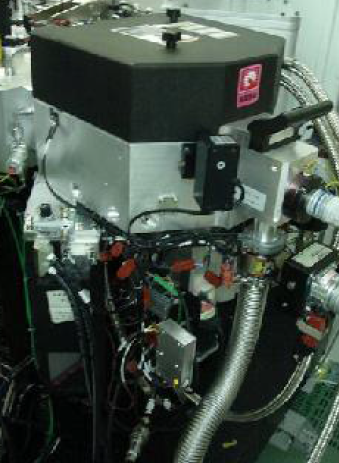

Used AMAT / APPLIED MATERIALS Centura DxZ #9096727 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9096727

Wafer Size: 8"

SACVD / PECVD System, 8"

Process:PE Silane

(2) Chambers

Top mount RPS

Narrowbody loadlocks

HP robot

OTF

Seriplex gas panel, 2 chambers

Position A : DxZ PE Silane

Position C: DxZ SACVD, Top mount RPS

Position E: MSCD

Position F: Orienter

AX8200A ozone generator rack

Neslab HX-300 chiller

AMAT 0 heat exchanger.

AMAT / APPLIED MATERIALS Centura DxZ reactor is a state-of-the-art deposition equipment that combines physical vapor deposition (PVD), chemical vapor deposition (CVD) and etching equipment all in one machine. This reactor utilizes a fully configurable dual-zone chamber design which enables various process variations for the production of advanced devices. The DxZ has the capability to process any type of sample or substrate, such as silicon wafers and quartz slides, with an up to 4" diameter and a maximum sample size of 8x8 inches. AMAT Centura DxZ reactor system is designed to enable high-precision process control with advanced software that allows for repeatability and adjustment of various process parameters. This equipment is specifically designed to handle a wide range of deposition, etching and CVD processes, such as Atomic Layer Deposition (ALD), sputtering, annealing, etching and plasma assisted etching. For example, the temperature regime and vacuum level of the reaction chamber can be adjusted to optimize the respective application. In addition, APPLIED MATERIALS Centura DxZ reactor offers further control through its integrated electro-thermal throttling (ETT) technology and a fully automated substrate processing unit. This makes it a perfect choice for lithography and thin film growth, as well as an ideal foundation for industrial production and research of advanced semiconductor devices. Moreover, by harnessing the latest technologies in vacuum processing and integrated real-time monitoring, Centura DxZ reactor can easily switch between various deposition and etching processes. This provides great versatility for the application of a wide range of sophisticated processes such as auto-flow deposition or ultra-high vacuum (UHV) processes. AMAT / APPLIED MATERIALS Centura DxZ reactor is a top-of-the-line machine for advanced industrial and academic research. It brings together the high process control and advanced compatibility with various sample sizes and substrate materials, allowing for great creativity and innovation towards device fabrication. It is a powerful and versatile machine for developers, researchers and engineers to maximize their research results.

There are no reviews yet