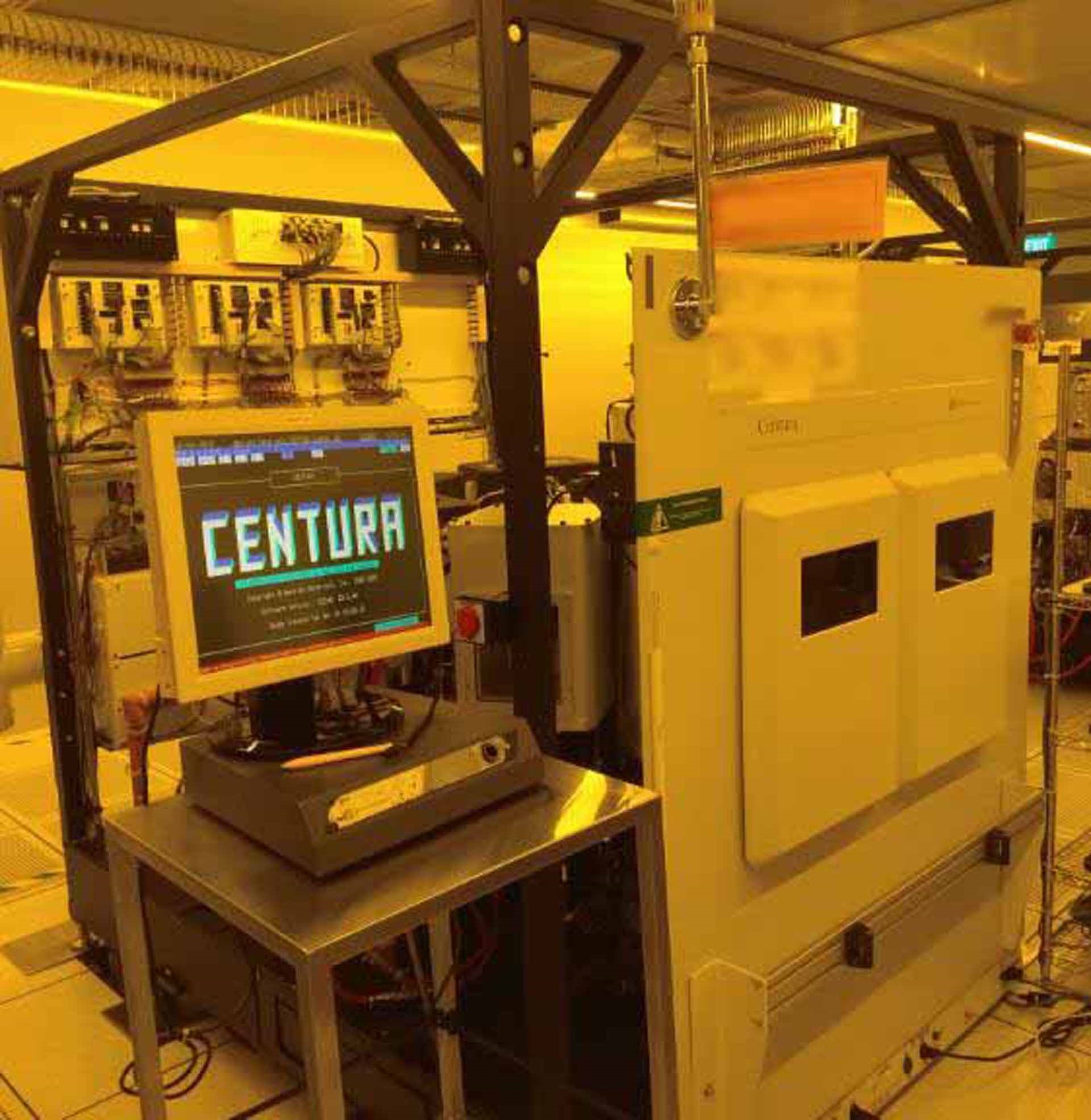

Used AMAT / APPLIED MATERIALS Centura 5200 #9261088 for sale

URL successfully copied!

