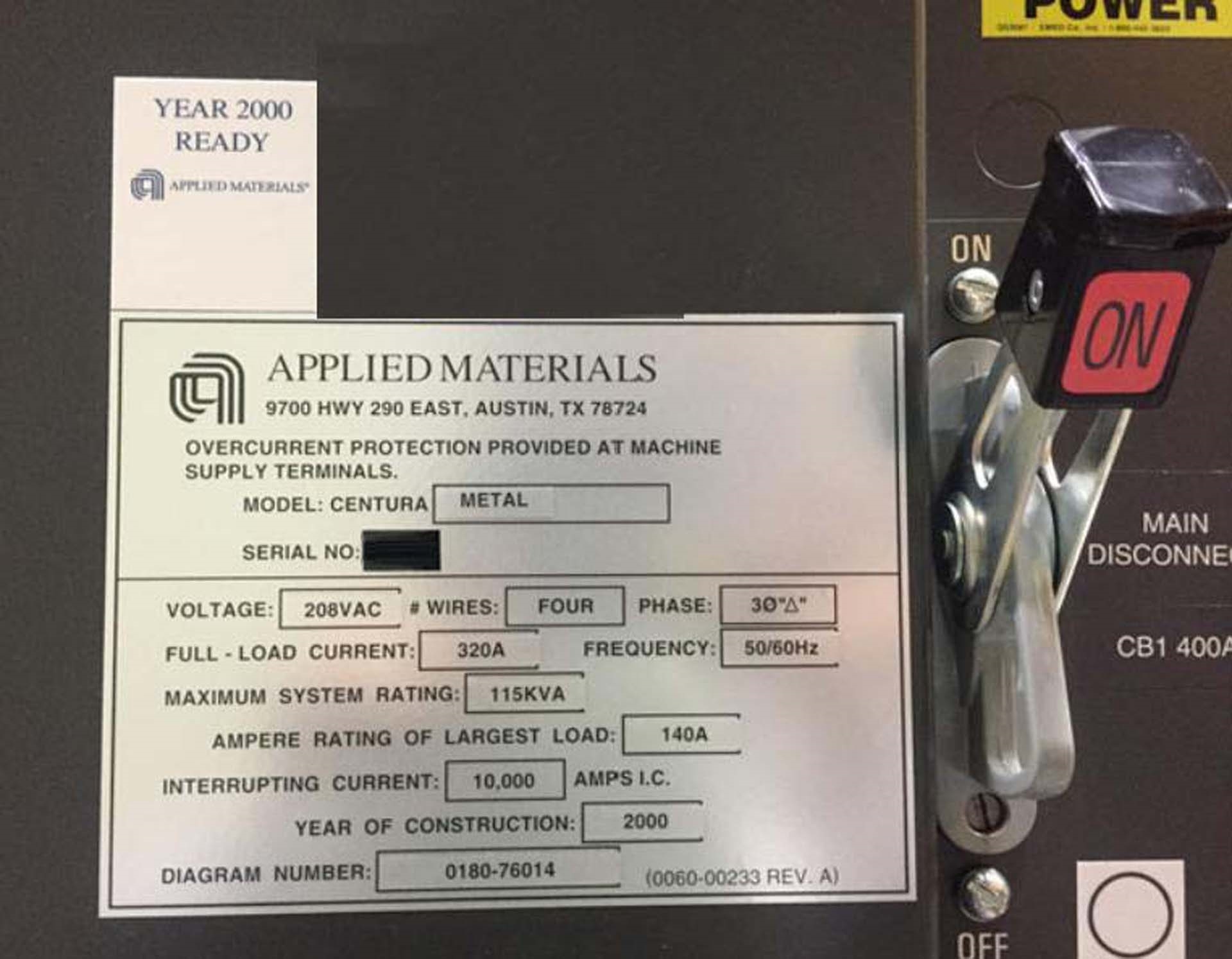

Used AMAT / APPLIED MATERIALS Centura DPS+ #9233287 for sale

URL successfully copied!

Tap to zoom

ID: 9233287

Wafer Size: 8"

Vintage: 2000

Metal etcher, 8"

