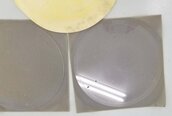

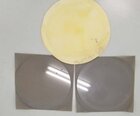

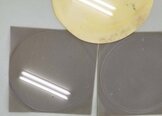

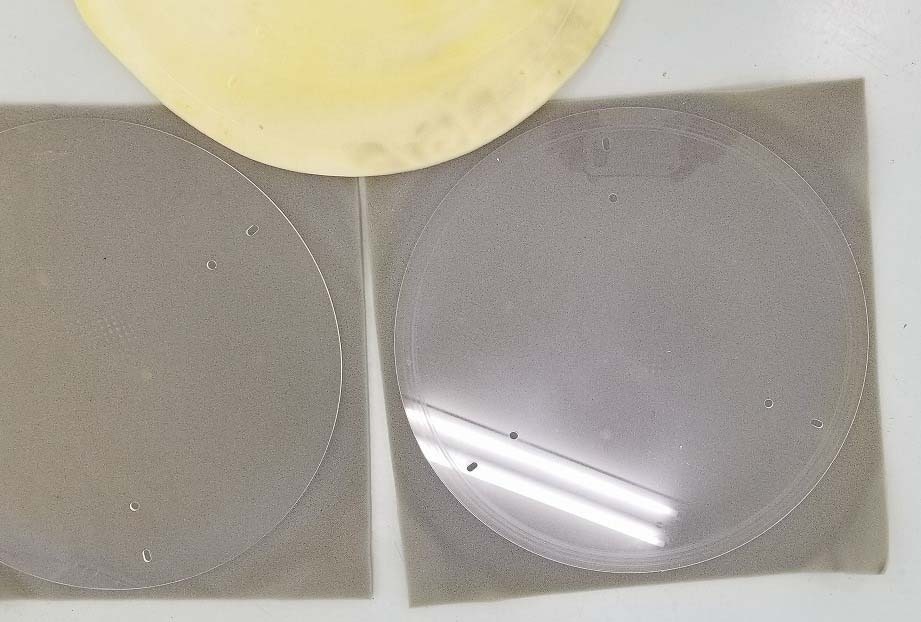

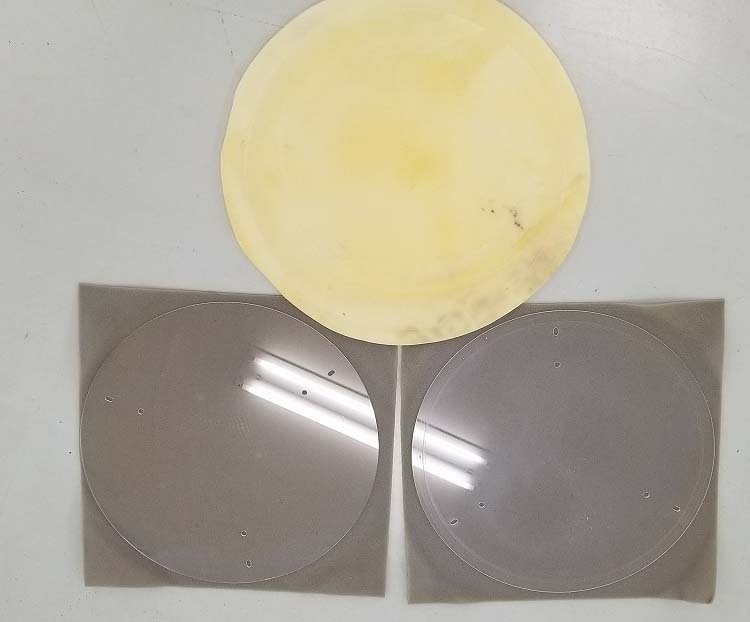

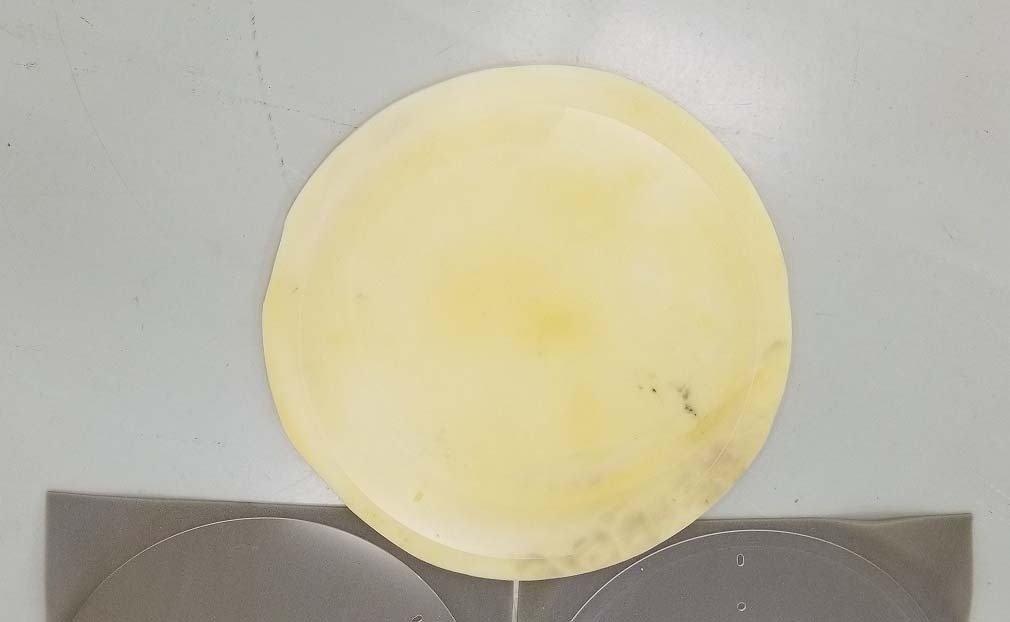

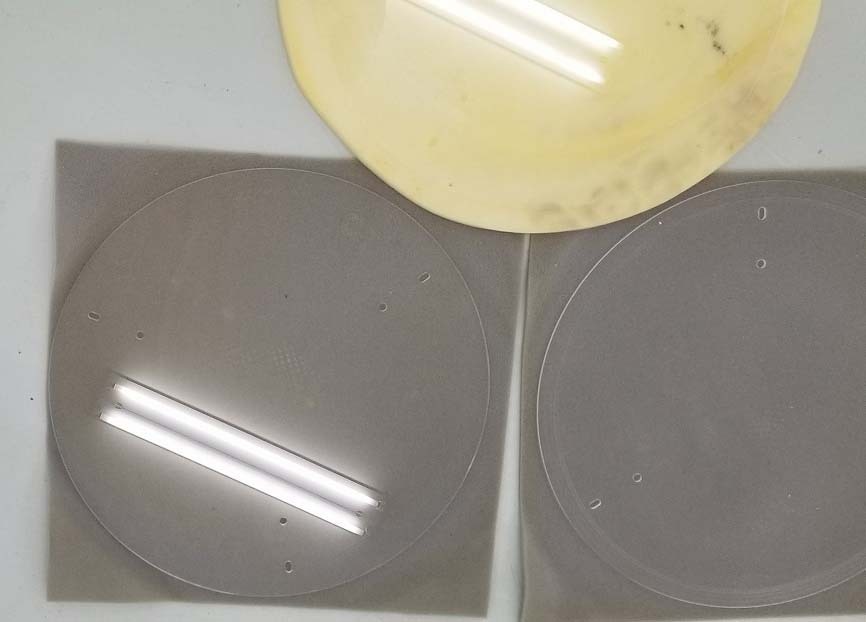

