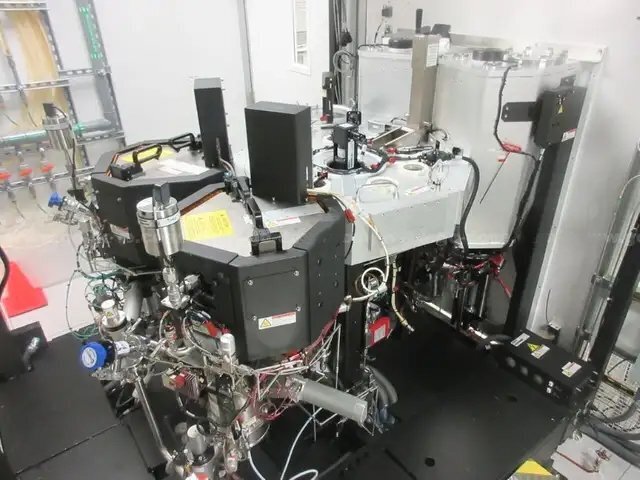

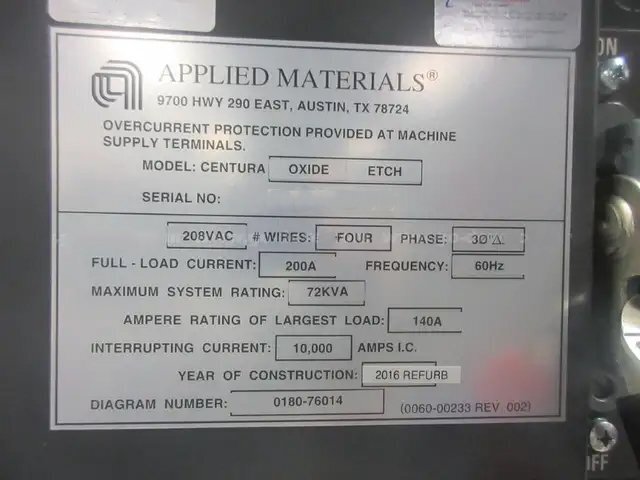

Used AMAT / APPLIED MATERIALS Centura 5200 #9401874 for sale

URL successfully copied!

