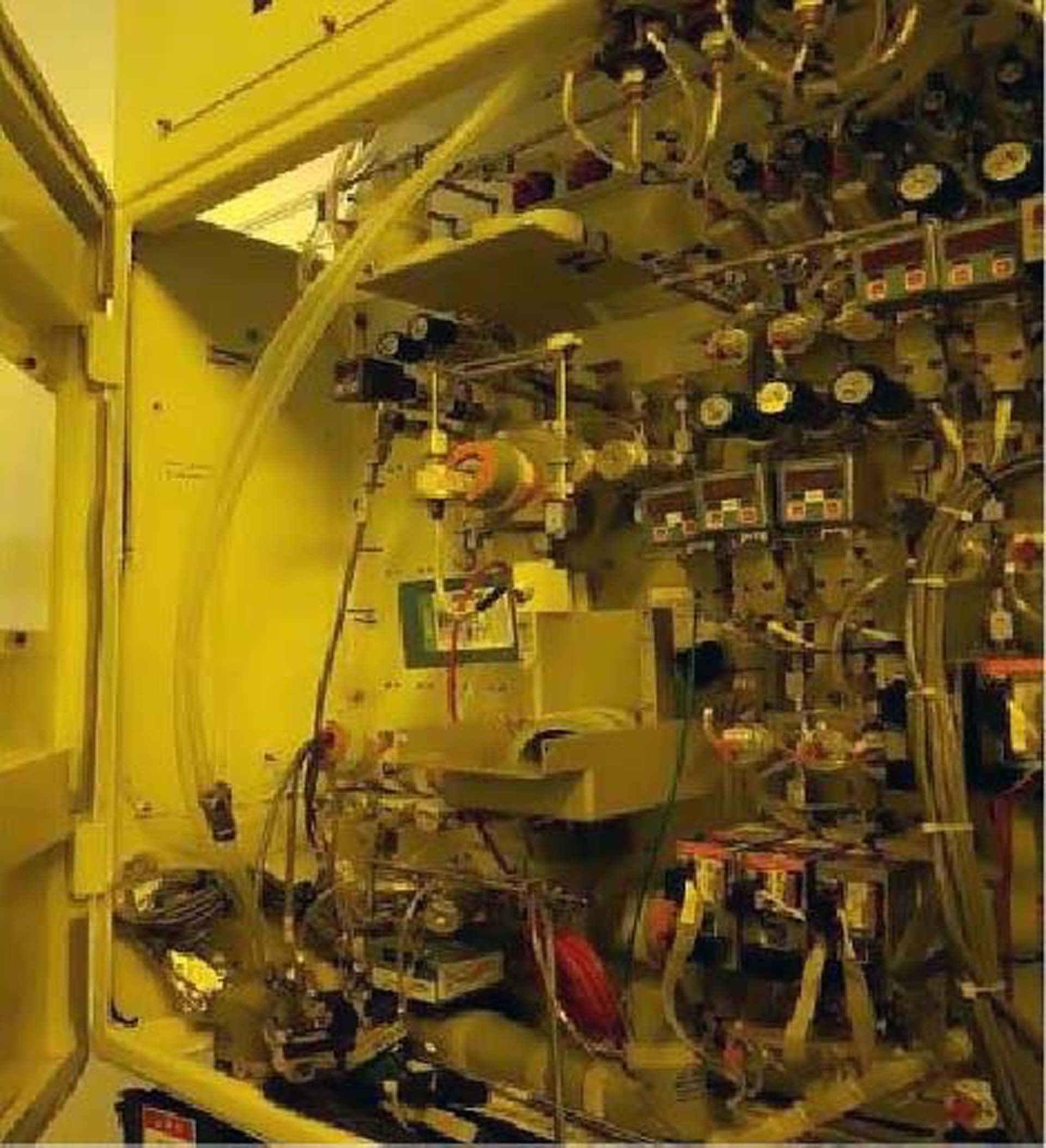

Used AMAT / APPLIED MATERIALS Centura II DPS+ #9253108 for sale

URL successfully copied!

Tap to zoom

ID: 9253108

Wafer Size: 8"

Vintage: 2000

Poly etcher, 8"

Loadlock: Narrow

Position A, B, C: Poly DPS+

Position F: Orienter

Chamber A, B, C:

Upper chamber body: Anodizing

Electrostatic chuck type: Ceramic

Turbo pump: SEIKO SEIKI STP-A2203

DTCU: E-EDTU

Endpoint missing

Bias generator: ENI ACG-6B

Bias match: 0010-36408

Source generator: ADVANCED ENERGY ALTAS 2012

Throttle valve and gate valve: VAT TGV

Gas box:

IHC Module: MKS 649

Transfer chamber manual lid hoist missing

Robot: VHP+

Umbrical cable: 50 ft

2000 vintage.

AMAT / APPLIED MATERIALS Centura II DPS+ Reactor is an enhanced plasma processing equipment specifically designed for high-volume semiconductor manufacturing and advanced application processes. It is a high-throughput, single-wafer dry etch tool for etching thin-film devices, such as polysilicon and silicon nitride. The reactor makes use of a proprietary Atmospheric Pressure Remote Plasma Source (APRPS), enabling the deposition of conformal films that can provide minimal deposition of extraneous material. AMAT Centura II DPS+ Reactor is suitable for a variety of etch and deposition processes that can achieve very high accuracy and repeatability. APPLIED MATERIALS Centura II DPS+ Reactor is a self-contained system, consisting of the process chamber, a gas distribution unit, and the APRPS source. The process chamber is made of durable stainless steel and is designed to provide highly precise, uniform wafer processing under precise control and monitoring. The gas distribution unit is used to deliver process gases, plasmas, and precursors to the wafer plane, allowing for a uniform plasma etch to be done over multiple wafers at a time. The APRPS source, also referred to as an "Atmospheric Pressure Self-purging Plasma Technology" or AP-SPT, is the driving force behind Centura II DPS+ Reactor. It consists of an advanced plasma source and can etch with either un-passivated or passivated wafers, while providing a precise etch profile that can be optimized to fit the particular process requirement. AMAT / APPLIED MATERIALS Centura II DPS+ Reactor offers a variety of process capabilities, such as time-based etch, reactive-ion etch (RIE), and anisotropic and isotropic dry etch. It can also be optimized for deep reactive-ion etch (DRIE) processes that enable ultra-shallow trench etching. It also features a sophisticated temperature monitoring unit, which helps provide optimal operational performance and productivity. Furthermore, it has advanced diagnostics, such as optical feedback and advanced temperature control, making it easier to adjust and maintain process parameters. In addition, AMAT Centura II DPS+ Reactor provides electrical feed-throughs to enable stable, high-power wafer processing with low voltage ranges. Overall, APPLIED MATERIALS Centura II DPS+ Reactor is a versatile and powerful semiconductor processing machine that enables precise, highly repeatable etch and deposition processes. It is an excellent choice for manufacturers who require reliable, high-throughput tools for advanced application processes. Its wide range of features, advanced diagnostics and temperature monitoring systems, and supportive technical services make it ideal for a variety of processing needs.

There are no reviews yet