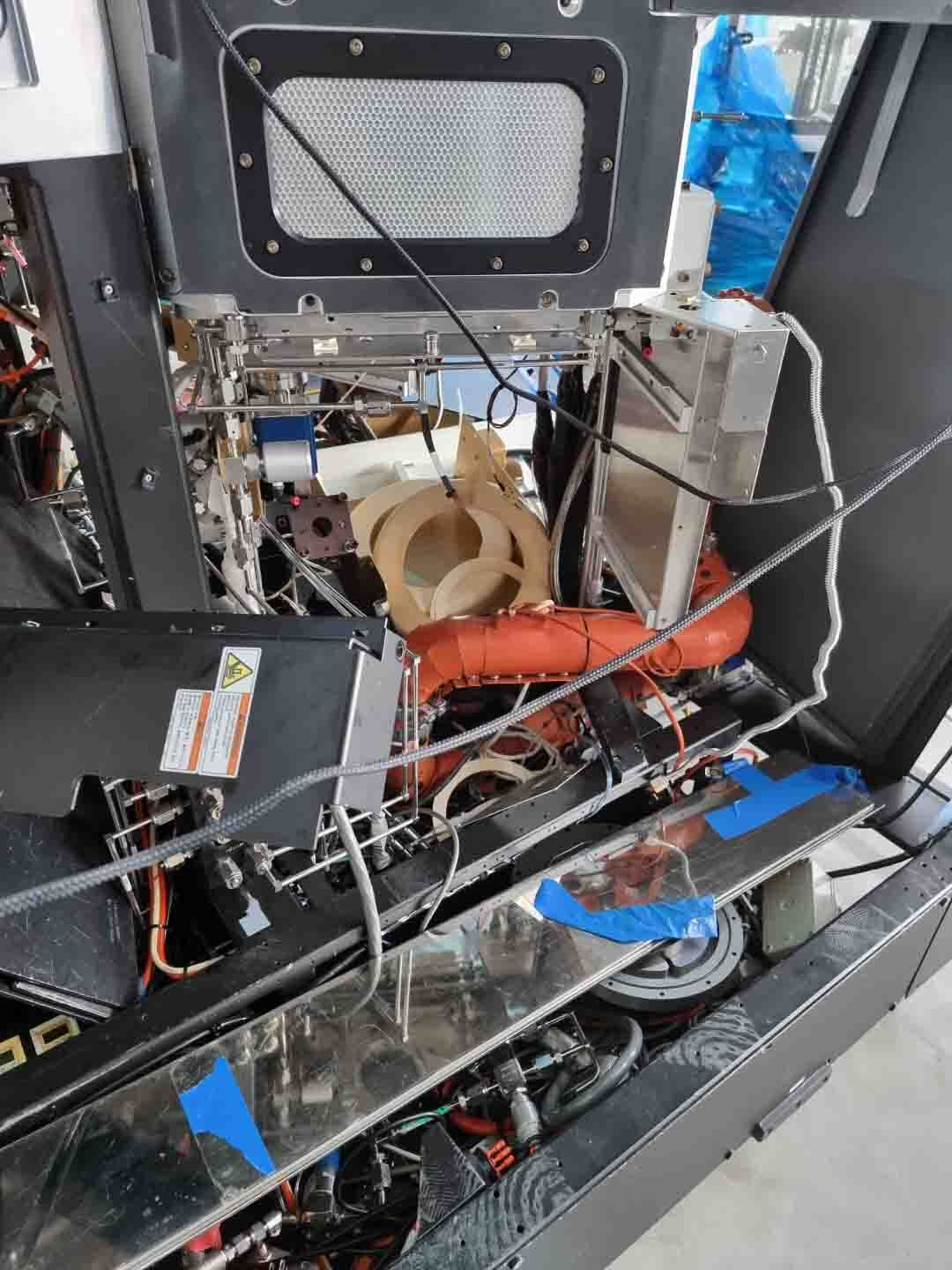

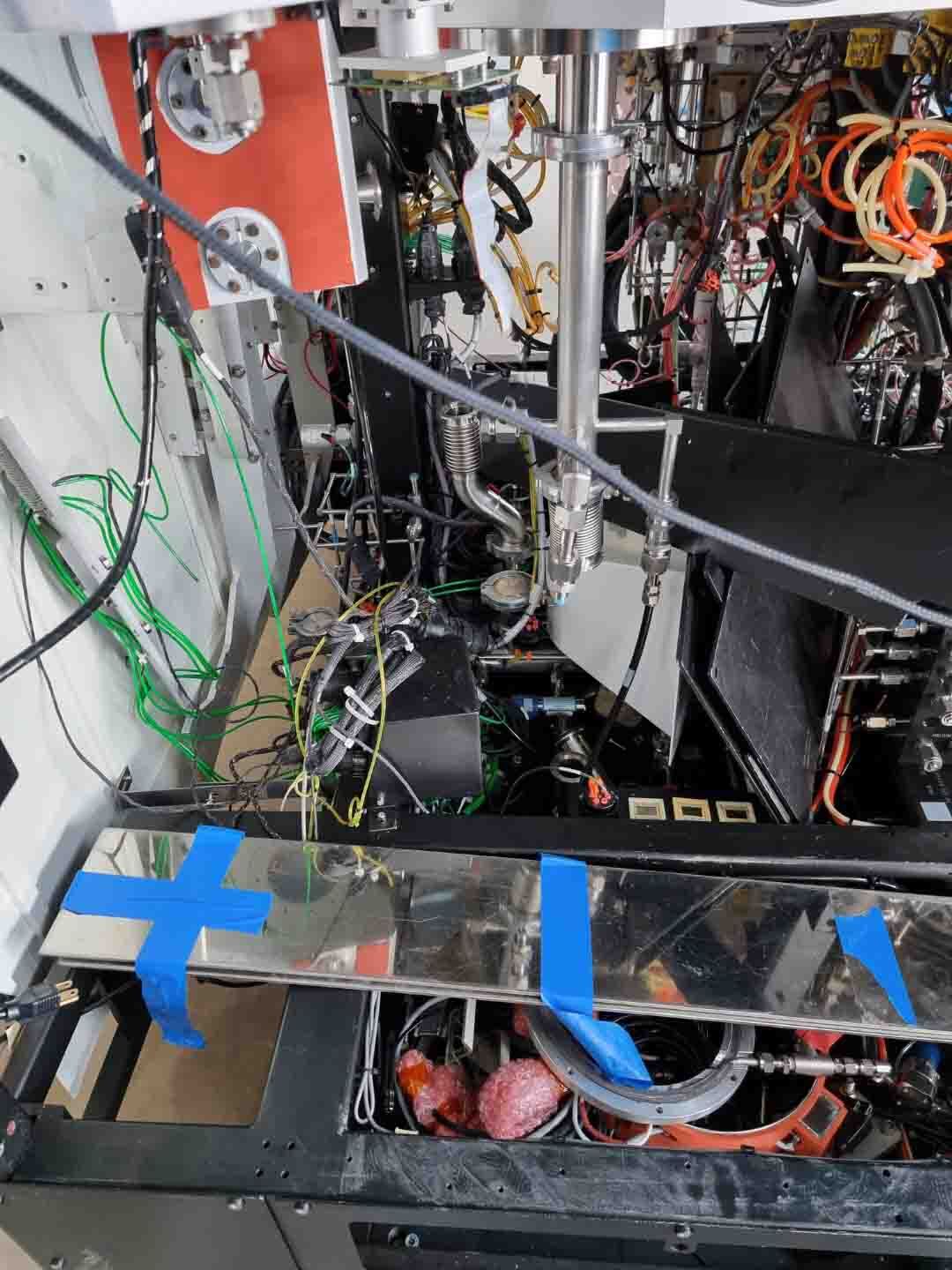

