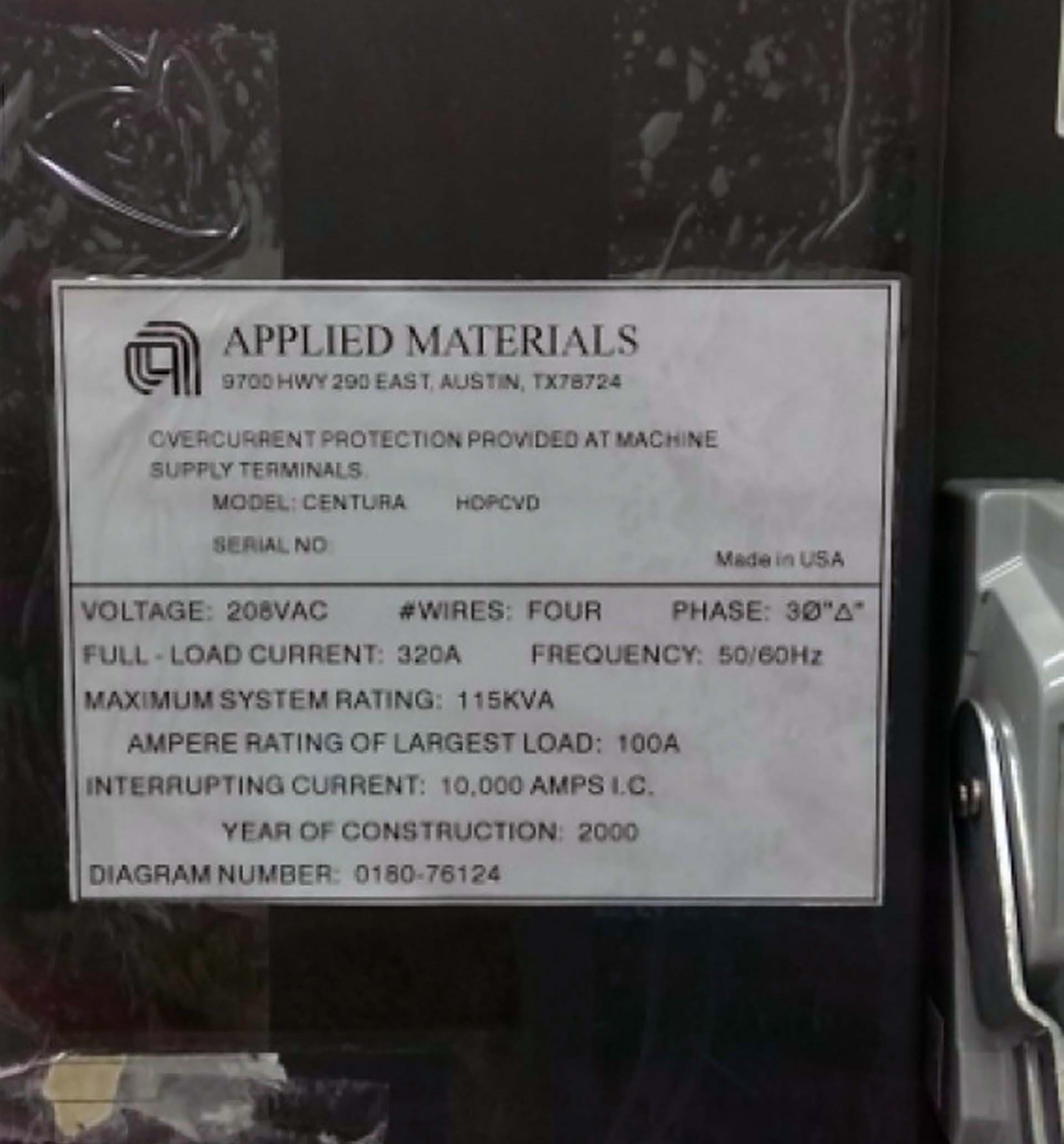

Used AMAT / APPLIED MATERIALS Centura 5200 #9248821 for sale

URL successfully copied!

