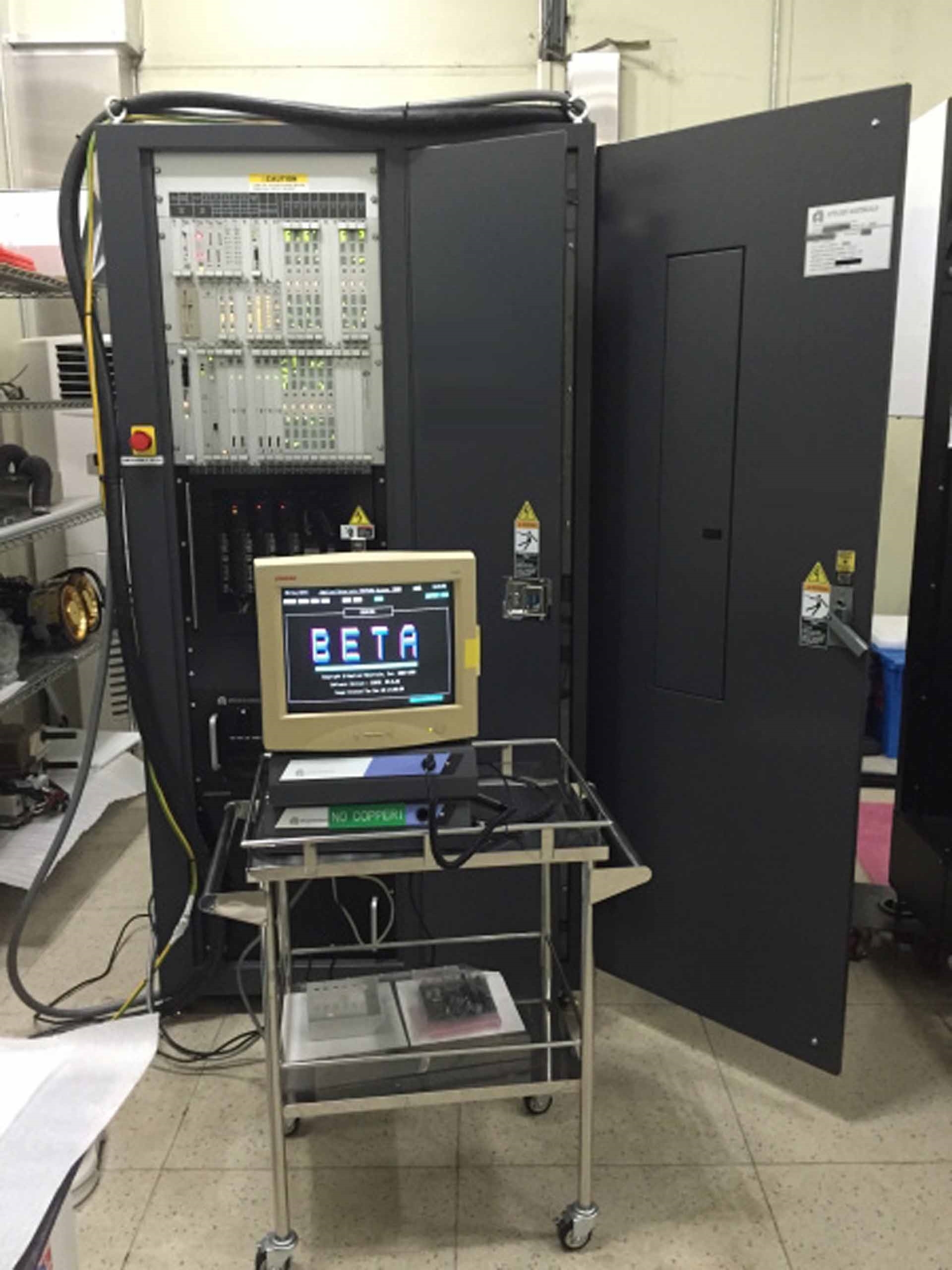

Used AMAT / APPLIED MATERIALS Centura DxZ #9230376 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9230376

Wafer Size: 8"

Vintage: 1996

CVD System, 8"

(3) Chambers: DxZ

Chamber A:

Manometer: 100/2

Heater: AL

Clean method: AE 2000-2V

Pressure method: Direct drive throttle valve

Chamber B:

Manometer:100/2

Heater: AL

Clean method: AE 2000-2V

Pressure method: Direct drive throttle valve

Chamber D:

Manometer:100/2

Heater: AL

Clean method: AE 2000-2V

Pressure method: Direct drive throttle valve

1st Monitor: Through the wall

2nd Monitor: Stand alone

Narrow body loadlock

HP Robot

OTF

Valves: Unit MFCs

Filters: MILIPORE

Regulators: VERIFLO

System cabinet exhaust: Top

Single line drop

Gas pallet configuration:

Chamber A / Size / Model

SiH4 / 500 sccm / Stec MFCs

NH3 / 200 sccm / Unit MFCs

NF3 / 1 Slm / Unit MFCs

N2O / 500 sccm / Unit MFCs

N2 / 5 Slm / Unit MFCs

Chamber B / Size / Model

SiH4 / 500 sccm / Stec MFCs

NH3 / 200 sccm / Unit MFCs

NF3 / 2 Slm / Unit MFCs

N2O / 500 sccm / Unit MFCs

N2 / 5 Slm / Unit MFCs

Chamber D / Size / Model

SiH4 / 500 sccm / Stec MFCs

NH3 / 200 sccm / Unit MFCs

NF3 / 1 Slm / Unit MFCs

N2O / 500 sccm / Unit MFCs

N2 / 5 Slm / Unit MFCs

Process: Nitride deposition (Nit. Pass.)

1996 vintage.

AMAT / APPLIED MATERIALS Centura DxZ Reactor is a production-level batch reactor, capable of producing high-performance materials for a variety of applications. The DxZ Reactor is uniquely designed for the production of plasma enhanced chemical vapor deposition (PE-CVD). The DxZ reactor is designed with a turntable base and a 4-segment multi-targeted plasma. This allows the equipment to synthesize a variety of materials such as nitride, oxide, diamond-like carbon (DLC), and silicon-based compounds that can be tailored to specific applications. The turntable is also used to switch between different targets, allowing for wear-resistant multi-segment targets. In operation, the DxZ reactor uses a three-stage process. The first stage is gas introduction, where gases enter the chamber and are mixed appropriately for synthesis. In the second stage, the pulsed plasma is generated and maintained by a power system that supplies power matched to the process. Finally, in the third stage, a substrate is placed in the chamber, and the reactive species formed from the mix of high frequency electric fields and gases are deposited onto the substrate to form the material. The DxZ reactor also has multiple safety features to ensure reliable operation. These include safety interlocks and pressure sensors for the gas inlet unit and a gas exhaust machine with an adjustable timer, as well as high efficiency particulate and noxious gas filtration. Thanks to its design and features, the Corning AMAT Centura DxZ Reactor is an excellent tool for producing high-quality, high-performance materials. Its robust design, safety features and multiple substrate materials makes it a great choice for commercial, industrial and research applications.

There are no reviews yet