Used AMAT / APPLIED MATERIALS Centura DxZ #9233113 for sale

URL successfully copied!

Tap to zoom

ID: 9233113

System, 8"

Process: SIN

Wafer shape: Notch

Chamber type:

Chamber A, B & C: DxZ (SIN)

Chamber E (MS Cool)

Chamber A & B & C:

Manometer: 100/2

Heater: AL

Clean method: AE 2000-2V

Pressure method: Direct drive throttle valve

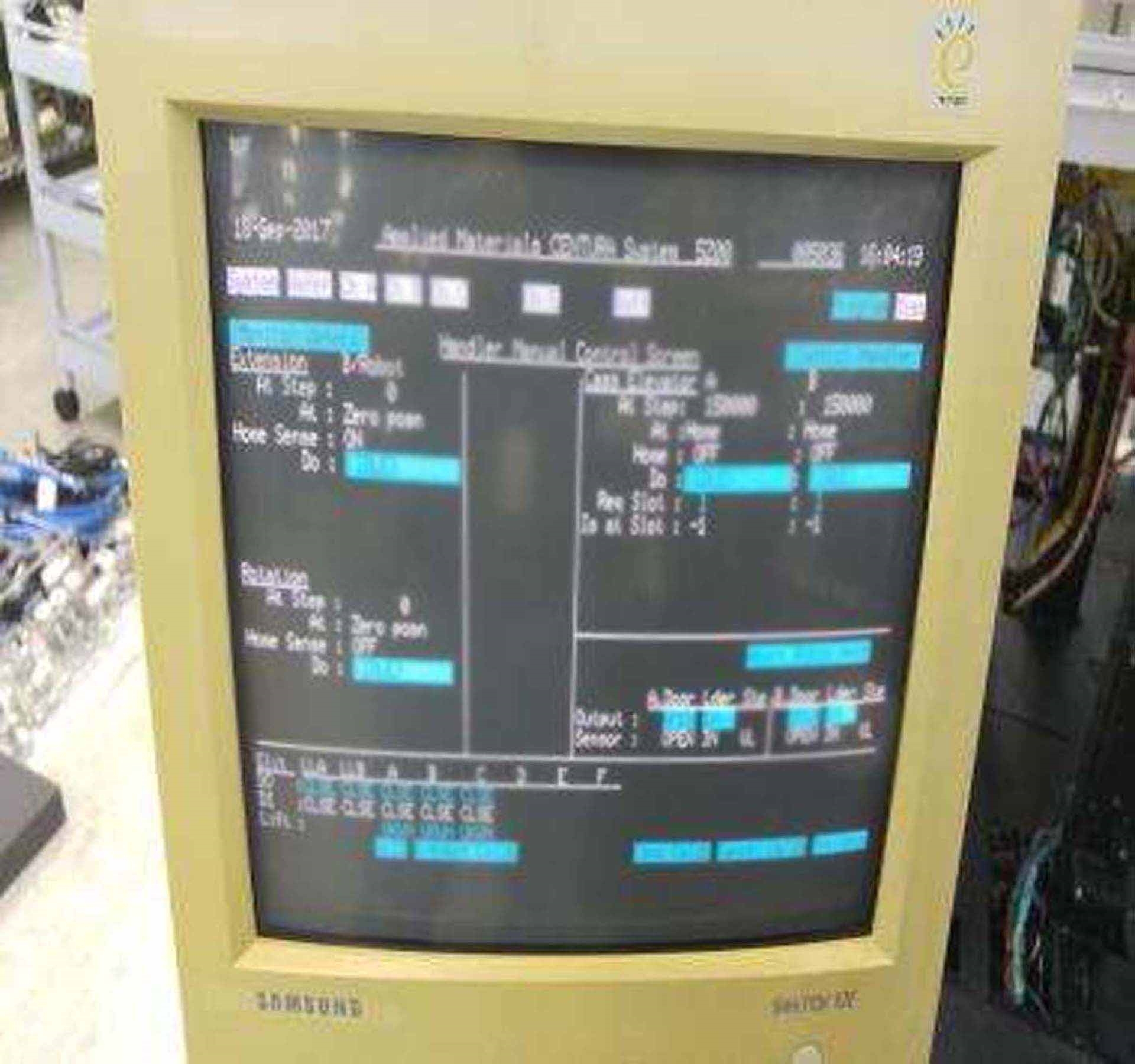

System monitor:

Monitor 1: Through the wall

Monitor 2: Stand alone

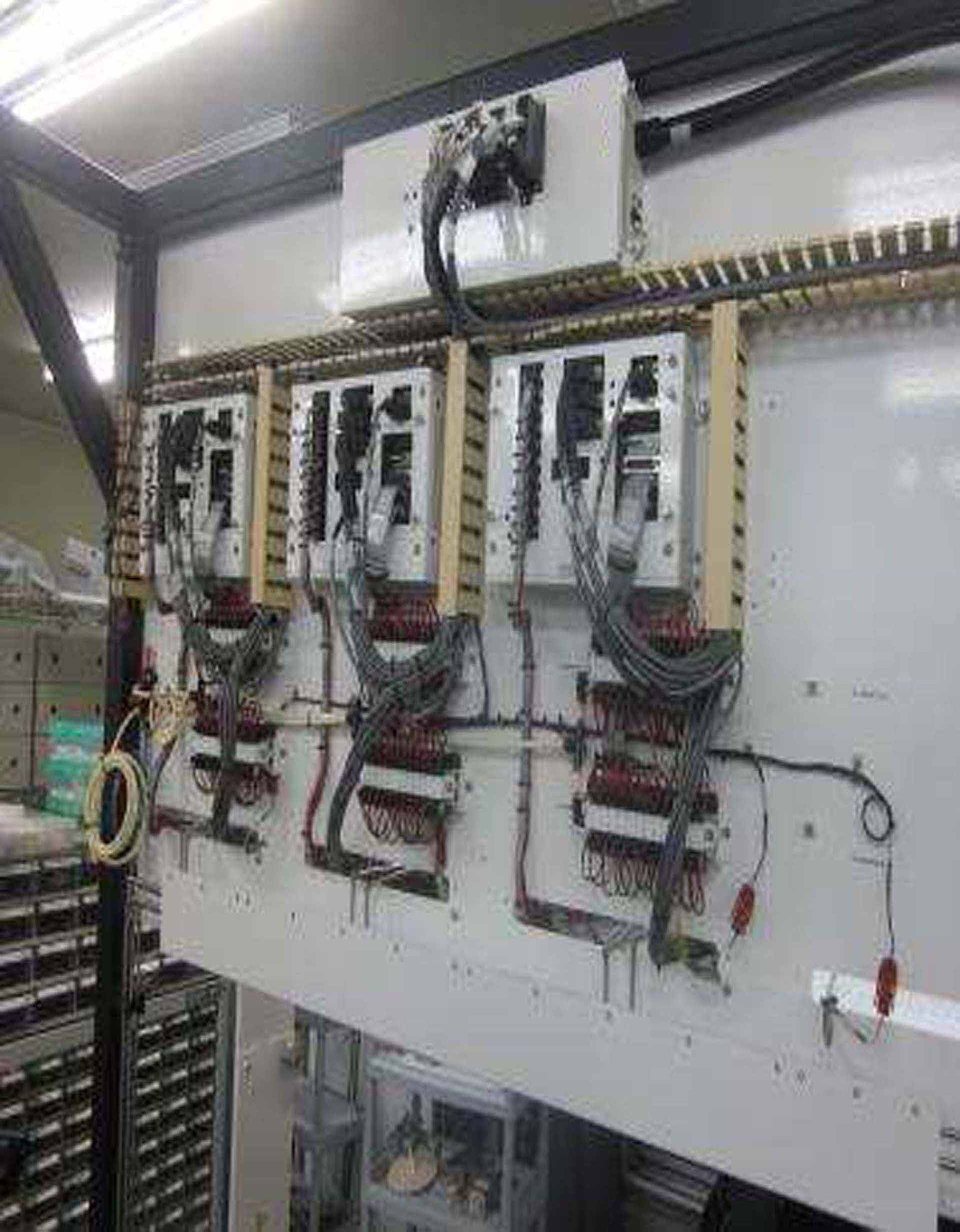

Mainframe:

Loadlock: Narrow body

HP Robot

OTF

Gas delivery option:

MFC Type: STEC 4400MC

Filters: MILLIPORE

Regulators: VERIFLO

System cabinet exhaust: Top

Single line drop

Cables:

Qty / Part number / Description

(1) / 0150-76207 / Cable, assy main frame umbilical

(1) / 0150-76208 / Cable, assy main frame umbilical

(1) / 0150-76209 / Cable, assy main frame umbilical

(1) / 0150-76211 / Cable, assy pneumatics umbilical

(3) / 0150-76206 / Cables, assy, chamber umbilical

(1) / 0150-76210 / Cable, assy, load lock umbilical

(1) / 0150-76176 / Cable, assy, chamber E umbilical

(1) / 0150-35880 / Cable, assy, robot controller

(1) / 0150-10234 / SYS Interconnect cable

(1) / 0150-76198 / Assy cable

(1) / 0150-20100 / Cable, assy.

AMAT / APPLIED MATERIALS Centura DxZ is a high-powered plasma etch reactor designed for removing different kinds of material from semiconductors. It uses a patented High Density Plasma (HCD) technology to generate high-power plasma by using a remotely heated high-density plasma source. The process of removing material from the substrate is called etching, and AMAT Centura DxZ is designed to etch substrates on dielectric, metal, and organic layers with exceptional accuracy and surface uniformity. APPLIED MATERIALS Centura DxZ is a fully automated equipment, comprised of a rotating table that can handle up to ten substrates at once and a vertical cylindrical reactor chamber. Samples are placed onto the platform of the table and automatically fed into the chamber where the plasma is created. The plasma is generated in a vacuum and is maintained at a certain temperature and pressure to ensure that the etching process is as effective and uniform as possible. The system also features an end-point detection unit to accurately monitor the process and detect when the desired etching depth is achieved. The main advantage of using Centura DxZ is its ability to etch at higher etch rates. The high-power plasma allows for faster processing, allowing for the creation of devices with higher quality, faster turnarounds and lower production costs. Additionally, the machine is designed to provide extremely high process uniformity, meaning that multiple wafers will have similar characteristics. AMAT / APPLIED MATERIALS Centura DxZ is an ideal choice for those needing a high-powered etching process for their substrates. With its automation capabilities, higher etch rates, improved uniformity and low cost of ownership, AMAT Centura DxZ is a powerful choice for etching semiconductor substrates.

There are no reviews yet