Tap to zoom

ID: 9248821

Wafer Size: 8"

Vintage: 2000

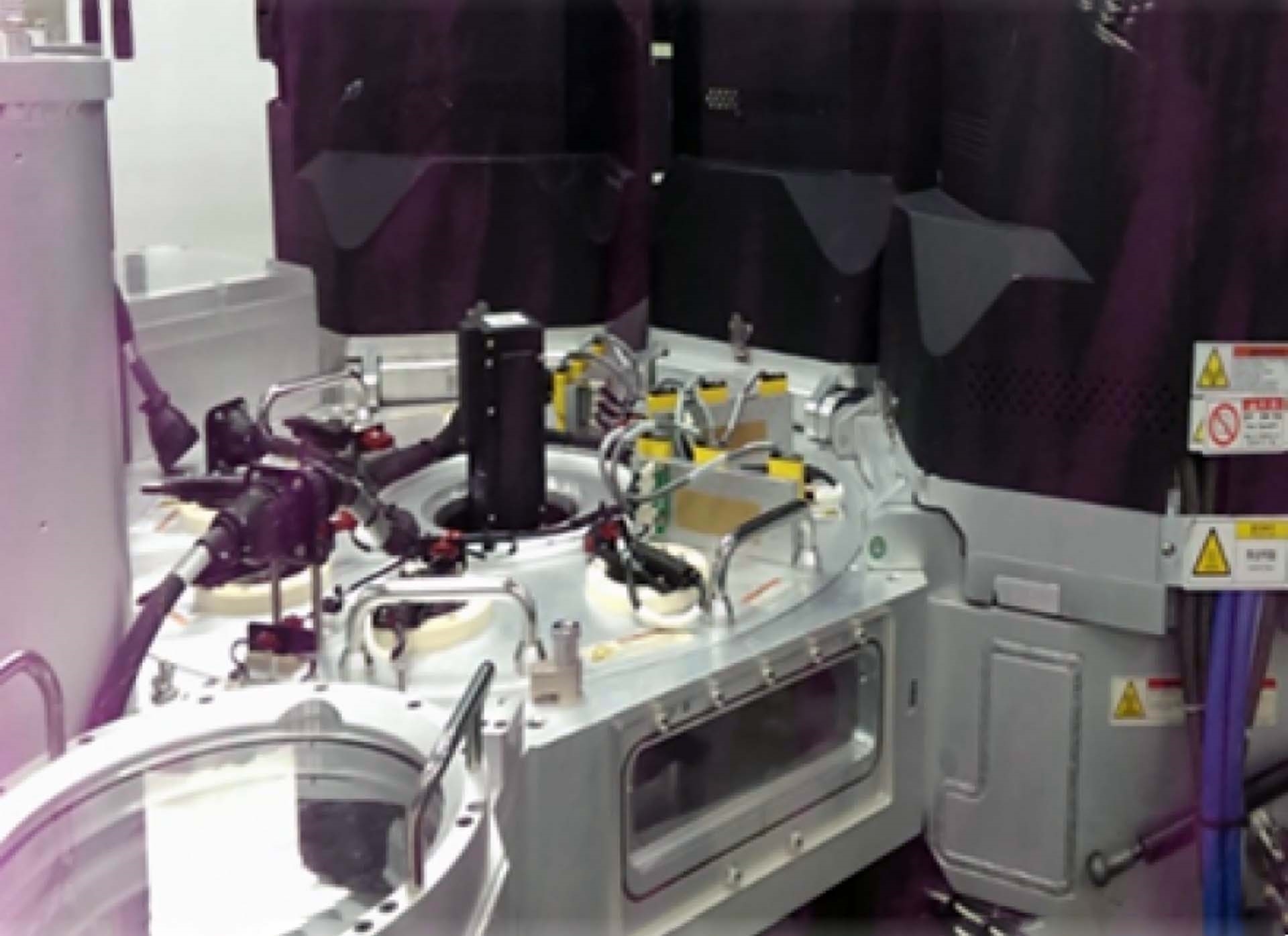

HDP CVD System, 8"