Tap to zoom

ID: 9261088

Wafer Size: 8"

Vintage: 1998

CVD System, 8"

Process: HPTEOS

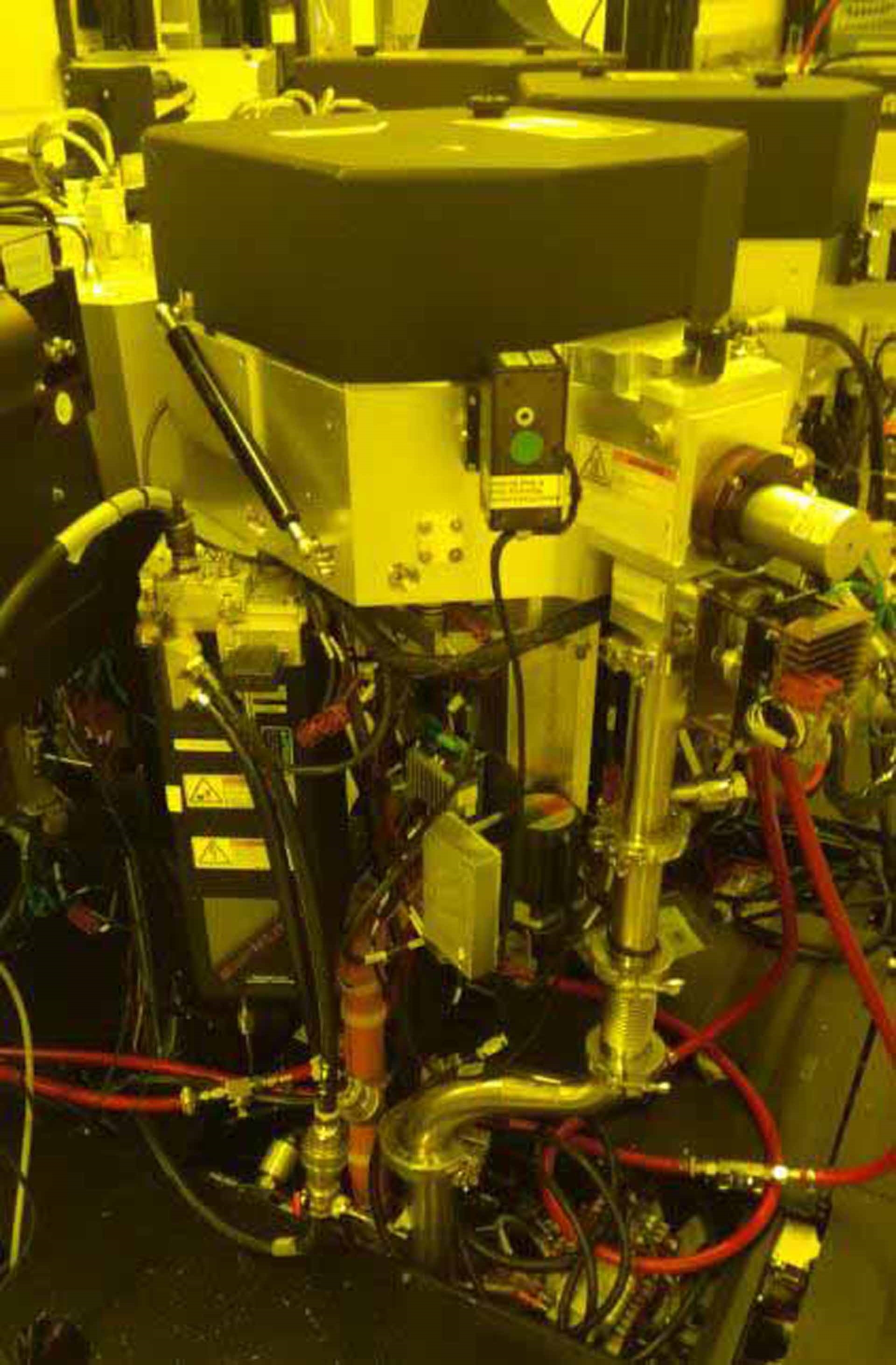

(2) Loadlocks

Robot assembly

(3) CVD Deposition chambers

Chamber type: DxZ

Includes:

