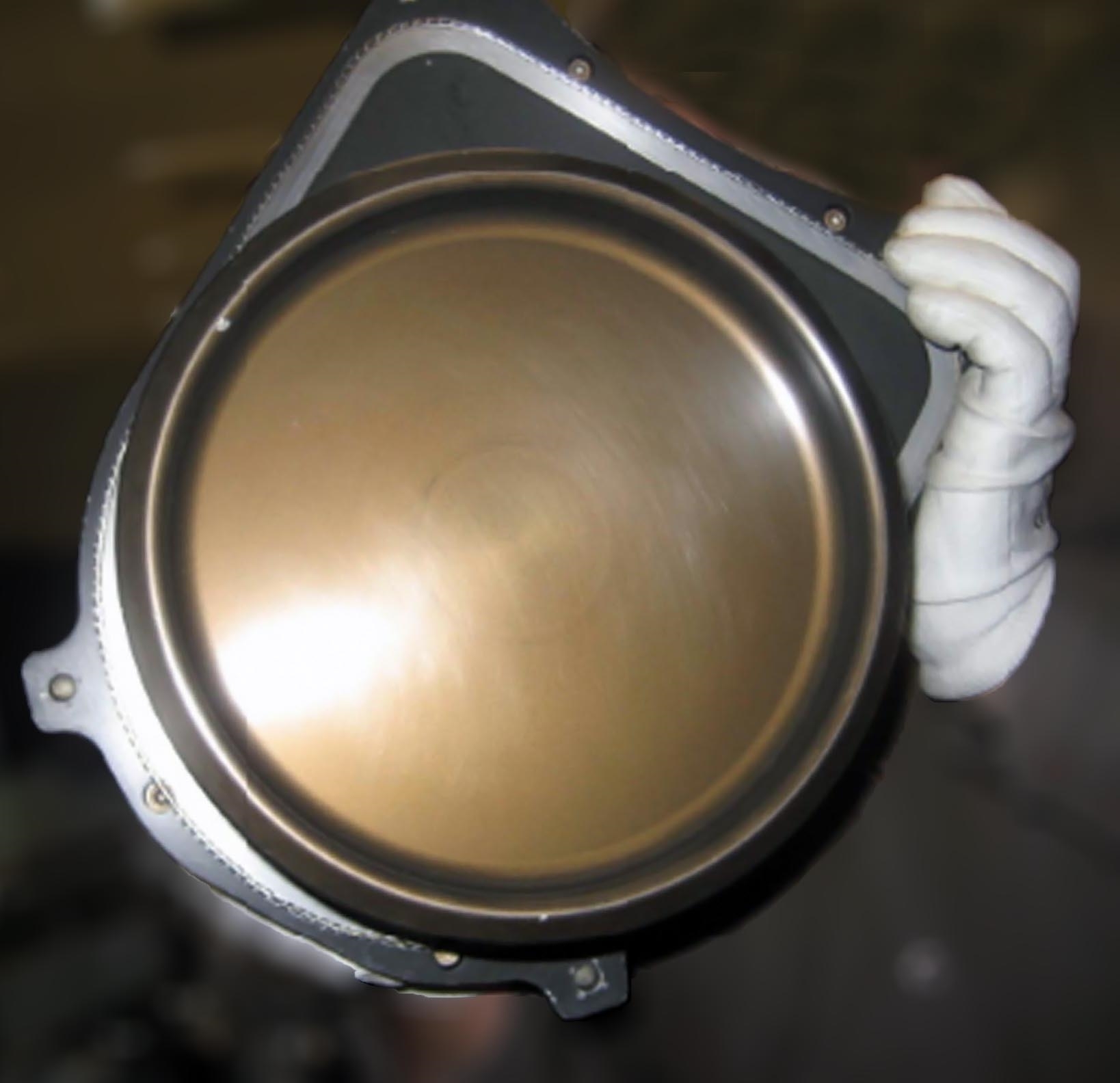

Wafer Size: 8"

