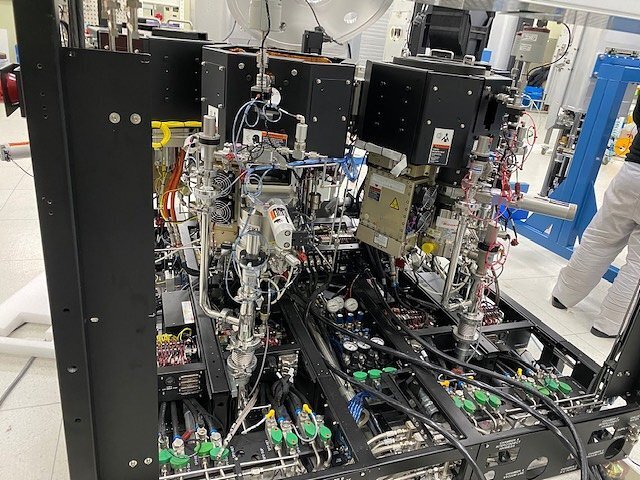

Used AMAT / APPLIED MATERIALS Centura MxP+ #9351620 for sale

URL successfully copied!

Tap to zoom

ID: 9351620

Wafer Size: 8"

Vintage: 1997

Poly etcher, 8"

Wafer shape: SNNF (Notch)

Type: Centura 1 P-2

No SMIF interface

Chamber A, B, C and D: MxP+

Buff robot type: HP

Loadlock: Wide body

Metal buff robot blade

Water detector: Alarm

Wafer sensor: Standard

Smoke detector: Alarm

EMO

AC Rack: Single phase

Monitor and EDP monitor: Standalone

Controller rack: Single phase

Umbilical cables:

Controller to mainframe: 25 ft

Controller to AC rack: 25 ft

RF to chamber coaxial: 50 ft

Pump interface cable: 50 ft

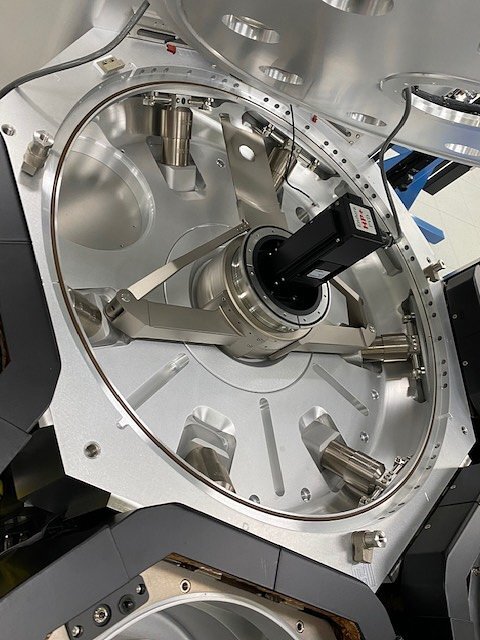

Chamber A:

Chamber type: MxP+

ESC Type: Polymide

IHC Type: MKS 640

Manometer type: 1 Torr

Lid type: Clamp

Slit valve O-ring: Viton

Bias RF match: Standard

OEM 12B RF Generator

No autobias

End point: Monochromator

SEIKO SEIKI 301 Turbo pump

Magnet driver

Simply cathode

Butterfly throttle valve

VAT Gate valve

Standard process kit

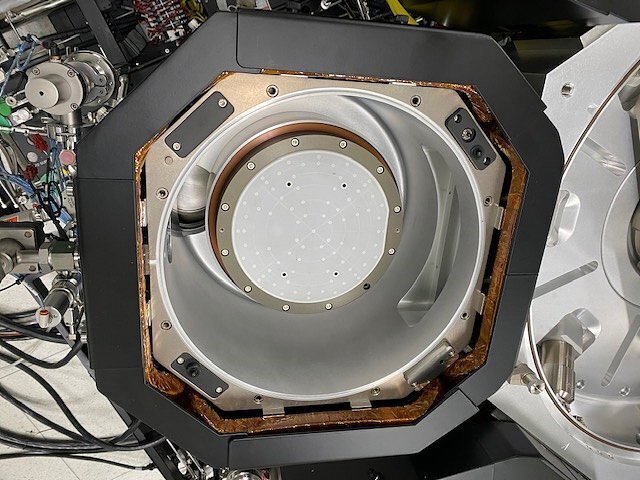

Chamber B, C and D:

Chamber type: MxP+

IHC Type: MKS640

Manometer type: 1 Torr

Lid type: Clamp

Slit valve O-ring: Viton

Bias RF match: Standard

OEM 12B RF Generator

No autobias

End point: Monochromator

SEIKO SEIKI 301 Turbo pump

Magnet driver

Simply cathode

Throttle valve: Butterfly

VAT Gate valve

Gases:

Chamber A and B:

Gas / Name / MFC Size / Make / Model

Gas 1 / CL2 / 200 / STEC / SEC-4400MC

Gas 2 / HBR / 200 / STEC / SEC-4400MC

Gas 3 / N2 / 20 / STEC / SEC-4400MC

Gas 4 / CF4 / 200 / STEC / SEC-4400MC

Gas 5 / O2 / 10 / STEC / SEC-4400MC

Gas 6 / O2 / 100 / STEC / SEC-4400MC

Gas delivery:

MFC Maker: STEC

MKS Transducer display

NIPPON SEISEN Mykrolis Filter

Regulator: Veriflo

MKS Transducer

FUJIKIN Valve

Gas connection: Multiline drop

Chiller:

Chiller valve connections: Manifold

Generator rack valve connection: Manifold

Chiller hose size: 3/8 Quick

Valve connection:

Wall: Chamber A, B and C

Cathode: Chamber A, B and C

Power supply: 208 V, 400 A, 60 Hz

1997 vintage.

AMAT / APPLIED MATERIALS Centura MxP+ is a high-performance reactor designed to facilitate the fabrication of semiconductor devices, such as transistors, diodes, and resistors, in the manufacturing of integrated circuits. This reactor is ideal for semiconductor manufacturing processes that require high-temperature processing and precise control over gas flow, pressure, and temperature. The reactor features a patented High-Efficiency Direct Gas Distribution Equipment (HEDGDS) that enables uniform gas distribution and pressure control over the entire chamber. This system eliminates the need for manual gas pumps and allows for precise control of gas flows and pressure. The HEDGDS does not require any gas lines or external connections, making the reactor easier to install and operate. The reactor's internal temperature can be set between 25°C and 1000°C with precision of 0.1°C. This allows for optimized temperature control to ensure accurate process results and efficient workflow management. Further, the MxP+ includes a low-pressure electric pulse unit that eliminates the need for manual vacuum pumps. The electric pulse machine is also capable of maintaining a constant chamber pressure in order to minimize gas breakthrough during thru-process applications. The reactor also boasts an advanced two-phase gas flow protection tool that effectively prevents gas flow contamination. This asset uses a Dynamic Flow Splitter which maximizes the uniformity of the gas flow while simultaneously preventing the cross-contamination of process and carrier gases. The model also features an Active Gas Control Equipment that constantly monitors the chamber pressure and automatically adjusts the flow of the carrier gas to ensure process repeatability. The reactor is also equipped with temperature sensors and a programmable logic controller (PLC) that enable precise temperature control and automated process monitoring. This PLC control system is also capable of executing a sequence of complex events ensuring optimal process quality and efficiency. The reactor also offers a variety of additional features, such as a switch-based power supply and flexible induction heating that provide further control over the semiconductor fabrication process. Furthermore, this reactor is also ETL-listed and RoHS-certified, ensuring that the it meets or exceeds the safety standards of the semiconductor industry. Overall, AMAT Centura MxP+ reactor is an advanced semiconductor fabrication solution that is designed to deliver reliable and consistent results while streamlining manufacturing operations.

There are no reviews yet