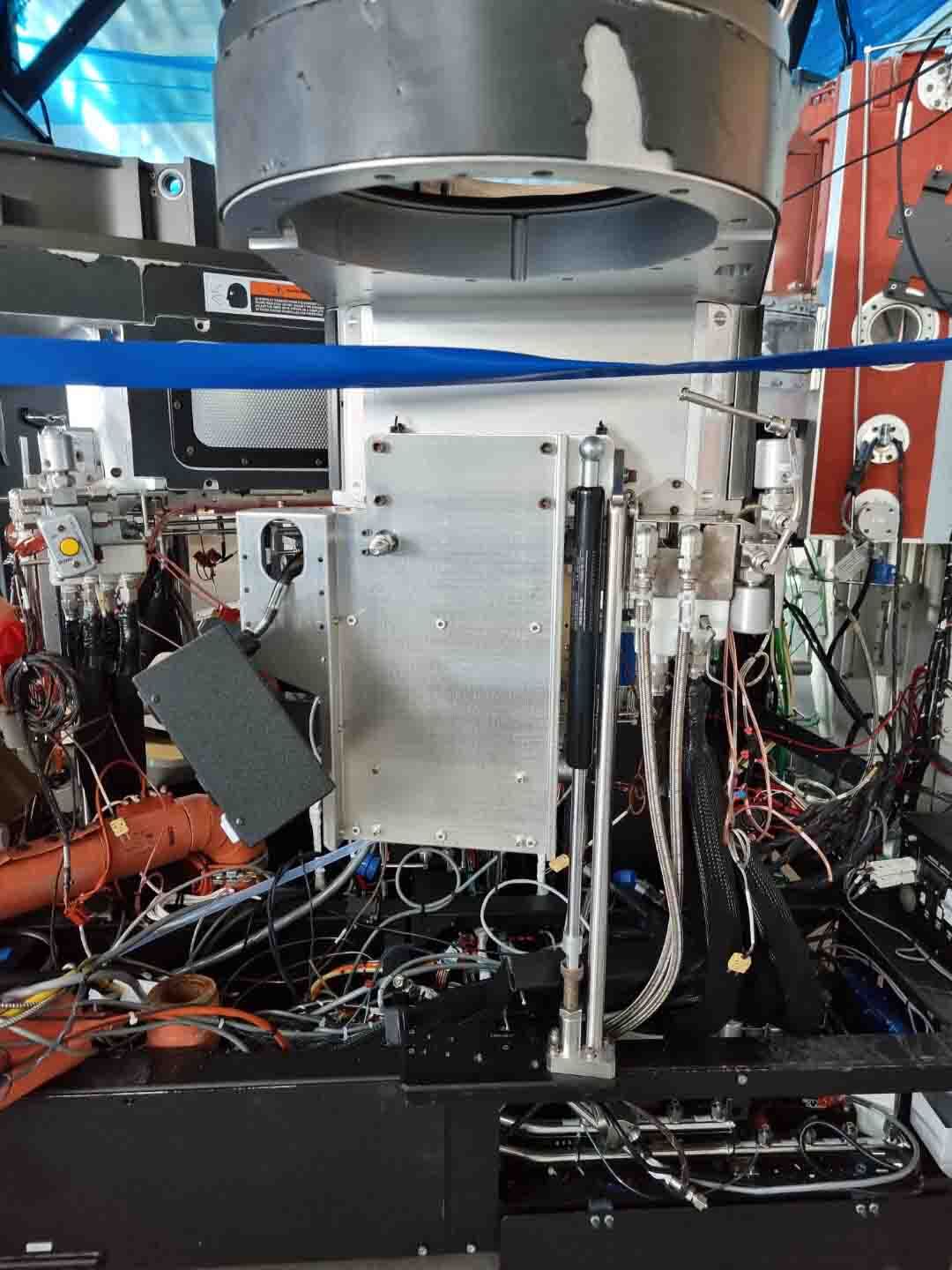

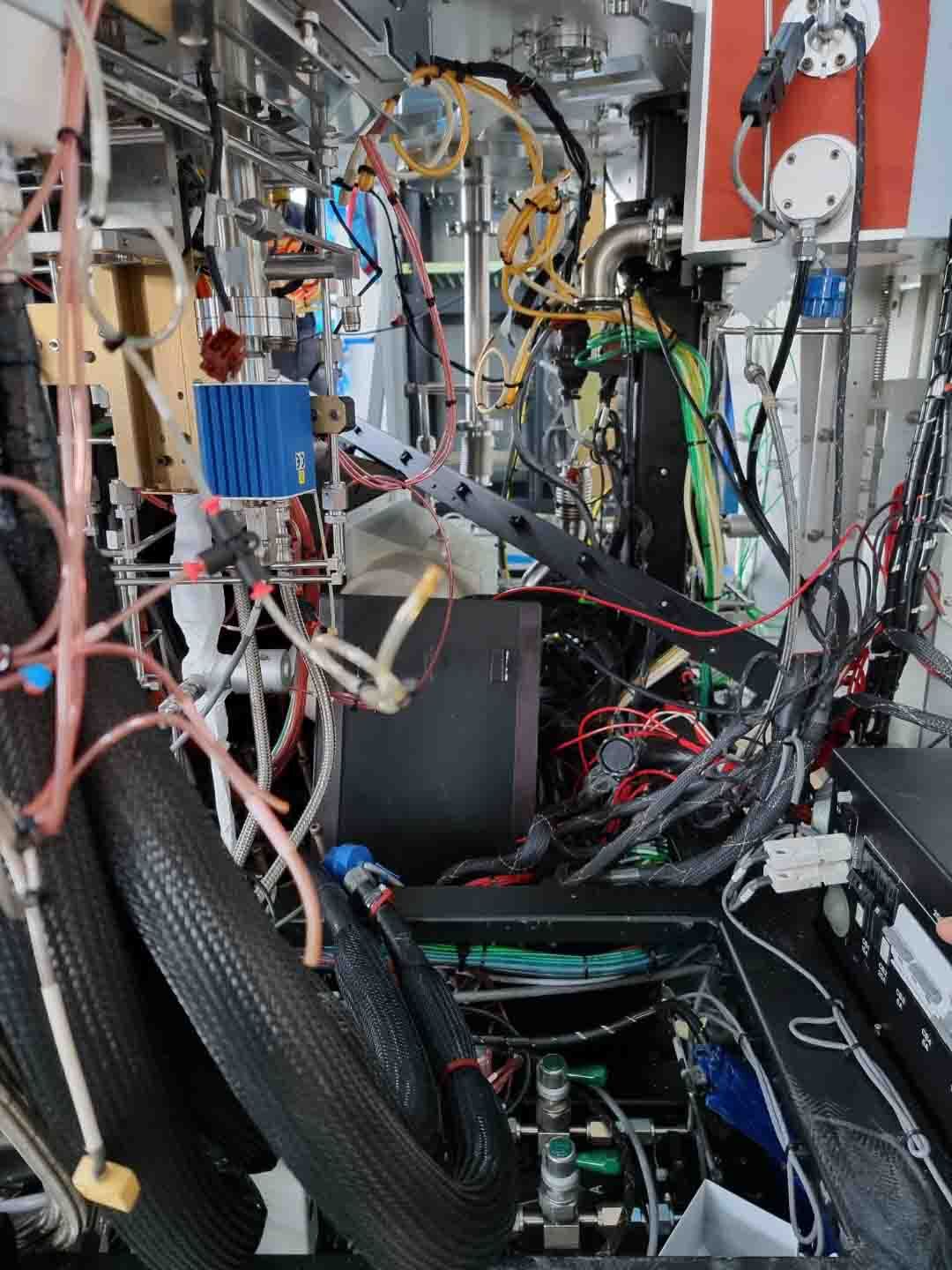

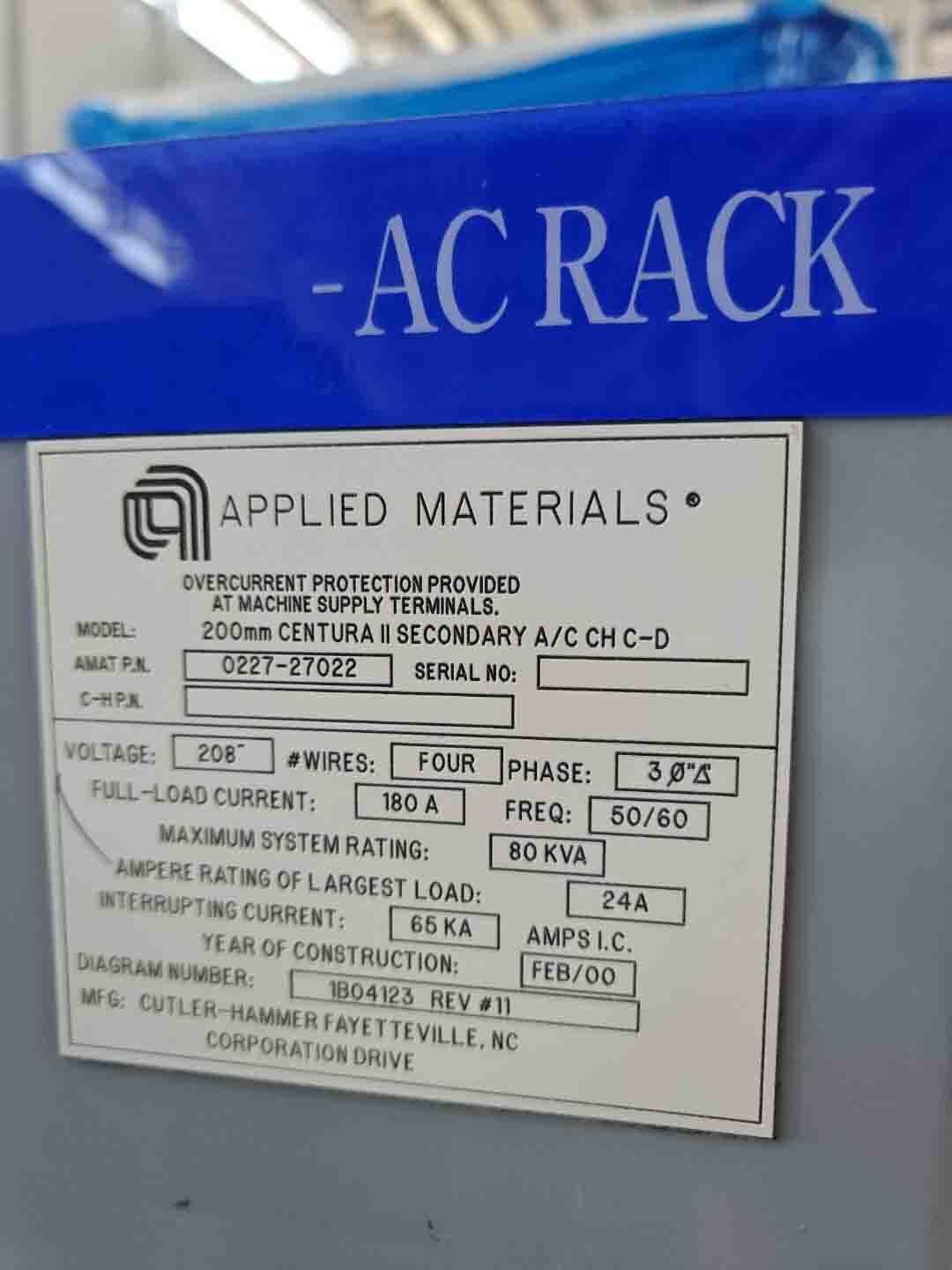

Used AMAT / APPLIED MATERIALS Centura DPS+ #293607518 for sale

URL successfully copied!