Wafer shape: SNNF

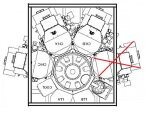

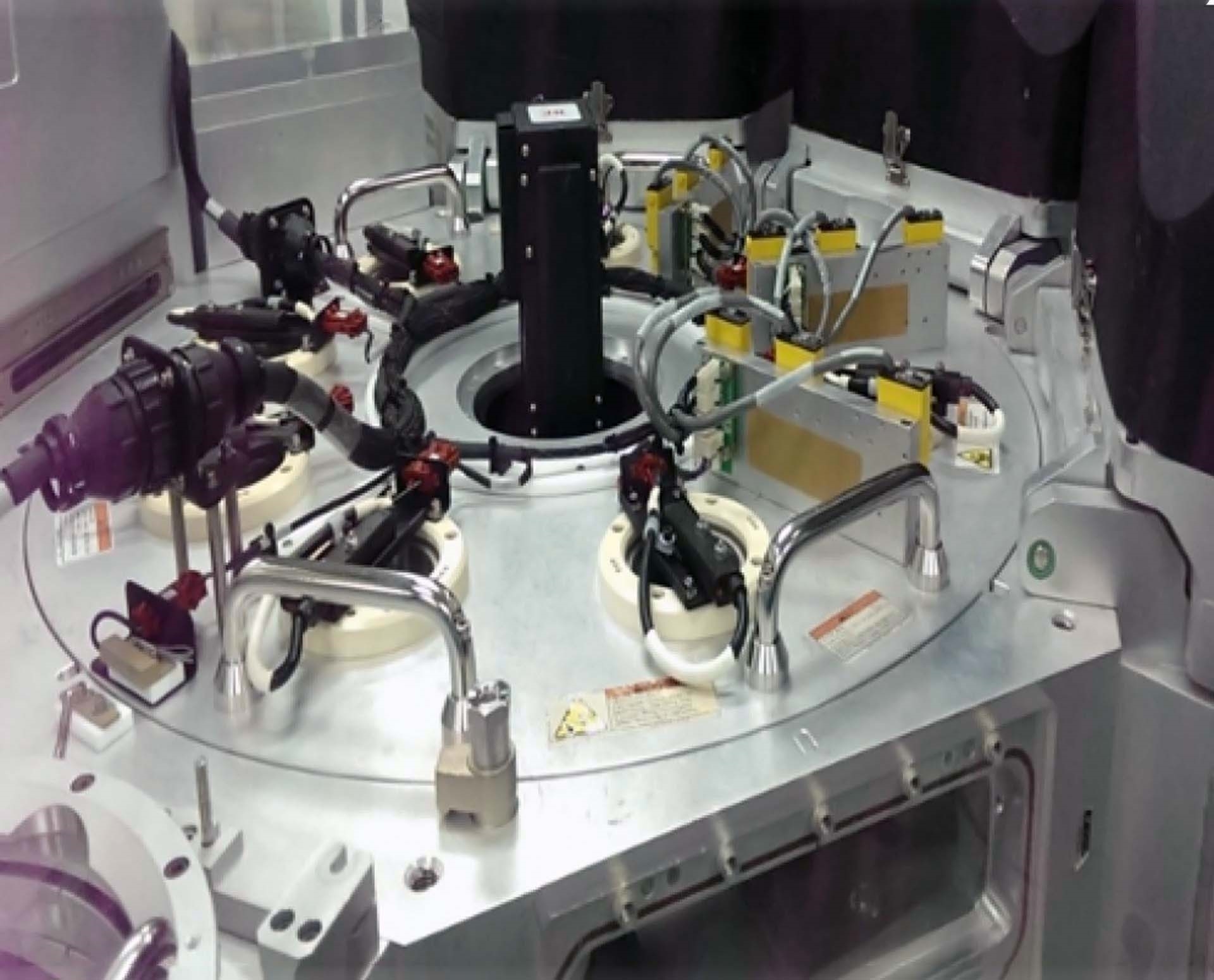