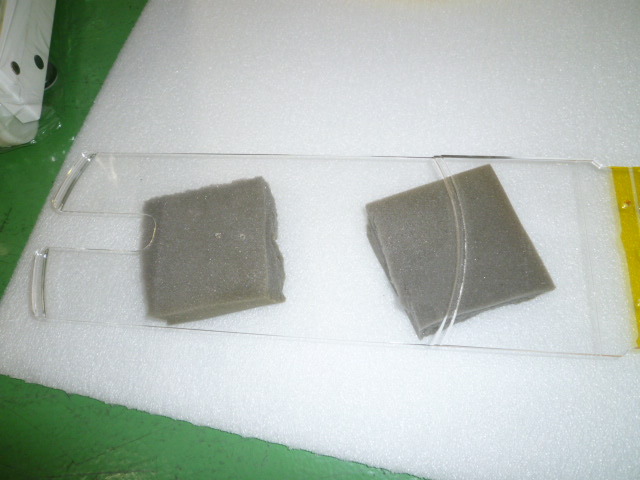

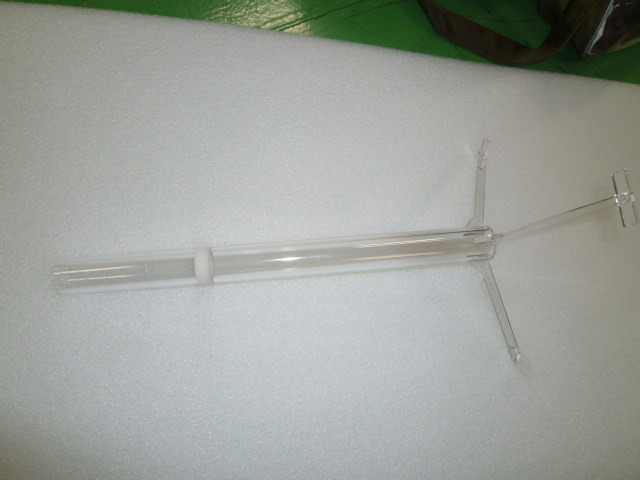

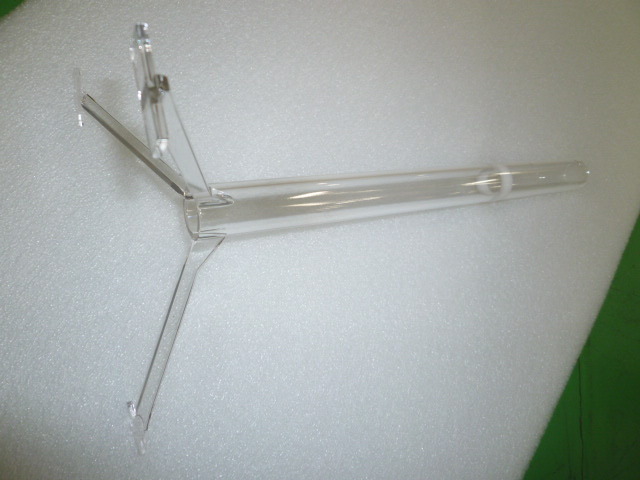

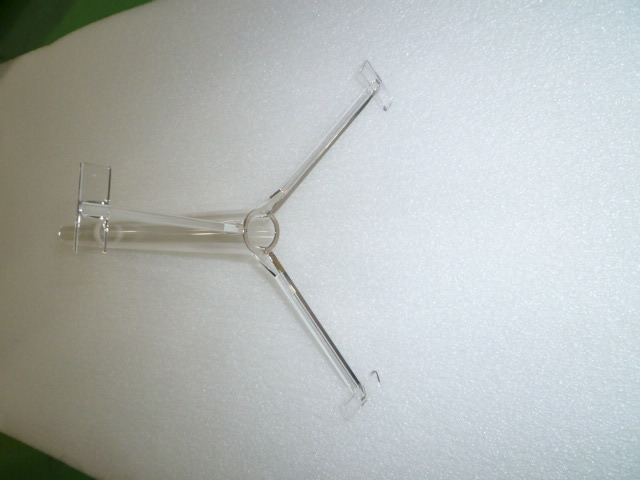

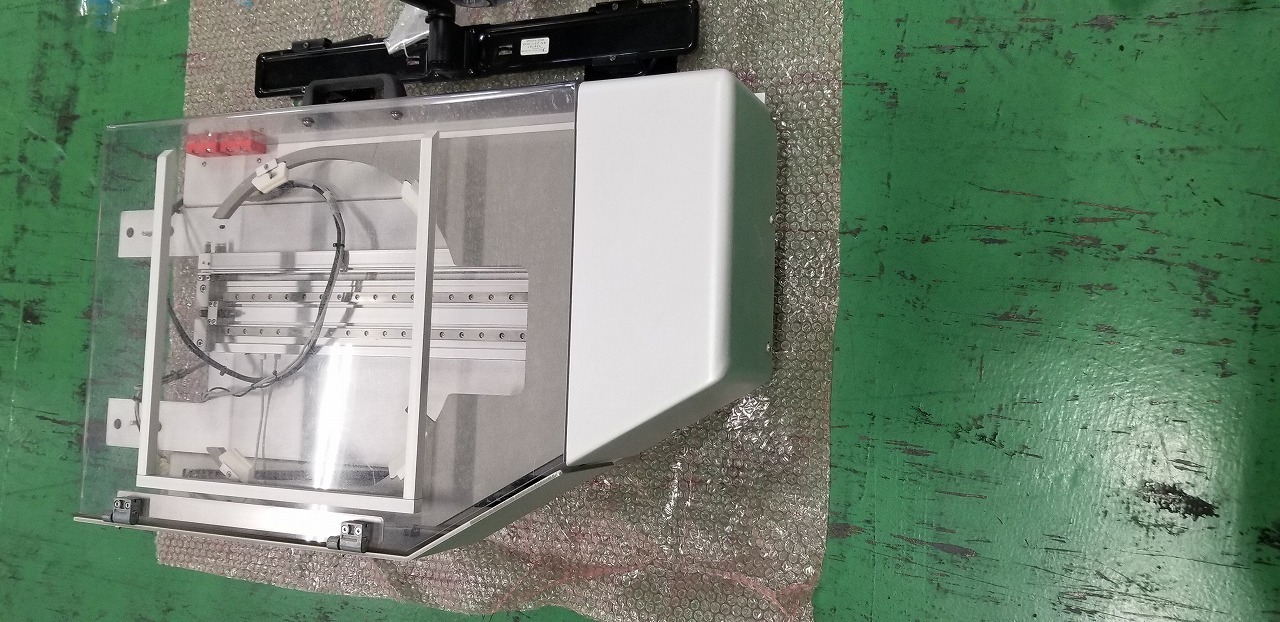

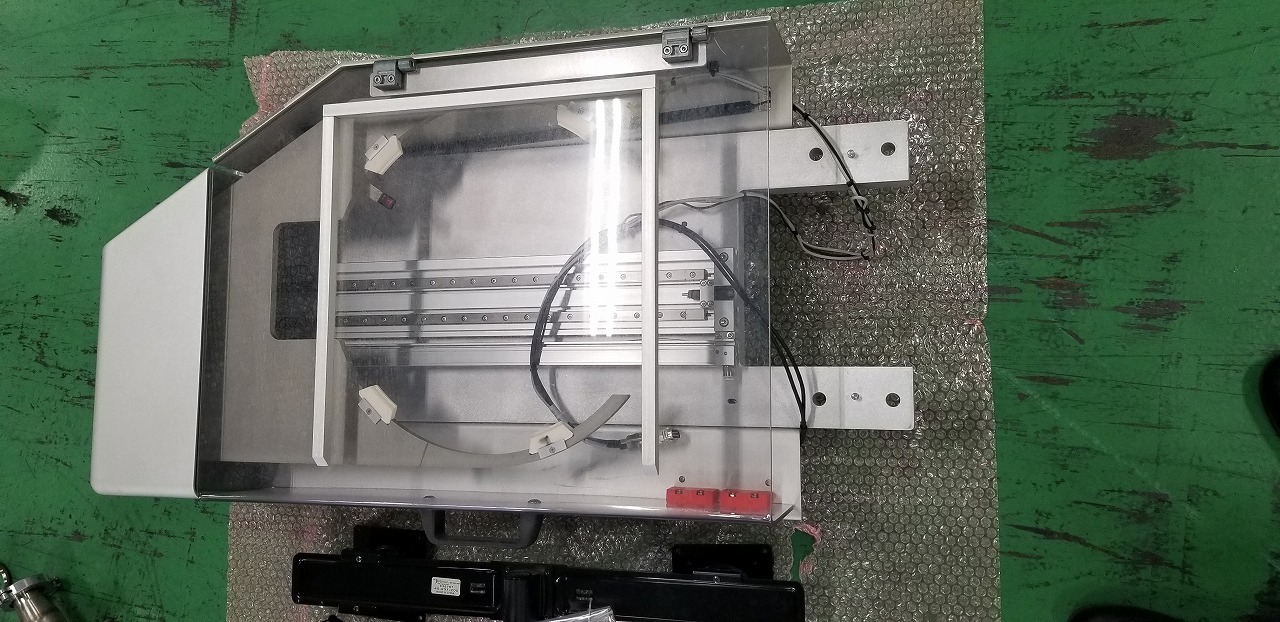

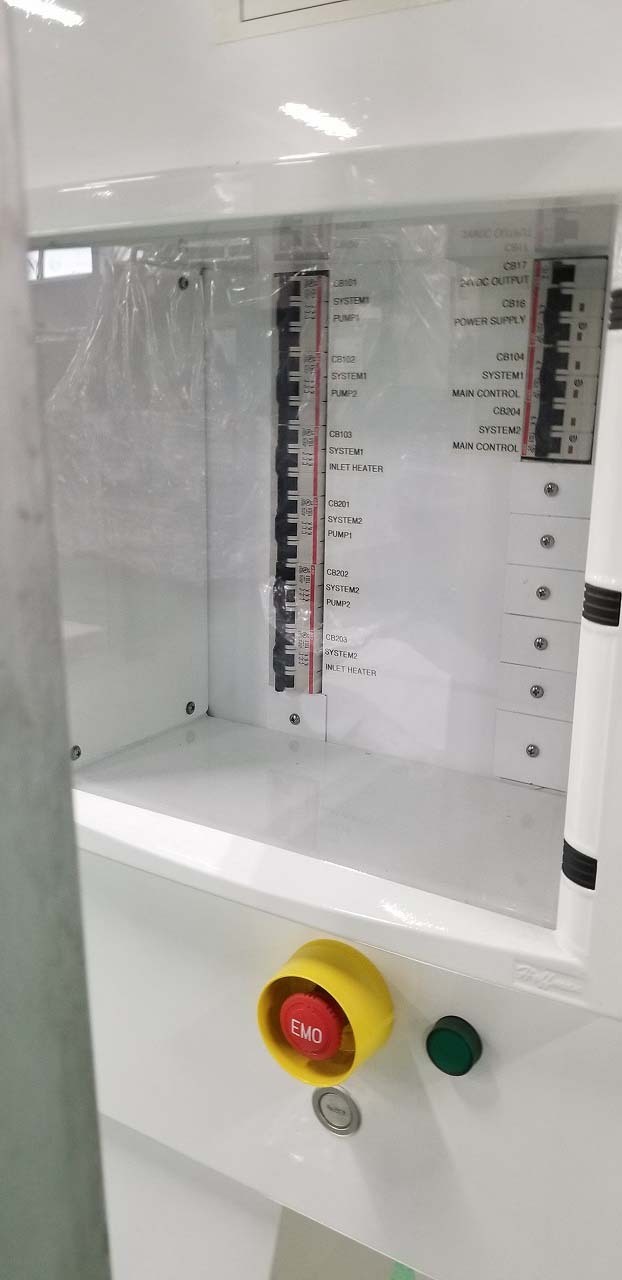

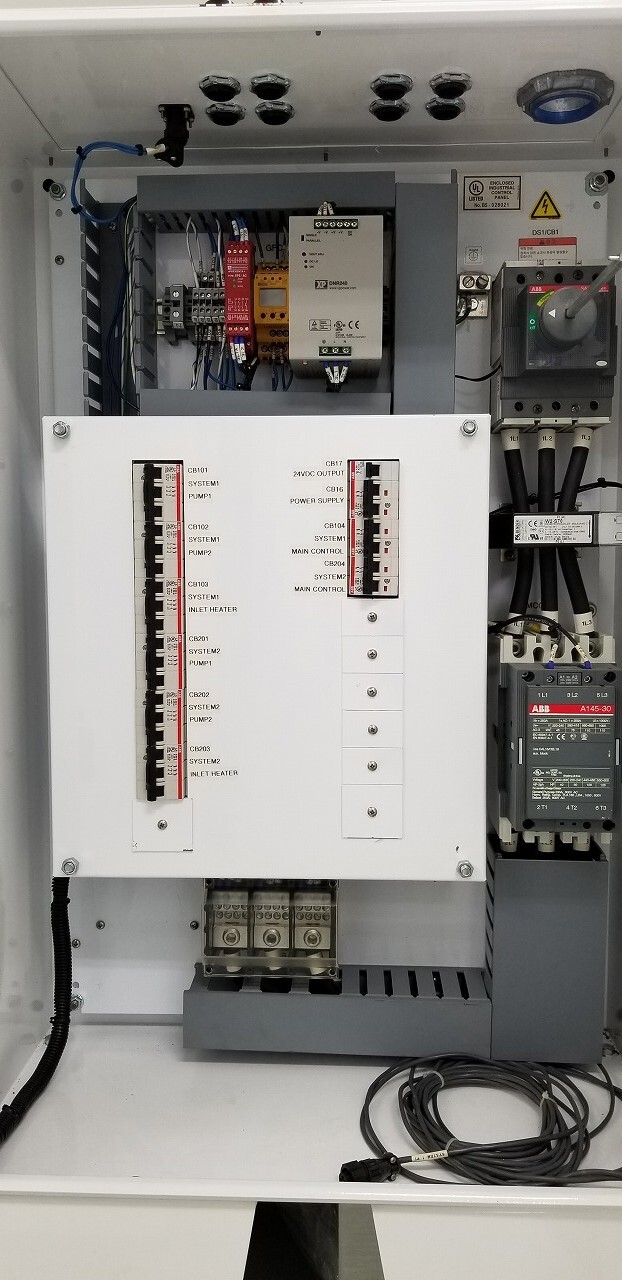