Tap to zoom

ID: 293607518

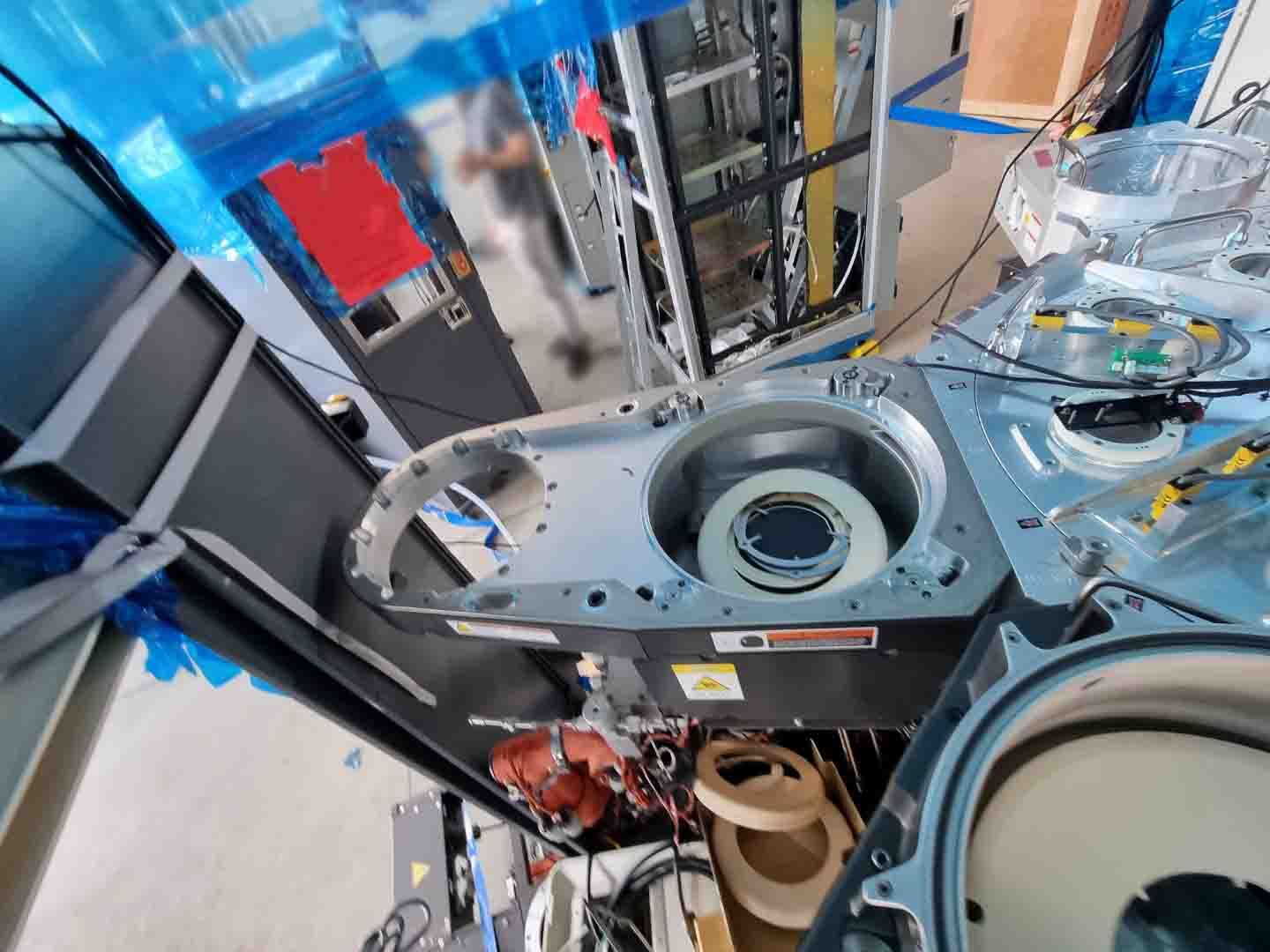

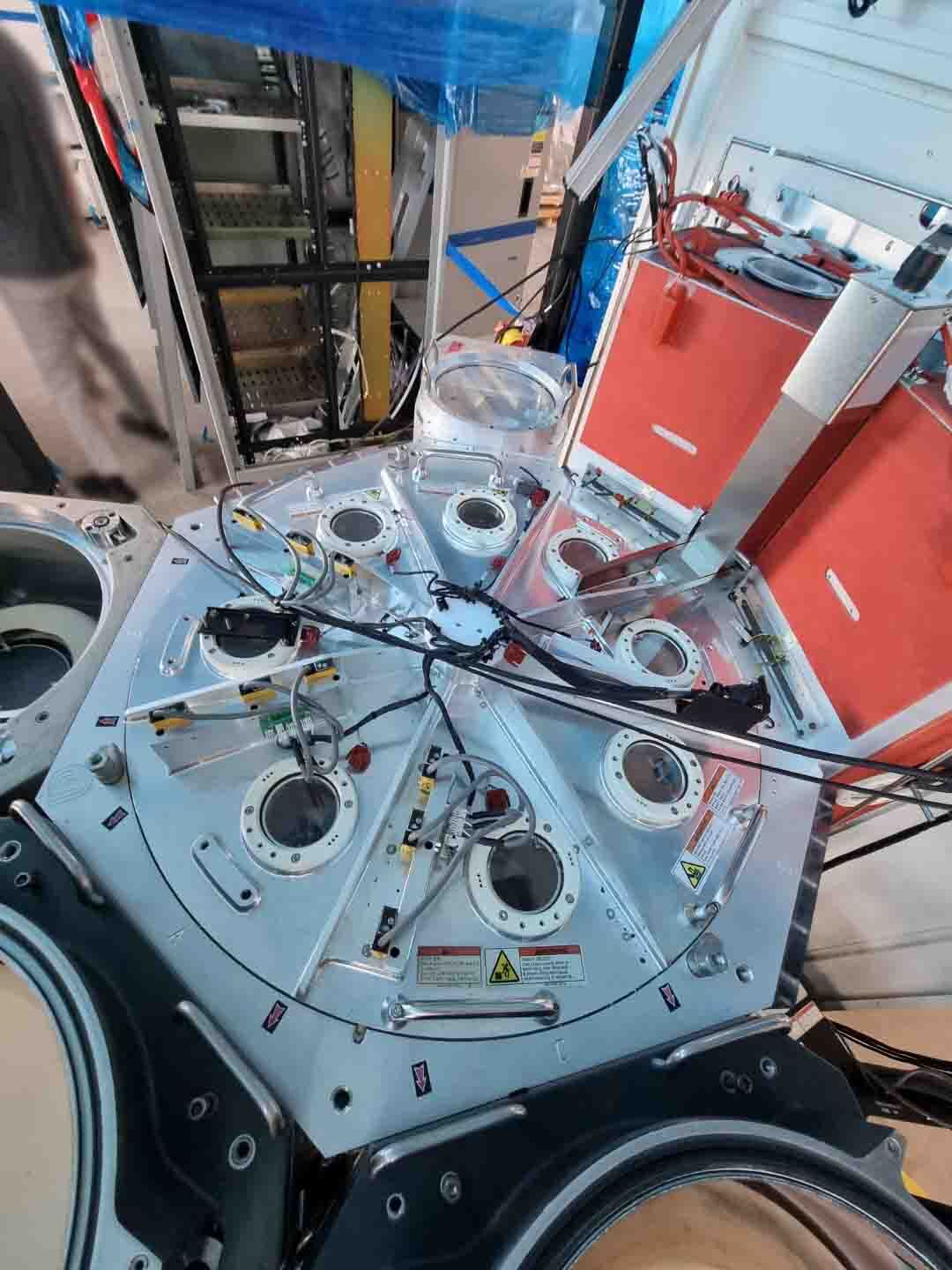