Tap to zoom

ID: 9401874

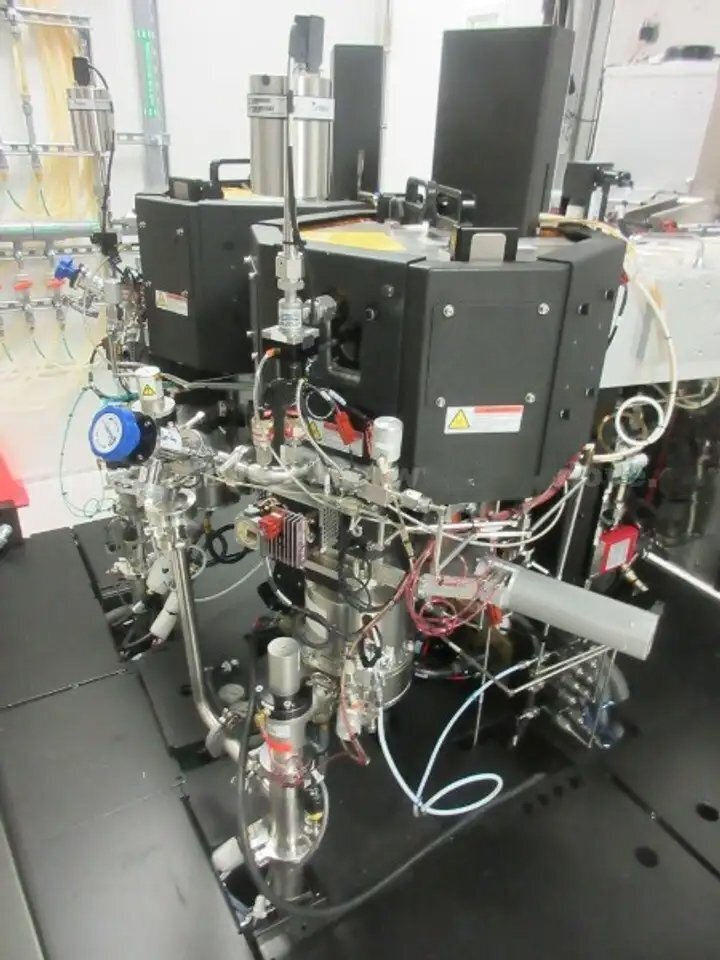

Dry oxide etcher

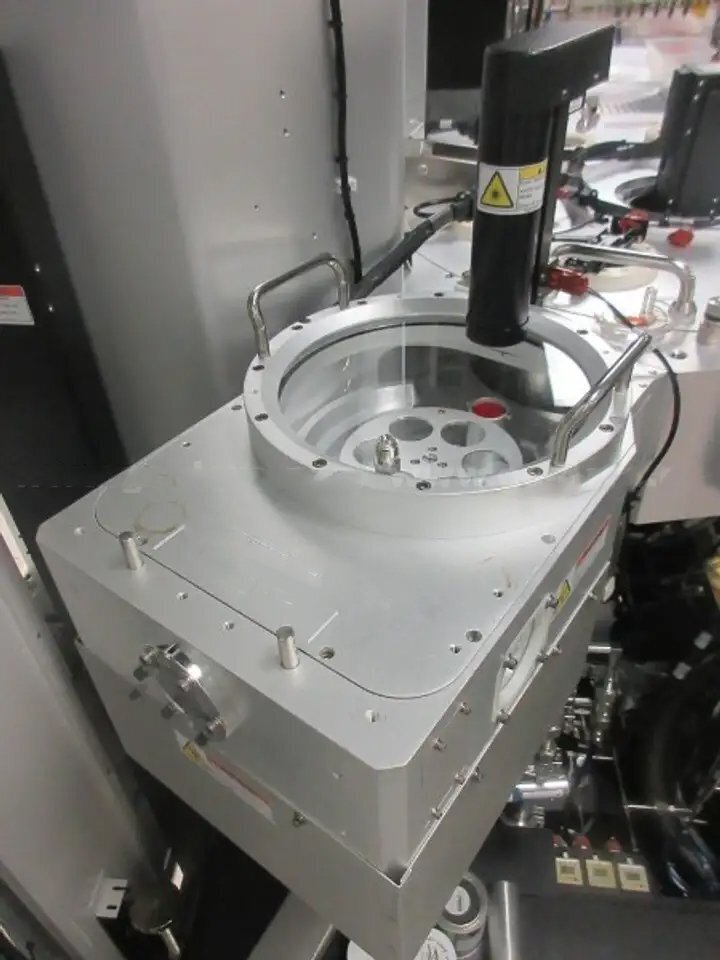

Dual process chambers

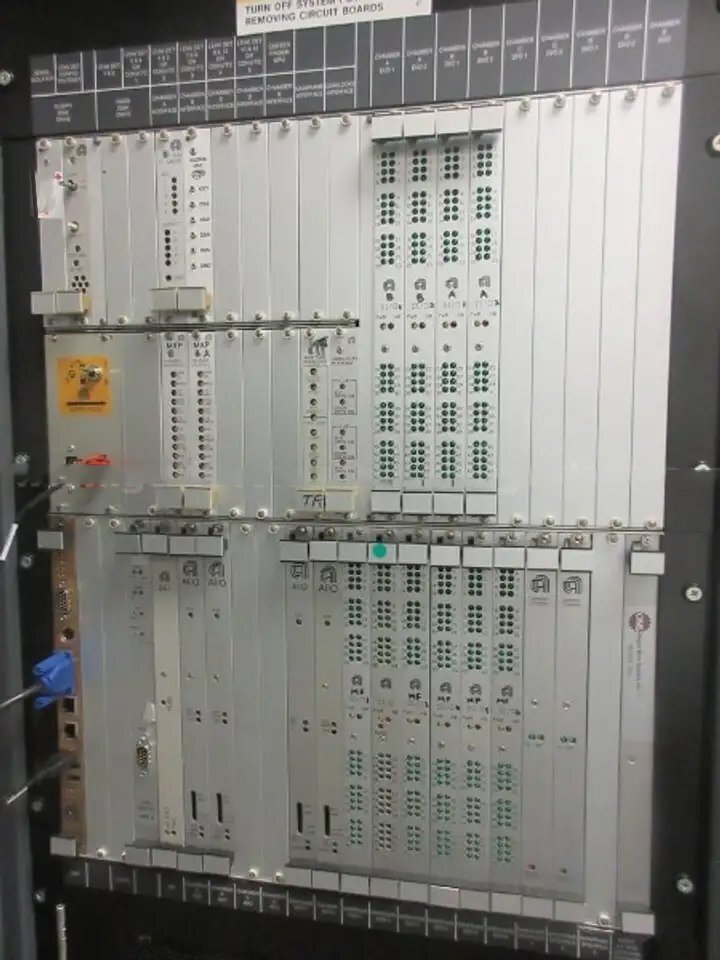

Control

Power cabinet

Transformer module

SEIKO Turbo pump controllers

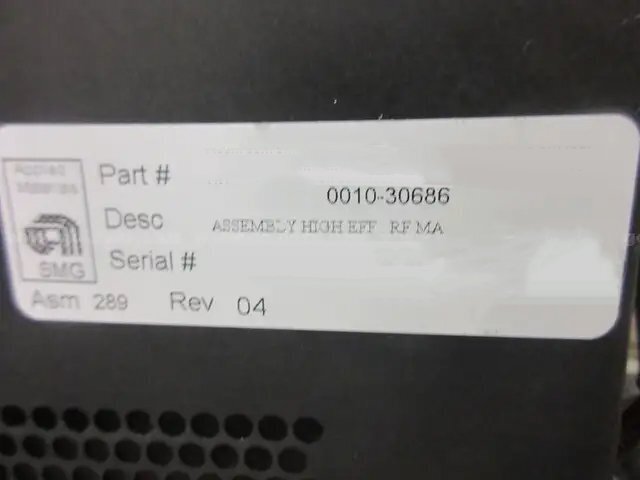

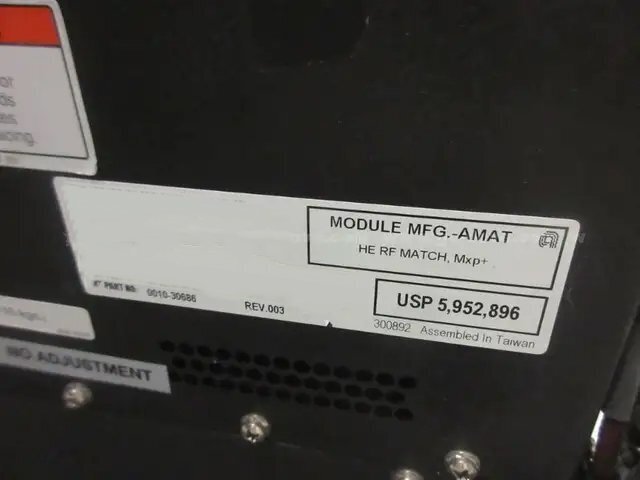

RF Cabinet

(2) ENI OEM-12B3 RF Generators

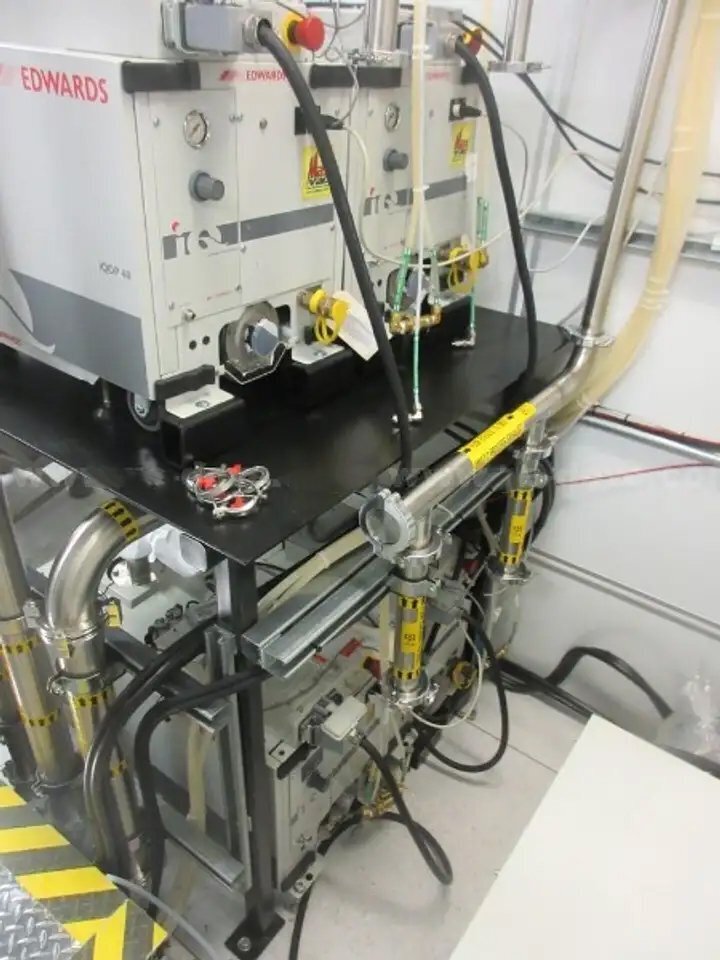

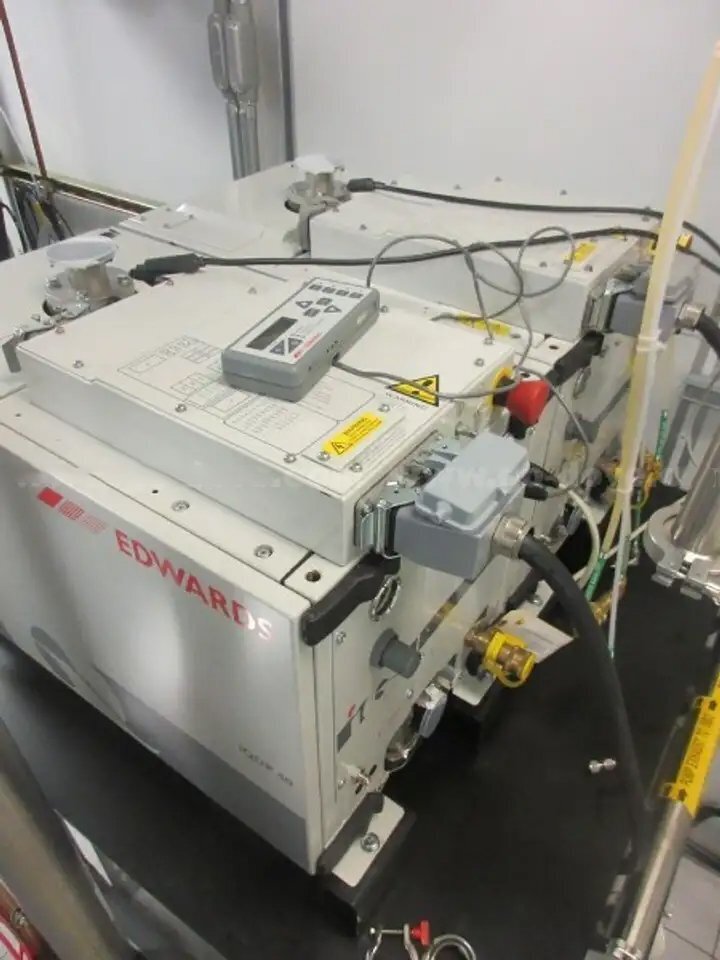

(2) BOC EDWARDS iQDP80 Vacuum pumps

(2) iQDP40 Vacuum pumps

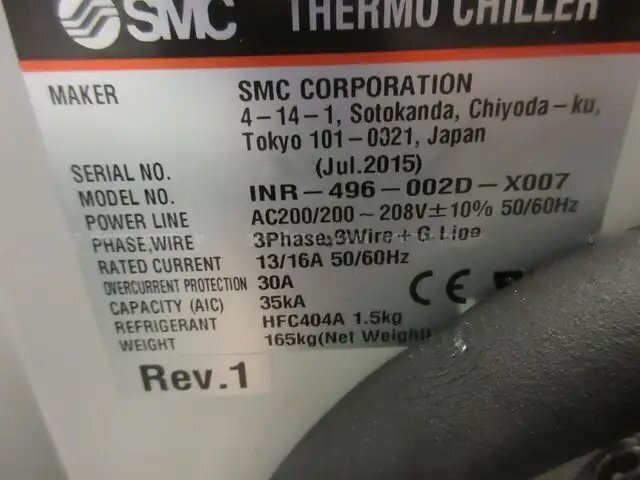

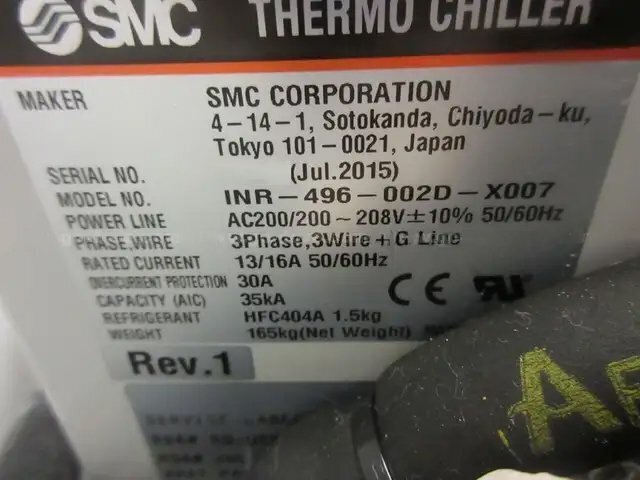

(2) SMC INR-496-002D-X007 Recirculating chillers

Power supply: 208 V, 3 Phase, 60 Hz, 72 kVA.

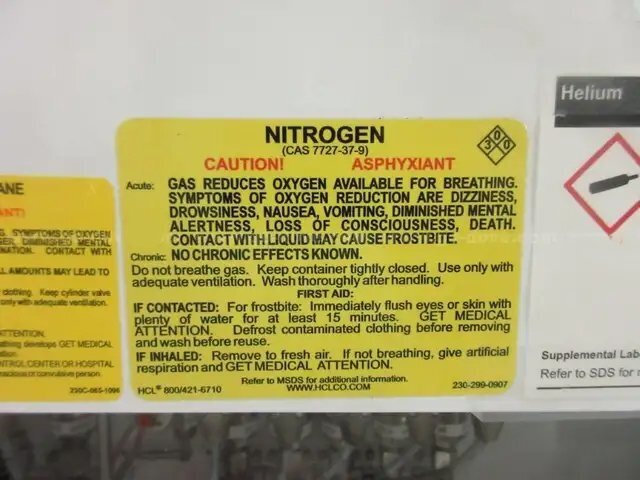

