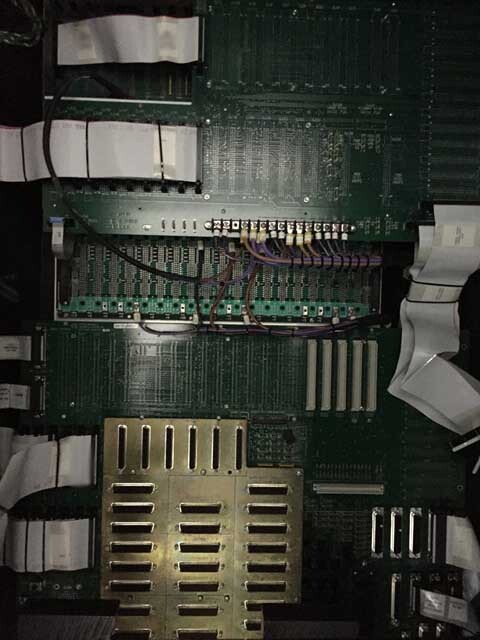

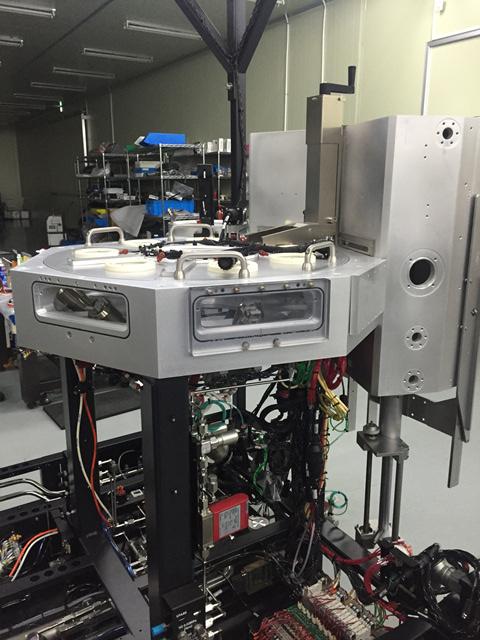

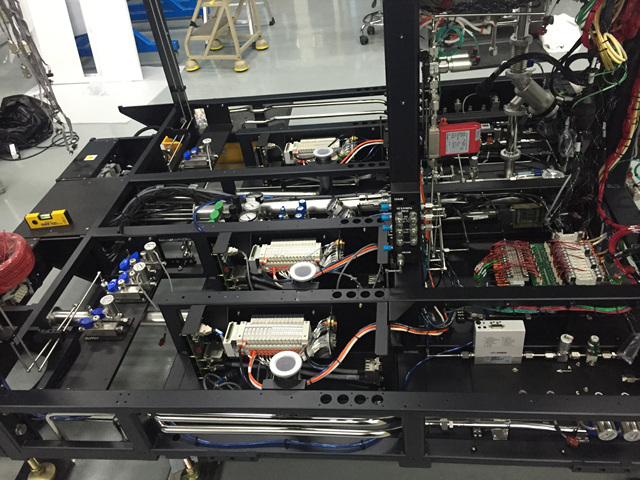

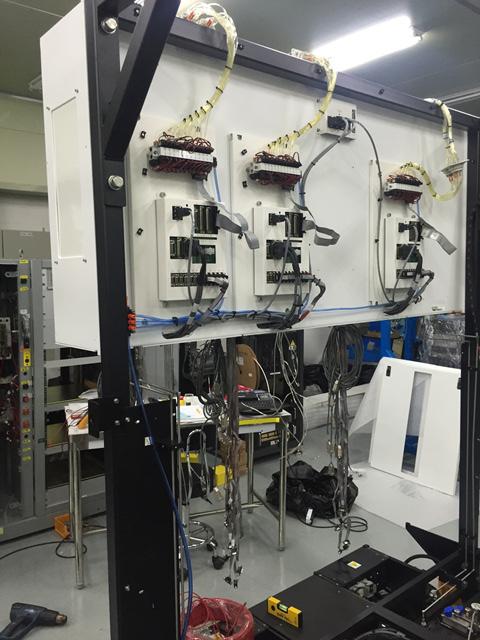

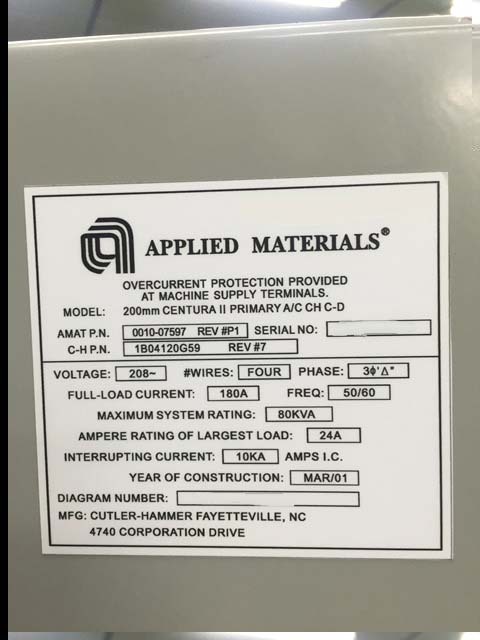

Used AMAT / APPLIED MATERIALS Centura II #9140763 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS Centura II is a semiconductor substrate processing reactor used in the fabrication of Integrated Circuits (ICs) for high volume manufacturing. It is an advanced version of the original Centura Reactor. AMAT Centura II is a cluster-type equipment, equipped with four independent load-lock chambersand two process chambers. The load-locks are used to introduce and remove substrates from the reactor. The load-locks use a knife-edge edge gate valve and provide vacuum isolation of the process chamber while keeping the process ambient clean and preventing contamination. This ensures a high level of environmental control within the process chambers. The process chambers feature a load-monitoring system which records all process related data, including temperature and pressure data during each cycle. This data is used to monitor and optimize the overall performance of the reactor. APPLIED MATERIALS CENTURA-II reactor is equipped with an ultra-thin film deposition chamber which can produce silicon oxide, silicon nitride, and many other dielectric materials used in the fabrication of ICs. The deposition chamber is equipped with a high-purity gas feed unit and an uniform shower head for sustained high-temperature deposition. APPLIED MATERIALS Centura II is also equipped with an etching chamber for reactive ion etching (RIE) which removes unwanted material from the process chamber. This chamber is equipped with a high-velocity plasma source and a magnetic field generator to generate uniform etching. The magnetic field is used to enhance the uniformity across the substrate surface and improve etching rate and uniformity. The chamber is also equipped with a high-power RF source to provide stable plasma uniformity and uniform etching. CENTURA-II reactor is also equipped with Novellus' proprietary Off-Platform Purge (OPP) machine. The OPP tool consists of a fully integrated chamber which eliminates the need for an additional heated transfer chamber. This advanced chamber has integrated gas jets and a gas recirculation asset which together serves to remove unwanted by-products from the chamber and reduce parasitic losses. AMAT / APPLIED MATERIALS CENTURA-II is specifically designed for high-volume production, and is capable of operating at high temperatures and pressures with minimum downtime. It is engineered with advanced control and diagnostics systems, making it a highly reliable and cost-effective substrate processing reactor.

There are no reviews yet