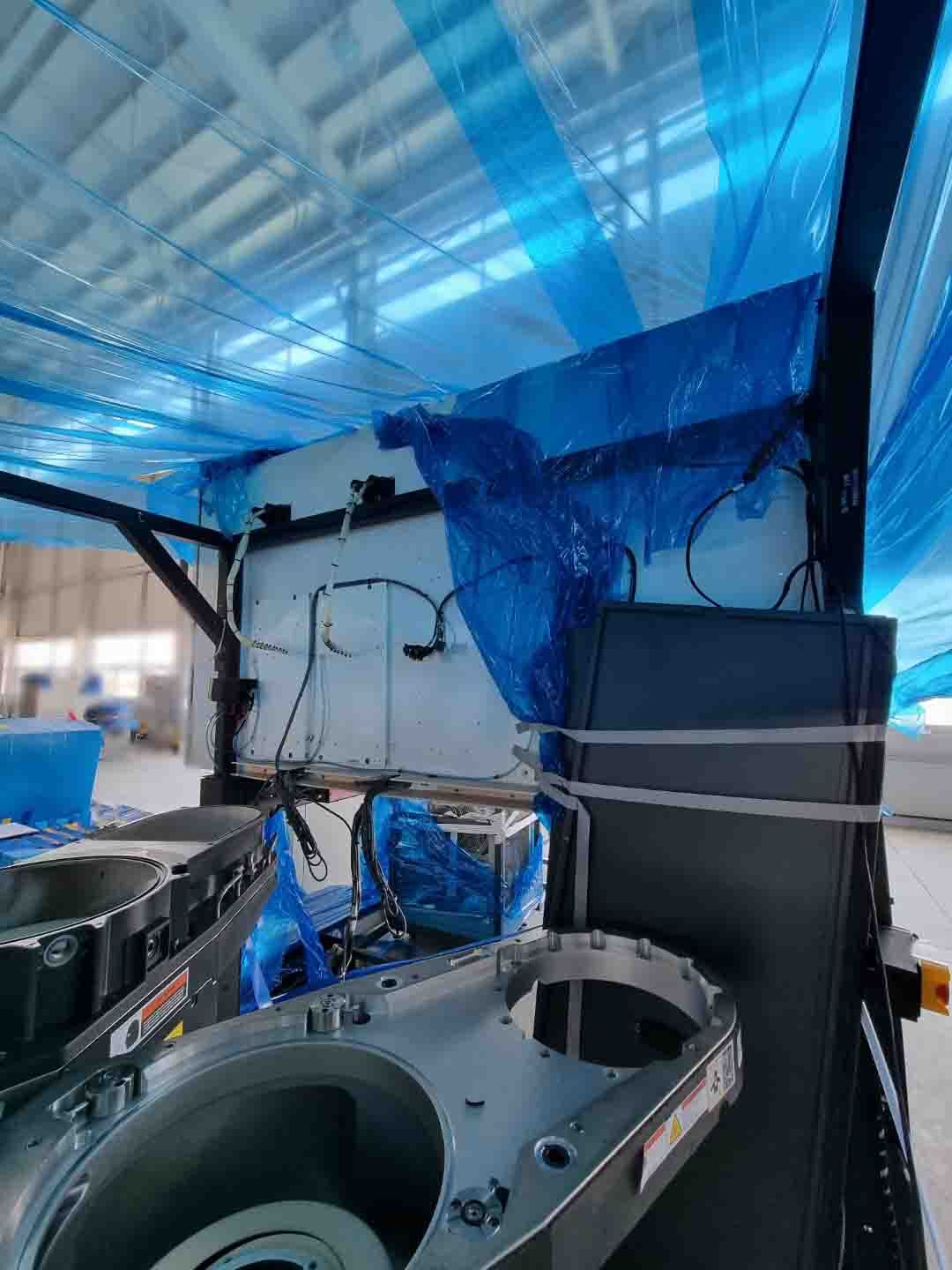

Wafer Size: 4"-8"

Vintage: 2012

Dry etcher, 4"-8"

