Used AMAT / APPLIED MATERIALS Centura DxL #117144 for sale

URL successfully copied!

Tap to zoom

ID: 117144

Wafer Size: 8"

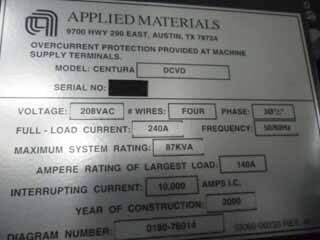

Vintage: 2000

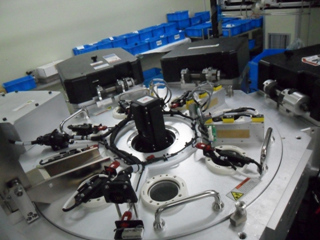

PECVD SiO2 system, 8"

Specifications:

(3) Chambers: SiO2

Cool down chamber

HP robot

Notched wafers

Gases:

Ch A, B, C: SiH4, NF3, N2O, CF4, N2, Ar

Front and rear monitors

SMC chiller

(3) RF generators: ENI OEM 12B

(2) EBARA A30W dry pumps

(3) EBARA A70W dry pumps

Process kits

English software

All cables and hoses

Packing list:

Mainframe

System controller

RF generator rack

Rear monitor

Rear monitor base

Front monitor set

Chamber A ceramic shield

Chamber A susceptor

Chamber A ceramic edge ring

Chamber A ceramic hoop

(4) Chamber A ceramic lift pins

Chamber B ceramic shield

Chamber B susceptor

Chamber B ceramic edge ring

Chamber B ceramic hoop

(4) Chamber B ceramic lift pins

Chamber C ceramic shield

Chamber C susceptor

Chamber C ceramic edge ring

Chamber C ceramic hoop

(4) Chamber C ceramic lift pins

Cables 1-12

Water hose

Chamber A pump

Chamber B pump

Chamber C pump

T/M pump

L/L pump

SMC chiller

Cables 13-20

Power: 208VAC, 3 phase, 50 / 60 Hz

De-installed Q4 2009

Currently warehoused / plastic-wrapped

2000 vintage.

AMAT / APPLIED MATERIALS Centura DxL is a revolutionary semiconductor reactor that offers a versatile, cost-effective solution for micro-electronic device fabrication. It is powered by AMAT proven PECVD platform featuring the Centura XL engineering equipment. With its advanced features, AMAT Centura DxL sets a new standard for ultra-high aspect ratio processing. APPLIED MATERIALS Centura DxL is designed to provide the highest deposition rate and uniformity, maximizing production throughput and yields. Its high-performance PECVD platform operates up to 530°C, allowing for the deposition of a wide range of oxide, nitride, and metal films. The reactor combines APPLIED MATERIALS patented IntelliPath control system with on-board temperature and pressure control, enabling the deposition of films with both uniformity and repeatability. Centura DxL also offers a variety of high-aspect ratio processing options, including planarization and anisotropic patterning. The reactor offers simultaneous and independent control of both process chamber and upper substrate temperature, allowing for precise control of film deposition and planarization. An advanced wafer boat handling unit enables quick, efficient loading and unloading of wafers. AMAT / APPLIED MATERIALS Centura DxL reactor offers advanced features that make it one of the most versatile reactors for micro-electronic device fabrication. It has the capability of depositing a wide range of oxides, nitrides, and metals with extreme accuracy and repeatability. Its high aspect ratio processing capabilities make it the ideal choice for ultra-high aspect ratio applications such as MEMS and nanotechnology. The machine is also easy to use and maintain, with its IntelliPath, on-board temperature and pressure control, and advanced wafer boat handling tool.

There are no reviews yet