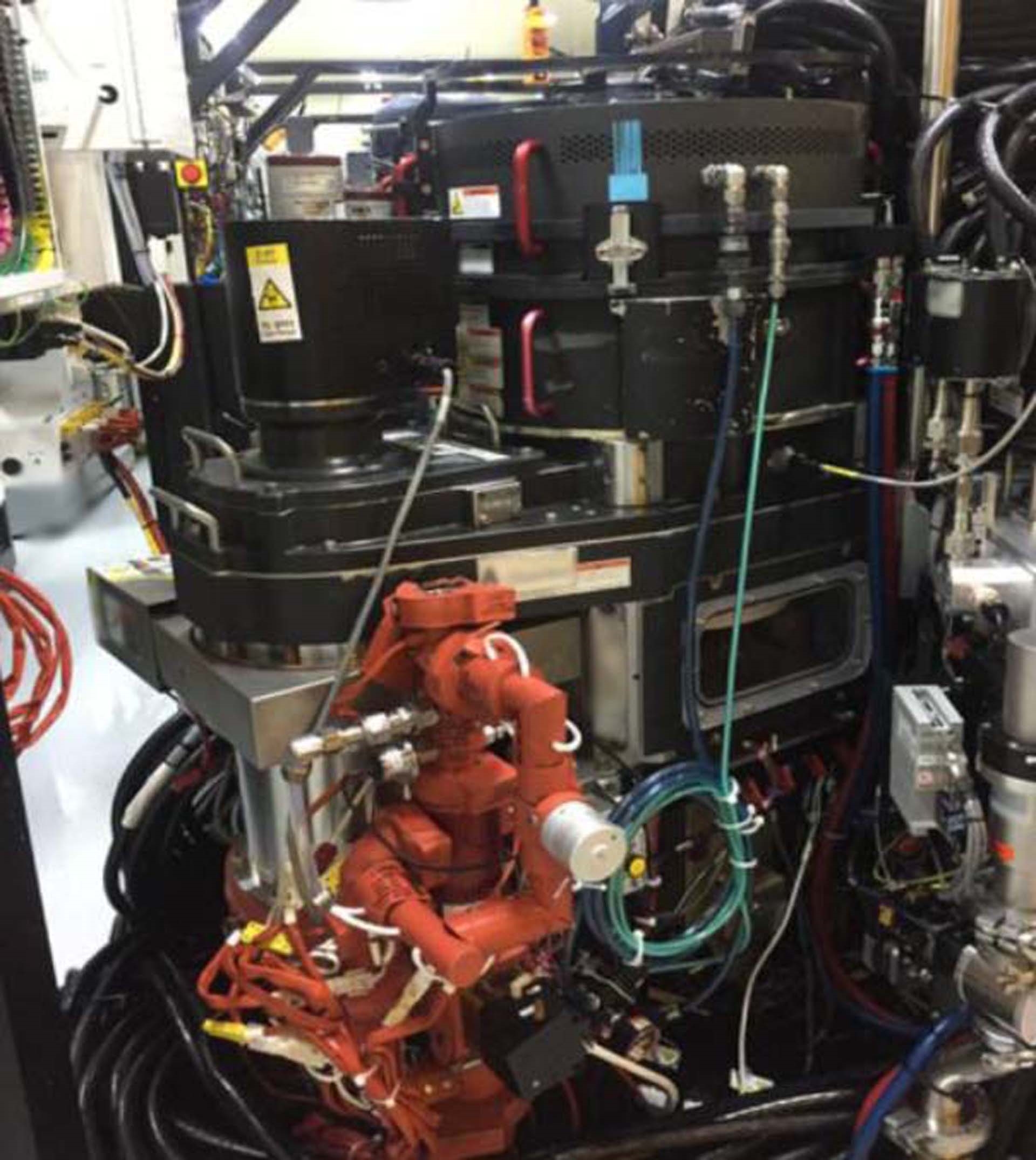

Mainframe: Centura Phase2

Chamber A & B:

DTCU: EDTCU

Gate & throttle valve: Pentium & throttle valve, VAT

EDWARDS STP-H1303C Turbo pump

Pumping tube: Heated

ENI QMW-25 Generator (Source)

ENI OEM-12B Generator (Bias)

ESC: Ceramic

EPD: Monochromator

Chamber C&D (ASP+):

ASTEX AX-2115 Microwave generator

Tuner: Auto tuner

Chamber E: Fast cooldown

Chamber F: Orieter

Xfer: VHP Robot

L/L: Narrow tilt-out

Gas panel:

Chamber A & B:

Gas / Size / Model

N2 / 20sccm / 8160

O2 / 500sccm / 8160

Ar / 200sccm / 8160

CHF3 / 20sccm / 8160

SF6 / 200sccm / 8160

BCL3 / 100sccm / 8160

CL2 / 200sccm / 8161

Chamber C & D

Gas / Size / Model

N2 / 500sccm / 8160

O2 / 5000sccm / 8160

N2 / 1000sccm / 8160

VDS

Missing parts:

Process chamber chiller & hose

EPD Monitor rack

2000 vintage.

AMAT / APPLIED MATERIALS Centura DPS+ is an advanced plasma-enhanced chemical vapor deposition (PECVD) equipment designed to meet the demands of next-generation OLED displays and other microelectronics applications. AMAT Centura DPS+ provides a selection of chambers to suit any deposition requirements, with a Delta chamber designed for the deposition of basic cells, a sigma chamber designed for compound semiconductor deposition, and a Stripe chamber designed for depositing rectifying films with stripe-shaped targets. This allows for a broad range of deposition capability, from ultra-thin films to films over two millimeters thick. The apparatus comes with many features to improve processing speeds and yields, such as multiple process control capabilities, including temperature control using ultra-precision control systems, micron-level uniformity and repeatability, real-time automated load-locking, variable-frequency RF sputter power supplies, and customizable end-point detection. In addition, the system operates semi-automatically and can be programmed accordingly to process wafers in a variety of shapes and sizes. It features low-temperature processing, and plasma-activated gas discharges enhance deposition rate, uniformity, and quality. The high-purity process gases used in the unit offer excellent film uniformity and process stability. APPLIED MATERIALS CENTURA DPS+ also offers exceptional plasma control with fully adjustable power and pressure levels, allowing users to fine-tune process parameters to achieve optimal material performance. Special multi-chamber clustering architectures enable high-throughput cluster processing. Furthermore, high-precision integrated alignment fixtures and automatic wafer loading platforms minimize manual labour. Overall, AMAT / APPLIED MATERIALS CENTURA DPS+ offers advanced processing capabilities for next-generation OLED display deposition and other microelectronics needs. With its range of features, the machine offers an efficient and reliable platform for deposition and etching requirements.

There are no reviews yet