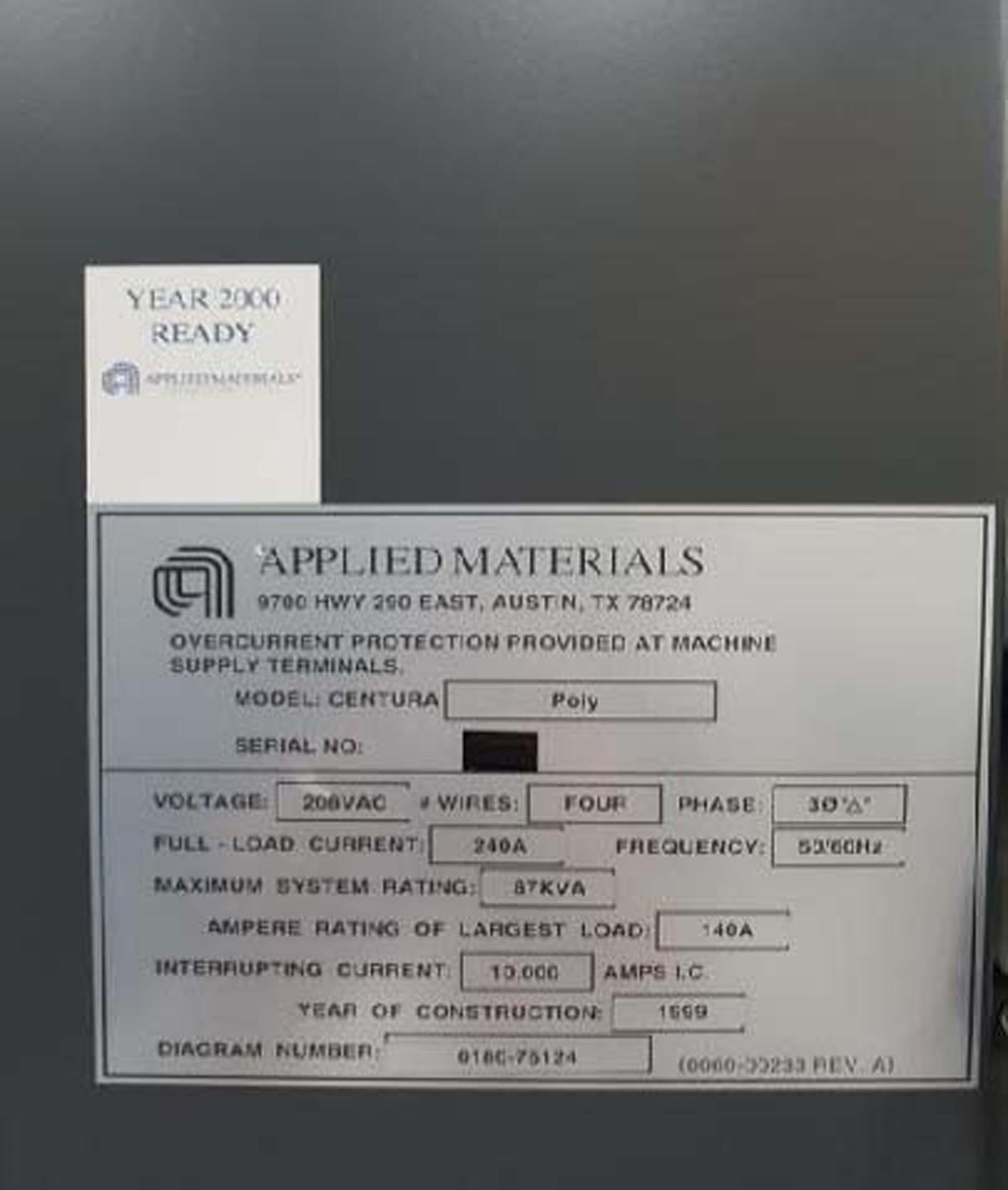

Used AMAT / APPLIED MATERIALS Centura DPS+ #9233293 for sale

URL successfully copied!

Tap to zoom

ID: 9233293

Wafer Size: 8"

Vintage: 1999

Poly etcher, 8"