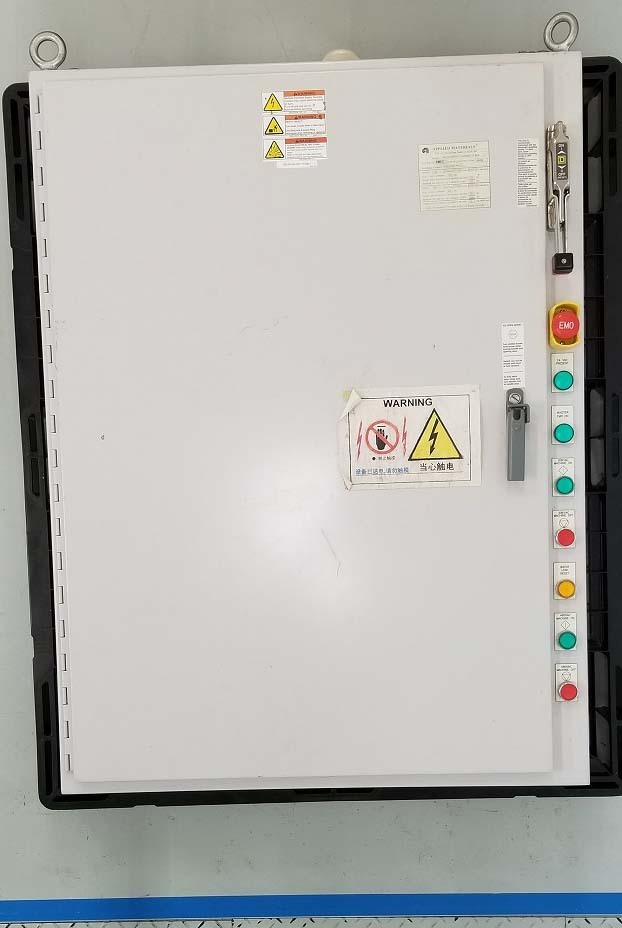

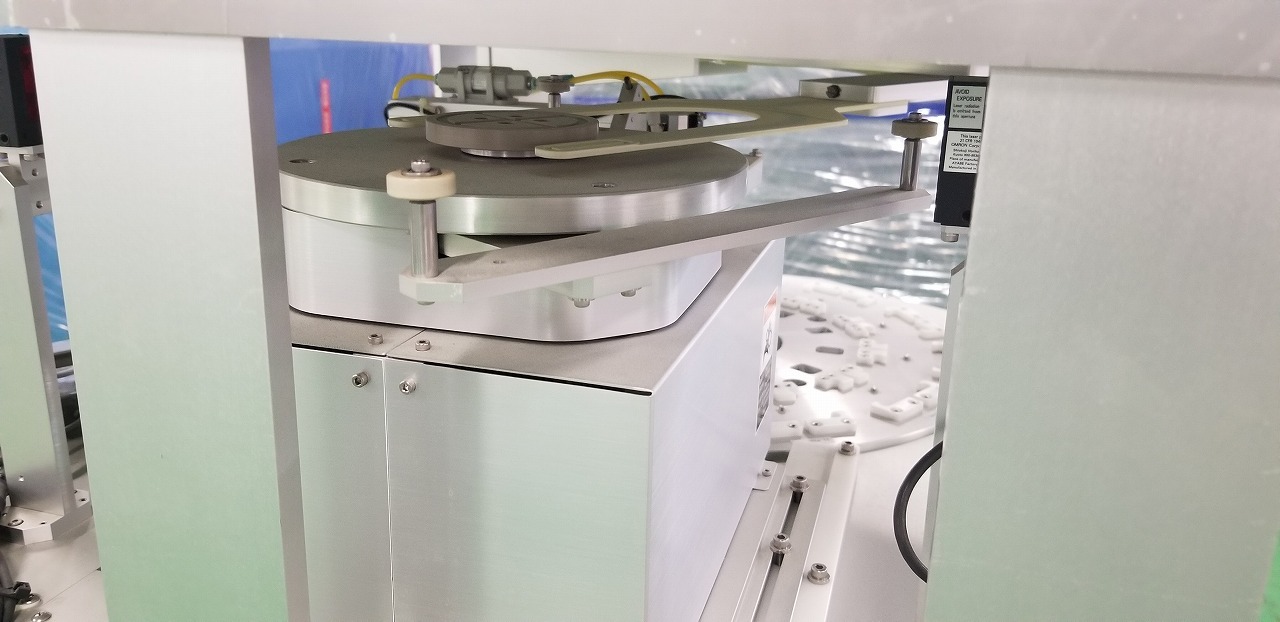

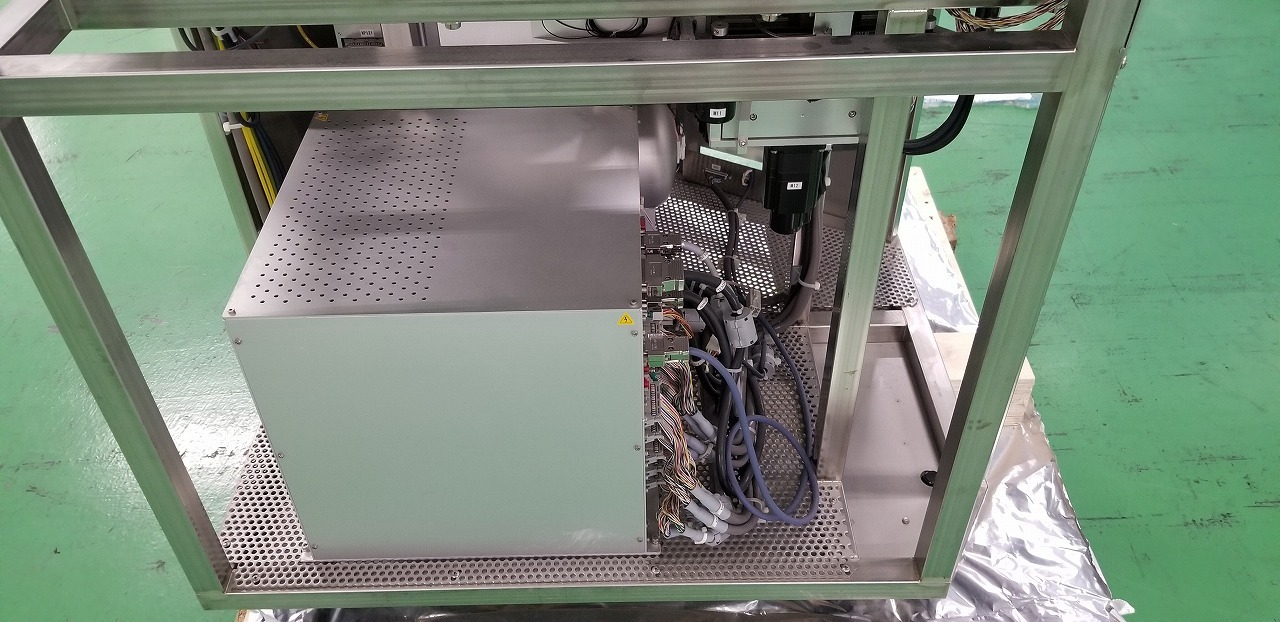

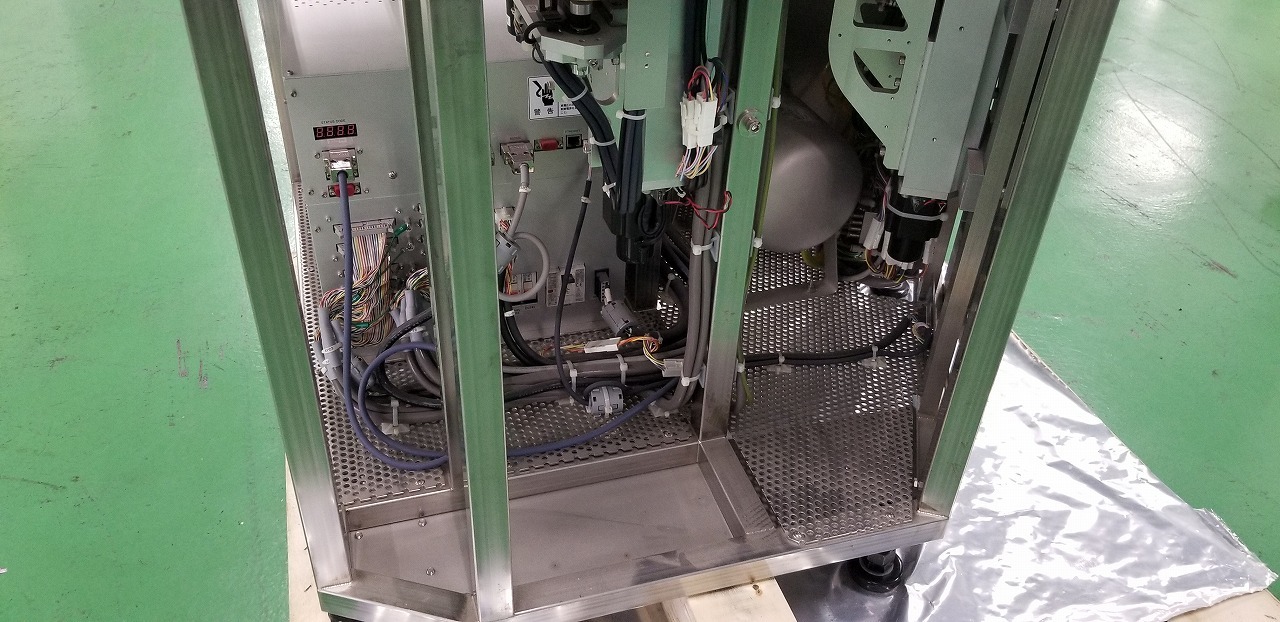

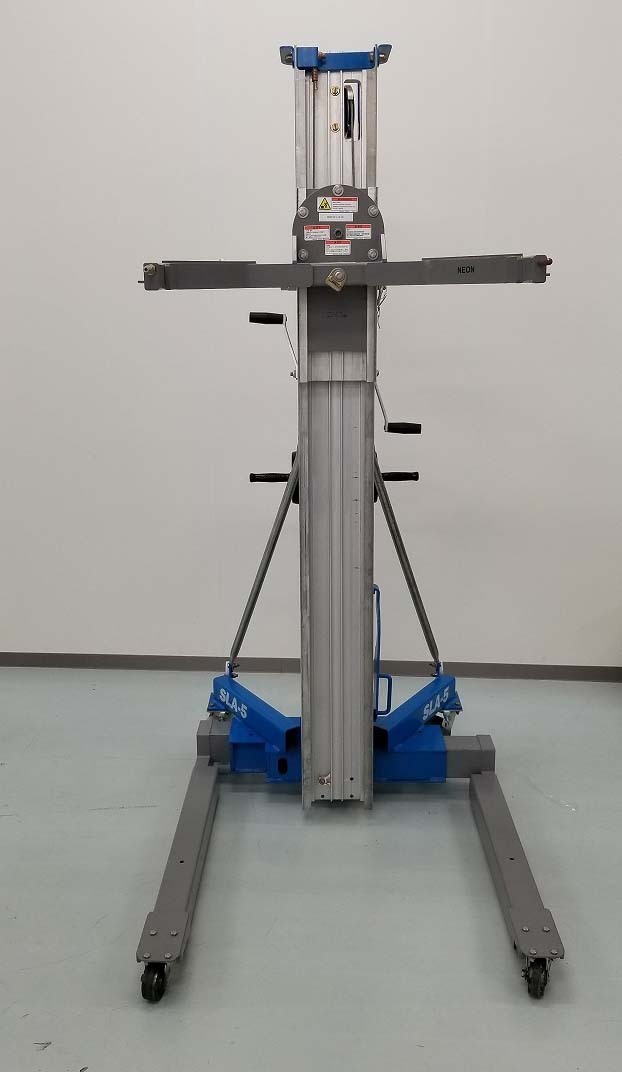

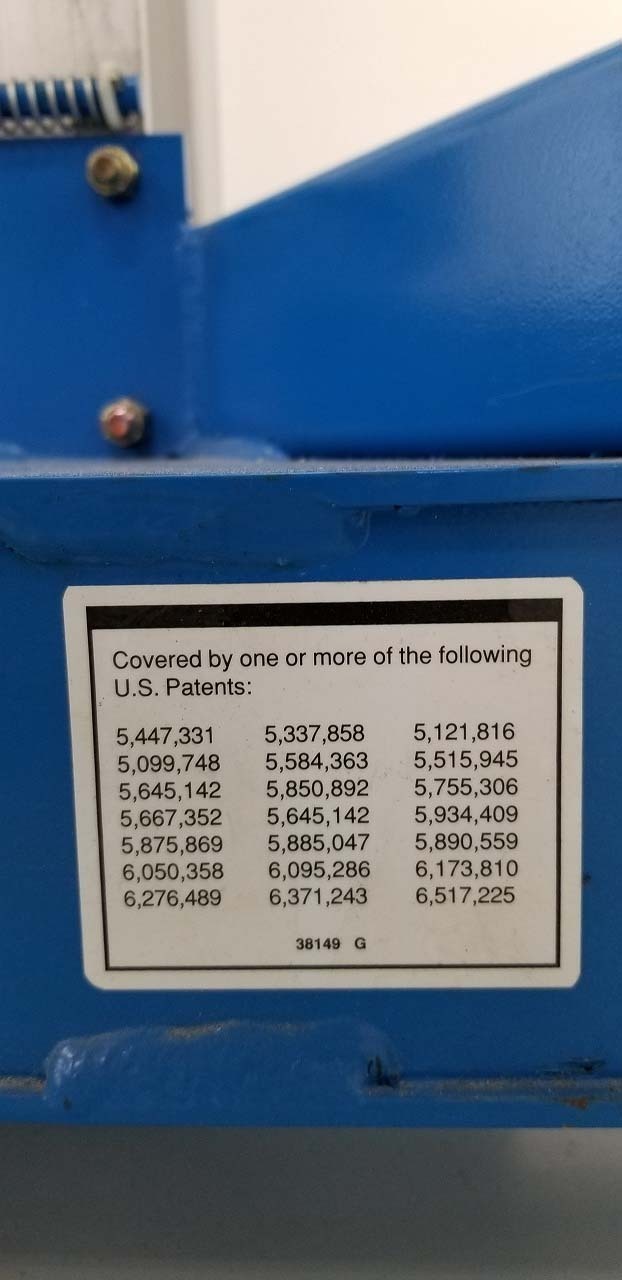

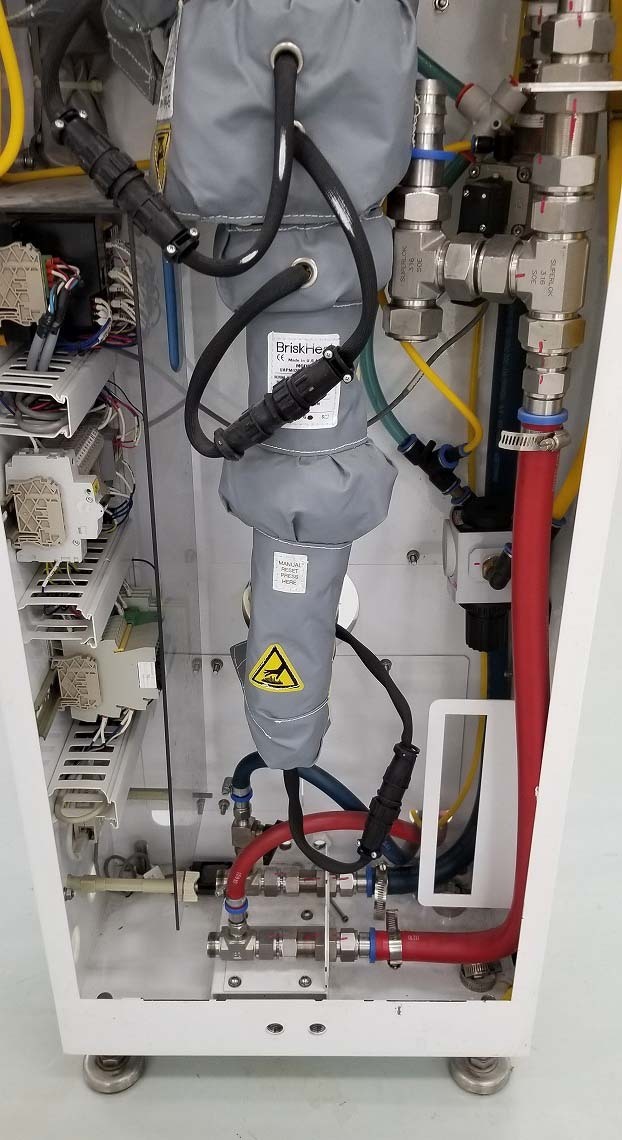

