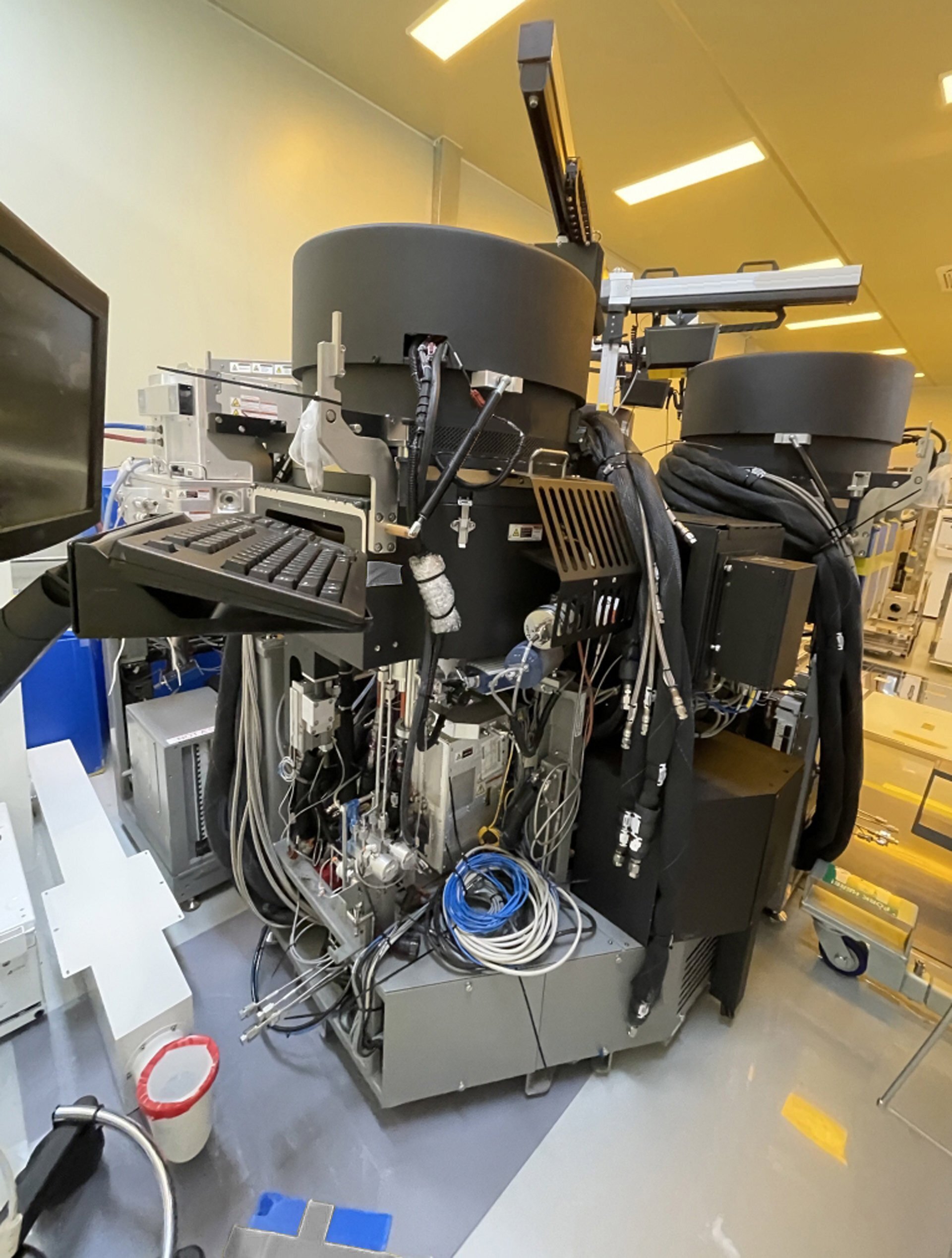

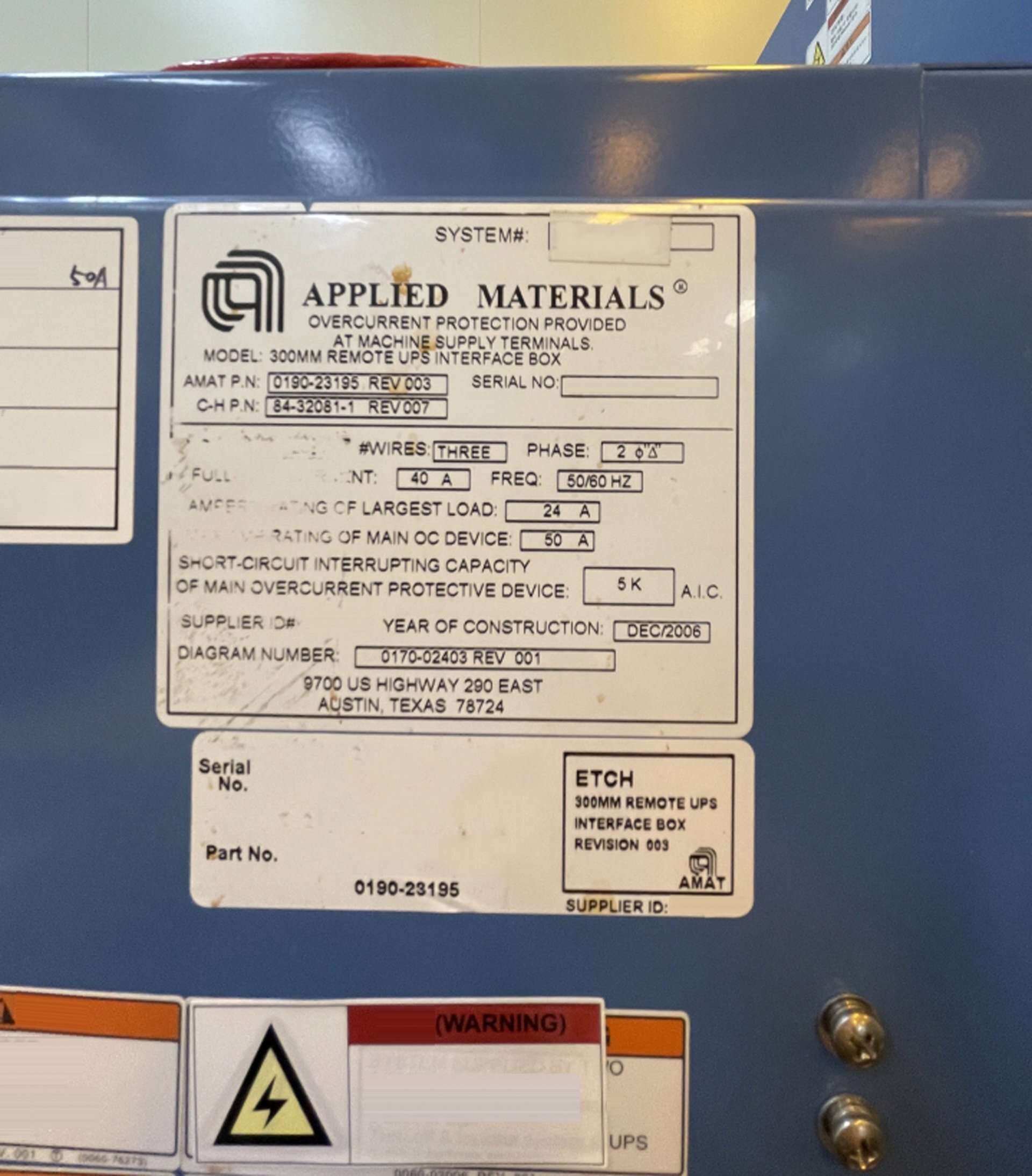

Used AMAT / APPLIED MATERIALS Centura AP #9364673 for sale

URL successfully copied!