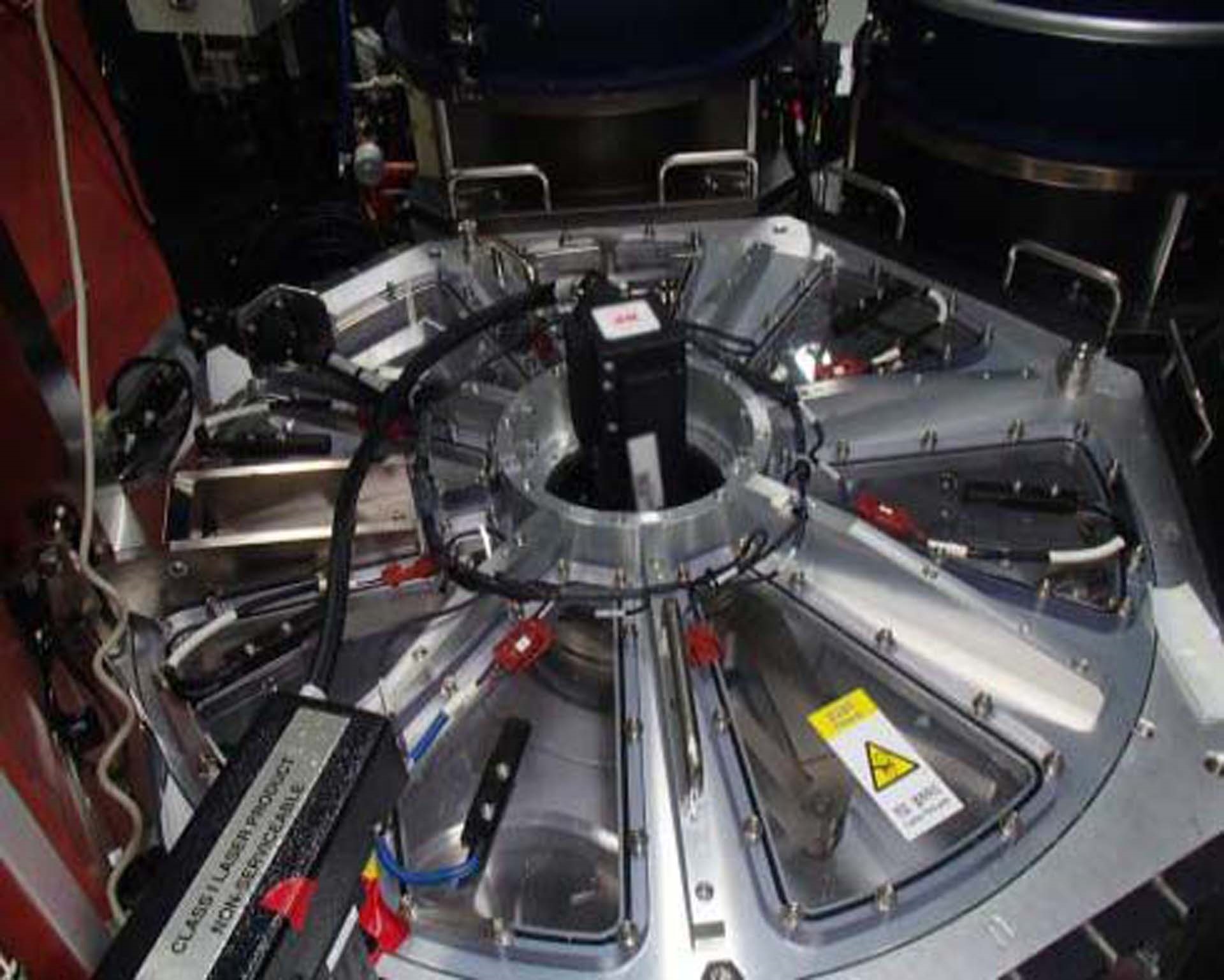

Mainframe: Centura Phase2

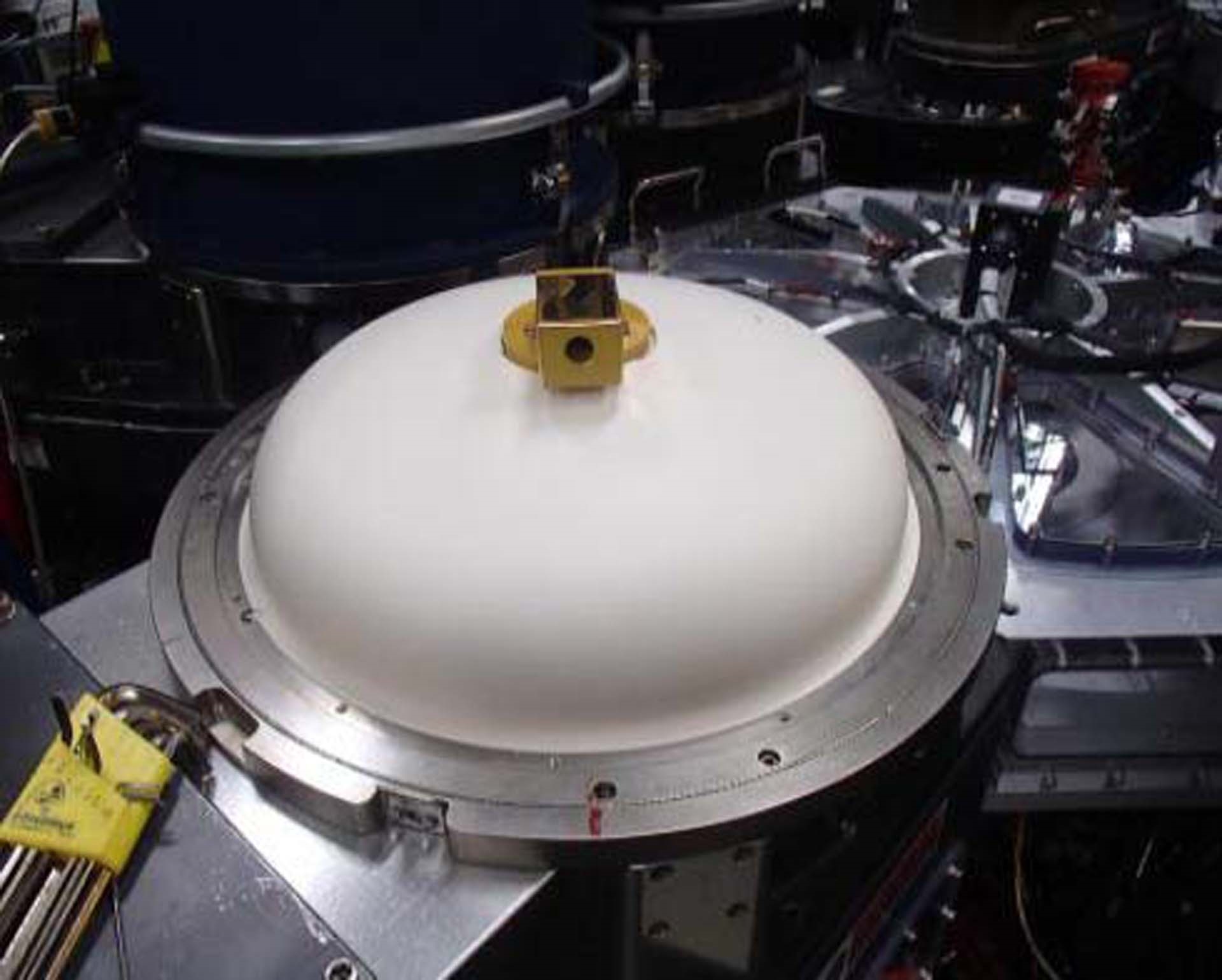

Chamber A, B & C:

DTCU: ES-DTCU

Gate & throttle valve: TGV, VAT

EDWARDS STP-A2203 Turbo pump

Pumping tube: Heated

ADVANCED ENERGY Altas 2012 Generator (Source)

ENI ACG-6B Generator (Bias)

ESC: Ceramic

EPD: IEP

Chamber F: Orieter

Xfer: HP Robot

L/L: Narrow, heated, tilt-out

Hoist: Local hoist

Gas panel:

Chamber A & C:

Gas / Size / Model

HBr / 200sccm / 8160

Cl2 / 200sccm / 8160

Cl2 / 50sccm / 8160

SF6 / 50sccm / 8160

N2 / 20sccm / 8160

Ar / 200sccm / 8160

CF4 / 100sccm / 8161

He / 20sccm / 8160

O2 / 100sccm / 8161C

Chamber B:

Gas / Size / Model

HBr / 200sccm / 8160

Cl2 / 200sccm / 8161C

Cl2 / 50sccm / 8160

SF6 / 50sccm / 8160

N2 / 20sccm / 8160

Ar / 200sccm / 8160

CF4 / 100sccm / 8161C

He / 20sccm / 8160

O2 / 100sccm / 8161C

Missing parts: Process chamber chiller & hose

1999 vintage.

AMAT / APPLIED MATERIALS Centura DPS+ is a state-of-the-art reactor used to perform various semiconductor fabrication processes. It is a dielectric deposition product suite that provides fast and accurate deposition of dielectric films for a wide range of semiconductor device applications. The equipment is capable of producing passivated layers on a variety of substrates such as silicon, quartz, glass, polyimide and other surfaces. AMAT Centura DPS+ has a maximum field size of 25 square inches, with a minimum dose capability of 1-microamp. Its reactors feature a four-quadrant rotary sputter configuration that ensures uniform processing of all substrates. The system is also equipped with a high-speed sputtering source capable of achieving adoption rates of up to 1nm/s. This helps to give the unit high throughput capabilities. The machine also has an advanced thermal control for achieving precise temperature control for deposition processes, resulting in a more uniform and consistent result. APPLIED MATERIALS CENTURA DPS+ also features a suite of chemical-based cleaning and pre-clean capabilities, allowing for efficient wafer processing. It also comes with a touch-screen monitor that allows for real-time monitoring of various parameters during the processing cycle. The tool is compliant with various protocol standards such as UNI-Core, SEMI and GCR. It also has an ISO-9002 certification and operates at a Class II cleanroom grade, ensuring consistent and reliable results inevery processing cycle. The Centura is constructed with a sturdy, highly corrosion-resistant stainless-steel frame, which ensures a long lifetime of reliable operation in the harshest of environment. Overall, CENTURA DPS+ is a robust and reliable reactor, designed to provide high throughput and precise control over a variety of semiconductor fabrication processes. It is suitable for both research and industrial applications, offering precise temperature and chemical control over the process. With its impressive specifications, the Centura is one of the best tools for creating high-quality and reliable devices.

There are no reviews yet