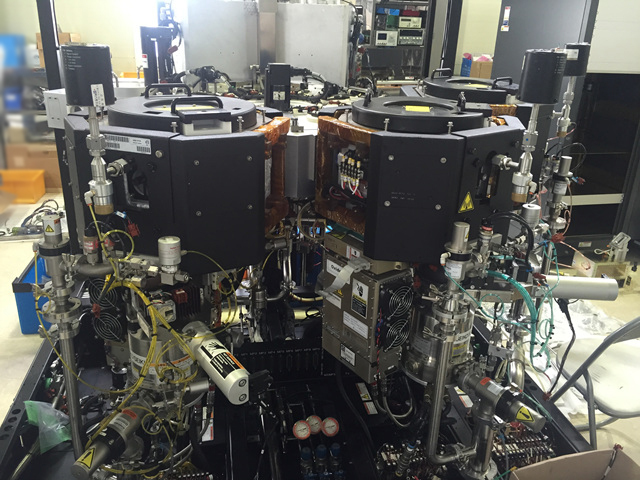

Used AMAT / APPLIED MATERIALS Centura MxP+ #9115015 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9115015

Poly etcher, 8"

Wafer shape: JMF flat

208 V, 400A, 60 Hz

Centura type: Centura 1

No SMIF interface

Chamber A: MXP+

Chamber B: MXP+

Chamber C: MXP+

Chamber D: Empty

Chamber E: Empty

Chamber F: Orient

Buff robot type: HP, metal blade

Narrow body loadlock

Standard Wafer sensor

Water detector alarm

Smoke detector alarm

Monitor & EDP monitor: Wall mount

AC Rack types: Phase 1 AC Rack

MF Facilities: Bottom

EMO's: Turn to release

Control rack type: Phase 1 controller

Chamber A: MXP+

Polymide ESC

MKS640 IHC

1 Torr manometer

Quick release lid

Vitron slit valve o-ring

Standard bias RF match

OEM 12B RF gen bias

No Autobias

Monochrometer endpoint system

ENDP30 endpoint software

SEIKO SEIKI 301 turbo pump

Magnet driver full installed

Chamber pump not included

Simply cathode type

Butterfly throttle valve

Vat gate valve

Process kit not included

Gas 1: CF4, 100, STEC SEC-4400MC

Gas 2: CHF3, 300, STEC SEC-4400MC

Gas 3: O2, 50, STEC SEC-4400MC

Gas 4: O2, 200, STEC SEC-4400MC

Gas 5: AR, 100, STEC SEC-4400MC

Gas 6: N2, 100, STEC SEC-4400MC

Chamber B: MXP+

Polymide ESC

MKS640 IHC

1 Torr manometer

Quick release lid

Vitron slit valve o-ring

Standard bias RF match

OEM 12B RF gen bias

No Autobias

Monochrometer endpoint system

ENDP30 endpoint software

SEIKO SEIKI 301 turbo pump

Magnet driver full installed

Chamber pump not included

Simply cathode type

Butterfly throttle valve

Vat gate valve

Process kit not included

Gas 1: CF4, 100, STEC SEC-4400MC

Gas 2: CHF3, 300, STEC SEC-4400MC

Gas 3: O2, 50, STEC SEC-4400MC

Gas 4: O2, 200, STEC SEC-4400MC

Gas 5: AR, 100, STEC SEC-4400MC

Gas 6: N2, 100, STEC SEC-4400MC

Chamber C: MXP+

Polymide ESC

MKS640 IHC

1 Torr manometer

Quick release lid

Vitron slit valve o-ring

High efficiency bias RF match

OEM 12B RF gen bias

No Autobias

Monochrometer endpoint system

ENDP30 endpoint software

SEIKO SEIKI 301 turbo pump

Magnet driver full installed

Chamber pump not included

Simply cathode type

Butterfly throttle valve

Vat gate valve

Process kit not included

Gas 1: CF4, 100, STEC SEC-4400MC

Gas 2: CHF3, 300, STEC SEC-4400MC

Gas 3: O2, 50, STEC SEC-4400MC

Gas 4: O2, 200, STEC SEC-4400MC

Gas 5: AR, 100, STEC SEC-4400MC

Gas 6: N2, 100, STEC SEC-4400MC

Gas delivery options:

MFC maker: STEC

Transducer displays: core tool

MOTT filter

Regulator: core tool

Transducer: core tool

Valve: core tool

Gas connection: Sing line drop

Gas line feed side: AC side

Gas line feed direction: bottom

Exhaust: Top

Exhaust feed side: BD side

Chiller:

Heat exchanger for cathode: ETC

Heat exchanger for wall: ETC

(2) Total chiller

W/ RS-485 interface

Chiller valve connections: Manifold

Generator rack valve connection: Manifold

Valve connections: 1 each for wall and cathode per chamber (A, B, C)

Chiller hose size: 3/8 Quick.

AMAT / APPLIED MATERIALS Centura MxP+ is an advanced semiconductor reactor that is designed for dual-metal etching and ion implantation applications. It features an integrated vacuum equipment, a chemical preconditioning system, and advanced digital controller and programming capabilities, all of which give users the flexibility to customize their process recipes for various uses. The unit utilizes a multi-zone, reactive gas distribution machine that allows for uniform delivery of reactive gases and good control of the process. Additionally, the tool includes a unique set of removable chambers, providing the ability to customize processes. The primary feature that sets AMAT Centura MxP+ apart from other reactors is its advanced multi-zone reactive gas distribution asset. This model allows for a uniform delivery of reactive gases, allowing for precise control of the process. The multi-zone gas distribution equipment is facilitated by a set of high-pressure nozzles connected to multiple gas lines, which signal the gases to be released into the reaction chamber. The gases can then be mixed for desired effects, allowing a user to customize their process for optimal results. The nozzles are built out of high-performance materials, ensuring a long operating life. APPLIED MATERIALS Centura MxP+ system also includes a unique set of removable chambers, giving users the ability to customize processes or explore new parameters. Additionally, the reactor's digital controller offers best-in-class precision and programming capabilities. The advanced digital controller utilizes an array of sensors and feedback points to monitor and control the chamber's parameters throughout the process, resulting in a more detailed and accurate process than with manual control. The integrated vacuum unit on Centura MxP+ provides a steady and reliable vacuum pressure to maintain a precise and consistent reaction within the chamber. This integrated machine also utilizes a separate purging tool to eliminate any residual gases in the chamber. Furthermore, the asset utilizes a chemical preconditioning model, which allows for the introduction of fresh reactive gases with each batch. AMAT / APPLIED MATERIALS Centura MxP+ is designed and manufactured to meet the highest standards for quality and performance. It is built out of high-quality materials, such as stainless steel and aluminum, ensuring that it is robust and long-lasting. Additionally, the equipment has been designed to be easily maintained and serviced, offering users an easy and cost-effective way to keep their systems running in top condition. AMAT Centura MxP+ is an advanced, multi-zone, digital controller-enabled reactor that is designed for dual-metal etching and ion implantation applications. Its integrated vacuum, chemical preconditioning, and gas distribution systems allow for precise and uniform process control and customization. Additionally, its removable chambers and digital programming capabilities give users the ability to customize their process recipes to their needs. Due to its quality construction and advanced features, APPLIED MATERIALS Centura MxP+ is an excellent choice for scientists and engineers who need reliable and precise results.

There are no reviews yet