Used AMAT / APPLIED MATERIALS Centura II eMax #9259043 for sale

URL successfully copied!

Tap to zoom

ID: 9259043

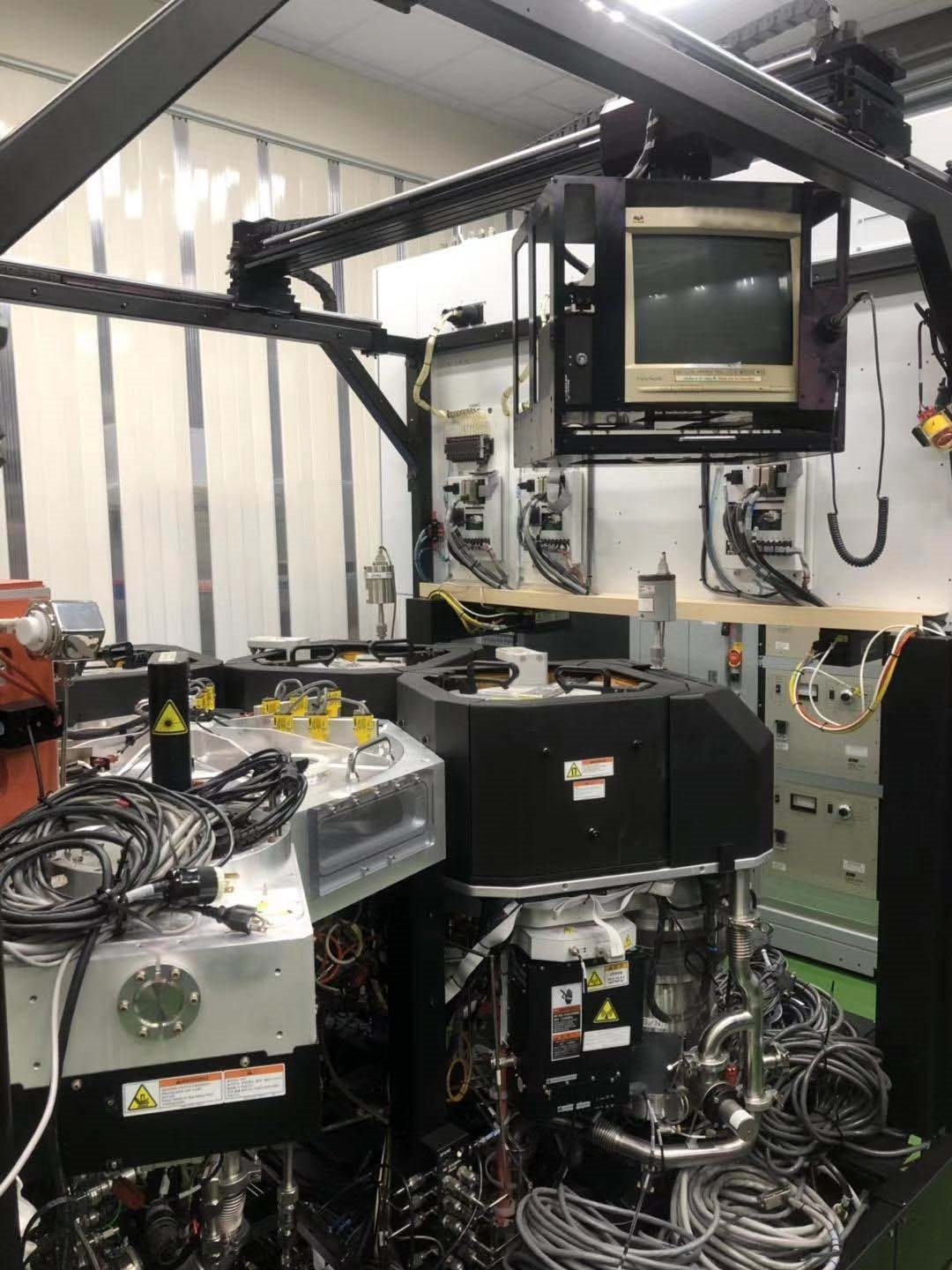

Wafer Size: 8"

Oxide etcher, 8"

