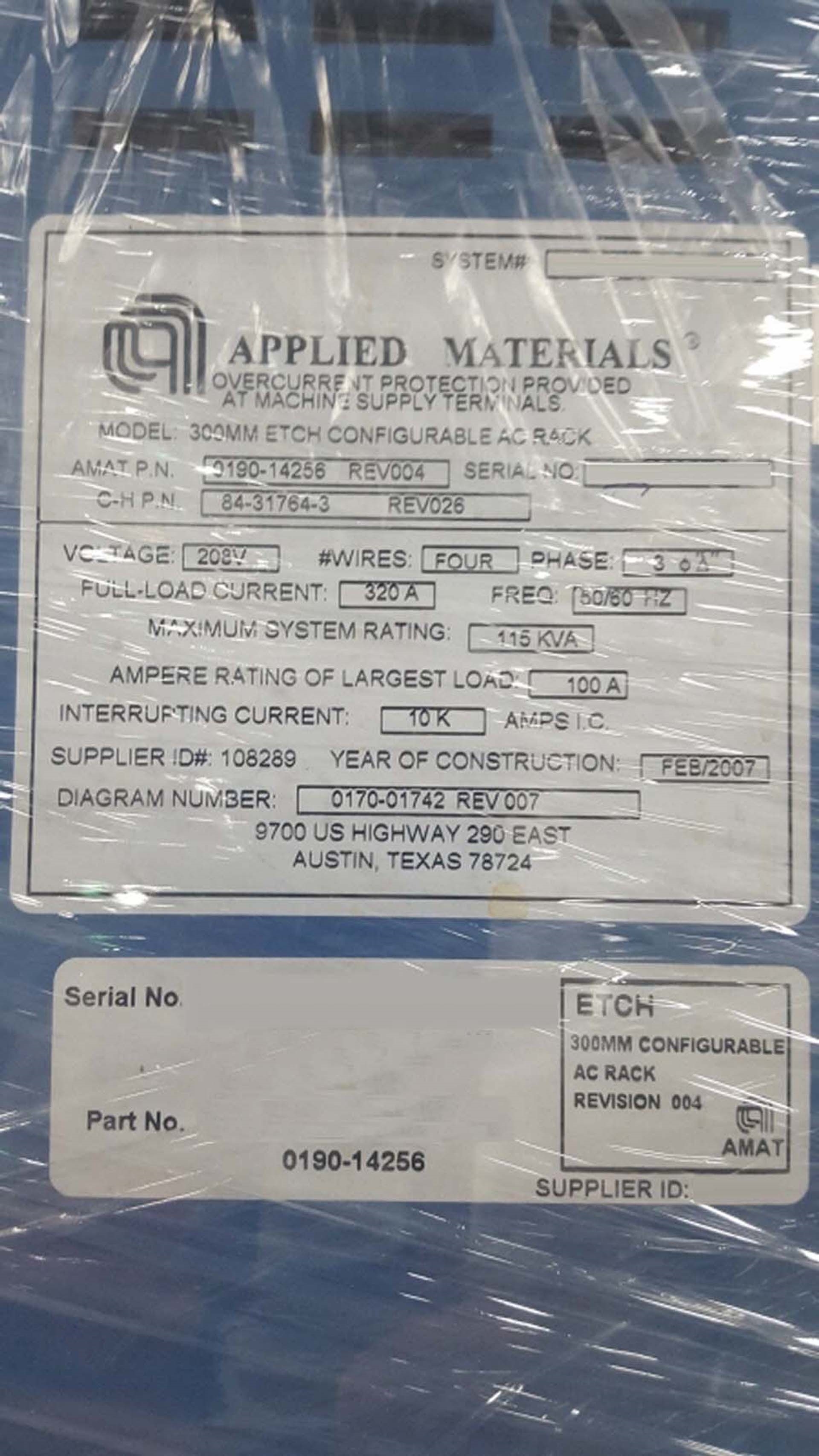

Used AMAT / APPLIED MATERIALS Centura DPS II AE Poly G3 #9195071 for sale

URL successfully copied!

