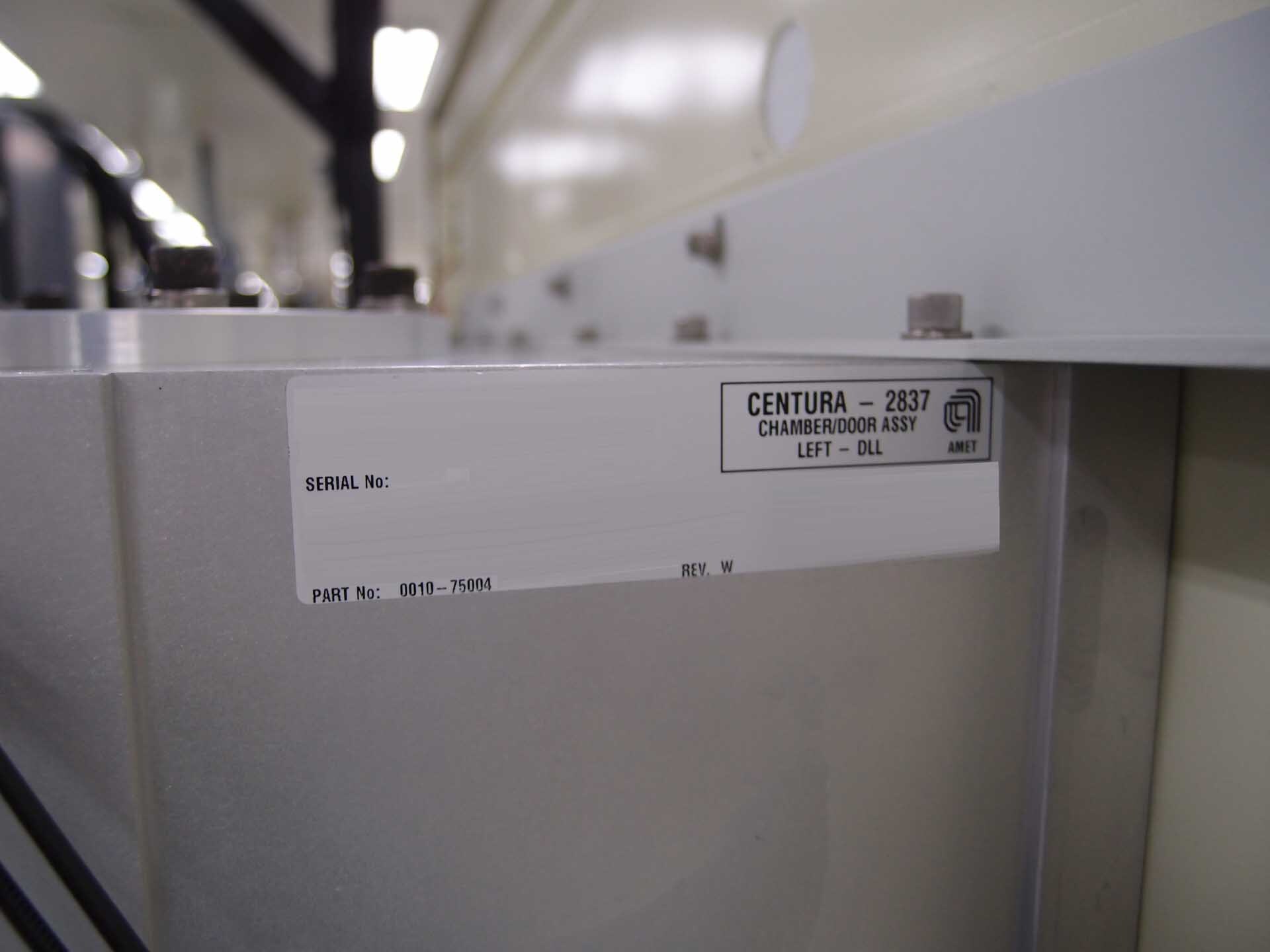

Used AMAT / APPLIED MATERIALS Centura 5200 #9364581 for sale

URL successfully copied!