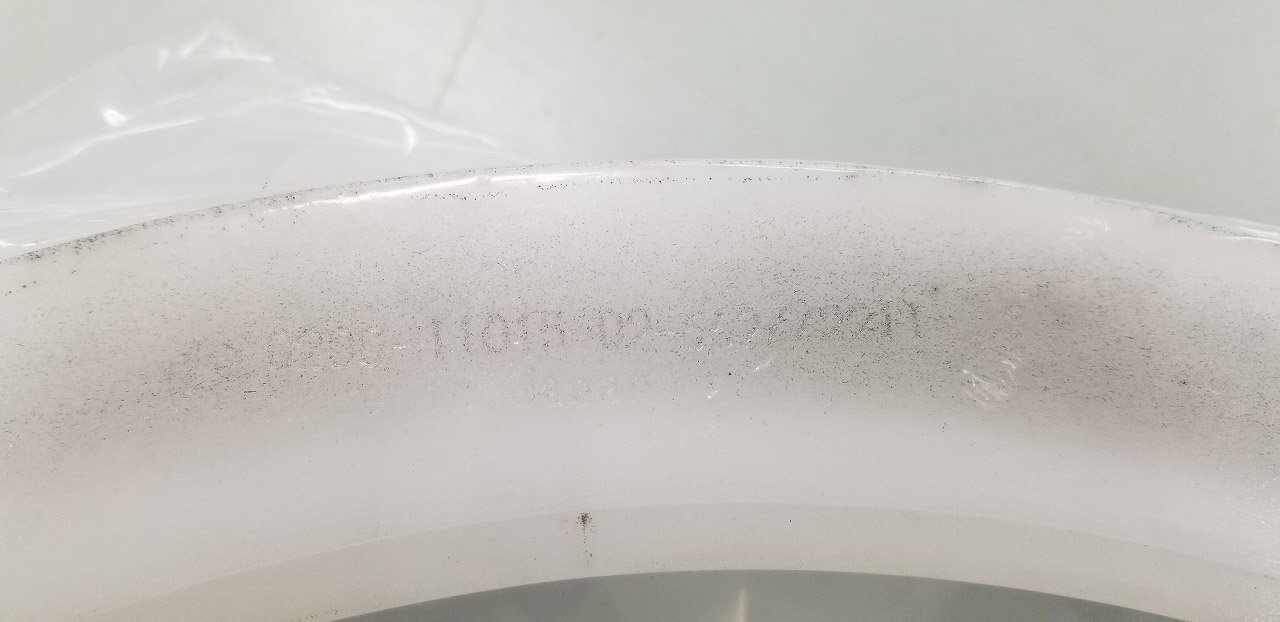

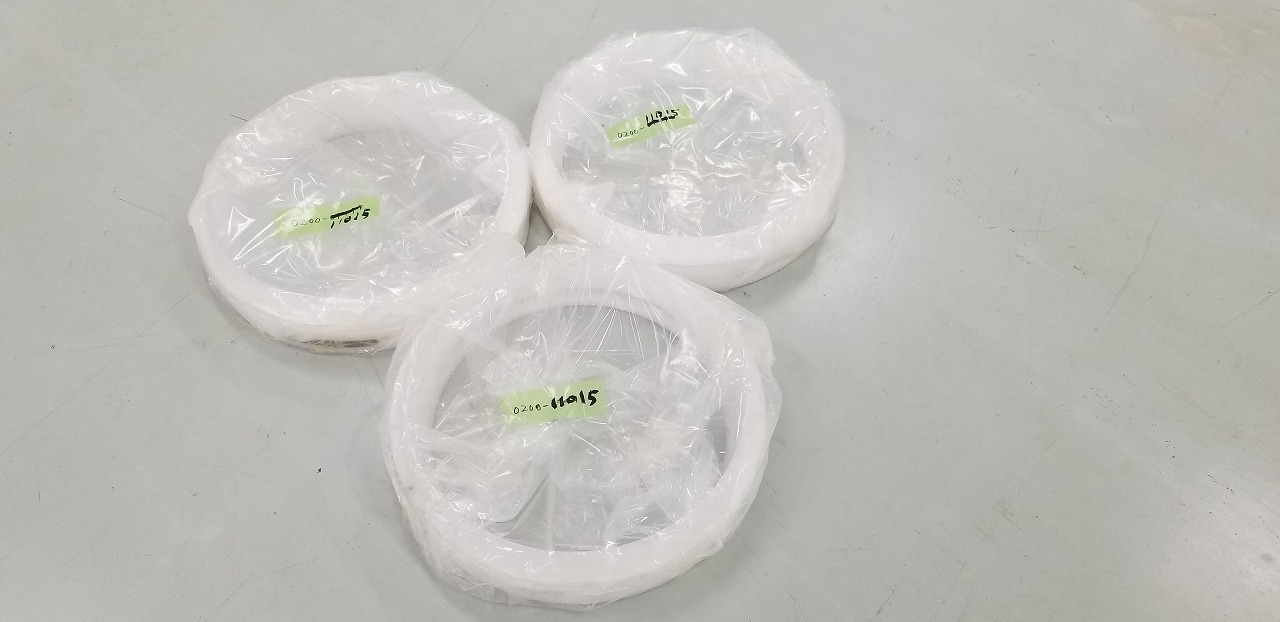

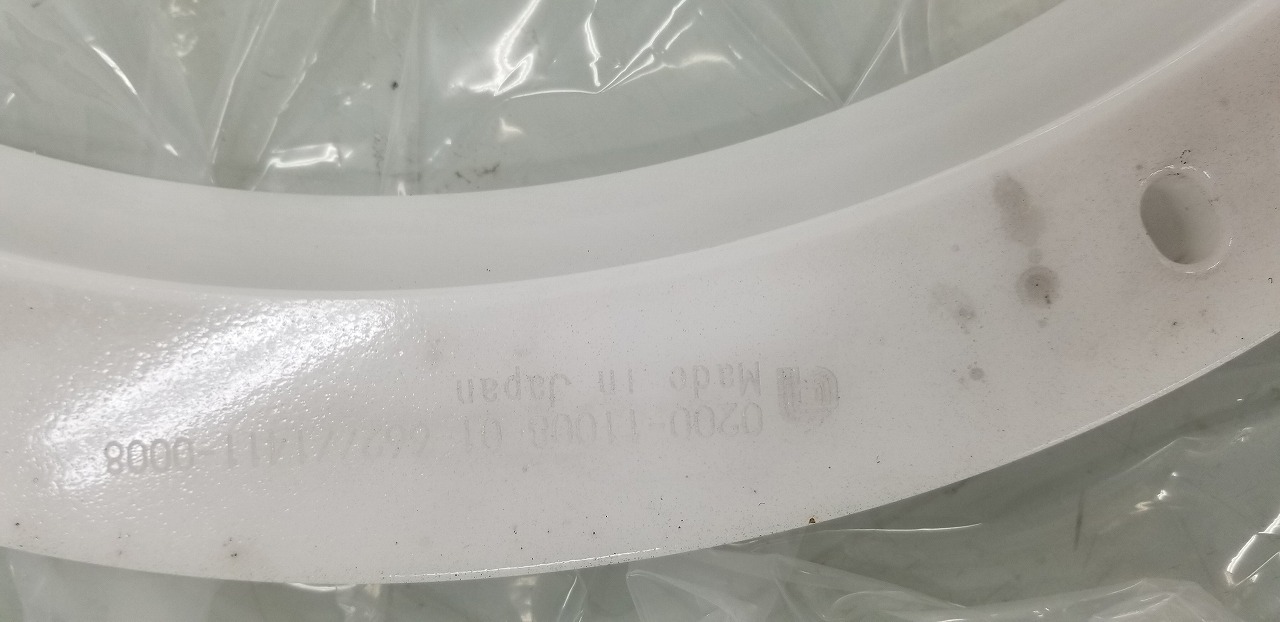

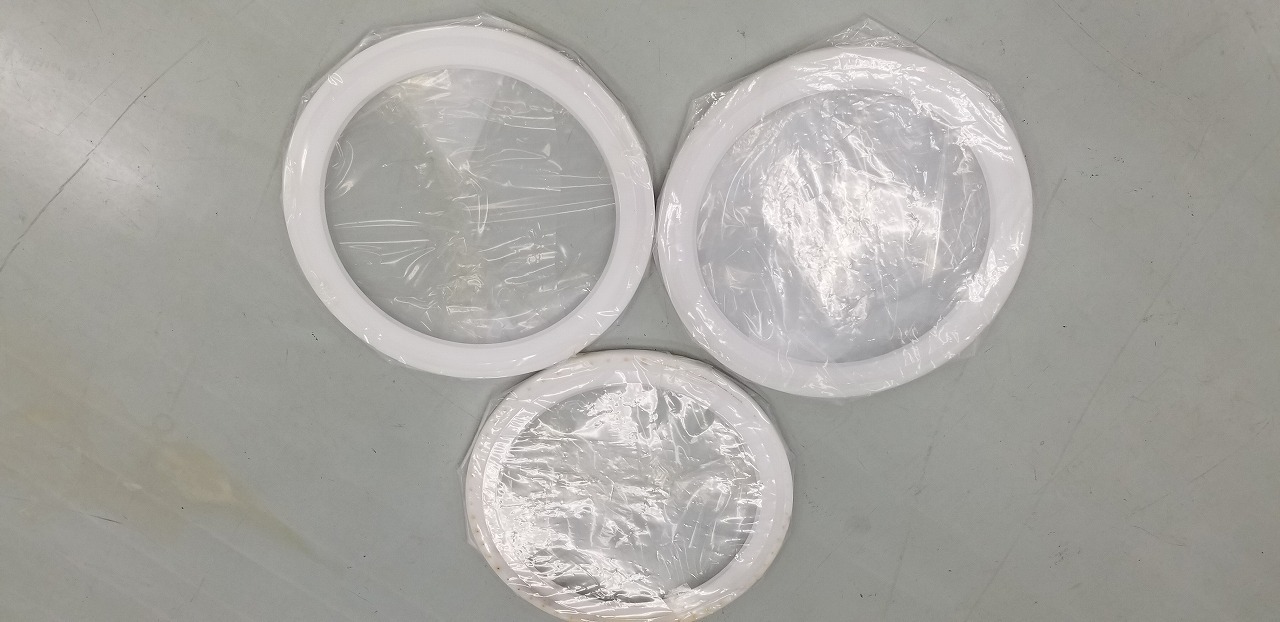

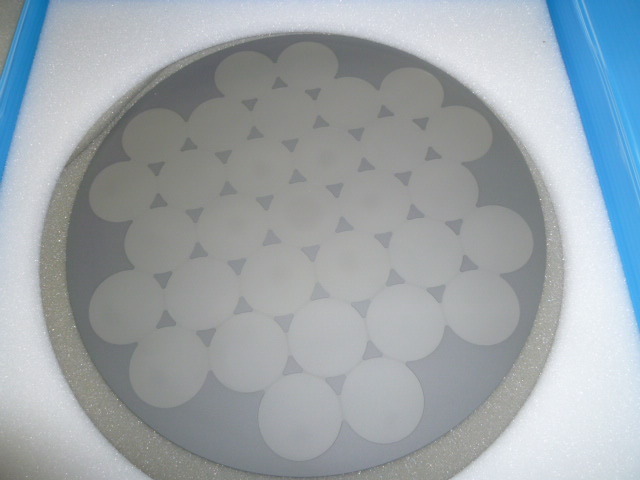

Used AMAT / APPLIED MATERIALS Centura NLighten NEON #9300660 for sale

URL successfully copied!

