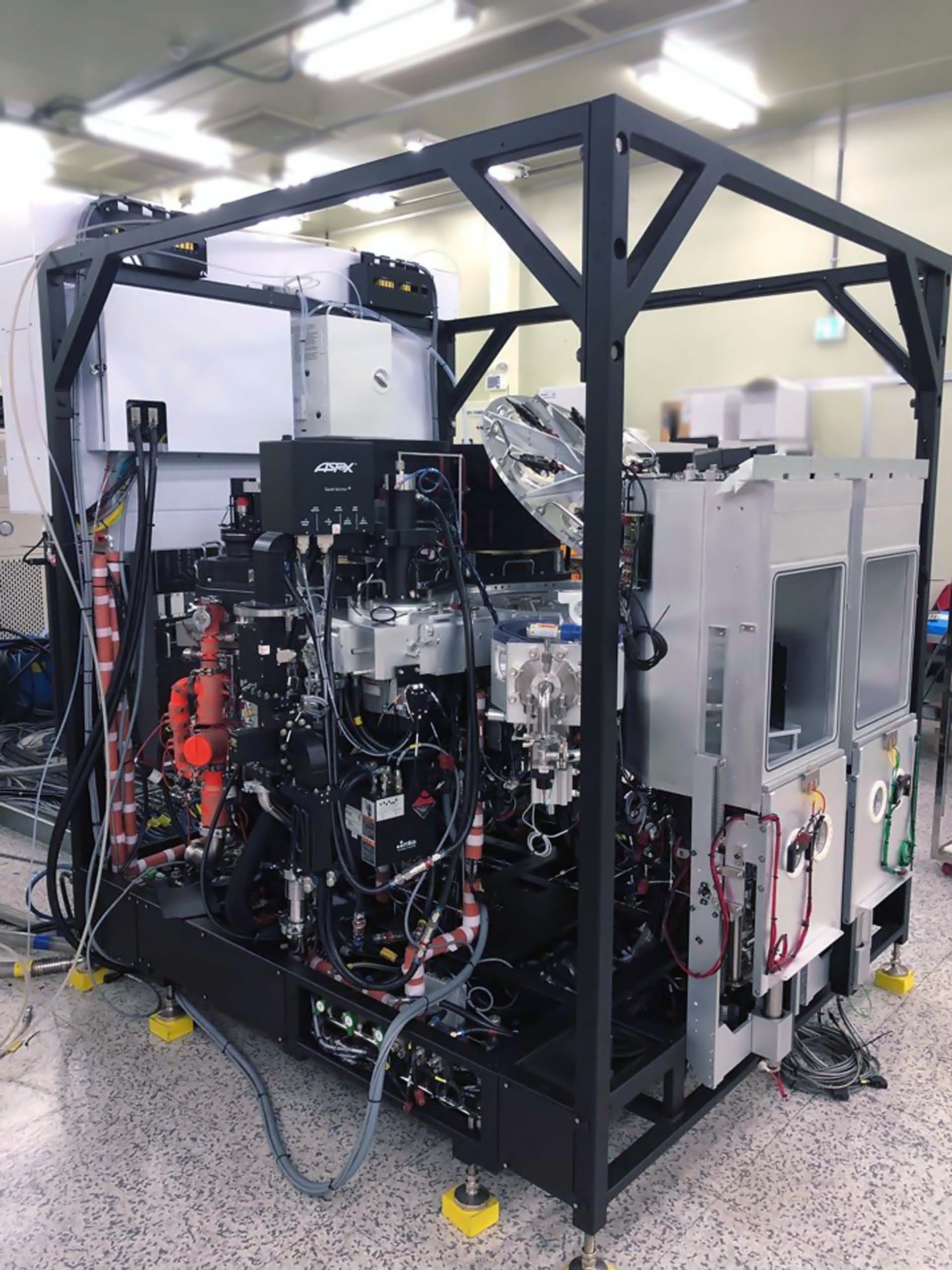

Used AMAT / APPLIED MATERIALS Centura DPS+ #9249570 for sale

URL successfully copied!

Tap to zoom

ID: 9249570

Metal etcher

Load lock: Wide

(2) Chambers DPS+ Metal

(2) Chambers ASP+

Robot: VHP+.

AMAT / APPLIED MATERIALS Centura DPS+ is a PECVD (plasma-enhanced chemical vapor deposition) reactor designed for manufacturing high-yield, high-quality semiconductor device products. The DPS+ PECVD utilizes advanced plasma technology to deposit thin films of SiN and SiO2, used in the fabrication of integrated integrated circuits and other microminiature devices. This PECVD reactor is especially well-suited for the deposition of conformal thin film layers. The DPS+ utilizes a load lock vacuum process chamber, enabling safe repeatable film thickness and conformality. Through the combination of magnetic and gas-based plasma production, the DPS+ allows for high-efficiency, low-cost and process stability with dielectric and insulating films. This makes it especially useful for high-volume production applications. The DPS+ PECVD system also features two advanced features and software specifically designed for device manufacturing. The first, Plasma Processing Isotopic Analysis (PPIA®), provides real-time process performance data. This allows for quick and intuitive process tuning, enabling reliable device fabrication. The second feature, Reactivity-Enhanced Formulation (REF), helps to provide uniform deposition of thin films with excellent step coverage. The DPS+ system is supported by advanced software, using proprietary algorithms and actionable graphical models to provide continuous optimization and maintenance of the process flow. This makes it significantly easier for production personnel to quickly and reproducibly fabricate semiconductor devices with improved device lifetime and reliability in a cost effective manner. Overall, this high-performance, cost effective PECVD system provides advanced thin film deposition and plasma processing capabilities, ideal for the fabrication of high-yield, high-quality semiconductor device products. It is the perfect tool for any semiconductor company or foundry looking to transition to high-volume manufacturing.

There are no reviews yet