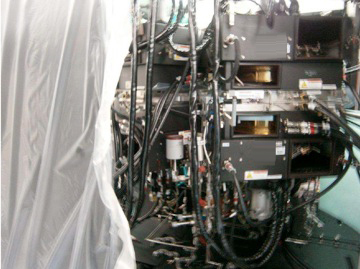

Used AMAT / APPLIED MATERIALS Centura HTF EPI #9045084 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9045084

System, 8"

(2) Process chambers:

Position A : RP Poly

Position B : RP Epi

Isolation valve

PCV wet cleaned

Rotation rev 4 with no wobbling kit

Upper and lower lamp modules

Dual manometer: 100, 1000Torr

Wide body loadlock mainframe:

SMIF option

Missing plastic door cover

Robot:

HP motor

Quartz blade reduced contact installed

Gas panel configuration: CCTP for HTF Centura EPI 01 with divert option

(3) Blowers: A, B, C

AC Rack:

Boards

HSMS

(2) Lamp drivers

Quartz parts:

EPI/POLY 2 Lower Dome 0200-35042

EPI/POLY 2 Upper Dome 0200-35007

EPI 2 Upper Liner 0200-35017

EPI 2 Lower Liner 0200-35023

EPI 4 Insert Quartz Inject 0200-35019

EPI 2 Baffle 0200-35020

EPI/POLY 4 Insert Quartz Exhaust 0200-35018

EPI/POLY 2 Wafer Lift Shaft 0200-35424

EPI 1 Pre-Heat Ring Toshiba 0200-35081

EPI 1 Susceptor Toshiba Non Center Post 0200-36727

EPI 1 Shaft Non Center Post 0200-00412

EPI 3 SiC Support Tips 0200-00207

EPI 3 Hollow Lift Pins (SiC) 0200-36642

POLY 1 Susceptor Support Shaft 0200-35573

POLY 1 Susceptor Xycarb 0200-35157

POLY 1 Preheat-Ring SGL 0200-35022

POLY 3 Lift Pins (Quartz) 0200-35207

EPI/POLY 2 Anti rotation pin 0200-03486

No process kit

No vacuum pumps

Crated and warehoused.

AMAT / APPLIED MATERIALS Centura HTF EPI (high-temperature rapid thermal flow) reactor is a semiconductor fabrication tool for processing substrates used in the production of integrated circuits (ICs). It is designed for high-efficiency process applications that require temperatures ranging from 500-900°C. This tool is a single-wafer process furnace which offers a range of user-defined processing parameters, including a patented thermal flow control to reduce process time. AMAT Centura HTF EPI provides enhanced uniformity of the substrate temperature across the entire wafer, while reducing processing time, thus making it an ideal choice for high-productivity IC manufacturing. APPLIED MATERIALS Centura HTF EPI is equipped with a modern microprocessor-based control equipment, to monitor and control the wafer temperature. It has an internal, customized gas-control module, which provides unlimited options for gas-mixing within the chamber. Centura HTF EPI also has a patented thermal flow control, which modulates the flow rate of the process gases to reduce the process time. This reactor is also equipped with a secondary heating system, enabling uniform and independent heating of the hot and cold chamber sections. AMAT / APPLIED MATERIALS Centura HTF EPI is a compact and energy-efficient unit, making it a reliable reactor for producing complex IC structures. With a capacity of 6-inch wafer per batch, AMAT Centura HTF EPI provides maximum throughput, while improving wafer uniformity and product yield, even at high temperatures. It also offers improved wafer contamination control and low-toxicity process chemicals. APPLIED MATERIALS Centura HTF EPI is designed with safety features such as, isolation gas pressure control valves and a vacuum purge feature, to reduce the risk of oxidation, contamination and electrical breakdown. Also, the machine's post-process cooling feature helps to minimize thermal ramping and thermal drift, improving process repeatability and reducing particle deposition on the wafer. By utilizing the most advanced technologies and modern control systems, Centura HTF EPI is designed to ensure efficient semiconductor processing with utmost safety. The high throughput and accurate control this reactor provides makes it the ideal choice for high-productivity IC manufacturing.

There are no reviews yet