Vintage: 1997

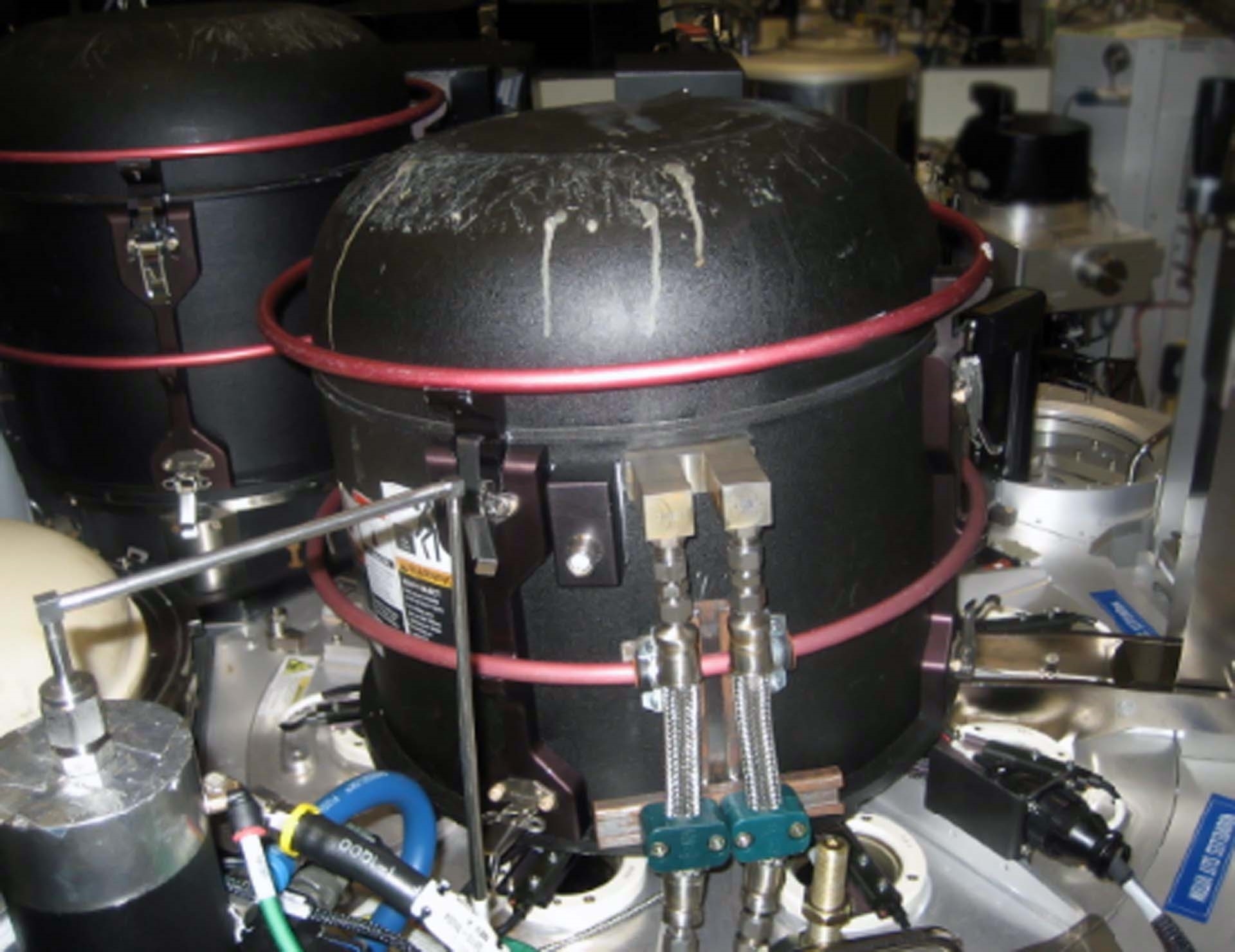

DPS Etcher, 8"

