Used AMAT / APPLIED MATERIALS Centura II DPS #115097 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 115097

Poly etch system

Wafer Shape: SNNF (Notch)

Centura II M/F:

Robot: HP+

Wafer on Blade Detect

Umbilicals :

Cntrl M/F: 40ft

Cntrl AC: 75ft

AC Rack M/F: 60ft

Pump M/F Intfc: 75ft

RF PS Chamber: 75ft

Facility Connections: M/F Rear

System AC / Controller:

66” Common Controller

System SW: Legacy E4.5

GEMS / SECS Interface

GEMS SW ver.: E4.5

Load Locks:

Narrow Body w/Tilt-out

25-Wafer Cassettes

Chambers:

Position Chamber Type

E Orienter (OA)

F Orienter (OA)

A DPS+ Poly

B DPS+ Poly

C -

D DPS+ Poly

Chamber A/B/D: DPS+ Poly

Pedestal Type: Ceramic ESC

Single zone independent He control

Endpoint Type: Monochromator

Chamber E: Orienter (OA), narrow hoop

Chamber F: Orienter (OA), narrow hoop

Heat Exchanger / Chiller:

H2000 DI EG

Fluid Type: 50/50 (water/glycol)

Power Requirements: V 208, 3-Phase, 4-Wire, Freq 50 / 60Hz

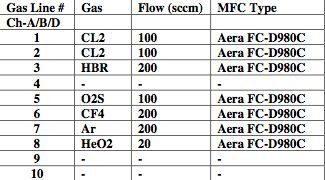

Gas Box Config:

Vertical height: 31”

(10) Gas line positions per Pallet

Valve Type: Veriflo

Filter Type: Millipore

Transducer Type: MKS

Controller Type: Standard (VME/VMEII)

Facility Line Connection: Single Line Drop, AC side, Bottom Fed.

AMAT / APPLIED MATERIALS Centura II DPS is a high-temperature chemical vapor deposition (CVD) reactor designed for advanced materials production. Using CVD technology, the Centura II allows for the deposition of thin films and layers with extreme precision and accuracy on to various substrates. The process is highly controllable and can be tailored to the desired application, making it an ideal choice for applications such as semiconductor fabrication, dielectric film layers, and metal interconnect layers. The Centura II is designed to be energy efficient and enable fast production rates. The CVD chamber and process are designed to reduce chemical byproducts, reducing time and cost of operation. This also helps to increase the lifetime of the parts and components used in the equipment. Its temperature control system allows for precise temperature control and guarantees process uniformity and repeatability. The Centura II offers a dynamic pressure scaling unit, allowing for the adjustment of in-situ chamber pressure. This ensures uniformity in reaction byproducts, and the ability to tune reactivity and deposition rates. The machine is equipped with multi-zone control, allowing for wider substrate temperature control, increasing uniformity and reducing defects in coating and film layers. The Centura II is also extremely versatile, with the ability to accommodate a variety of substrates, including silicon, quartz and quartz/silicon substrates. It also has the capability to work with a variety of precursors, including gaseous precursors and organometallic precursors. This enables it to be used in a variety of applications beyond semiconductor fabrication. The Centura II is also easy to operate and configure, with a simple user interface. This makes it easy to quickly add or change operating parameters, reducing the time and cost of training operators. Additionally, the tool also features advanced features such as excimer metallicseed and precursors delivery to increase accuracy and uniformity of layer deposition. The Centura II is a high-performing and reliable CVD asset designed for depositing thin film layers with extreme accuracy and precision. Its efficient design and versatility makes it an ideal choice for semiconductor fabrication, dielectric film layers, and metal interconnects. Its user-friendly interface and advanced features make it an excellent choice for any application.

There are no reviews yet