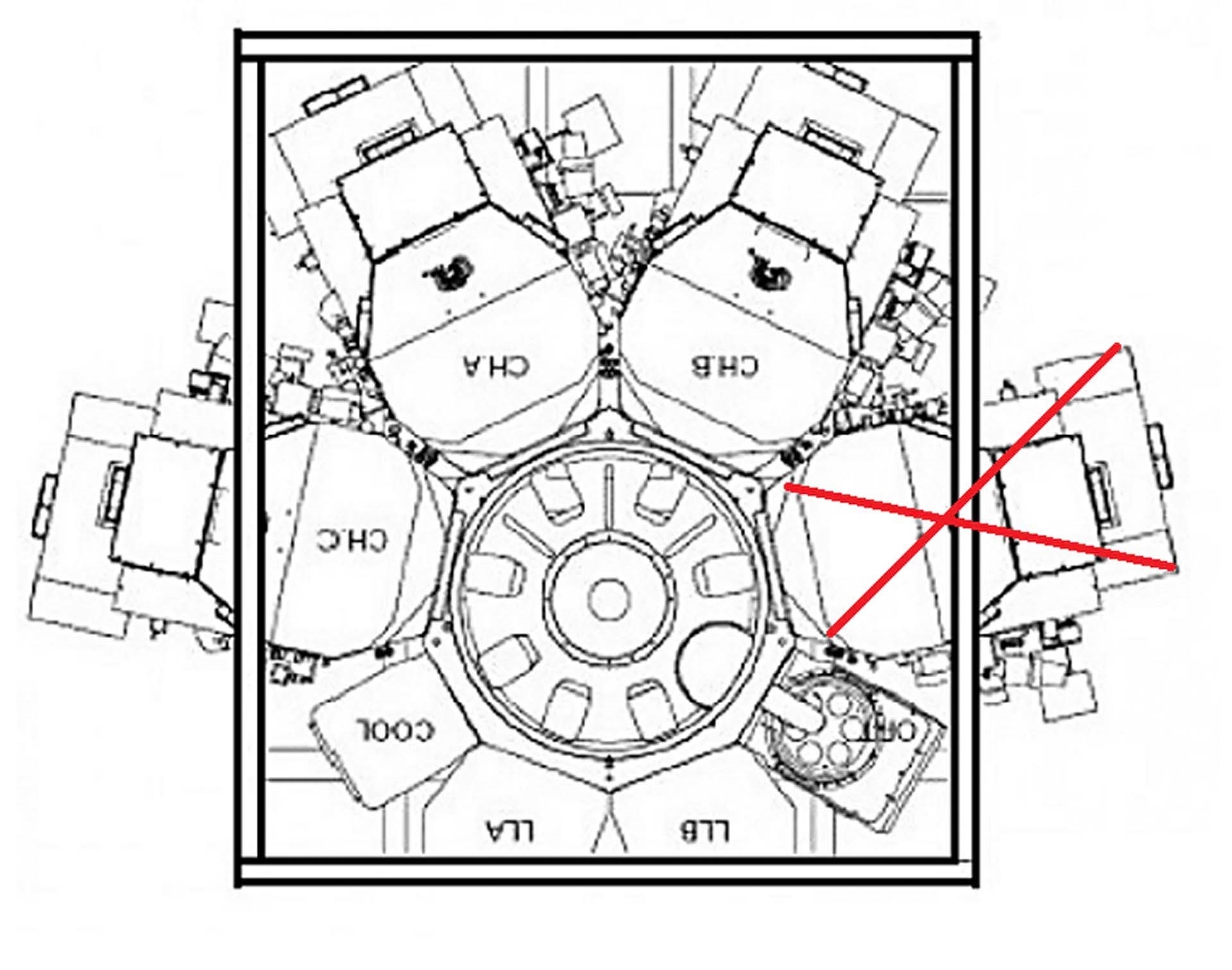

Chamber configuration:

