Used AMAT / APPLIED MATERIALS Centura DxZ #9162773 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9162773

Wafer Size: 8"

Vintage: 1988

CVD System, 8"

Wafer type: Notch

Narrow body load locks

Manual lid hoist

HP Robot

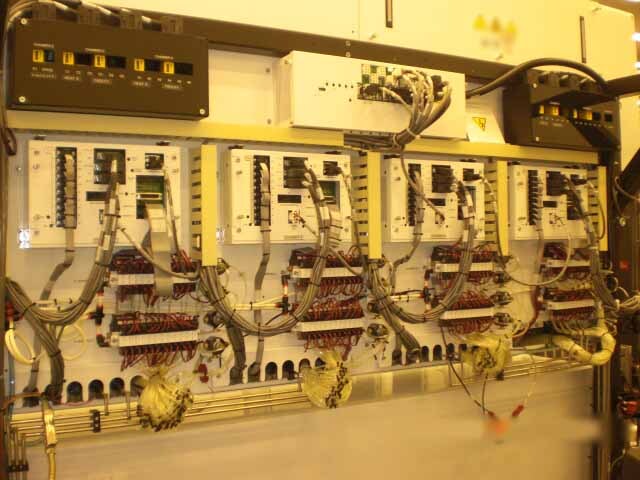

(4) Chambers:

A, B, C, D – DxZ Silane oxide

Direct drive throttle valve

AE RFG 2000-2V

10Torr Baratron

100Torr Baratron

Gasses (Unit MFCs)

300cc N2O

3SLM N2O

5SLM He

3SLM CF4

150cc SiH4

5SLM N2

Seriplex gas control

Chamber E – Multi slot cool down

Bottom feed exhaust

Facilities bottom feed

OTF Centerfind

1988 vintage.

AMAT / APPLIED MATERIALS Centura DxZ is an advanced etching/reactive ion etching (RIE) reactor designed to be used in the fabrication of integrated circuits. The DxZ is capable of etching, cleaning, ion implantation, and thermal processing of substrates. The process chamber is made of stainless steel for corrosion resistance and has an integrated cathode and anode for substrate processing and an auto-tune system for precise etching. The DxZ is equipped with the latest in gas control technology, including a gas flow rate monitor and a gas cabinet with multiple choice nozzles for consistent flow rates. The reactor has a deep traps configuration to maximize the etch rate and quality, as well as two gas manifolds that optimize mass flow uniformity. The interlocks and safety features ensure proper procedure when operation is stopped or restarted, and the auto-tune system ensures precise etching during operation. The DxZ is equipped with an advanced substrate loader, which accurately handles up to thirty two substrates of various sizes. The borosilicate glass top is engineered to provide temperature uniformity and heat dissipation, while the pulsing shield increases the plasma uniformity and decreases wafer bumping. The RF impedance matching networks provide safe and accurate power delivery. The DxZ is also equipped with advanced cooling systems such as a liquid nitrogen cycle cooling unit and RF thermal management for optimal cooling performance. AMAT Centura DxZ is designed to be a reliable and efficient production grade etch/RIE reactor. The advanced gas control technology, high process temperature uniformity, the ability to accommodate a wide range of substrates up to 32 in number and RF impedance matching networks ensure maximum etching speed, accuracy and product quality. The high throughput, optimization and performance of the DxZ makes it an ideal choice for integrated circuit production for high value and high yield applications.

There are no reviews yet