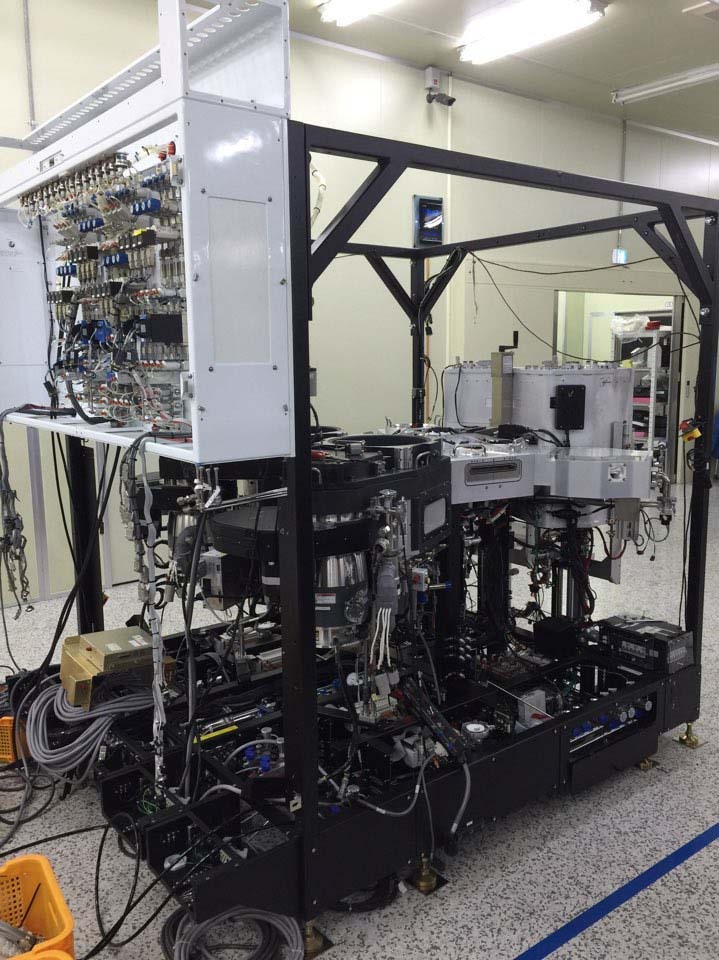

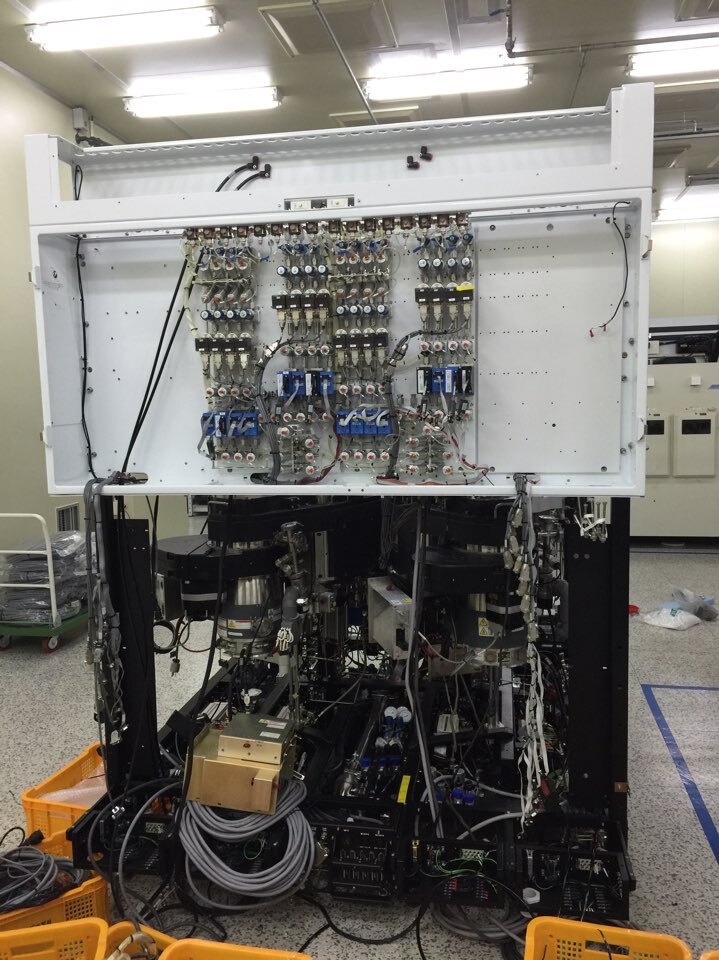

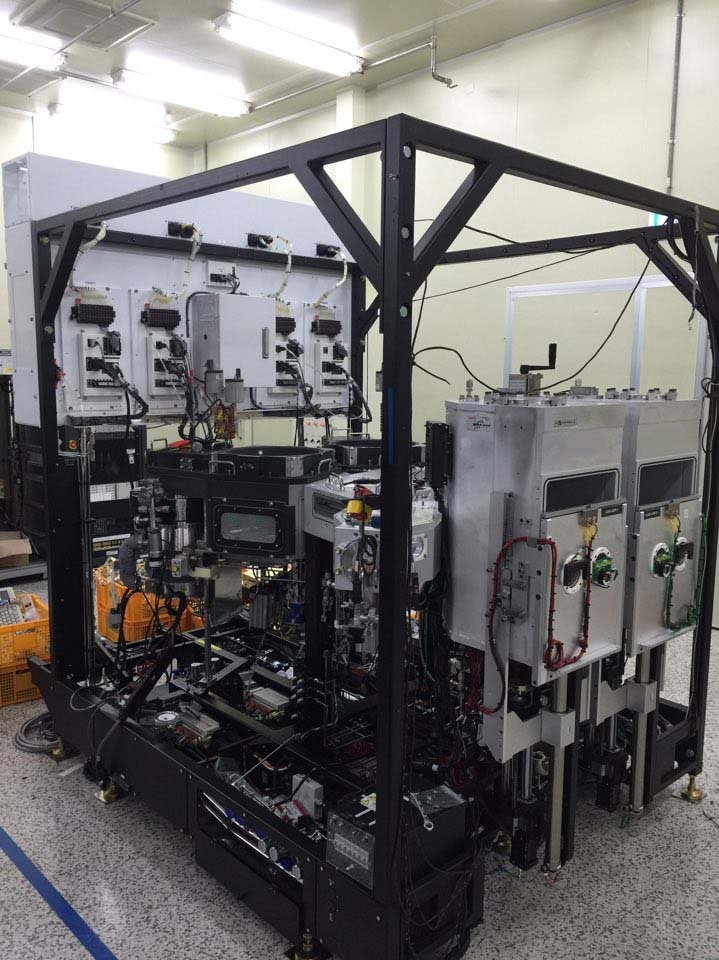

Used AMAT / APPLIED MATERIALS Centura II #9139418 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS Centura II reactor is an industry-leading diffusion/oxidation furnace designed for use in the production of high-quality semiconductor wafers. The equipment utilizes advanced heating and cooling technology to create optimal conditions for achieving desired process results. The system is designed to facilitate maximum throughput by supporting semiconductor production at levels up to 500W/square centimeter. AMAT Centura II reactor features a graphite-encapsulated crucible, allowing for uniform heating and cooling during processing. This design also helps maintain a safe environment due to the cooling unit's ability to quickly reduce temperature if a fault occurs. The crucible is capable of withstanding temperatures up to 1500°C for up to 12 hours. Advanced technology employed by APPLIED MATERIALS CENTURA-II reactor includes a proprietary process control machine. This tool allows for precise temperature control as well as adaptability to a wide range of available wafer sizes. Furthermore, it is also easy to interface with other existing process tools. This ensures that all process steps are accurately monitored and controlled. The substrate support logic built into Centura II reactor further contributes to uniform wafer temperature control. This helps ensure that incoming substrates are evenly exposed to process conditions. Using a CENTURA-II reactor also means that chip manufacturers are not limited to a particular process. It supports diffusion, oxidation, and other related processes with good repeatability and reproducibility. Each product has been subject to rigorous testing, ensuring that users can confidently depend on the asset to produce quality parts. AMAT CENTURA-II reactor is an important tool for semiconductor manufacturing. Its advanced technologies, robust construction, and reliability make it an ideal choice for chip producers that require high throughput and consistent results. It is well-suited for a wide range of application requirements and may be easily incorporated into existing semiconductor manufacturing processes.

There are no reviews yet