SMIF / FOUP

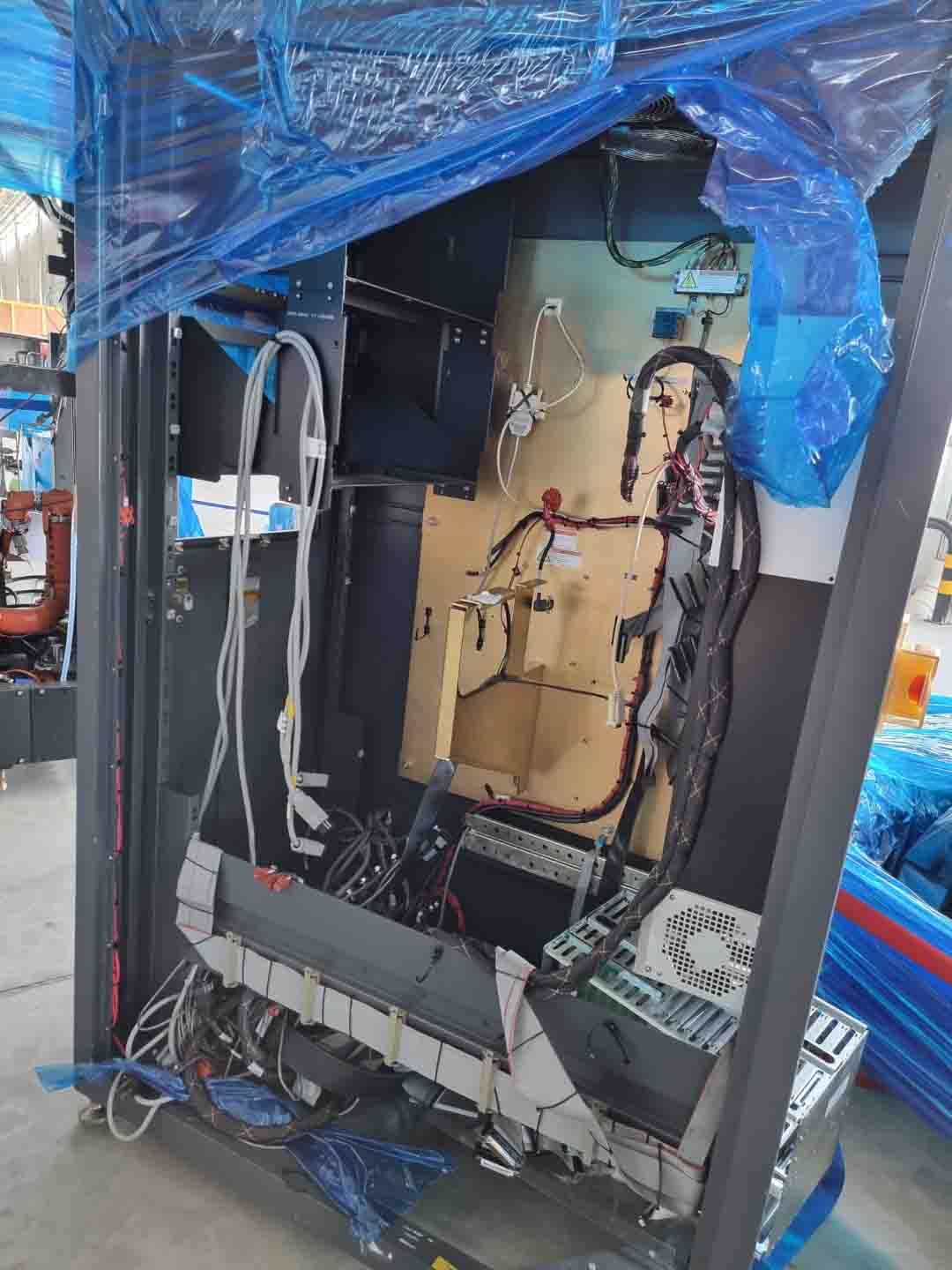

AC Rack

2012 vintage.

