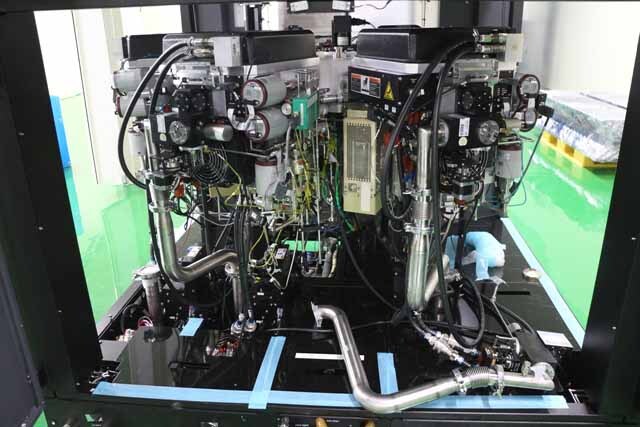

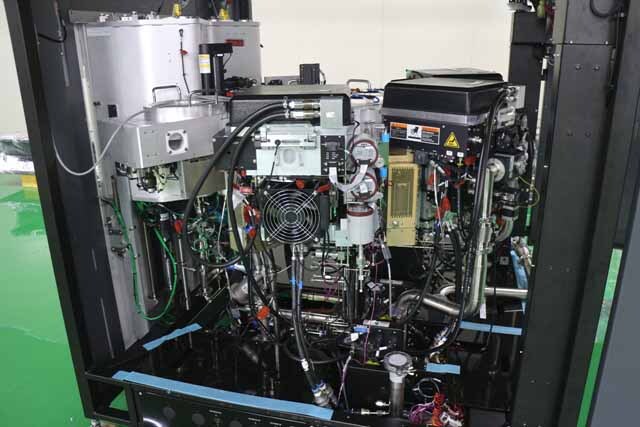

Used AMAT / APPLIED MATERIALS Centura I #9184826 for sale

URL successfully copied!

Tap to zoom

ID: 9184826

Wafer Size: 8"

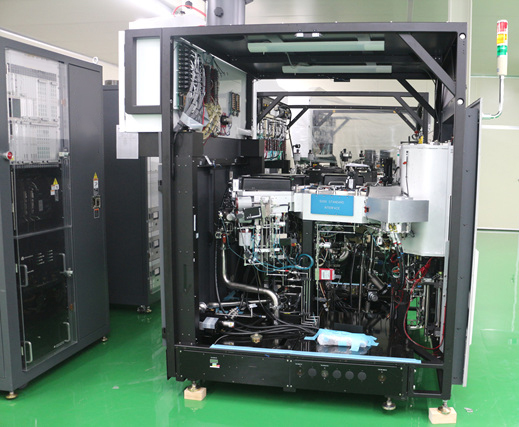

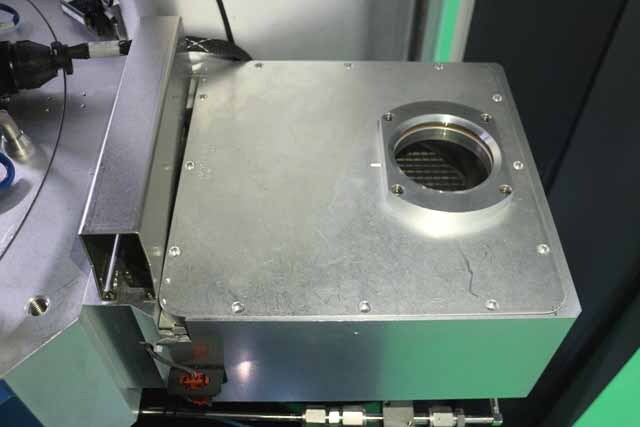

WCVD System, 8"