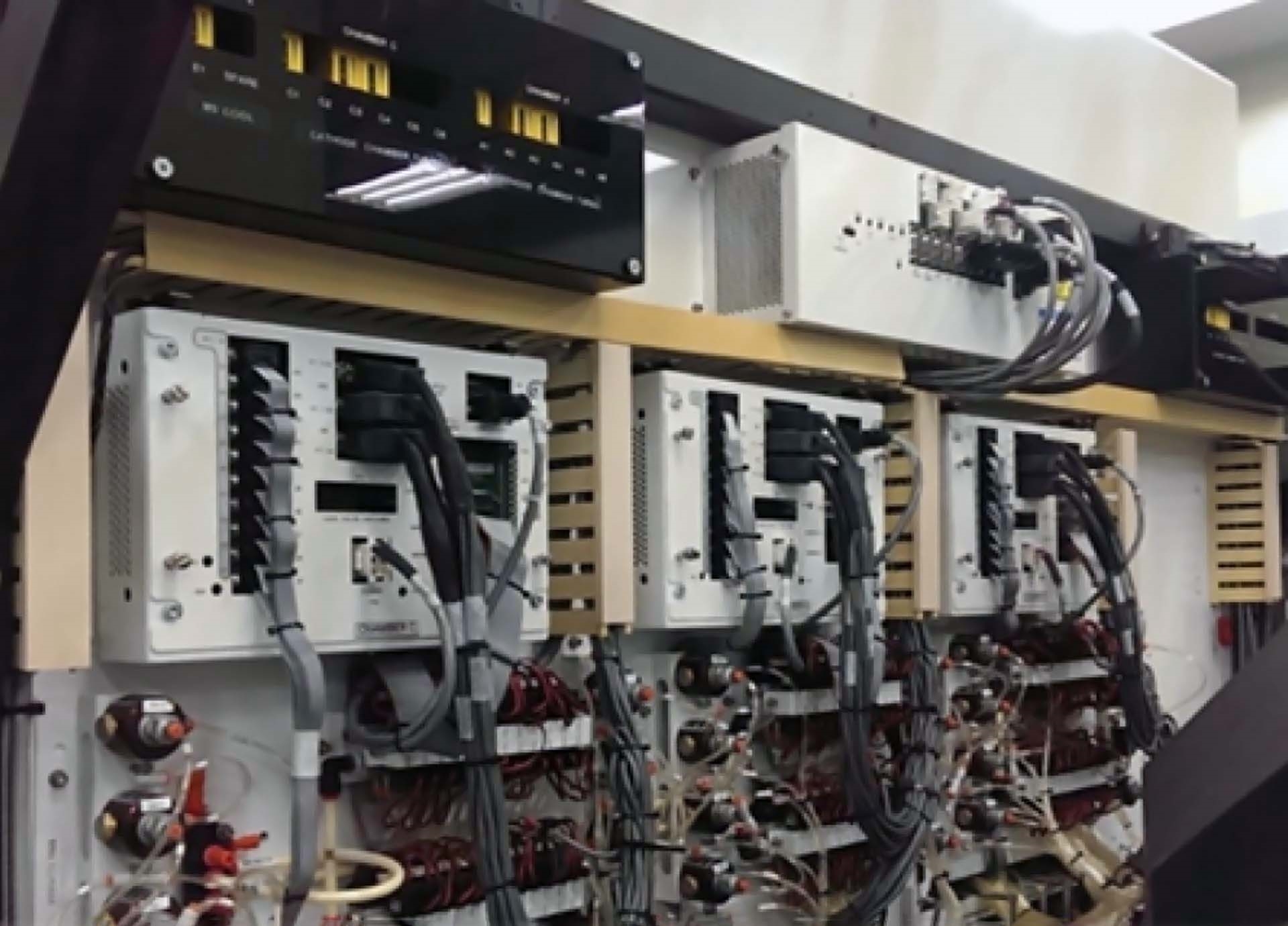

Chamber A: HDP Ultima plus process chamber

Chamber B: HDP Ultima plus process chamber

Chamber C: HDP Ultima plus process chamber

