Used AMAT / APPLIED MATERIALS Centura DPS #9301836 for sale

URL successfully copied!

Tap to zoom

ID: 9301836

Wafer Size: 12"

Vintage: 2005

Etcher, 12"

(3) FI Port

FI Robot: TBC

PC: TBC

Thickness metrology: NANOMETRICS 9010 Integrated metrology (1000-00829)

Mainframe: Centura AP

Xfer robot: VHP Ceramic blade

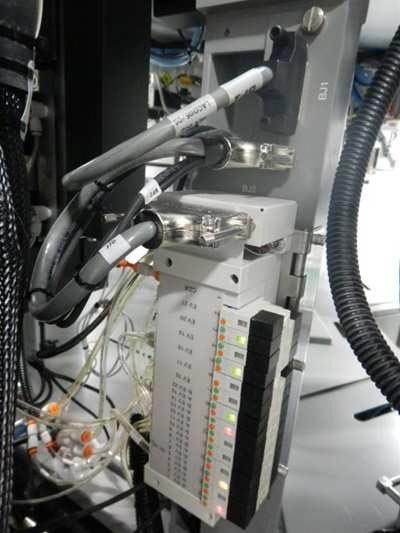

Chamber A: DPS Tsubasa

Chamber B: DPS Advance edge

EDWARDS Turbo pump

Controller: SCV-1500

Gate valve: VAT

RF Generator: ADVANCED ENERGY Apex 1513 and Apex 3013

Gases:

MFC No / Make / Gases / SCCM

31 / CELERITY / SiCl4 / 100

32 / CELERITY / Cl2 / 100

33 / CELERITY / CH2F2 / 100

34 / CELERITY / BCl3 / 400

35 / CELERITY / NF3 / 100

36 / CELERITY / H2 / 200

37 / CELERITY / HBr / 500

38 / CELERITY / C4F8 / 100

39 / HORIBA / O2 / 200

40 / CELERITY / Ar / 200

41 / CELERITY / N2 / 50

42 / CELERITY / CF4 / 200

43 / CELERITY / CHF3 / 200

44 / CELERITY / H2 / 200

Chamber D: Axiom

MFC No / Make / Gases / SCCM

37 / CELERITY / O2 / 10000

38 / CELERITY / 4%H2/N2 / 500

40 / CELERITY / N2 / 10000

Chiller:

Chamber A and B: SMC INR-498-043A

Chamber A: SMC INR-498-016

Chamber B: SMC INR-498-003D

Xfer and L/L pump: TOYOTA T100L

Missing parts:

Hard Disk Drive (HDD)

(3) Dry pumps

2005 vintage.

AMAT/AMAT / APPLIED MATERIALS Centura DPS is a versatile reactor designed for etching and deposition of materials in the semiconductor manufacturing process. AMAT Centura DPS operates as a comprehensive standalone unit, capable of creating cost-effective and reliable processing solutions for multiple process applications. The DPS's dual-chamber design makes it ideal for use on multiple levels, allowing it to simultaneously immerse substrates and perform complex etching operations and material deposition duties. The dual chamber is optimized to support up to 7 process gas lines; while the first chamber is lined with quartz and operates at a temperature of between 75 to 325 degrees Celsius, the second chamber supports up to 16 quartz trays and operates at a temperature of -10 to 600 degrees Celsius. APPLIED MATERIALS Centura DPS has been engineered with a comprehensive range of controls, allowing optimal performance of various process duties. For instance, the chamber is equipped with vacuum, matching, and purge control features; temperature controllers; and multi-gas meter functions. Additionally, the cavity design of the system allows for easy integration of single-wafer or batch loaders and the decentralized mechanical design guarantees fast and easy maintenance. APPLIED MATERIALS/Centura DPS supports a wide range of fabrication processes such as etchback, oxide growth, oxynitride deposition, laser lift-off, and alkyl silicate deposition. Reliability isn't compromised when it comes to tasks such as oxide ashing, oxide deposition, nitride deposition, stripping or etching, or liftoff. What's more, AMAT / APPLIED MATERIALS Centura DPS is built with superior safety and environmental concerns in mind; it is a UL-approved device loaded with emergency shutoff valves and non-flammable process gases. AMAT / APPLIED MATERIALS/AMAT Centura DPS is the perfect choice for a range of fabrication applications. It offers complete process control and flexibility, combined with easy maintenance and great reliability. The machine is designed for robust operation, reliability and long-term performance, optimizing efficiency and quality of semiconductor processing processes.

There are no reviews yet