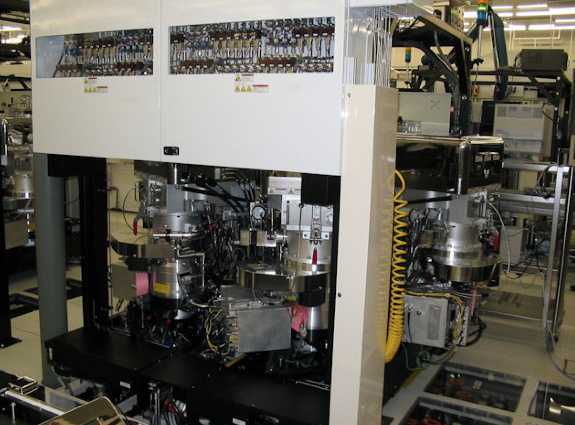

Used AMAT / APPLIED MATERIALS Centura II IPS #115406 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 115406

Vintage: 2001

dielectric etch system

Install type: Stand Alone

CE Marked

Cassette Interface:

(2) Bolt-on Asyst LPT-2200

Centura II M/F

Robot: HP+ Extended Reach w/Single Blade (Ceramic)

Manual Lid Lift Assist

Load Locks:

Wide-Body w/Auto-Rotation for cassettes

Enhanced wafer mapping (fast-detect)

Chambers:

Ch-E: Blank

Ch-F: Standard Orienter

Ch-A, B, C& D: IPS

ESC Pedestal w/Helium Cooling

RF Generators: Astex Model 80-510-HP

Turbo: Leybold MAG2010C

Throttle Valve: NorCal

H.O.T. Endpoint

Chiller Dome: Bay Voltex LT-HRE

Chiller Cathode: Bay Voltex LT-HRE

Gas Box Config (Pallet modules):

Bottom Feed SLD Gas Panel

Bottom Exhaust w/Vane Switch

GP Controller: VME II

75 feet Umbilicals

System Controller:

66” IPS Controller

Bottom Feed AC, Top Exhaust

30mA GFI

AC Rack:

Main AC Rack IPS Position AB

Secondary AC Rack IPS Position CD

2001 vintage

As-is, where-is.

AMAT / APPLIED MATERIALS Centura II IPS is an advanced multi-wafer manufacturing reactor equipment used in semiconductor manufacturing processes. This reactor system can perform high-temperature and high-pressure reactive ion etching (RIE), plasma-enhanced chemical vapor deposition (PECVD), and other advanced manufacturing processes. The unit is capable of processing up to 200 wafers per hour in a wide range of wafer sizes up to 8 inches. The machine is designed to provide a safe and cost-effective production process, while maintaining precision and repeatability. AMAT Centura II IPS is equipped with a unique IPS chamber that has two independent process zones, allowing users to independently control the gas flow and temperature in each of these chambers. The IPs chamber also offers superior temperature uniformity over the entire chamber, resulting in more uniform processing results. The reactor also features a large chamber-keepout plate, which allows for larger and more complex design rules. The tool also utilizes a high-voltage power supply, enabling faster reactive ion etching. The asset can handle a variety of processes, including etching, deposition, planarization, and several other process-related tasks. The model can also process a variety of materials, such as polysilicon, poly-SiO2, poly-SiN, and many other materials. The equipment also features a range of safety features, such as redundant safety shutters, interlock valves, and explosion-proof seals. The system is equipped with advanced software and electronics that enable greater control over the reactor environment, enabling high repeatability, accuracy, and quality. The unit also utilizes predictive analytics, allowing for the prediction of process defects and the rejection of wafers before saturation occurs. In conclusion, APPLIED MATERIALS Centura II IPS is a highly advanced and extremely efficient multi-wafer manufacturing reactor machine. It is capable of processing up to 200 wafers per hour, while maintaining a high level of accuracy and repeatability. The unique IPS chamber and other safety features make the tool safe and cost-effective. The advanced software and electronics offer greater control over the reactor environment, enabling higher yields and fewer disruptions.

There are no reviews yet