Tap to zoom

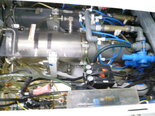

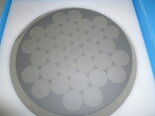

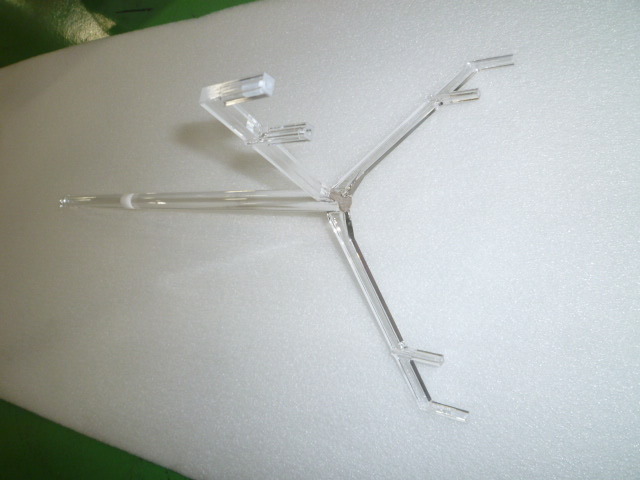

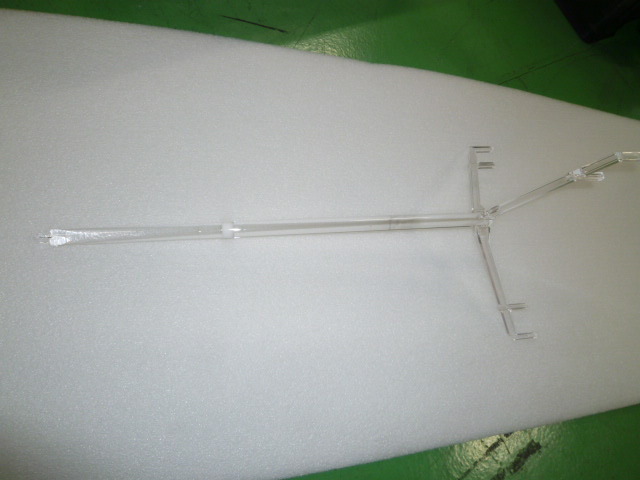

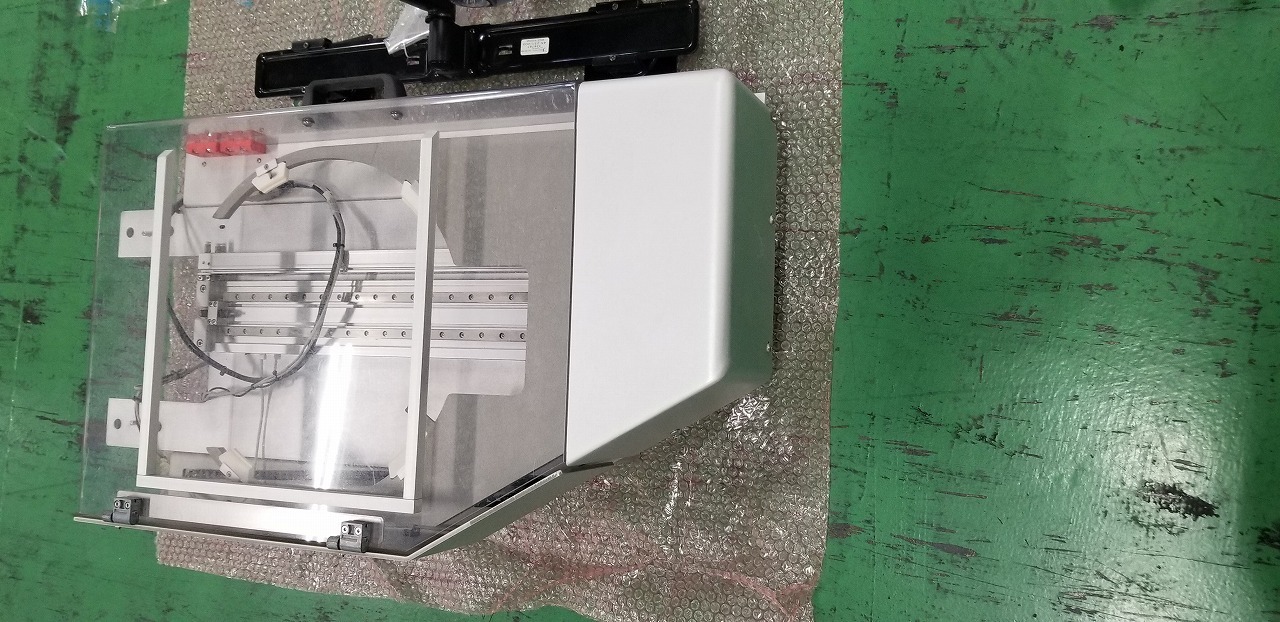

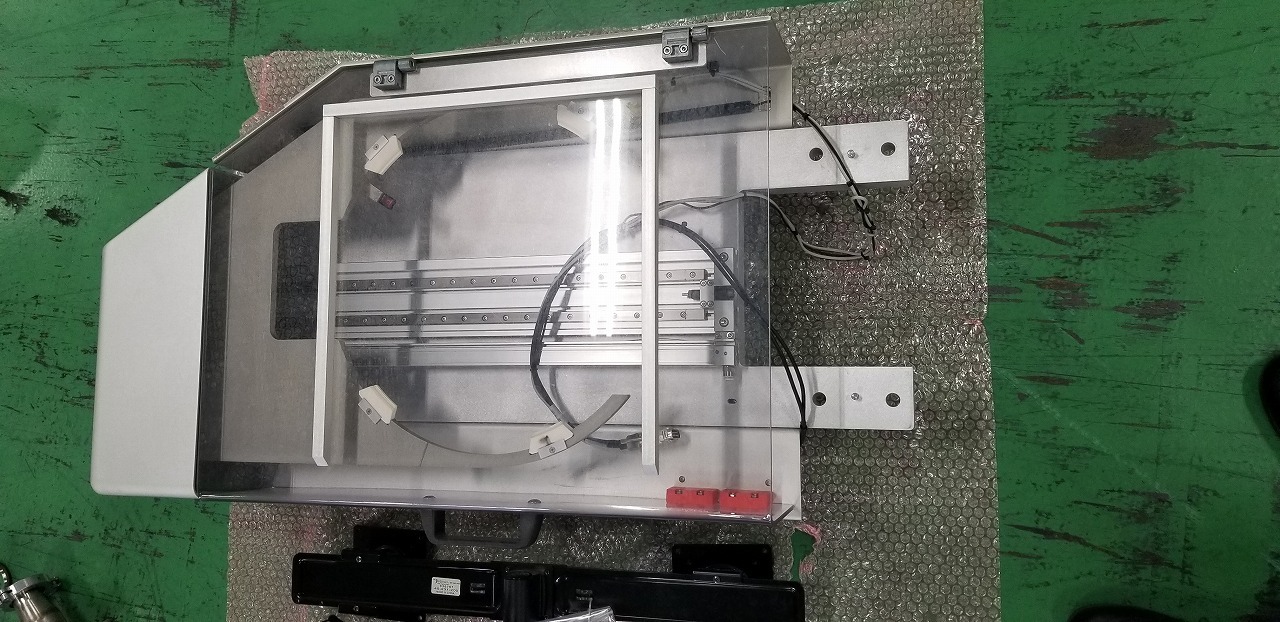

