Used AMAT / APPLIED MATERIALS Centura Epi #9137479 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9137479

Wafer Size: 8"

Vintage: 1995

CVD Reactors, 8"

Chamber type:

Position A : HTF Nitride

Position B : HTF Nitride

Position F : (CA) Single slot cooldown

Electrical requirements

Line voltage : 480V With transformer

Line frequency : 60 HZ

Line amperage : 600A

System safety:

EMO Switch type : Momentary EMO

EMO Guard ring

HTF NITRIDE EPI

RP Pressure chamber

Thickness control options : BMV

Third manometer : 200 TORR

Leak check port

RGA Port and valve

HTF NITRIDE EPI :

RP Pressure Chamber Selected Option

Thickness Control Options BMV

Third Manometer 200 TORR

Gas Line Isolation

Leak check port

RGA Port and Valve

Gas Delivery Options:

Epi Gas Delivery Options:

Gas Panel Type Surface Mount Gas Panel

Gas Panel Exhaust CHAMBER B SIDE

MFC : AREA,UNIT,STEC,ETC

Filter Milipore

Pump Purge

CH A Gas Options

CH A ATM Pressure

CH A H2

CH A N2

CH A SIH4

CH A SIH4

CH A H2

CH A NF3

CH B Gas Options:

CH B ATM Pressure

CH A H2

CH A N2

CH A SIH4

CH A SIH4

CH A H2

CH A NF3

Mainframe

Loadlock

Loadlock Type : Wide body

Cassette Platform Type : Universal

Common Chamber Options :

Variable Speed Blower

SWmonitor Quartz Pyrometer Kit 2

Lamps Type USHIO BNA6

Susceptors STANDARD NCP

Brands XYCARB

Lift Pin Type HOLLOW SILICON CARBIDE

Susceptor Support Shaft NCP SUSCEPTOR SUPPORT SHAFT

Tips SILICON CARBIDE REMOVABLE TIPS

Exhaust Inserts Quartz

Transfer Chamber

Wafer Sensing : OTF

Transfer chamber Lid Hoist :

Robot :HP ENP

Transfer Chamber Purge 15 SLM

Diagnostics and Control :

SecsTrac

Remotes :

System controller :

Controller Plexiglass Cover

Flash Memory Drive : SCSI

Vacuum pumps :

Loadlock chamber pump : Edwards QDP40

Process chamber pump : Edwards QDP80

System Monitors:

Monitor Type : CRT

(1) Monitor

Wall

(1) Table mount

Cable Lengths (Effective) :

Controller to Mainframe : 23 ft

Controller to Pump : 48 ft

Controller To TTW Monitor : 50 ft

Controller to table Mount Monitor : 24 ft

1995 vintage.

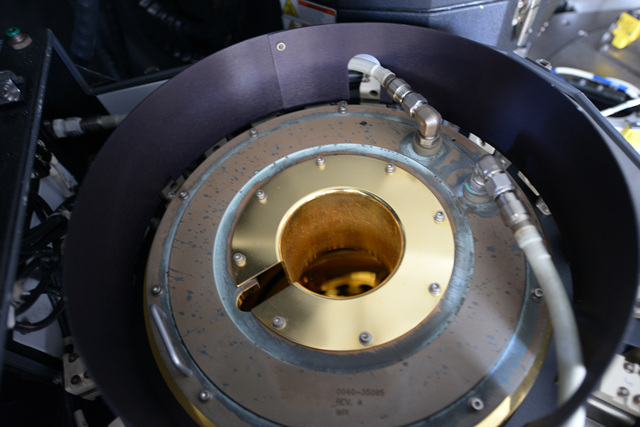

AMAT / APPLIED MATERIALS Centura Epi is a leading-edge multi-zone equipment for the deposition of epitaxial layers. This reactor uses a highly efficient design, thanks to its highly optimized injector, even heating zones, and low temperature coefficient of performance. AMAT Centura Epi features an advanced multi-zone injector, which helps to ensure the uniformity of the thick layers by using a diffusion controlled process. This injector has a high throughput and a low temperature coefficient of performance, making it highly efficient in its operations. The reactor has heating zones with an advanced thermal processing, which helps to provide an even and uniform heating of the substrate. This allows for uniformity of thermal layers, which helps to maintain the highest yields of epitaxial layers during the deposition process. APPLIED MATERIALS Centura Epi is designed to be highly reliable by incorporating a vacuum pump and a gas blower system. These systems help in controlling the vacuum pressure, as well as providing a steady flow of gas. This ensures a stable and consistent environment for the deposition process. The unit also includes several monitoring and control systems, such as flow rate, pressure, and temperature controls. These systems help to keep the process parameters consistent, ensuring high quality and reliable deposition of epitaxial layers. Centura Epi includes a digital interface for automated data collection, which helps in capturing and analyzing data from the deposition process. This data can be used to adjust the parameters of the machine, helping to optimize the results of the deposition process. AMAT / APPLIED MATERIALS Centura Epi is a high-performance tool designed to enable the deposition of uniform epitaxial layers. This reactor features a highly efficient design, thanks to its multi-zone injector, even heating zones, and low temperature coefficient of performance. Additionally, it also features a range of monitoring and control systems, which helps to ensure the uniformity, reliability, and quality of the deposition process.

There are no reviews yet