Wafer shape: SNNF

EMO Type

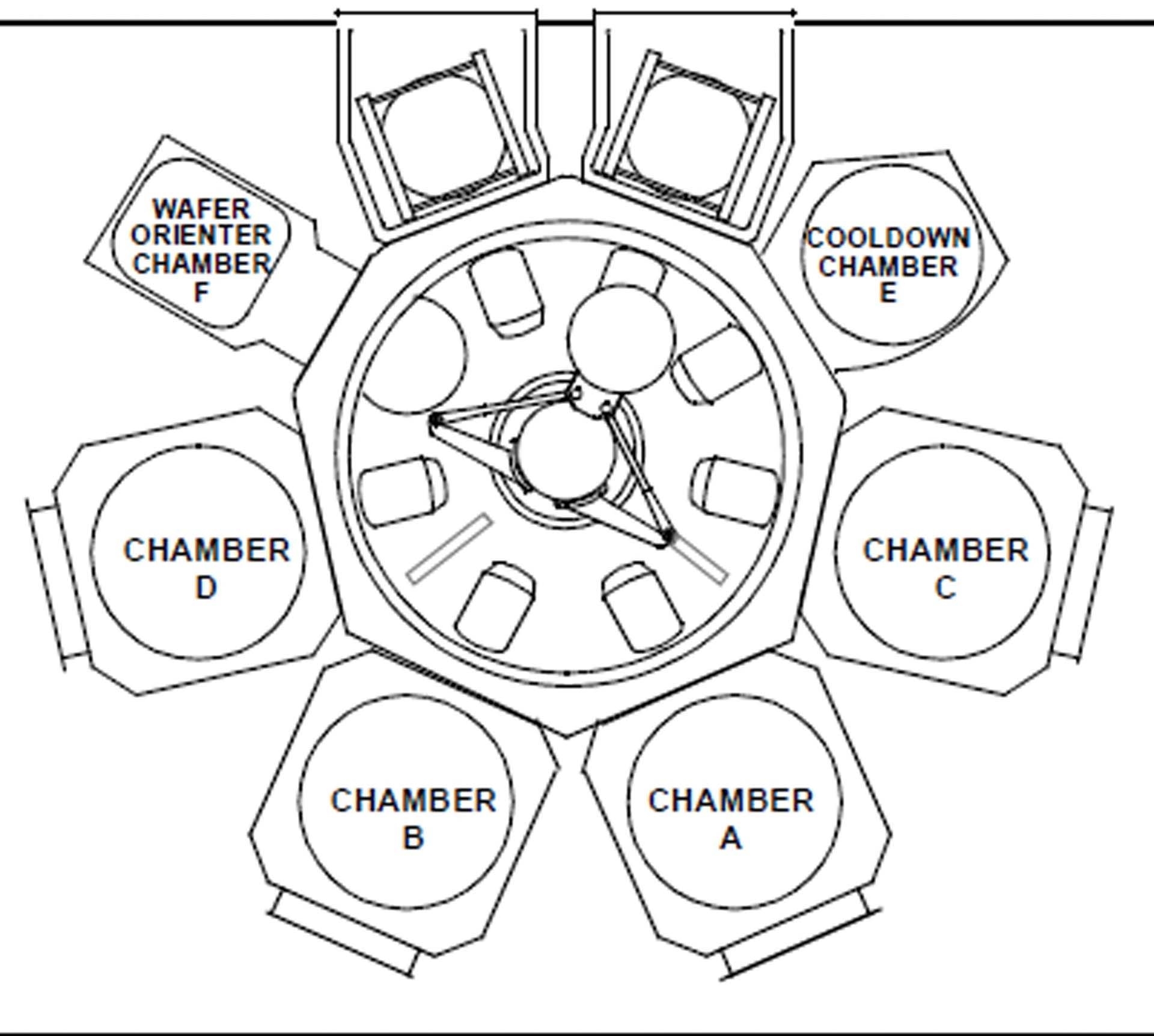

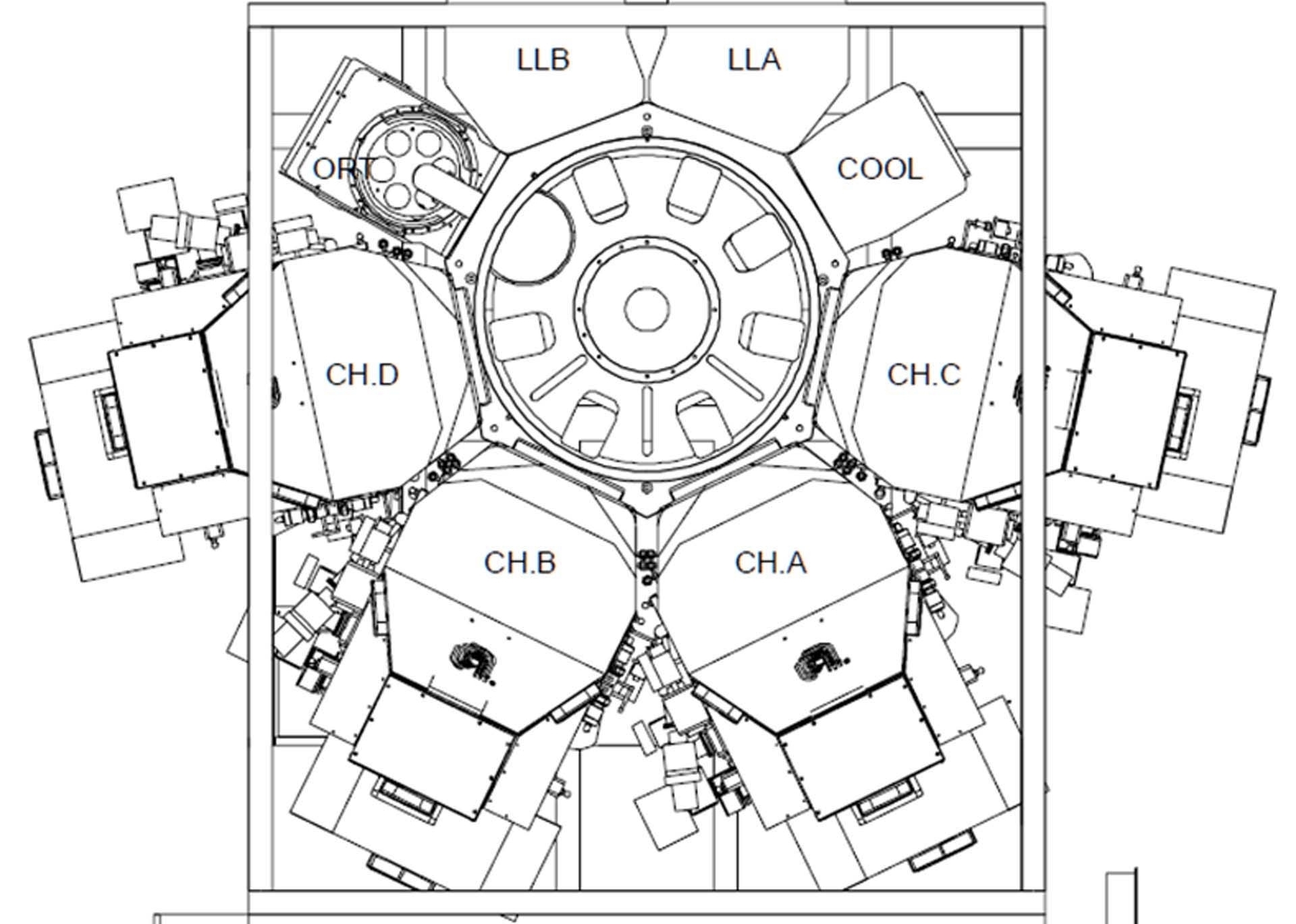

Chamber configuration:

Chamber A, B: DPS Metal process chamber

Chamber C, D: ASP Process chamber

Chamber E: Cool down chamber

Chamber F: Orient chamber

Load lock:

Load lock type: Narrow body

Auto rotation

Cassette type, 8"