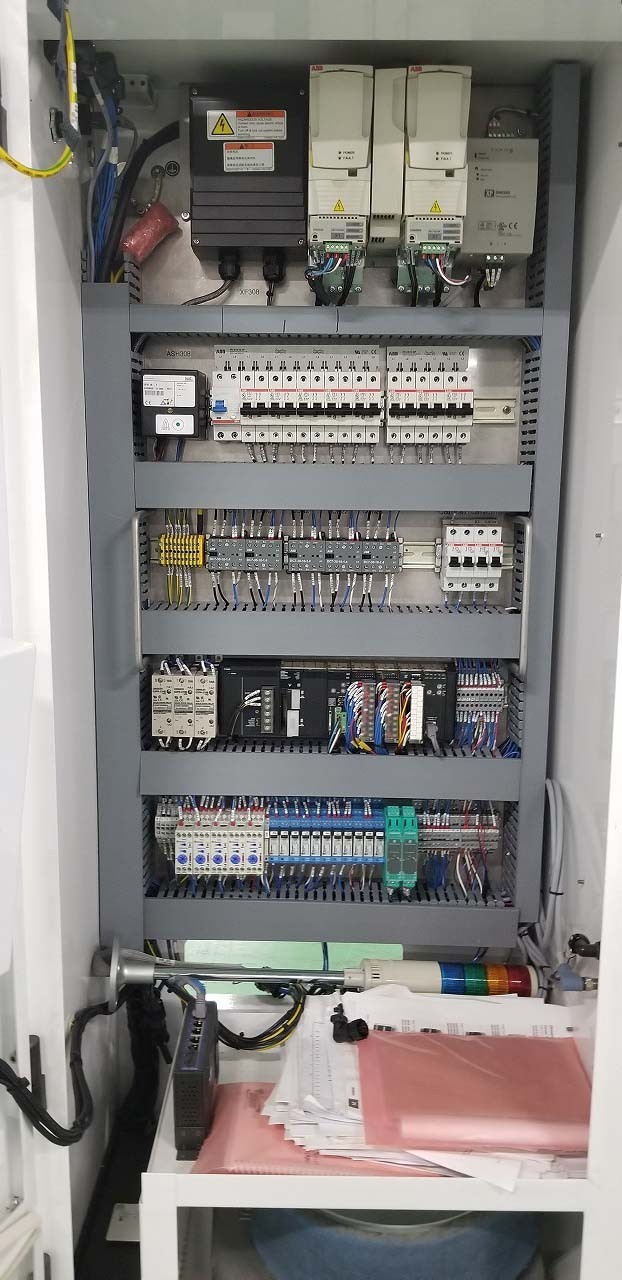

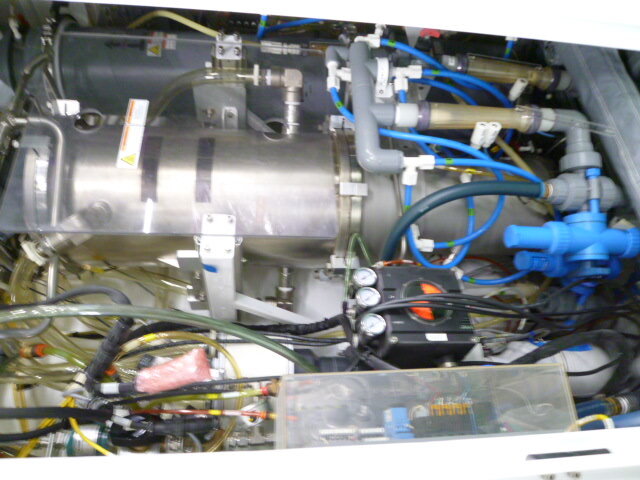

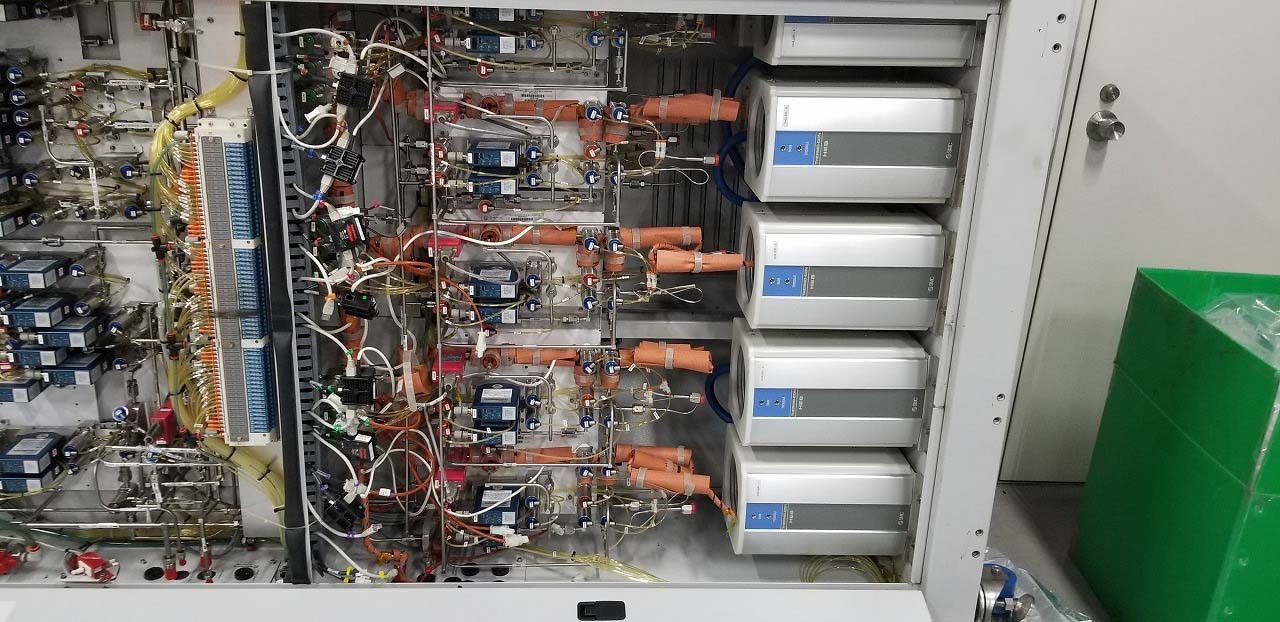

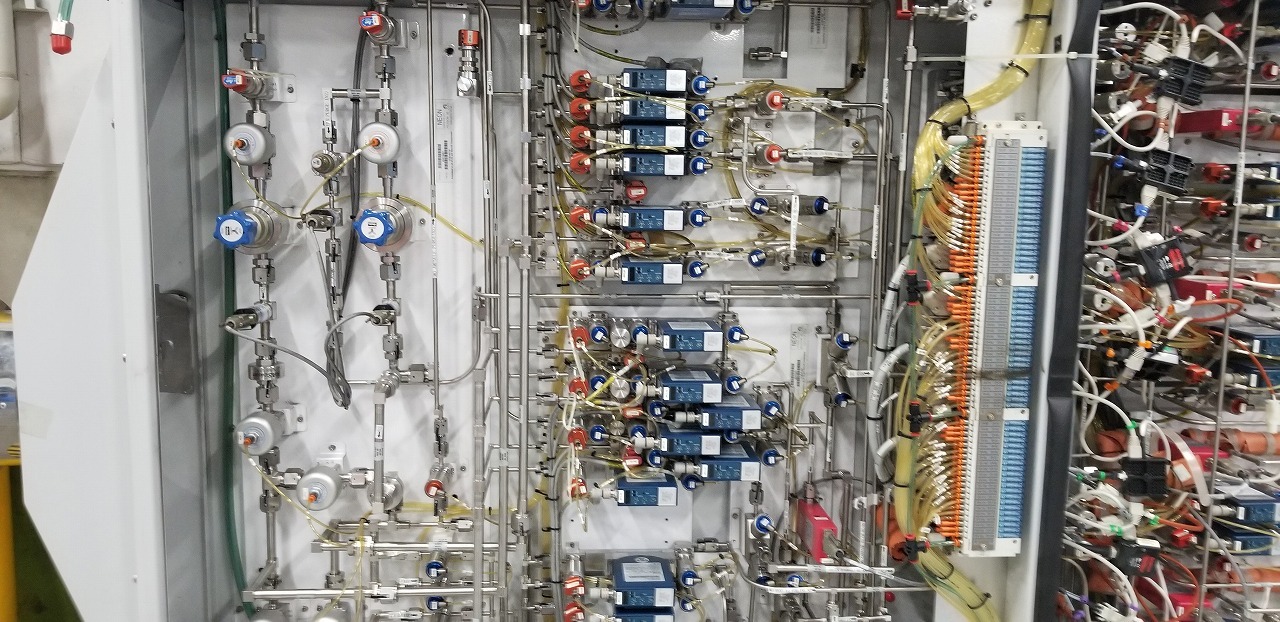

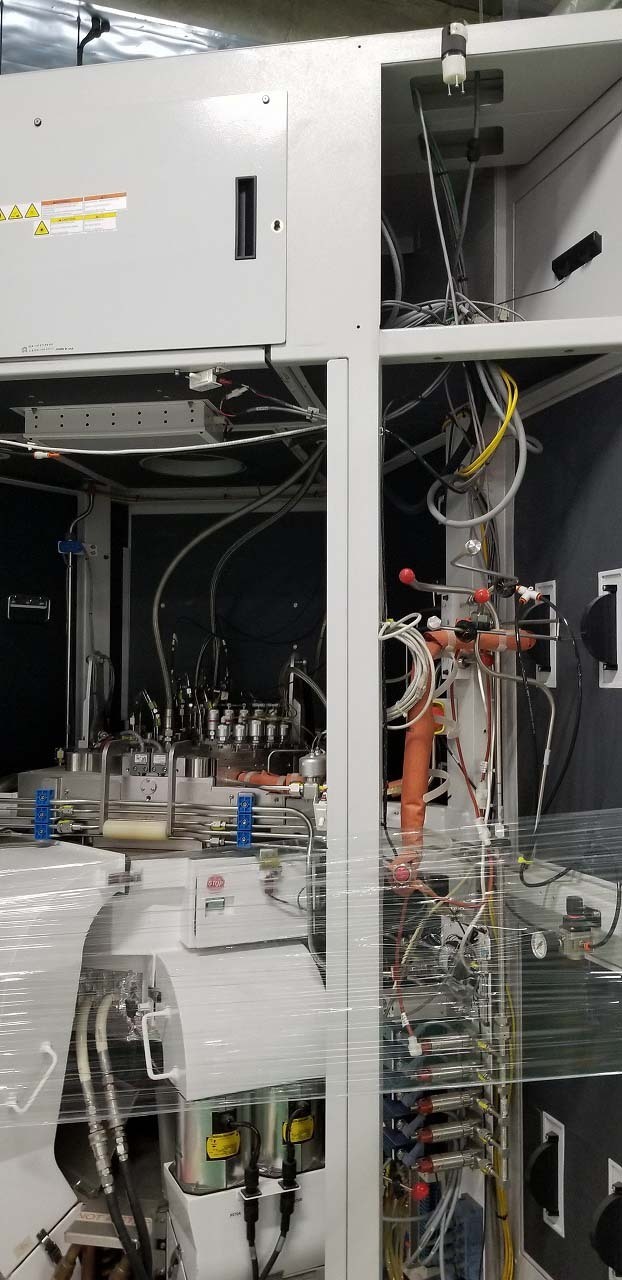

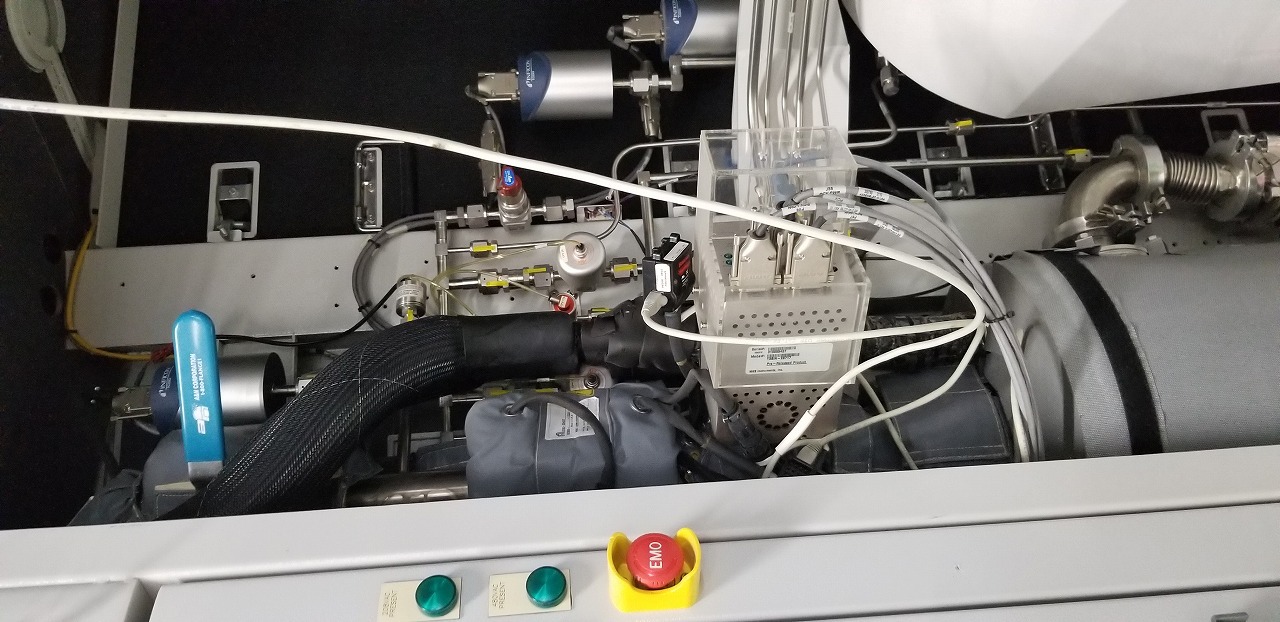

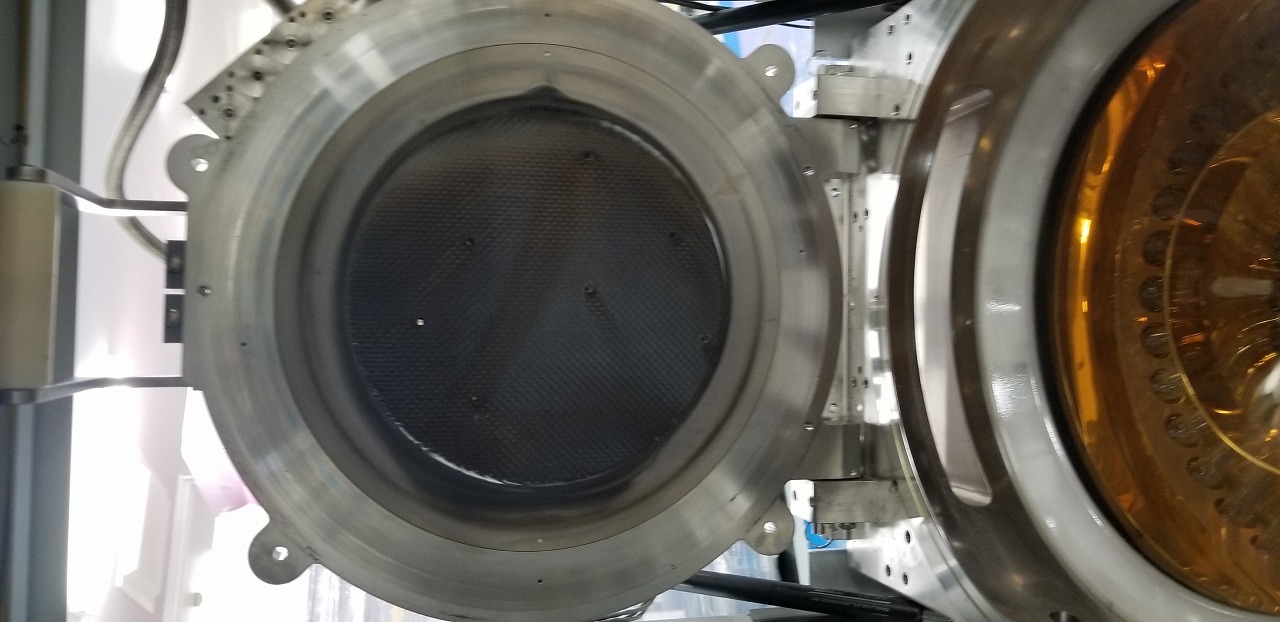