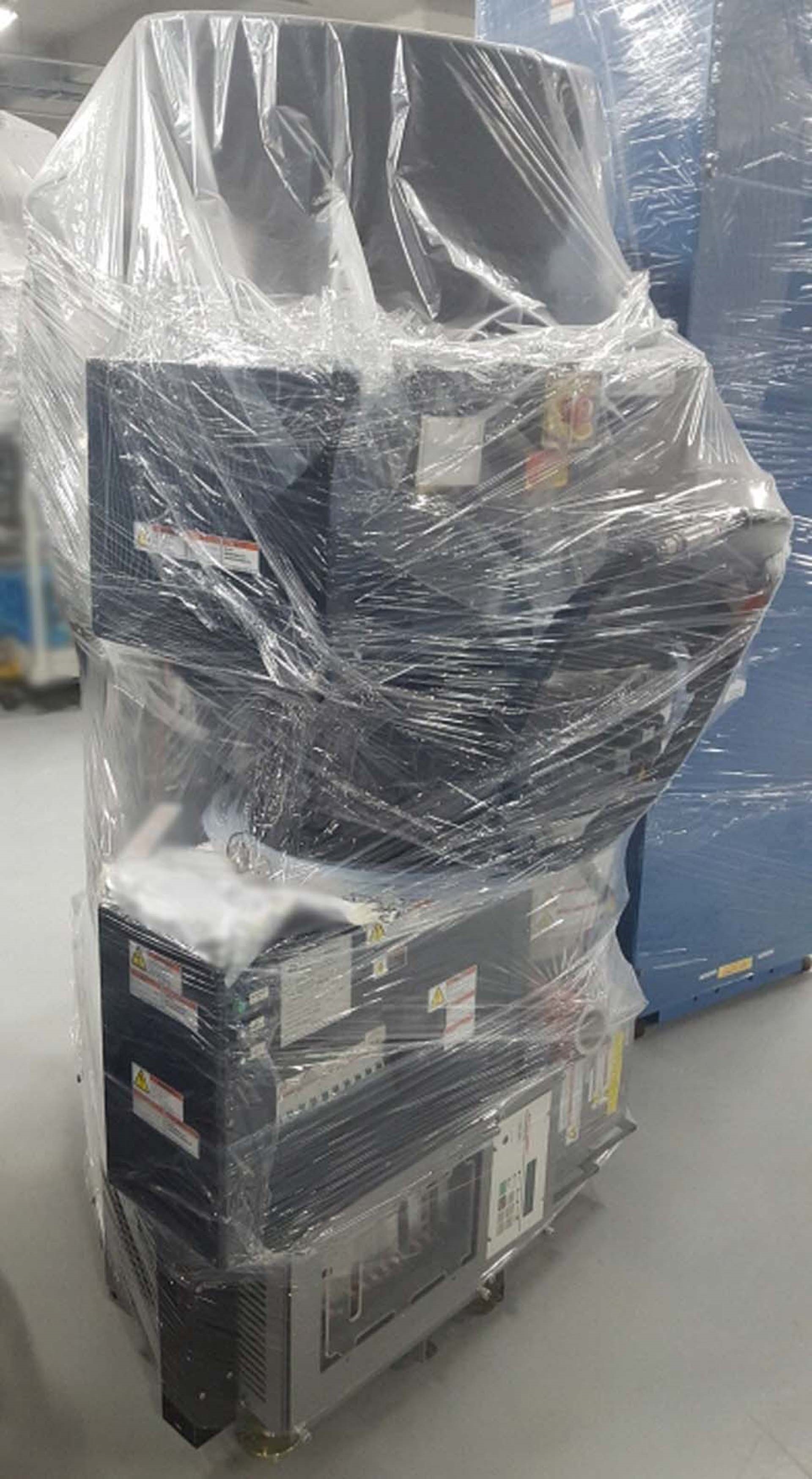

Tap to zoom

ID: 9195071

Wafer Size: 12"

Vintage: 2007

Poly etcher, 12"

(3) Process chambers

Factory interface configuration

Front end PC type: 4.0 FEPC

FIC PC Type: CPCI

(3) Load ports

A3 Type: Atmospheric robot KAWASAKI single fixed robot

Side storage: Right and left

Mainframe configuration

IPUP Type: ALCATEL A100L

Gas panel type: Standard

VHP Robot: Dual blade

MF PC Type: CL7

Chamber configuration:

Chamber A:

Chamber model: DPS II Poly

Bias gen: AE APEX 1513, 13.56 MHz

Bias match: AE 13.56 MHz, 3 kv navigation

Source gen: AE APEX 3013, 13.56 MHz

Source match: AE 13.56 MHz, 6 kv navigation

Turbo pump: STP-A2503PV

Throttle valve: VAT Pendulum valve DN-320

FRC: MKS FRCA-52163310

ESC: Dual zone ceramic ESC

End point type: EyeD IEP

Chamber B / C:

Chamber model: DPS II Poly

Bias gen: AE APEX 1513, 13.56 MHz

Bias match: AE 13.56 MHz, 3 kv navigation

Source gen: AE APEX 3013, 13.56 MHz

Source match: AE 13.56 MHz, 6 kv navigation

Turbo pump: STP-A3003CV

Throttle valve: VAT Pendulum valve DN-320

FRC: MKS FRCA-52163310

ESC: Dual zone ceramic ESC

End point type: EyeD IEP

Missing parts:

AXIOM Chamber

RF Source

VODM

Throttle valve

2007 vintage.

AMAT / APPLIED MATERIALS Centura DPS II AE Poly G3 is a highly advanced plasma etching reactor designed for use in the semiconductor industry. This reactor is particularly well-suited to processes involving sub-500nm high-aspect ratio features, making it ideal for the demands of the most modern chip designs. The reactor is part of the Centura DPS II series and features a modular design that enables it to meet a variety of applications as requirements evolve from process optimization. The reactor contains a WF-loadable vessel, meaning that various options such as non-standard wafer sizes or quartz orientations can be supported. The reactor is powered by an advanced AMAT Endura 5500 power delivery system delivering superior performance with precise control and high uniformity. This enables customers to achieve both high etch rates and excellent repeatability of results with each batch. The power delivery system also features multi-frequency flexibility that the user can adjust to their specific needs. The reactor has a silicon-based gate compatibility and is compliant with the 300mm standards, making it suitable for a wide variety of chip designs. It is also engineered with advanced features such as an integrated pump and gas analyzer system to maximize performance and operational efficiency, which ensures that process windows can be optimized to achieve the highest yield. The reactor is available with several options and features, such as a substrate chuck set, optional source lamps, and plasma monitoring systems. It also features built-in safety mechanisms to ensure that optimal safety and productivity is maintained at all times. AMAT Centura DPS II AE Poly G3 is a highly advanced and reliable reactor designed to meet the needs of the semiconductor industry. It offers superior performance and flexibility and features a modular design tailored to meet specific application requirements. It is suitable for designs ranging from sub-500nm features to 300mm chips. This makes it a great choice for all types of semiconductor applications.

There are no reviews yet