Chamber E: Multi cooldown chamber

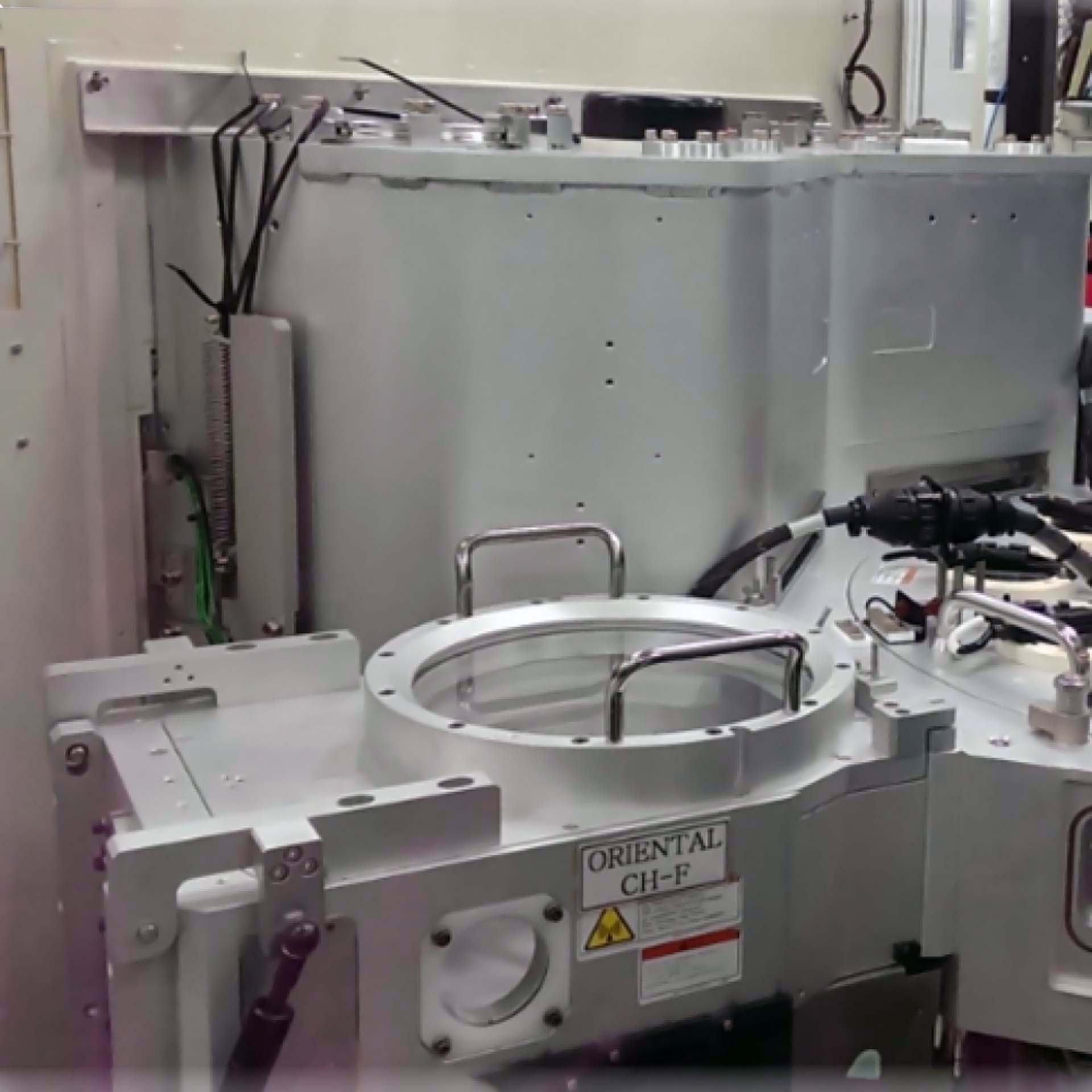

Chamber F: Orient chamber

EMO Type: Turn to release

CE Marked

2000 vintage.