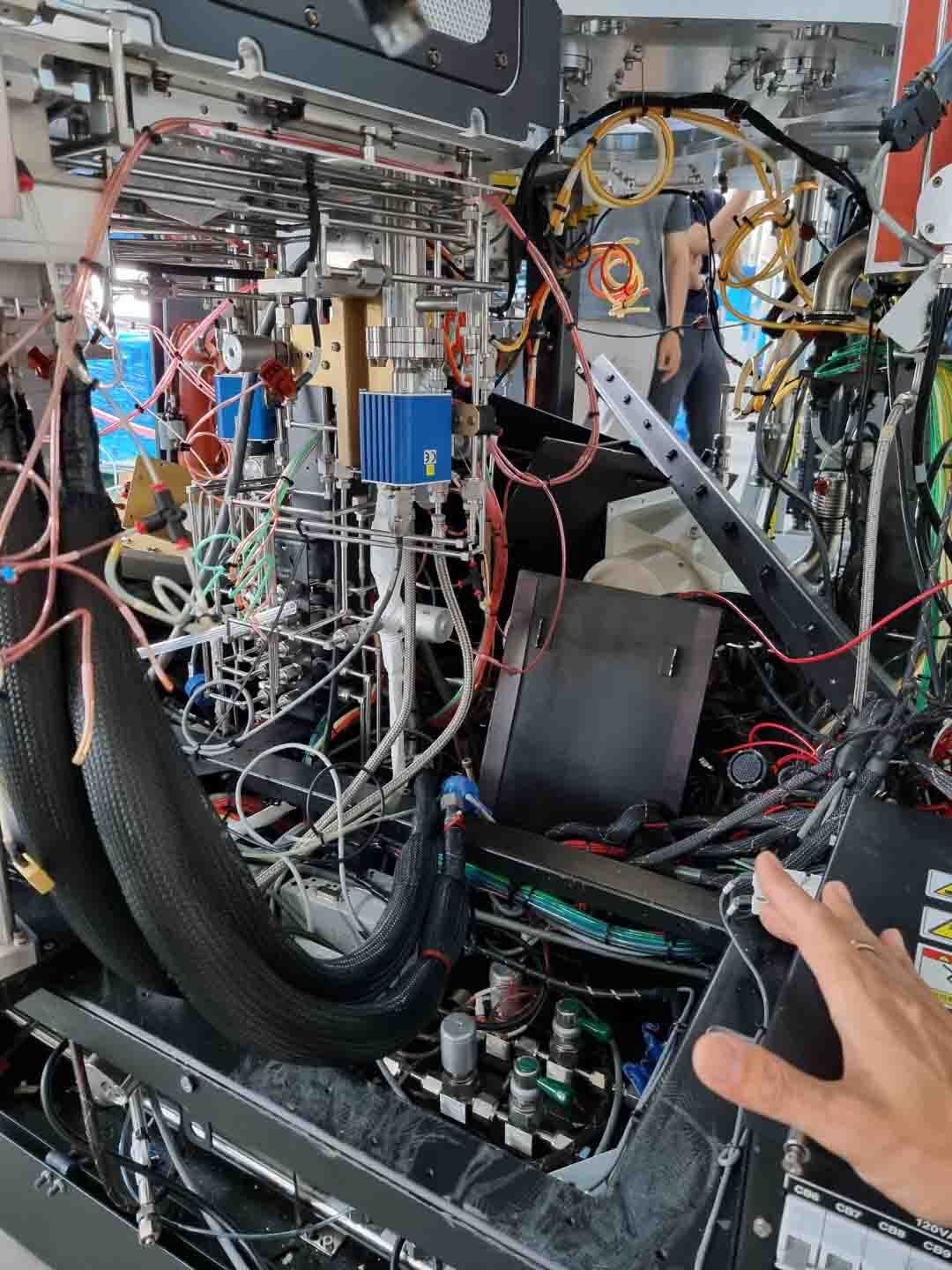

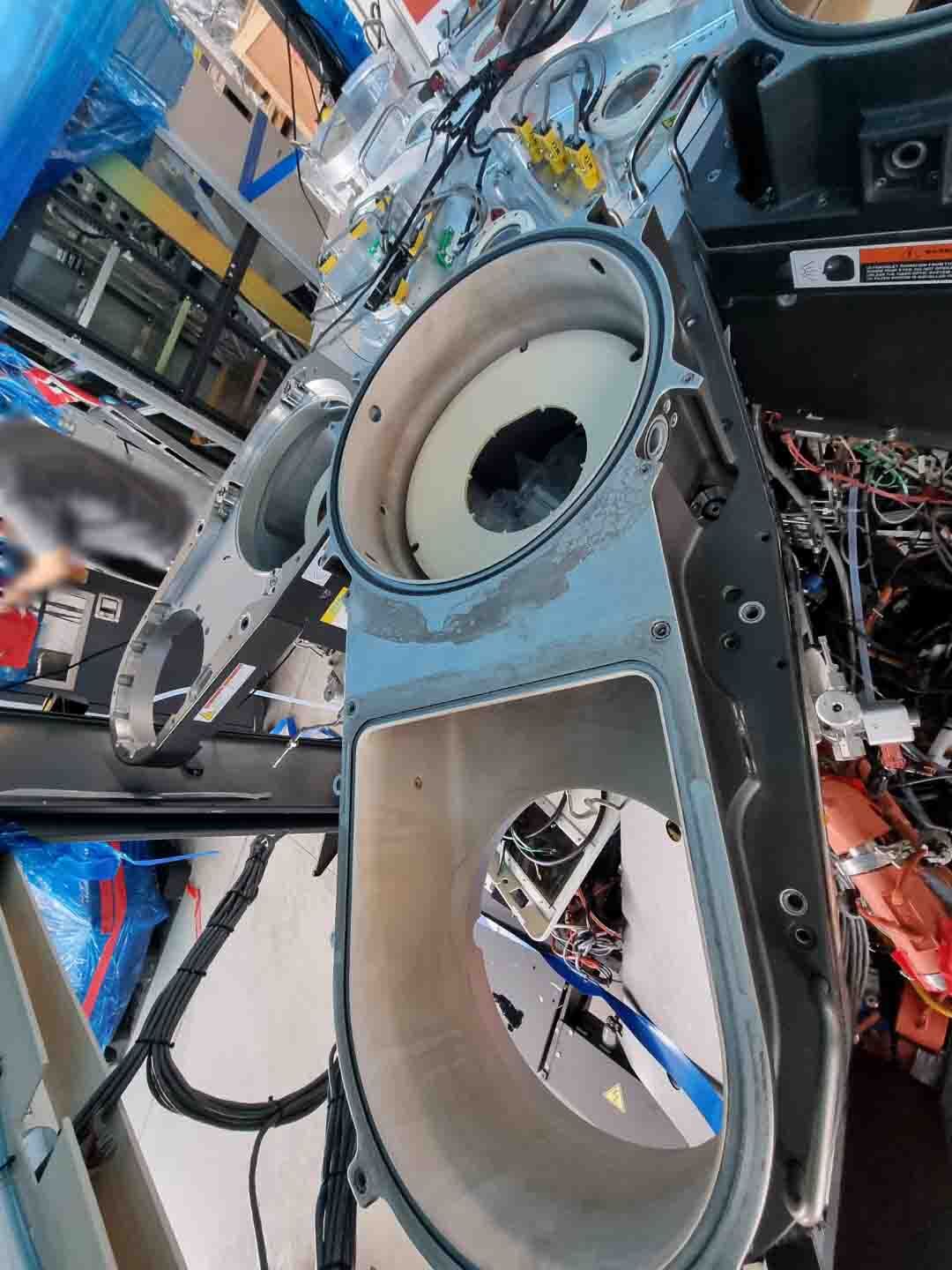

AMAT / APPLIED MATERIALS Centura DPS+ is a high-performance, thermal-reaction process chamber developed for the deposition of advanced IC and MEMS devices. Utilizing a unique LEAN process innovation, the DPS+ equipment leverages a combination of plasma activation, reactive ion etching (RIE), and unified process modules with low-power process capabilities and direct-drive controllers that allow for precise control of process chemistry and parameters. Its integrated tool utilizes AMAT proprietary SmartScan Technology. This automates process optimization and rapid parameter adjustments to accommodate for substrate-to-substrate and chamber-to-chamber variability, allowing for more repeatable process results. The system's Ultra-Low Pressure Technology (ULPT) allows for temperatures as low as 20°C. This makes this chamber ideal for the deposition of fragile low-k dielectric materials. Along with its superior uniformity, the Advanced Process Control (APC) further enhances the repeatability and reproducibility of the process. The integrated APC features a high-performance Proportional Integral Derivative (PID) algorithm that actively monitors and adjusts the working environment to ensure process purity, robustness and other desired specifications per layer. The unit measures approximately 41m wide x 5.1m high x 6m deep and conforms to ISO 5 cleanroom grade. It is an advanced machine for the deposition of compressive and tensile films including high k dielectric, barrier layers and metal, organic and organic-metallization layers. The tool also offers superior profiling capabilities for advanced film morphology control. It includes an advanced 8-chamber design, as well as additional components such as a heater, a quartz tank, a showerhead and a heated RTP (reactive-ion etch). The asset is also equipped with a comprehensive safety model that ensures maximum working environment security. It features extensive safety features such as side wall protections, an anti-backblast cage, a process alarm and an automated emergency shut-off valve. The DPS+ works with APPLIED MATERIALS dedicated 3D software, which allows for efficient 3D process integration for advanced device manufacturing. Overall, AMAT Centura DPS+ is an advanced thermal-reaction process chamber for producing high-performance IC and MEMS. Its combination of low-power processes, direct-drive controllers, unified processing modules and SmartScan Technology give it countless advantages over other thermal reactors. In addition, its safety equipment and ULPT technology further ensure process safety and repeatability, while its 8-chamber design allows for 3D process integration.

There are no reviews yet