Tap to zoom

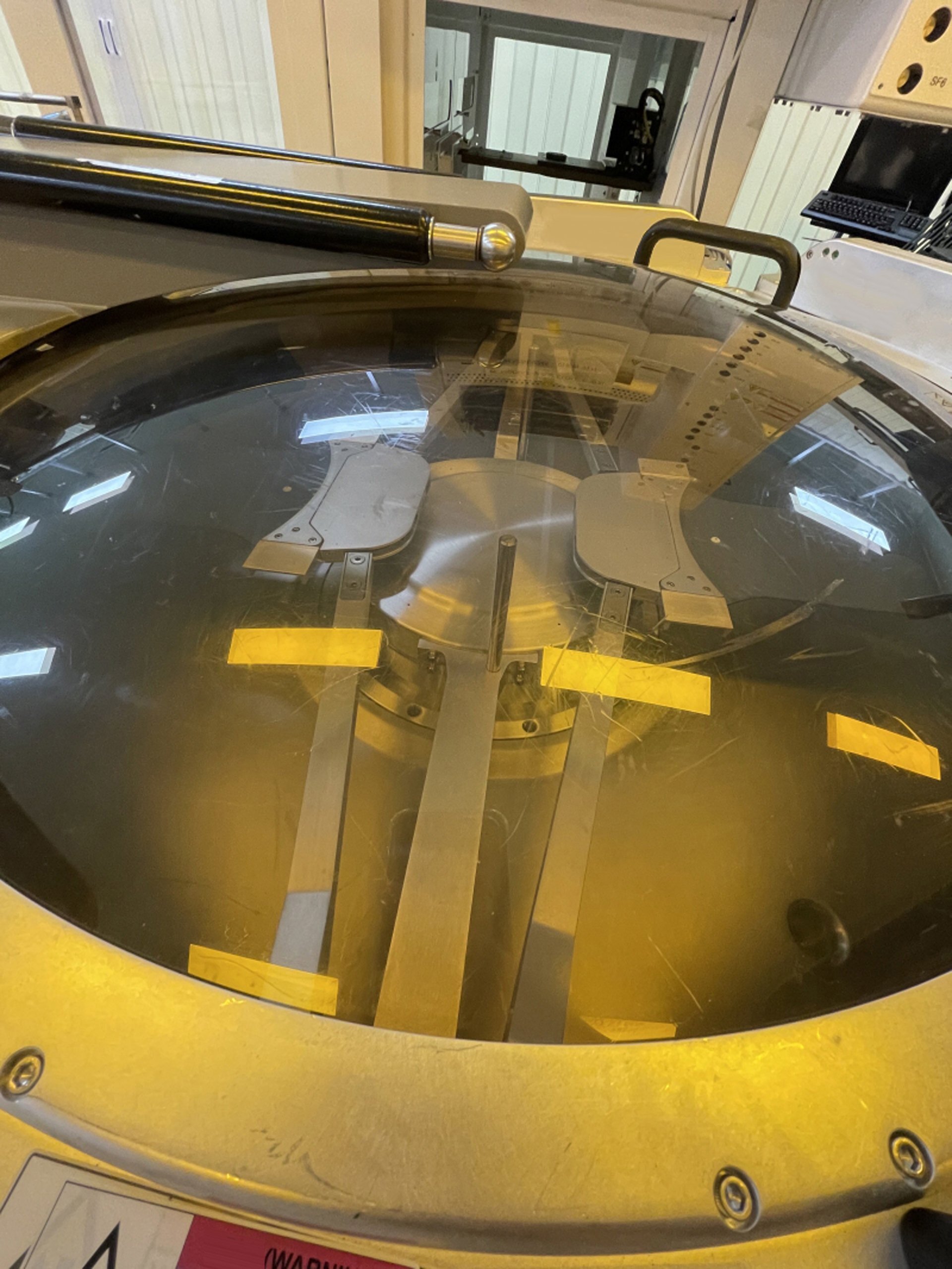

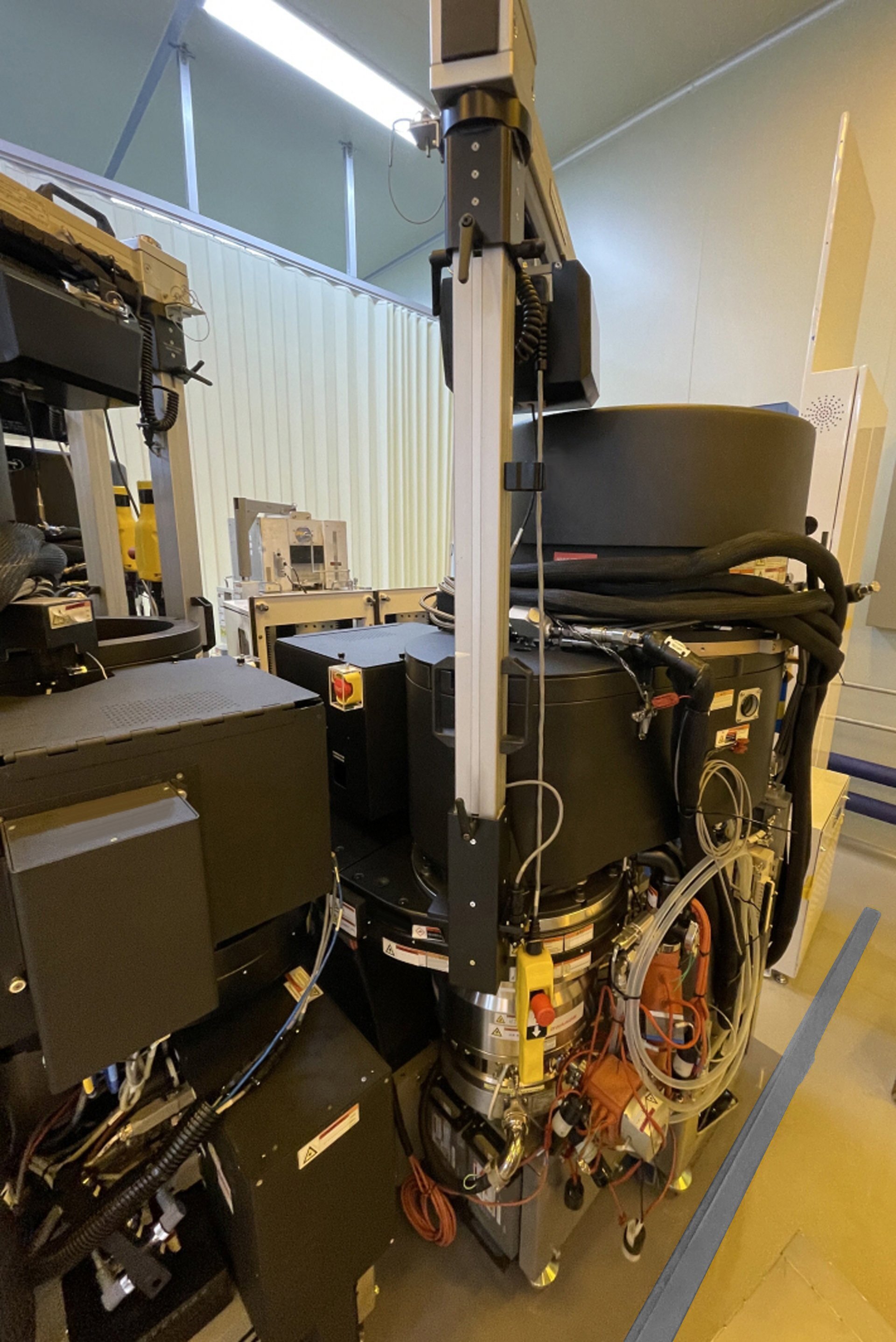

AMAT / APPLIED MATERIALS Centura AP is a chemical vapour deposition (CVD) reactor designed for a wide range of materials including semiconductors, conductors, dielectrics, III-V materials and Si/SiO2 films. The reactor offers excellent process control and repeatability at a cost-effective price. AMAT Centura AP reactor includes a dual chamber design and quartz tube in which a precursor material is heated to induce chemical reactions. The heated precursor material is then reacted with a reagent gas to produce a desired film on the substrate. The reactor has a heated gas line which allows the supply of regulated and safe precursor materials, a reagent gas supply line, and a vacuum pump with exhaust gas line. The reactor has a wide range of operating temperature ranges and pressure requirements, which makes it ideal for application in multiple crystal orientations, such as (100) and (111) faces ofSi substrates. The high throughput of APPLIED MATERIALS Centura AP makes it suitable for high-volume applications. The reactor is equipped with multi-level process control software that allows for the precise control of gas and temperature flows, along with the ability to maintain desired conditions throughout the process. The software interface provides ease of use, flexibility, and repeatability for executing experiments or production runs. Centura AP is modular in design and utilizes a load lock module that allows for quick and easy loading and transfer of substrates. It has a wide range of precursors which include elemental precursors (SiH4, PH3, B2H6) as well as organometallic precursors (propargyl, butyllithium, and trimethylgallium), but it has the capability to be used with other chemical precursors as well. The reactor is capable of growth rates ranging from tens of angstroms to microns per second by adjusting the automation and processes. AMAT / APPLIED MATERIALS Centura AP has a low level of maintenance and is a user-friendly design with a variety of safety features. The reactor is simple to operate and can be customized to meet specific requirements. The robustness of the reactor design makes it suitable for long-term, reliable operation in manufacturing environments.

There are no reviews yet