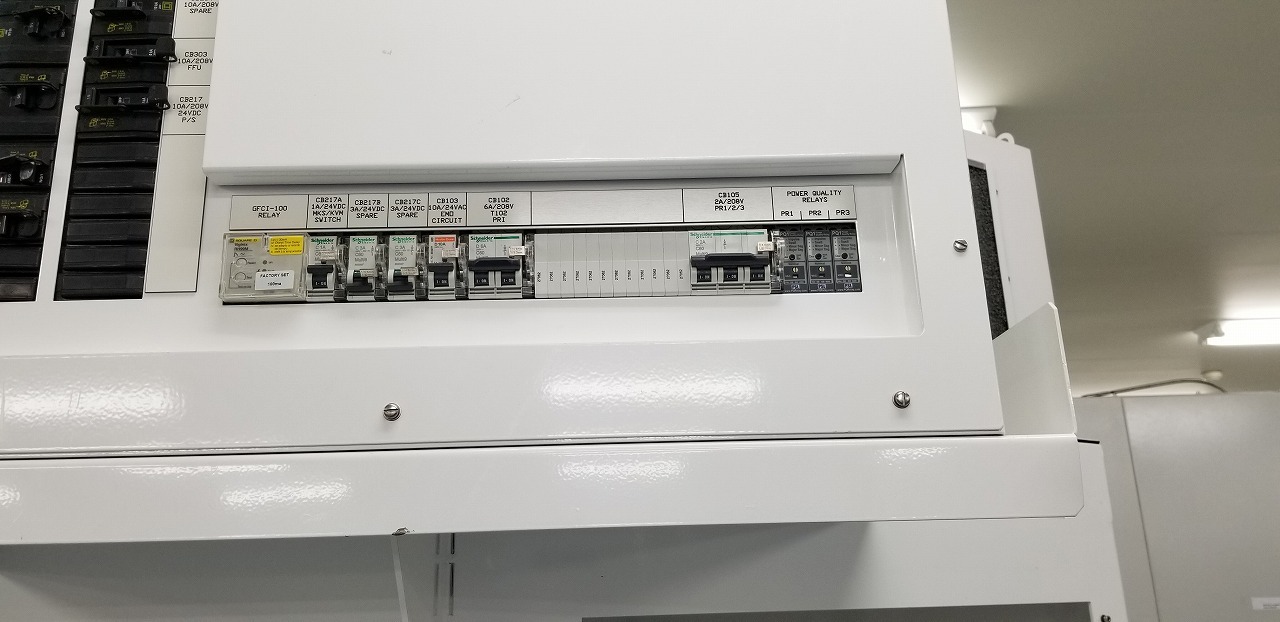

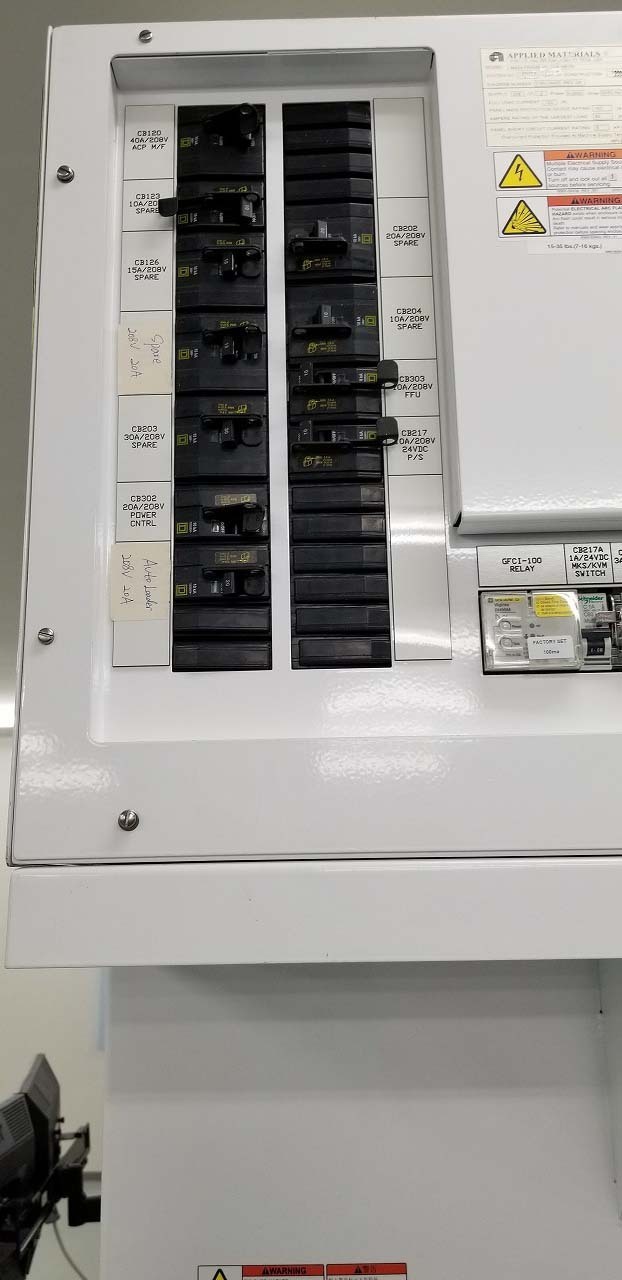

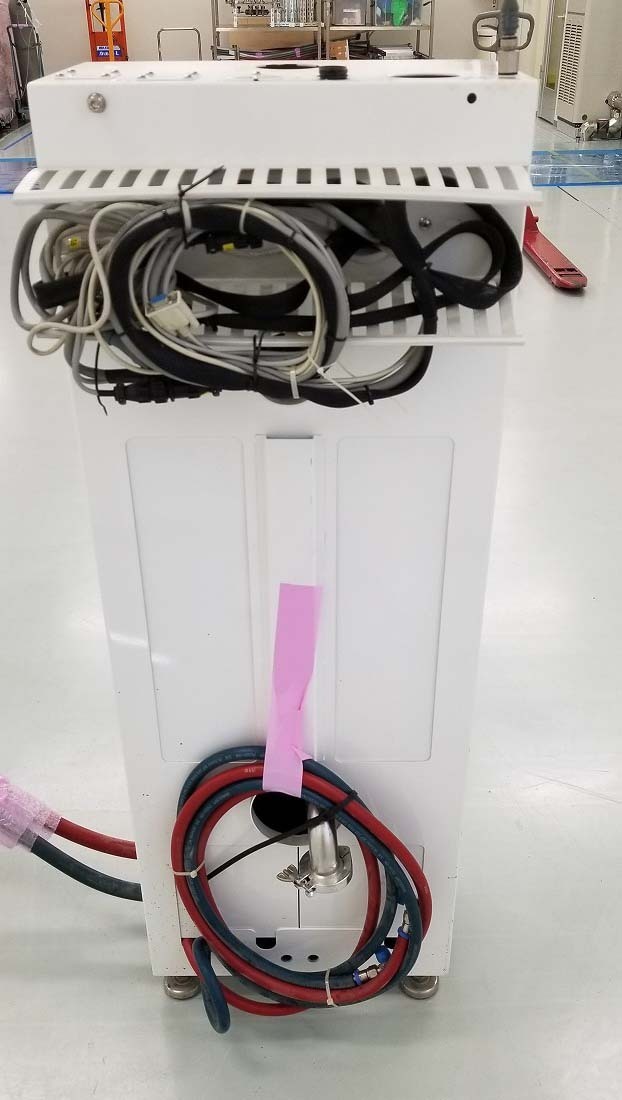

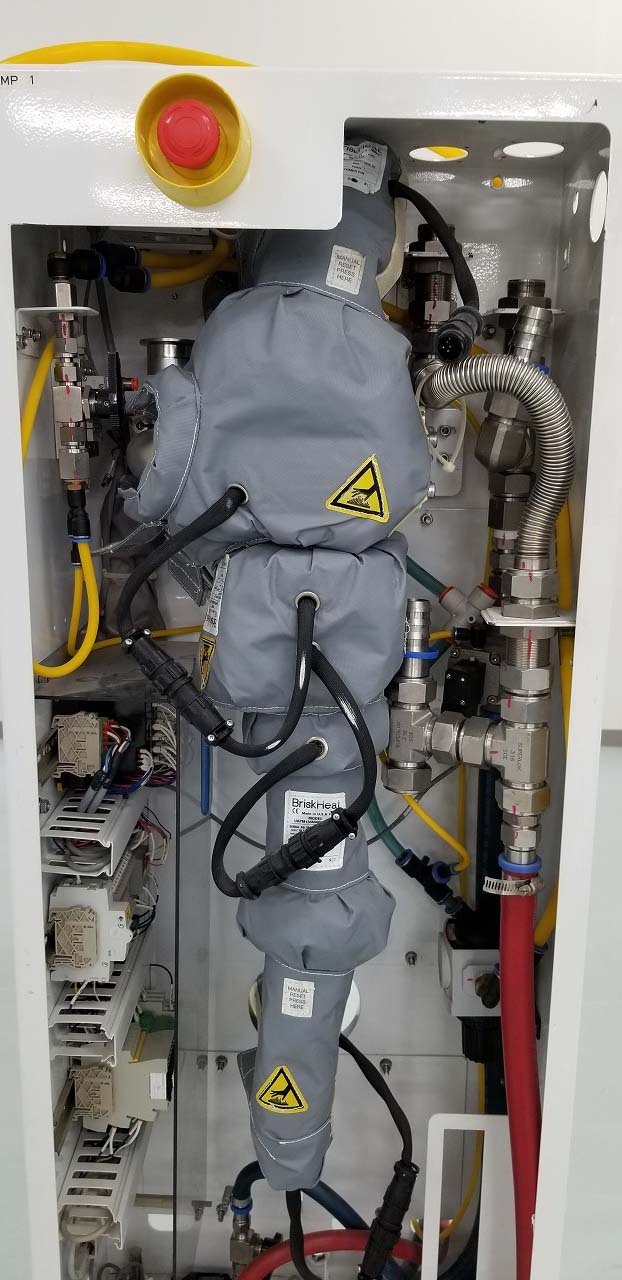

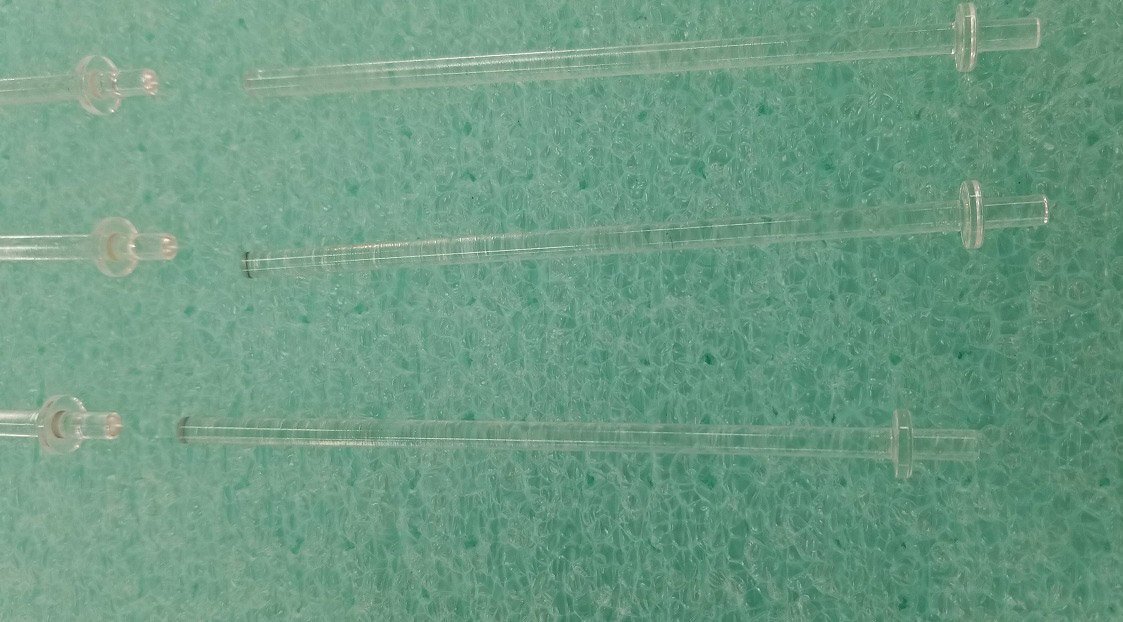

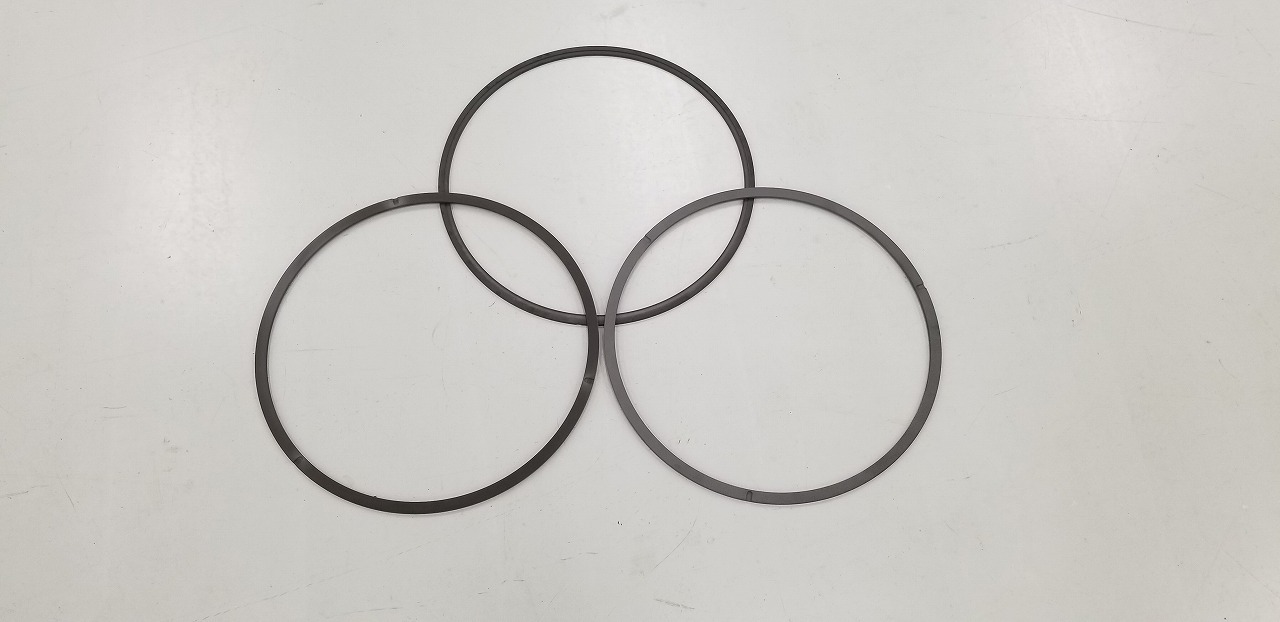