(5) EBARA Pumps

System controller

AA20 Loadlock pump

AA40W Pump

AA70W Pump

AA20 Buffer pump

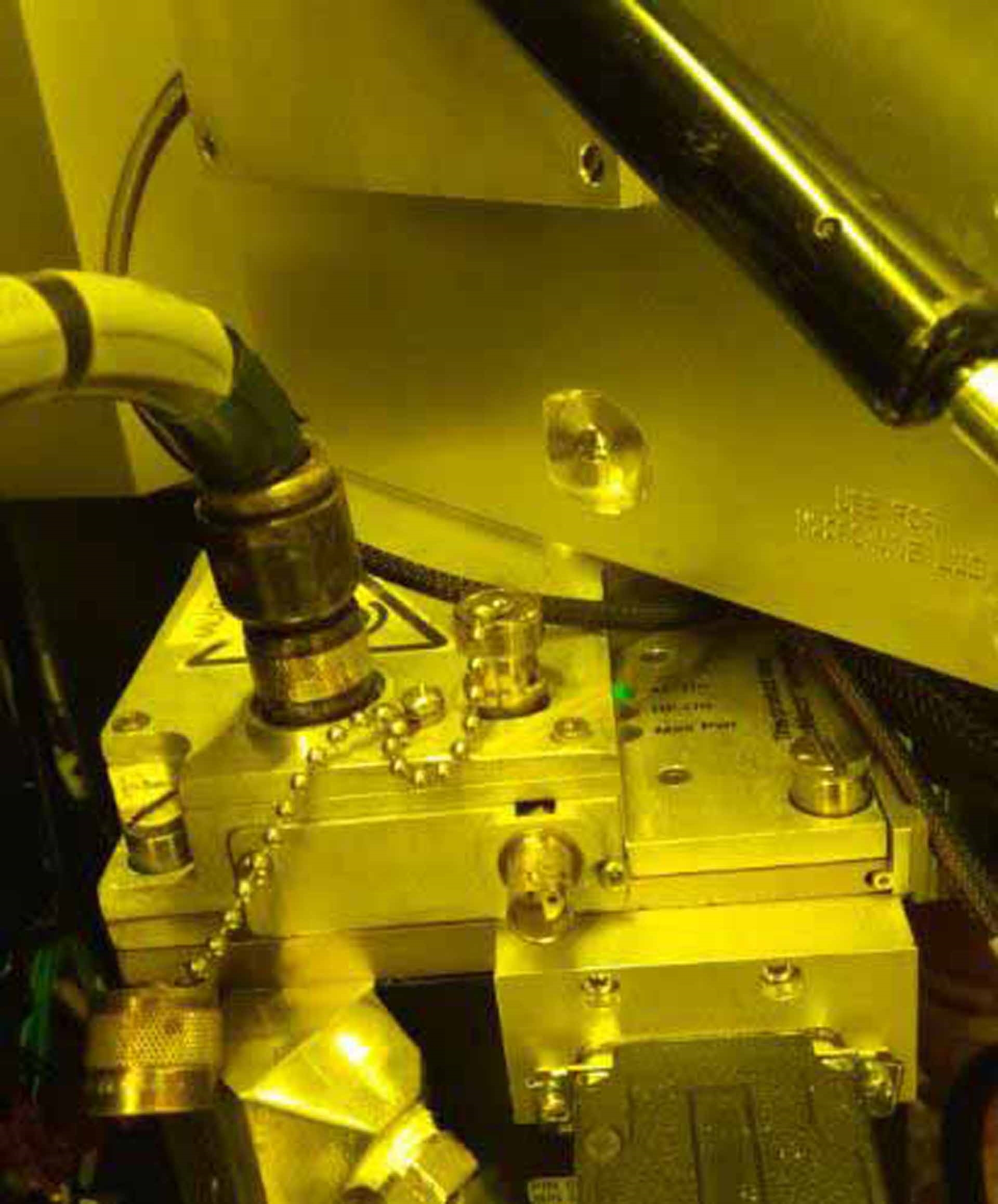

ADCS TEOS Cabinet

TEOS Canister size: (5) Gallons

Process tank pressure (Liquid Cabinet), TEOS: 35

AMAT 1 Heat exchanger

Heat exchanger temperature: 65°C

Mainframe:

OTF

HP End Enduro Robot

VEXTA Stepper motor, 5-Phase

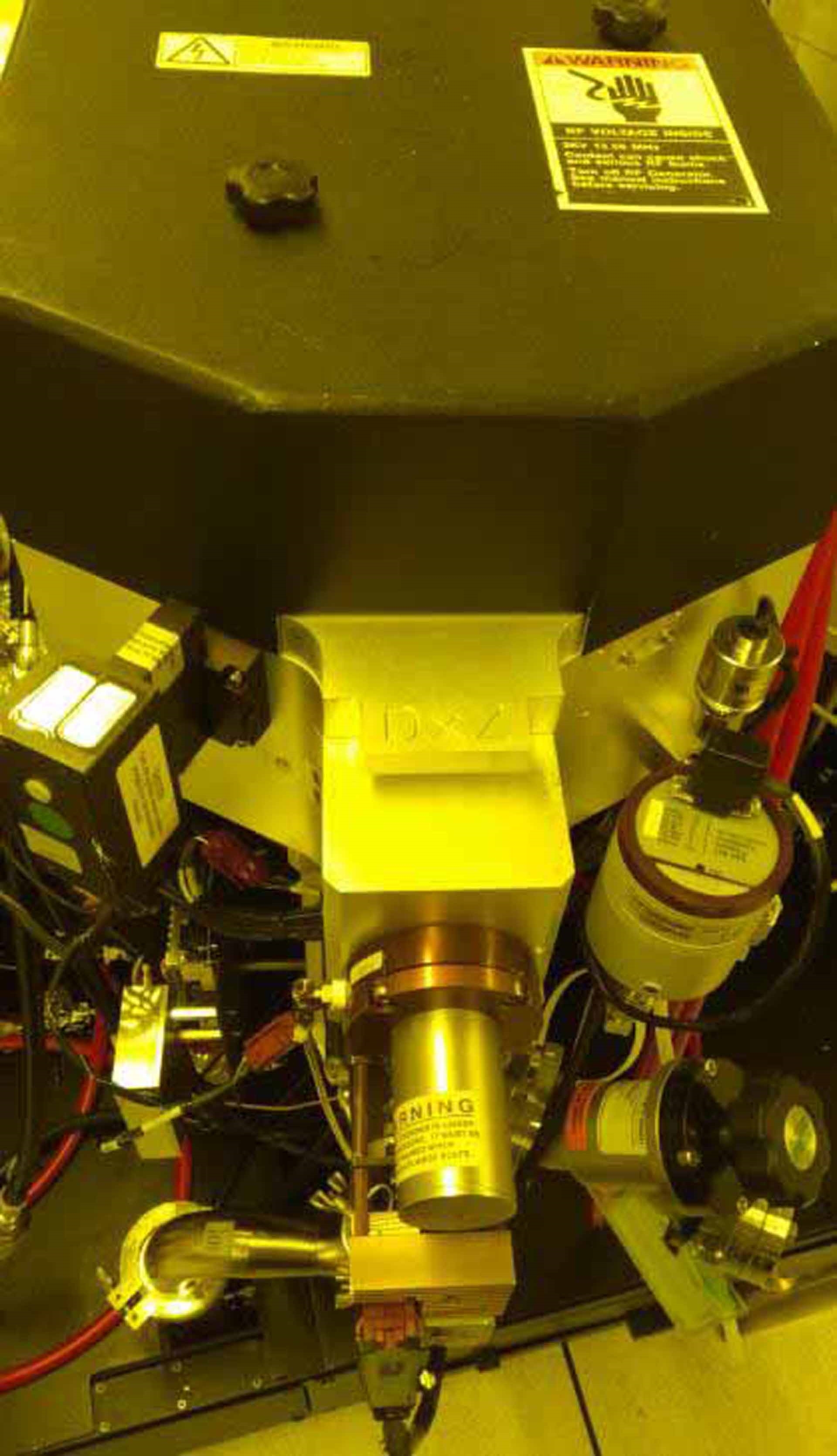

Process chamber:

(3) ADVANCED ENERGY RFG 2000-2V RF 1 Generators

(3) ADVANCED ENERGY PDX 900-2V RF 2 Generators

(5) ADVANCED ENERGY 3155094-003A RF Matches

MKS 122BA-0100EB-S Pressure manometer, 100 torr

Pressure control: Throttle valve

0040-32148 Heater

Process temperature: 400°C

MFC Gases:

N2: 3 slm

O2: 50 sccm

NF3: 500 sccm

C2F6: 500 and 1000 sccm

O2: 2 slm

He: 1 and 2 slm

LFM: STEC, TEOS 1.5 g/min

0500-01047 Endpoint

3870-04383 Injector valve

IV Line temperature, TEOS: 100

Gasline temperature: 100

1998 vintage.

AMAT / APPLIED MATERIALS Centura 5200 is a high-performance semiconductor wafer fabrication reactor designed for advanced-packaged device production. The reactor is built on APM's patented Plasma Enhanced Chemical Vapor Deposition (PECVD) technology. AMAT Centura 5200 is an advanced-packaged semiconductor wafer fabrication reactor that utilizes PECVD technology. The 5200 model provides an effective means of producing high-quality chips with minimal defects. The reactor is capable of metal and dielectric deposition, etch, and post-process treatments. The PECVD offers high-precision process repeatability, improved control of oxide stress and film thicknesses, as well as improved resistance to damage from static electricity. This allows chips manufactured with APPLIED MATERIALS Centura 5200 to feature high-yielding operations with exceptional reliability. Centura 5200 can process wafers ranging from 2 inches to 12 inches in diameter. The reactor is outfitted with advanced motion-control systems, as well as advanced thermal control and material-handling systems for maximum production accuracy and repeatability. The reactor features two reactant gas mixers and automated gas-flow control in order to ensure the highest levels of accuracy in production. These features allow for specialty processes that can improve the quality of chips produced on AMAT / APPLIED MATERIALS Centura 5200. AMAT Centura 5200 offers a wide range of capabilities, including precision process control, rapid curing, superior adhesion, improved yields, and decreased particle generation. This allows the production of better quality chips at a lower cost. The reactor's advanced technology also enables manufacturers to explore new and more cost-effective processes. To ensure optimal performance, APPLIED MATERIALS Centura 5200 is equipped with diagnostic systems that detect system problems and allow troubleshooting. The factory support team is available to provide assistance to customers who require assistance with their systems. Centura 5200 reactor provides a powerful and efficient solution to any semiconductor production challenges. Built with advanced PECVD technology, the reactor provides high-performance and reliable chip production. This allows for improved yields, superior chip quality, and decreased production costs. The reactor also features a wide range of features, including advanced motion-control, thermal-control, material-handling systems, and automated gas-flow control. Its flexible design makes AMAT / APPLIED MATERIALS Centura 5200 an ideal companion for any semiconductor fabrication line.

There are no reviews yet