Tap to zoom

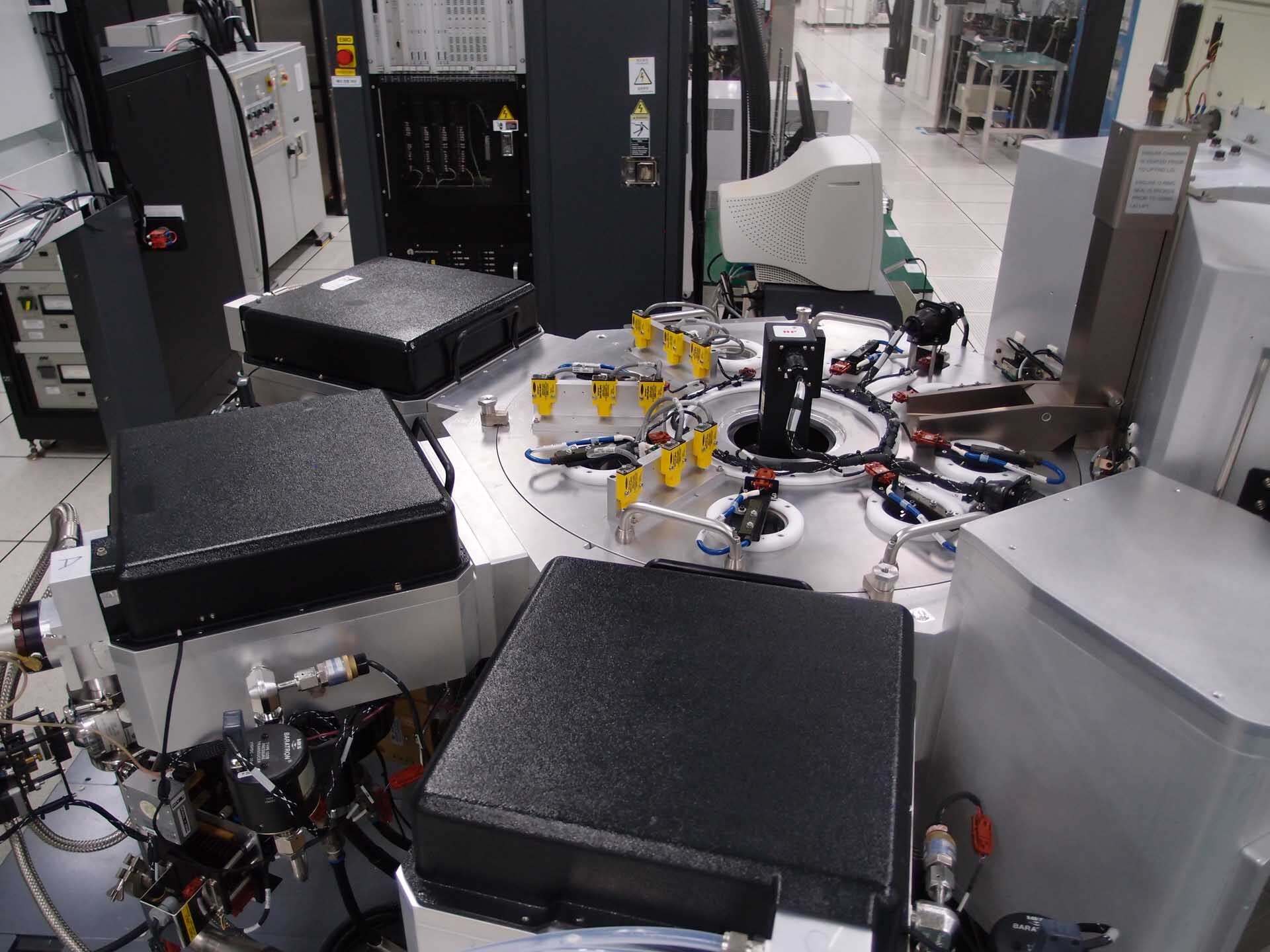

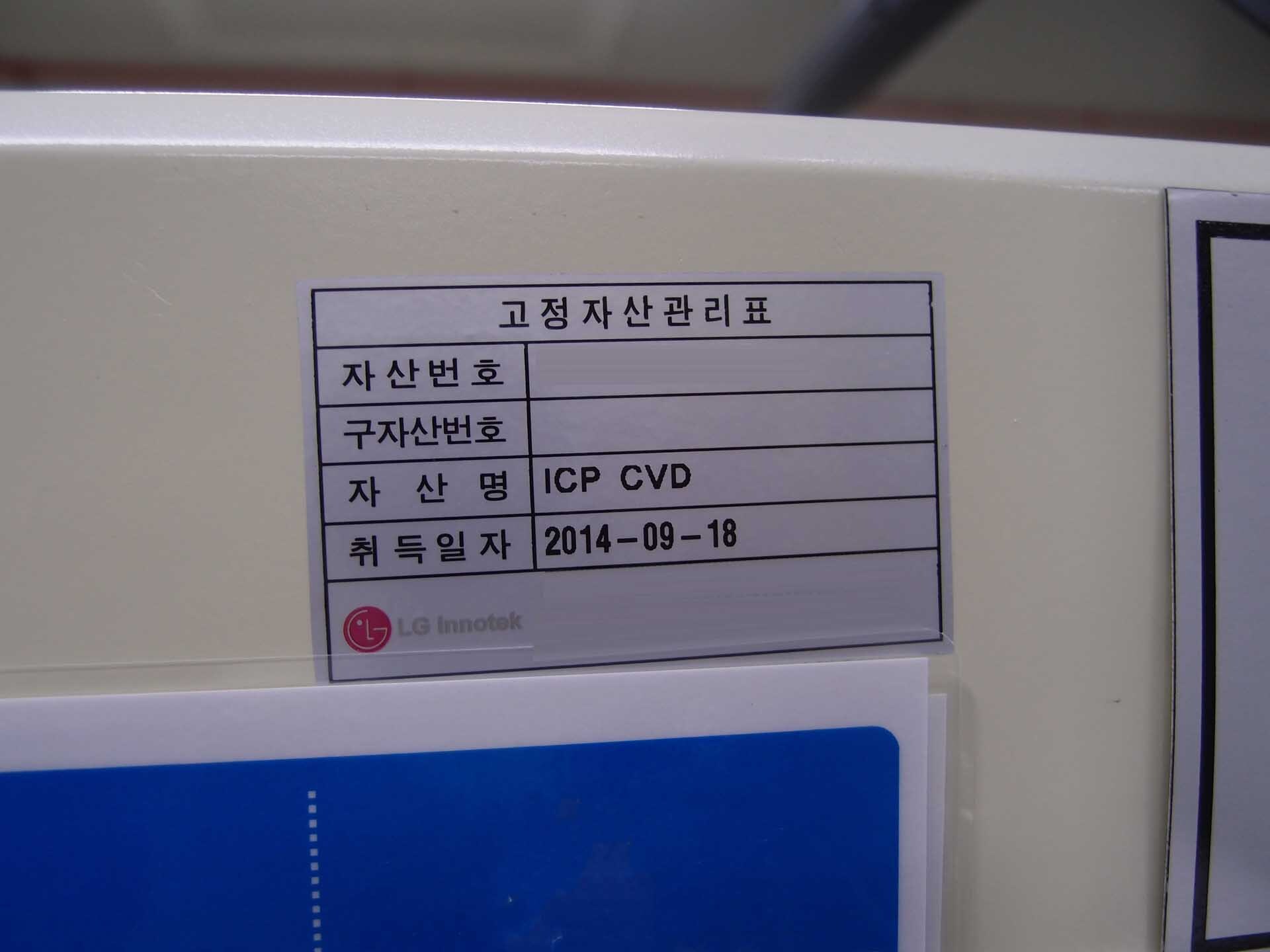

AMAT / APPLIED MATERIALS Centura 5200 is a highly advanced and versatile semiconductor processing reactor designed for post-gate insulation deposition, salicide and atomic layer deposition (ALD) applications. It is the industry-standard deposition equipment used in semiconductor fabrication. This reactor is mainly employed in the manufacture of thin-film transistors, semiconductors, light emitting diodes, sensors, and other semiconductor components. AMAT Centura 5200 has a modular design, reducing the requirement for complex single-wafer transfer arms and enabling operations to be carried out more efficiently. It also has several advanced features including a modular, auto-align source and target, capacitively coupled plasma (CCP) etch, remote plasma source (RPS) for ultra-low pressure deposition, and an integrated magnetic confinement plasma (ICP) system for high rates of etching. This makes it suitable for a variety of applications including conventional thermal oxidation, high rate sputter deposition, and high-temperature deposition of silicon nitride. With its low-temperature gas delivery unit, APPLIED MATERIALS Centura 5200 provides highly uniform, conformal thin-film deposition for high-end semiconductor device processing. It is capable of providing features as thin as 15 angstroms in diameter, making it ideal for gate insulation layers and contact layers. The vacuum environment of Centura 5200 also allows for highly precise and repeatable processing of dielectrics, metals, and other materials. The machine is also able to link directly to a number of etch sources, including plasma source ion implantation (PSII), plasma etch deep reactive ion etching (DRIE), and reactive ion beam etching (RIBE). AMAT / APPLIED MATERIALS Centura 5200 also offers a range of automated control systems, enabling operators to perform high-level miscellaneous recipes with minimal operator supervision. It has a full suite of visual inspections, machine-learning capabilities, multiple oven configuration, and a wide range of sample preparation algorithms. This ensures that the device results are consistent and reproducible. In summary, AMAT Centura 5200 is a highly advanced and versatile tool designed for semiconductor processing applications. It offers a wide range of features, including modular design, AVS and RPS for ultra-low pressure deposition, low-temperature gas delivery asset, multiple oven configurations, and automated control systems. This makes it highly suitable for the production of advanced semiconductor components.

There are no reviews yet