Gas panel type: VME2

Gas panel exhaust: Top feed

Chamber F: Orientor

Metal robot blade

Wafer type: Flat

Wafer sensors: Wafer slide

Robot type: VHP

Loadlock type: Narrow body with tilt out

System umbilicals: 75 ft

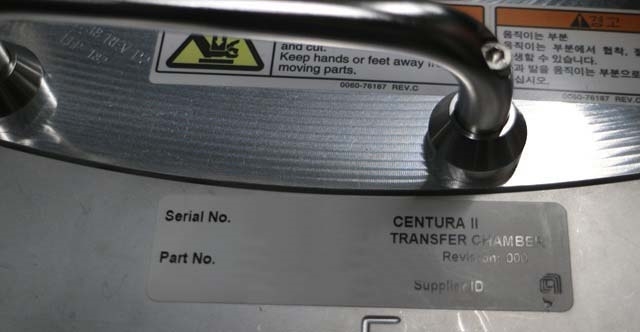

Mainframe: Centura II

Loadlock slit valves: Viton

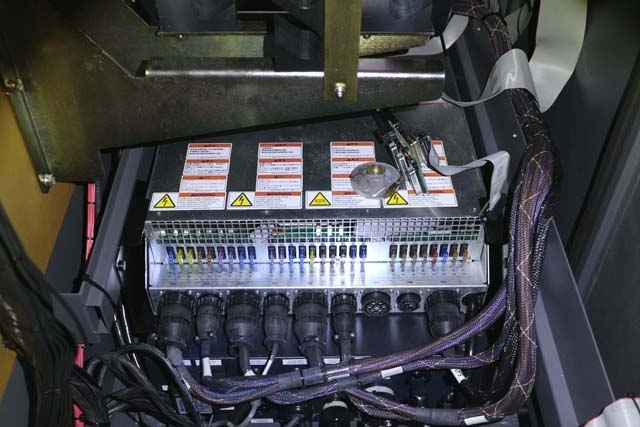

VME Rack

Chase CRT

No subfab CRT

No OTF

Chamber A, B and C:

Chamber type: E-Max

Process: Oxide

Dual manometer: 1 Torr

Slit valve and chamber O-ring: Viton

Lid type: Dual gas feed-thru

Throttle valve, P/N: 3930-00015

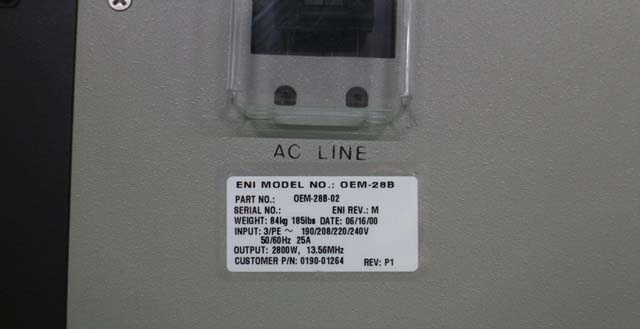

ENI 28B LF Generator

RF Match, P/N: 0010-30686

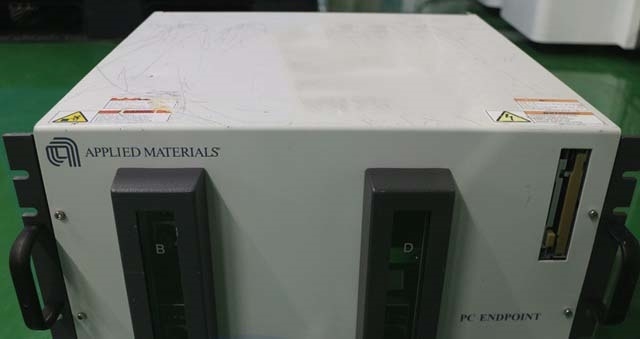

Endpoint system

Chamber clamps

Process kit type: ESC

ATH 1600M Turbo pump

No heated valve stack

Gas valves: Veriflo

Chamber A gases:

Gas / MFC Size / Gas name / MFC Type

Gas 1 / 50 sccm / C4F6 / BROOKS

Gas 2 / 100 sccm / CH2F2 / BROOKS

Gas 3 / 500 sccm / CO / BROOKS

Gas 4 / 50 sccm / C4F8 / BROOKS

Gas 5 / 1 slm / AR / BROOKS

Gas 6 / 20 sccm / O2 / Unti 8160

Gas 7 / 300 sccm / O2 / BROOKS

Gas 8 / 100 sccm / CF4 / BROOKS

Gas 9 / 100 sccm / CHF3 / BROOKS

Gas 9 / 200 sccm / ARSS / BROOKS

Chamber B gases:

Gas / MFC Size / Gas name / MFC Type

Gas 1 / 50 sccm / C4F6 / BROOKS

Gas 2 / 100 sccm / CH2F2 / BROOKS

Gas 3 / 500 sccm / CO / BROOKS

Gas 4 / 50 sccm / C4F8 / BROOKS

Gas 5 / 1 slm / AR / BROOKS

Gas 6 / 20 sccm / O2 / BROOKS

Gas 7 / 300 sccm / O2 / BROOKS

Gas 8 / 100 sccm / CF4 / BROOKS

Gas 9 / 20 sccm / CHF3 / BROOKS

Gas 10 / 200 sccm / ARSS / BROOKS

Chamber C gases:

Gas / MFC Size / Gas name / MFC Type

Gas 1 / 50 sccm / C4F6 / BROOKS

Gas 2 / 100 sccm / CH2F2 / BROOKS

Gas 3 / 500 sccm / CO / BROOKS

Gas 4 / 50 sccm / C4F8 / BROOKS

Gas 5 / 1 slm / AR / BROOKS

Gas 6 / 20 sccm / O2 / Unti 1660

Gas 7 / 300 sccm / O2 / BROOKS

Gas 8 / 100 sccm / CF4 / BROOKS

Gas 9 / 20 sccm / CHF3 / BROOKS

Gas 10 / 200 sccm / ARSS / BROOKS

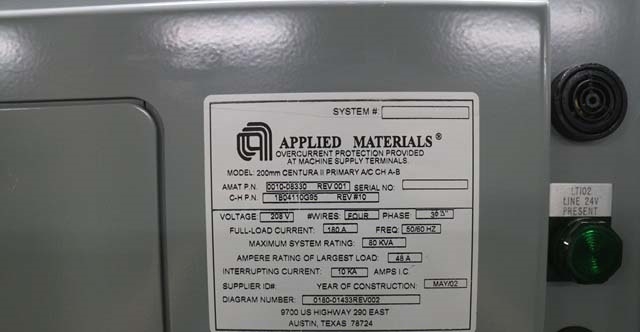

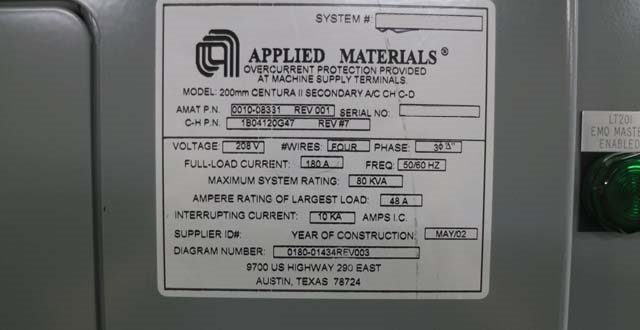

Power supply: 208 VAC, 180 Amps, 50/60 Hz.

AMAT / APPLIED MATERIALS Centura II eMax is an advanced reactive ion etching equipment designed for semiconductor fabrication processes. The system uses inductively coupled plasma (ICP) technology to enable high-precision, low-damage processing of a wide range of materials. It offers highly controllable etch depths, as well as excellent repeatability, to help ensure quality and consistency in the fabrication of advanced semiconductor devices. AMAT Centura II eMax integrates several advanced technologies to provide cutting-edge etching capability. These include an advanced ICP source with high power densities and frequency agility, a positional stage with direct control of the etching end-effector, high resolution image processing, and a Windows-based process control software suite. The integration of these components provides a fully-automated etching solution with a wide range of capabilities. APPLIED MATERIALS Centura II eMax is designed to be an economical option for semiconductor production. Its small footprint and high processing speed combine to make it a cost-effective choice for high volume fabrication environments. Additionally, the unit requires minimal maintenance and offers a range of features for further reducing operating costs. The machine's ICP source delivers high power densities and wide frequency agility to facilitate precise etch depth control, as well as excellent repeatability for better reliability and quality control. Additionally, the Direct Digital Control (DDC) stage provides highly precise motion and positioning for increased control over the etching process. This helps ensure high quality and precision etching. Centura II eMax also includes a high resolution image processing tool to further aid in etch quality control, as well as a Windows-based process control software suite to provide users with powerful and easy-to-use process control. AMAT / APPLIED MATERIALS Centura II eMax is a powerful and durable etching asset that is capable of providing high-precision etching to advanced semiconductor materials. Its advanced technologies provide excellent control over the etching process, while its economical design and easy-to-use process control software help streamline and reduce the total cost of ownership.

There are no reviews yet