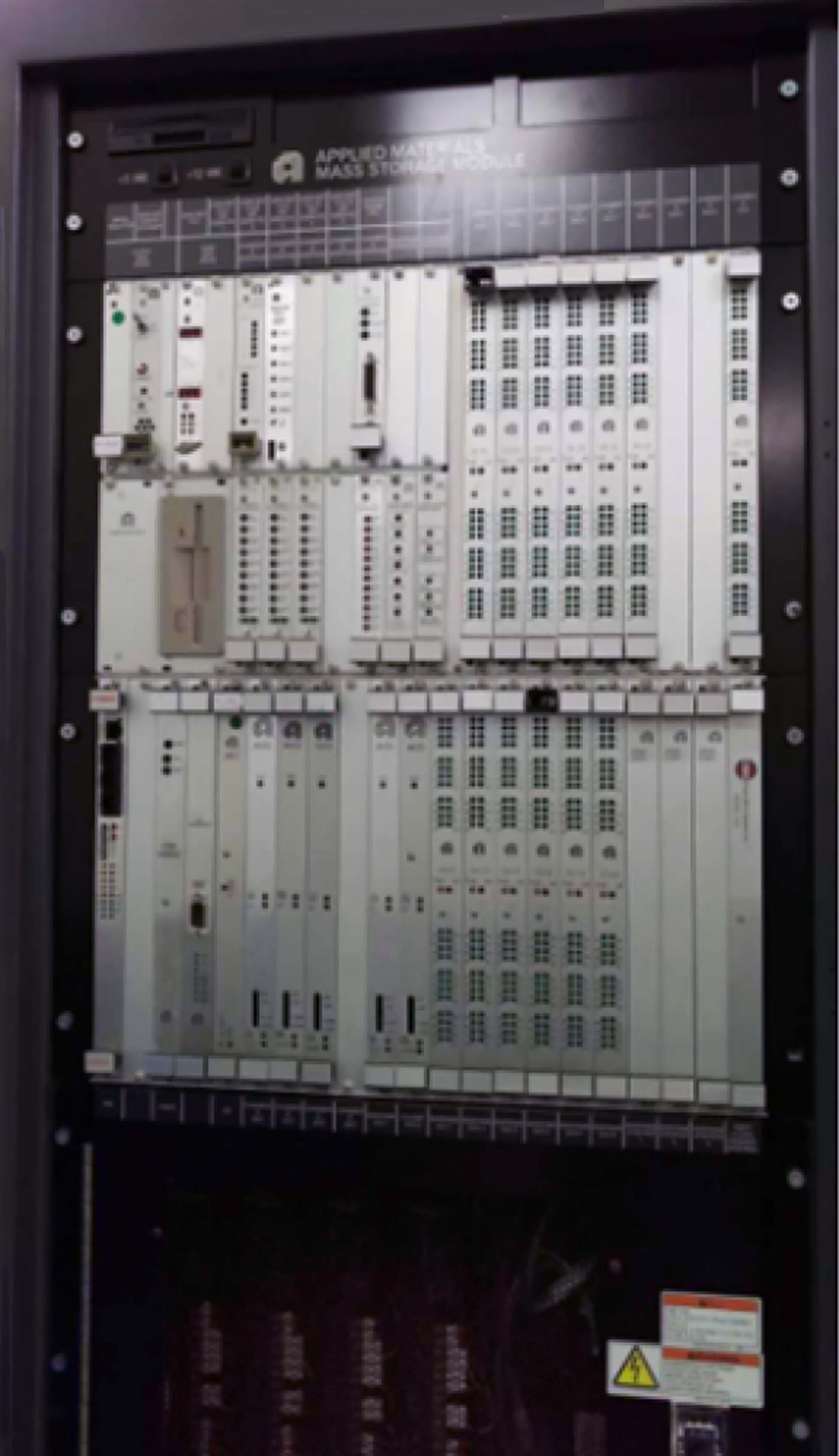

AMAT / APPLIED MATERIALS Centura 5200 atmospheric pressure CVD/PECVD reactor, is an advanced plasma assisted chemical vapor deposition equipment for depositing thin-films for MEMS, high-K, barrier, dielectric, anisotropic, and low-k applications. It has a highly versatile chamber design for meeting the demands of next generation technology nodes, by providing uniformity and selectivity for high-aspect-ratio with low-temperature processing. AMAT Centura 5200 reactor system includes a 4-inch quartz chamber, process pressure control, multi-gas injection, full function chamber heating and temperature control, up to 254 MHz RF plasma sources, and a turbulent-flow pumping unit. The chamber is designed to operate in a range of atmosphere and temperature, providing a wide processing range of 300 mTorr to 760 Torr. It is equipped with two 254 MHz 13.56Mhz RF bias source offering a total of up to 500 watts of power. The various process configurations allows for the simultaneous operation of multiple deposition recipes. APPLIED MATERIALS Centura 5200 reactor machine also features detailed process control capabilities, allowing you to adjust, monitor, and optimize reactive gas flow, process pressure, chamber temperature and surface temperature unique to each process recipe. It also includes a process monitoring user interface, which allows for easy tool set-up and recipe testing. Advanced data logging capabilities enable continuous monitoring of the deposition process. Centura 5200 reactor also supports advanced deposition control capabilities such as real-time process monitoring and live profile measurements for speed and layer uniformity optimization. The reactor's advanced plasma assisted deposition technology enables low-temperature deposition of high-temperature process steps, minimizing the risk of substrate damage and contamination. It is also equipped with high-temperature etching capabilities for more flexible process recipes. This advanced reactor asset allows you to achieve a wide range of process goals while maintaining an optimum process quality. It is well suited for prototype and small sensor production, research and development, and new technology development laboratories.

There are no reviews yet