WxZ

(3) Chambers

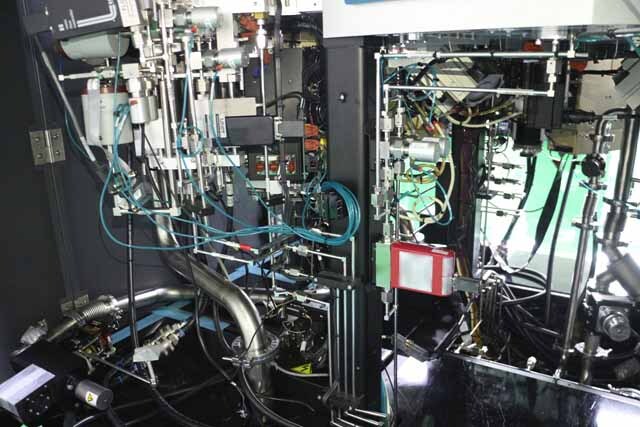

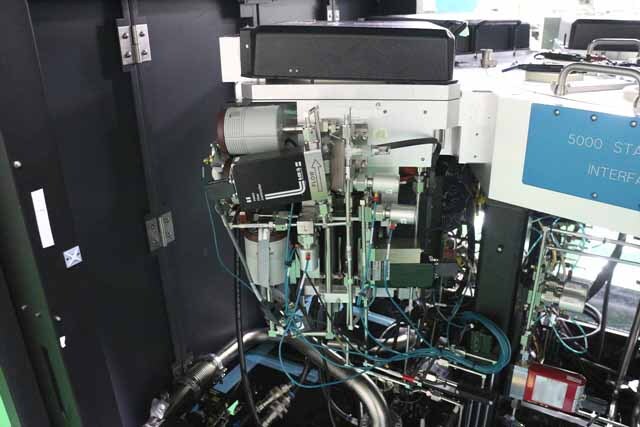

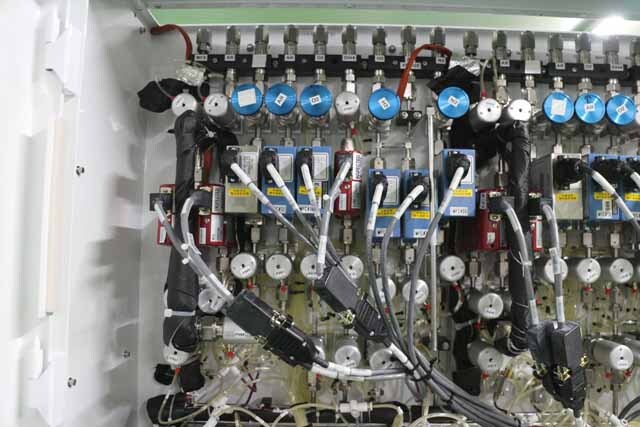

Main body

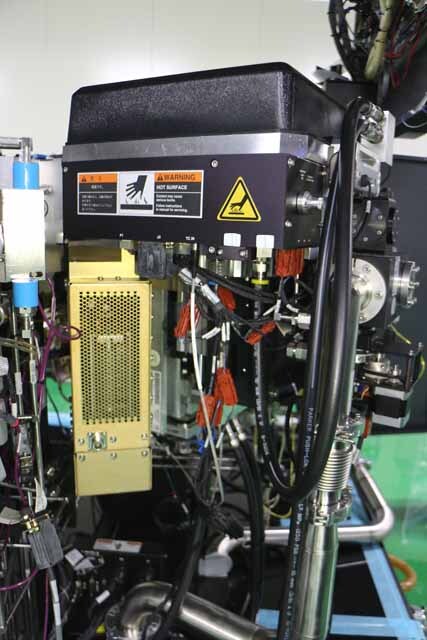

ENI Generator rack

Monitor rack

System controller

(4) Covers

(2) Cables

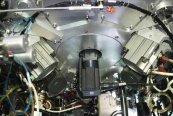

Mainframe: Centura I Phase I

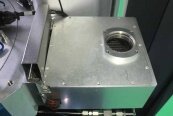

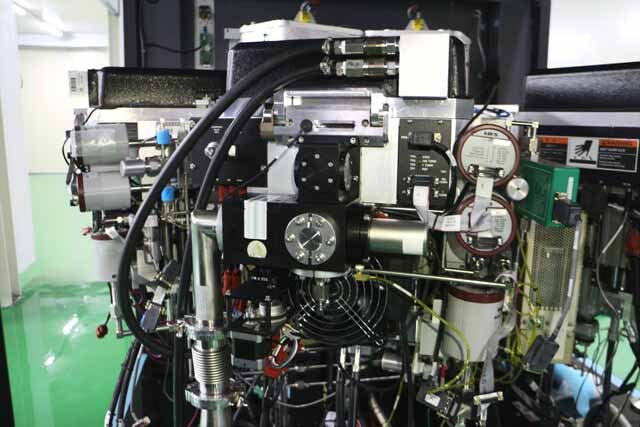

Chamber A:

Type: WXZ

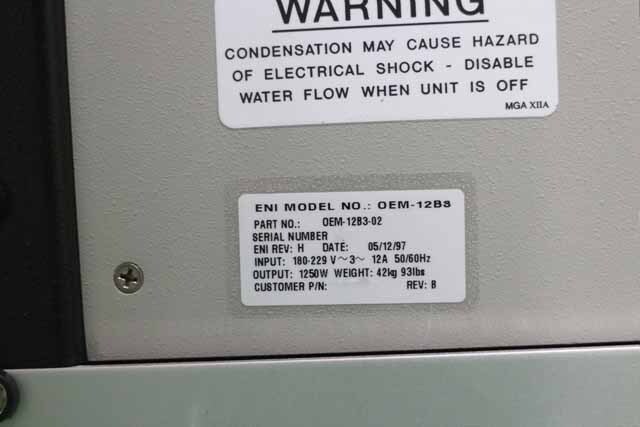

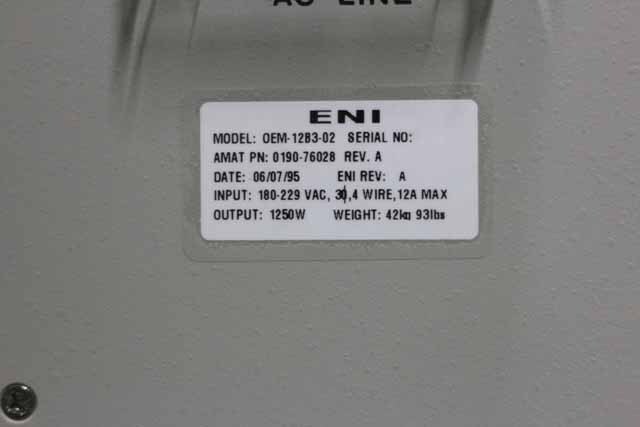

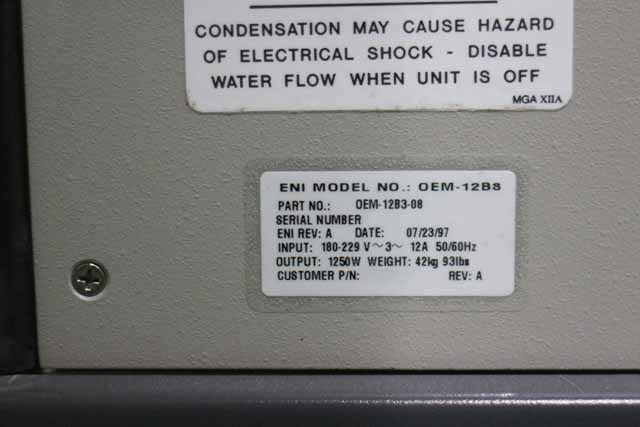

RF Generator: OEM-12B

RF Match: Phase IV

Process kit: 200mm

Heater: Ceramic

Back side baratron: MKS 100T

Purge MFC: AR 2000

Lid Assembly: STD

Process baratron:

MKS 100T

MKS 1T

Chamber B:

Type: WXZ

RF Generator: OEM-12B

RF Match: Phase IV

Process kit: 200mm JMF

Heater: Ceramic

Back side baratron: MKS 100T

Purge MFC: AR 2000

Lid Assembly: STD

Process baratron:

MKS 100T

MKS 1T

Chamber D:

Type: WXZ

RF Generator: OEM-12B

RF Match: Phase IV

Heater: Ceramic

Back side baratron: MKS 100T

Purge MFC: AR 2000

Lid Assembly: STD

Process baratron:

MKS 100T

MKS 1T

Chamber E: Single cool

Chamber F: Oriental

Robot: HP

Load lock: Wide body

Gas box: CI

No heat exchanger

Umbilical length:

CA Chamber A, B, C & D: 50 FT

Gas configuration:

Chamber A, B & D:

WF6 / 200

WF6 / 50

C2F6 / 500

AR / 3000

O2 / 1000

SiH4 / 300

H2 / 500

H2 / 2000

N2 / 300

Control rack:

Serial isolator

System reset

(2) Lk Det 1&2 / Conv/TC

No floppy disk drive

No hard disk drive

Chamber interfaces: A, B, D & E

Mainframe interface

Loadlock interface

Chamber A, B, D: DI/O 1&2

No chamber C: DI/O 1&2

Chamber E: DI/O

Synergy SBC

No controller, 486 V

No APC VME Seriplex PCB

SEI

Chamber A, B, D: AI/O

No chamber C AI/O

Mainframe AI/O

Chamber E/MF AI/O 2

(6) Mainframes DI/O

(3) Steppers

OMS.

AMAT / APPLIED MATERIALS Centura I is a compact, high-volume, high-performance chemical vapor deposition (CVD) reactor designed for single- or dual-chamber deposition of thin films of various materials. AMAT Centura I reactor is designed as a single-chamber equipment, with a closed, atmospheric-pressure reactor chamber. The system is powered by a powerful, variable-frequency induction heating unit, which is capable of achieving temperatures of up to 1,000°C. The metal vapor reactants are introduced into the reaction chamber through the top, while the substrates are loaded and unloaded from the front. APPLIED MATERIALS Centura I reactor is equipped with an RF generator, which provides a means of controlling the process in a variety of ways, including power control, temperature control, reactant flow rate control, and reactant mixture control. The enclosed deposition chamber is pressurized, permitting deposition of submicron thin films on a range of substrates, including metals and semiconductors. In addition, Centura I reactor features a variable-frequency power supply, permitting precise control of the process. AMAT / APPLIED MATERIALS Centura I reactor's enclosed deposition chamber is designed to minimize impurity exposure, offering improved film quality. The vacuum chamber is constructed from quartz, with an alumina liner, providing an inert atmosphere for the deposition process. The unit is finished in an extremely durable stainless steel, preventing contamination of the substrate, and is fitted with an optical window for monitoring the deposition process. AMAT Centura I is a cost-effective, high-performance CVD machine, which delivers reliable process control in deposition of high-quality thin films over a wide range of materials. The simple-to-operate tool is capable of consistently producing thin films with excellent durability and reliability, making it a popular choice for both prototyping and industrial production.

There are no reviews yet