Used AMAT / APPLIED MATERIALS Centura II IPS #115471 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 115471

Vintage: 2001

Dielectric etcher

Install type: Stand Alone

CE Marked

Cassette Interface:

(2) Bolt-on Asyst LPT-2200

Centura II M / F

Robot: HP+ Extended Reach w/Single Blade (Ceramic)

Manual Lid Lift Assist

Load Locks:

Wide-Body w/ Auto-Rotation for cassettes

Enhanced wafer mapping (fast-detect)

Chambers:

Ch-E: Blank

Ch-F: Standard Orienter

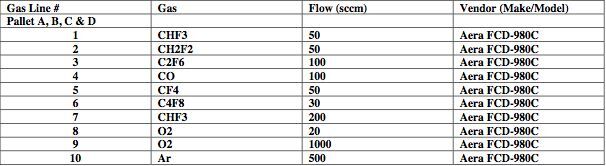

Ch-A, B, C& D: IPS

ESC Pedestal with Helium Cooling

RF Generators: Astex Model 80-510-HP

Turbo: Leybold MAG2010C

Throttle Valve: NorCal

H.O.T. Endpoint

Chiller Dome: Bay Voltex LT-HRE

Chiller Cathode: Bay Voltex LT-HRE

Gas Box Config (Pallet modules):

Bottom Feed SLD Gas Panel

Bottom Exhaust w/ Vane switch

GP Controller: VME II

75 feet umbilicals

System controller:

66” IPS controller

Bottom Feed AC, top exhaust

30mA GFI

AC Rack:

Main AC Rack IPS Position AB

Secondary AC rack IPS Position CD

2001 vintage

As-is, where-is.

AMAT / APPLIED MATERIALS Centura II IPS reactor is a highly reliable, long-life ion implant equipment that is used in the semiconductor manufacturing process. It is designed specifically for p-type and n-type layers at higher temperatures, making it ideal for VLSI applications. The system uses a single beam configuration for precision ions implantation. It has minimal arcing even at higher beam energies and minimal sputter erosion to minimize contaminants. This allows the implantation of such thin layers for MOSFETs, DRAMs, and other very large integrated circuits. AMAT Centura II IPS reactor uses a precision high-voltage modulator to control the voltage, current, and timing of the ion beam. This unit helps prevent thermal impact which can cause device leakage. The higher temperatures allow for more efficient use of beam energy to achieve a given number of dopant atoms per process step. The full-containment vacuum chamber is large enough to allow for both vertical and horizontal depositions and provides superior interface integrity. The machine has a modular design that provides flexibility while maintaining a small footprint. The tool includes a superior beam forming optics package, sample holders and feedthroughs, and the ion source. The ion source uses advanced magnetics and extraction optics to maintain a stable beam profile and beam energy, ensuring the highest repeatability in the desired process density. The robust design of the asset also utilizes advanced interlocks and environmental control for safe operation. APPLIED MATERIALS Centura II IPS reactor features three standard power supplies that provide adjustable ion beam voltage, beam current, and beam pulse width to enable complex implants across wafer surfaces. The reactor can operate at up to 70 kV and has an adjustable beam current range from 0.1 mAmp up to 1 Amp. The model has an integrated temperature control equipment that can reach and maintain temperatures up to 530°C. This allows for dynamic control of the implanted species in order to achieve the desired results for aggressive implants and shallow junction depth profiles. Centura II IPS reactor is a highly advanced system that provides superior levels of performance and cost effectiveness. It is a reliable and cost-effective solution that is well-suited to meet the challenges facing semiconductor manufacturers. It is an excellent choice for ion implantation applications that require high accuracy and repeatability.

There are no reviews yet