AMAT / APPLIED MATERIALS Centura 5200 is a high-performance, multi-purpose reactor designed for the high-volume production of semiconductor devices. With a maximum process temperature of 650 degrees Celsius and an ultra-high purity nitrogen and hydrogen atmosphere, this chamber offers the highest degree of thermal stability and cleanliness for the most demanding etch, deposition and impurity removal applications. AMAT Centura 5200 is equipped with several advanced technologies, including multi-mode plasma source and extreme high temperature capability, enabling users to carry out a variety of advanced processes at the same time for maximum productivity. The source is capable of producing a wide range of low-power plasma, ion bombardment and high power RF plasma for etching, stripping or implantation processes. At an impressive 30kg/cm² pressure, the all-ceramic crucible constructed, six elemental gas slit valves allow the process flow to be precisely controlled and regulated. The high-temperature oven delivers precisely maintained and regulated temperatures, while the mechanical inspection window consists of a viewport and radiation shield to further protect users from hazardous conditions. The temperature uniformity and temperature stability are maintained by an intuitive temperature control equipment composed of multiple internal and external sensors. An advanced and easily programmable digital monitor allows users to monitor a wide variety of parameters such as chamber gas composition, bowl pressure, gas flow, and substrate temperature. APPLIED MATERIALS Centura 5200's cooling system enables reliable and uniform cooling to various parts of the chamber, and its cooling cycle can be tailored to suit specific process requirements. Additionally, the chamber is equipped with multiple mounted components to facilitate easy and clean installation, maintenance, and relocation. Finally, an in-chamber isolation unit ensures that any process loss and contamination are minimized, and an integrated air-purification machine ensures a safe working environment. Thus, the Combined Centura 5200 offers an unbeatable price/quality ratio, enabling a wide variety of users to benefit from its advanced feature set.

There are no reviews yet