Mapping function: FWM

Fast vent option

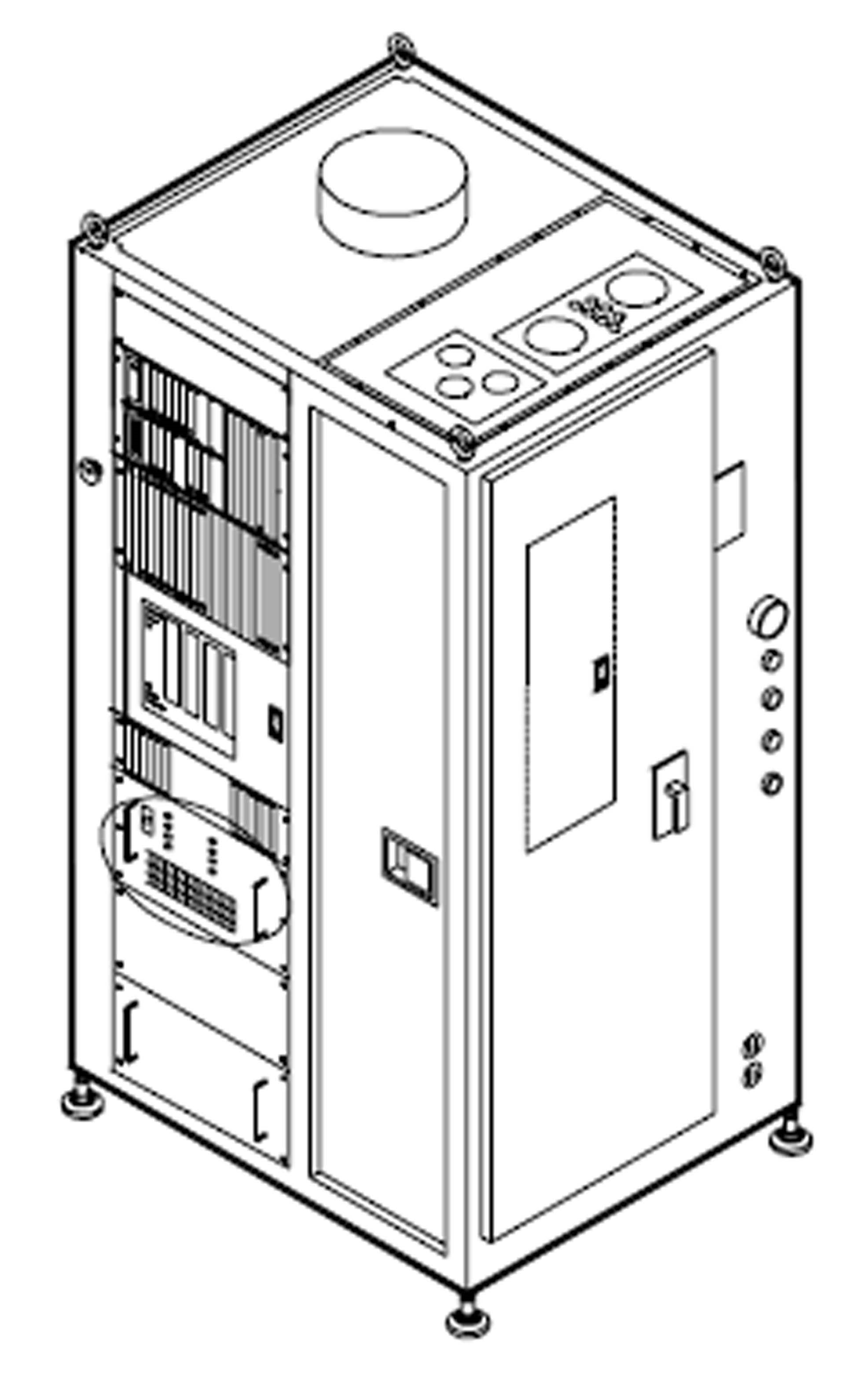

Mainframe:

AGILENT / HP / HEWLETT-PACKARD / KEYSIGHT Buffer robot

Buffer robot blade: Stander blade

Status light tower

Remote monitor: Table mount

(2) Chillers: HX-150 and Stead head0

(2) OEM-12B3 RF Generators

Gas panel configuration: VME1

EBARA ET800WS-A Turbo pump

NESLAB System II Heat exchanger

Control rack

Local AC rack

Accessories

Cables

Electrical configuration:

Line voltage: 208 V

Full load current: 300 A

Frequency: 50 / 60 Hz

CE Marked

1997 vintage.

AMAT / APPLIED MATERIALS Centura 5200 is a high-efficiency, fully automated chemical vapor deposition (CVD) reactor that is designed to meet the demanding production requirements of the electronics, optoelectronic, hard coating, and solar cell industries. AMAT Centura 5200 offers both scalable and modular configurations, allowing handling of a wide variety of materials and process chambers. It utilizes horizontal and vertical thermal uniformity levels to meet a precise deposition process. The high-speed deposition and improved reactor stability increases throughput while maintaining precise results. The high-temperature process chambers are designed to permit fast wafer throughput and precise deposition control. Its advanced physical vapor deposition toolset offers highly precise material sourcing, dynamic gas control, and custom gas flow settings. Additionally, it features superior end point accuracy and large nitride processing capacity. APPLIED MATERIALS Centura 5200's is highly versatile, offering advanced automation and programmatic capabilities to produce repetitive processing results. Its proprietary chamber architecture provides superior temperature uniformity with improved repeatability and overall performance quality. Centura 5200 is suitable for a range of materials, such as silicon, aluminum oxide, polysilicon, and an array of metals and alloys, up to temperatures of 900°C applications. The system can be configured to accommodate wafer sizes from 4- to 8-inch, providing enhanced flexibility. The total maintenance package from AMAT includes comprehensive preventive maintenance, technical IT support, and software upgrades. AMAT / APPLIED MATERIALS Centura 5200 is a powerful and reliable CVD reactor tailored for advanced materials deposition without requiring lengthy cooling and heating cycles. The system is an ideal solution for manufacturers looking to increase efficiency and improve process performance.

There are no reviews yet