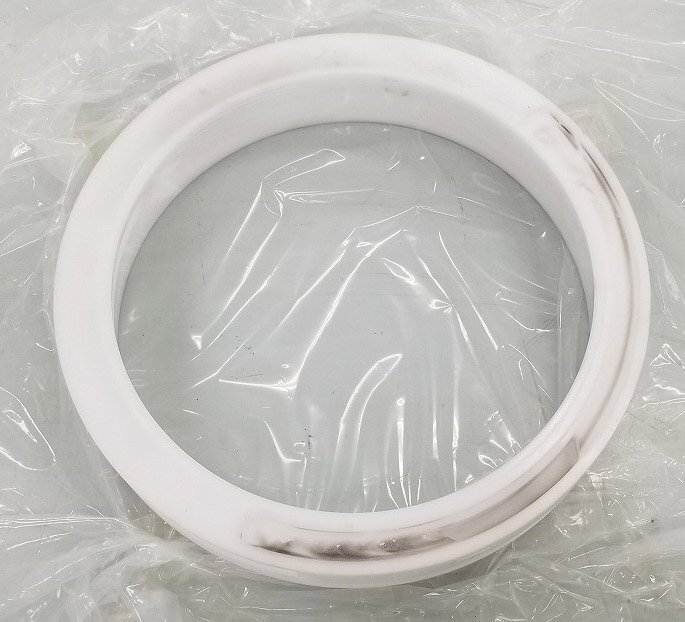

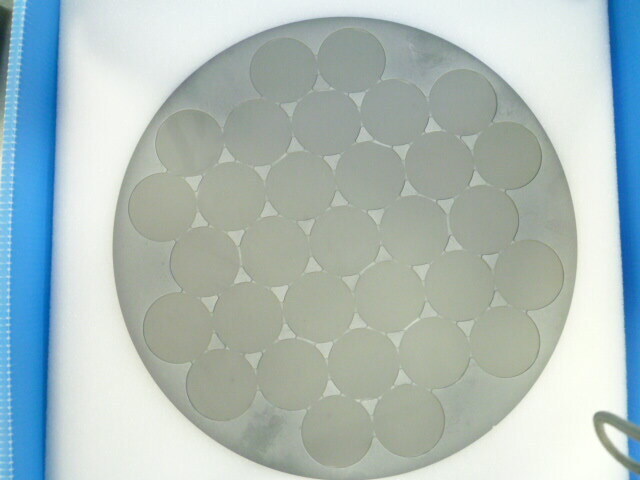

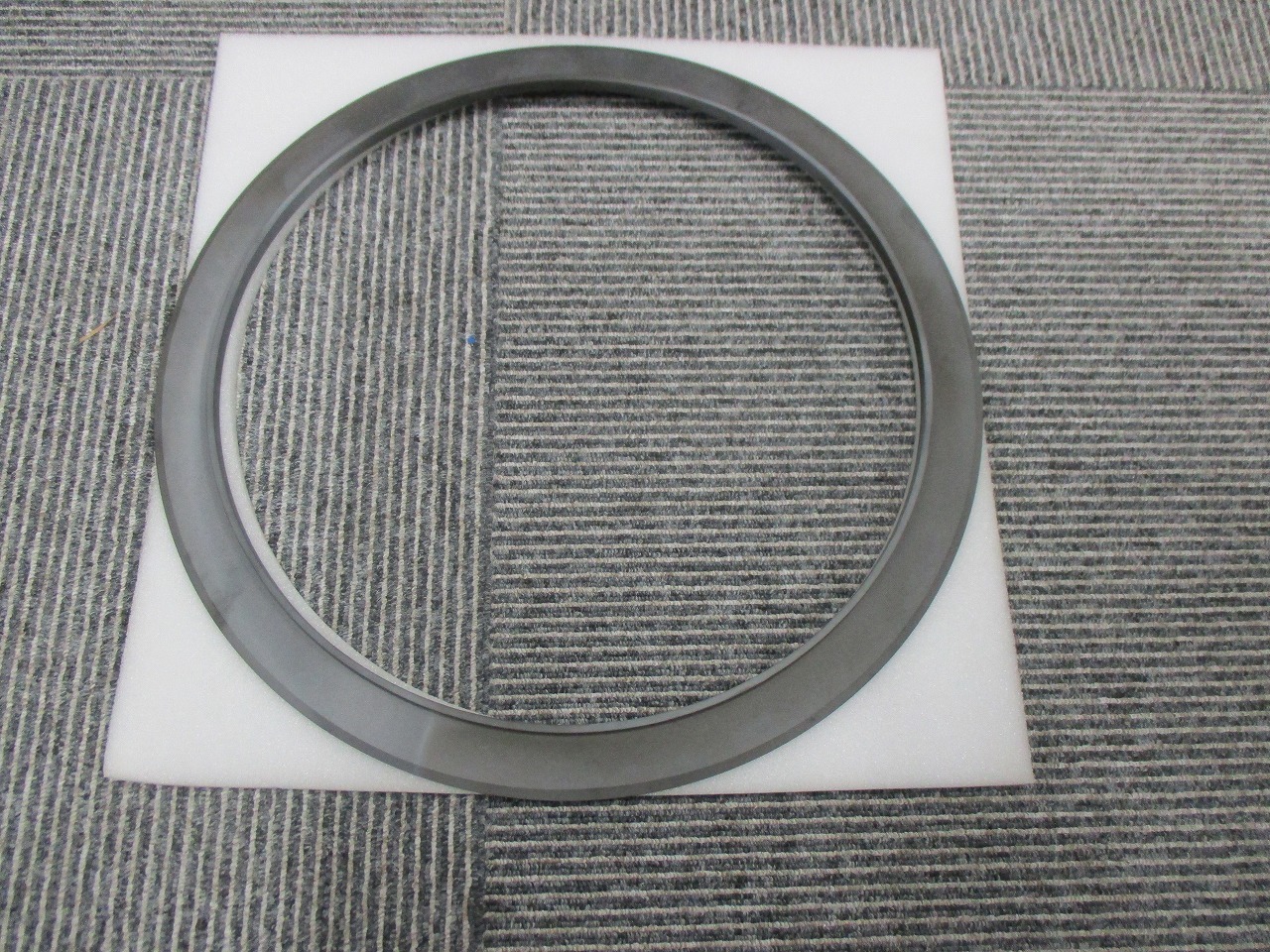

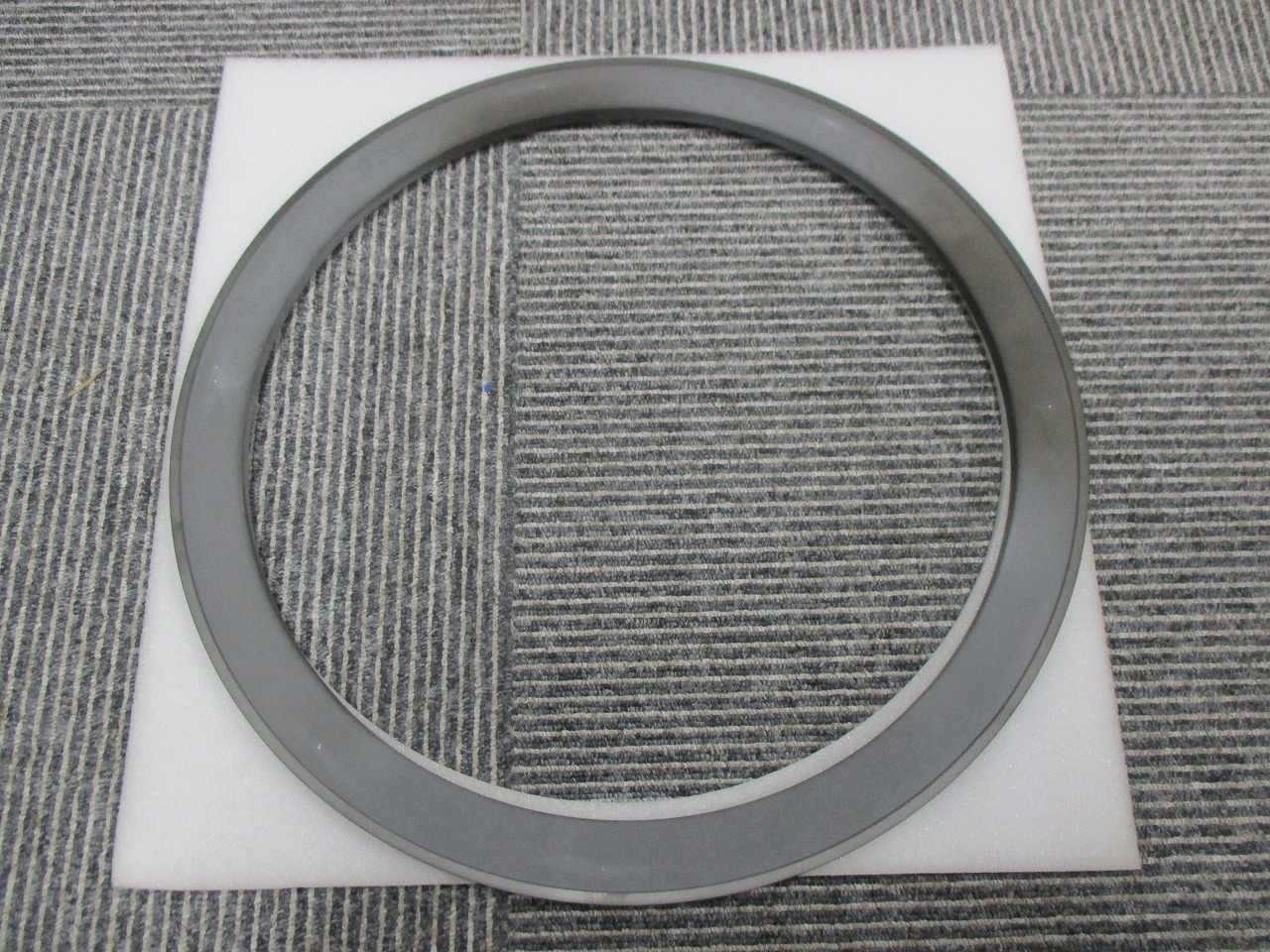

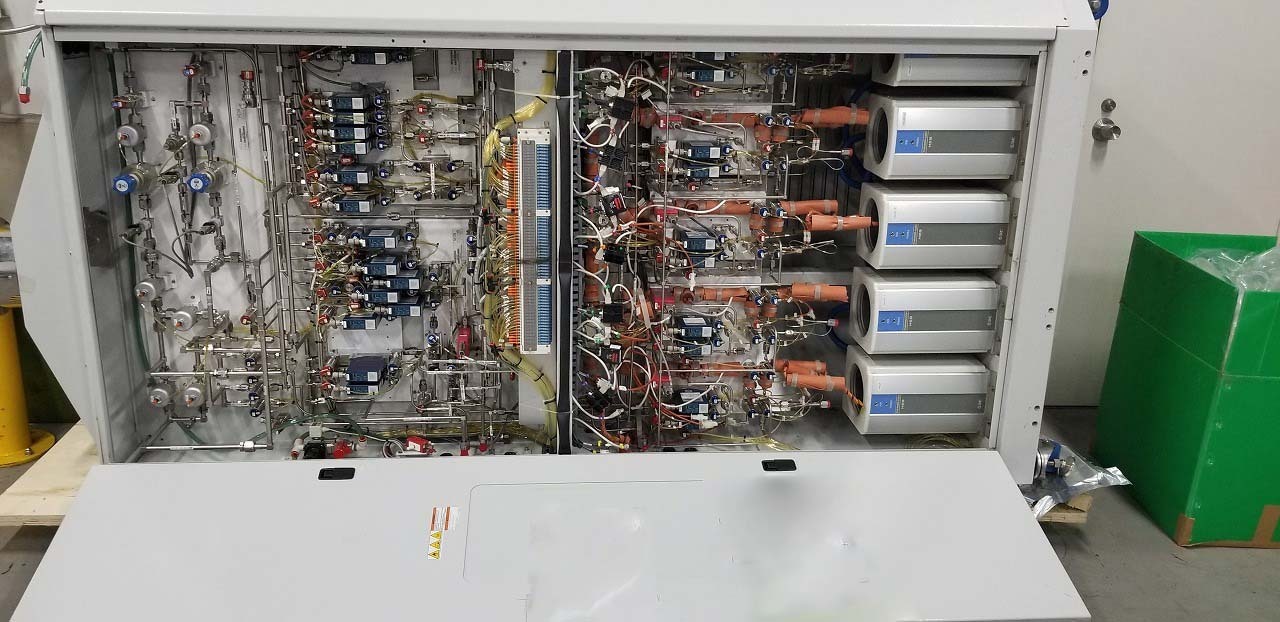

AMAT / APPLIED MATERIALS Centura NLighten NEON reactor is a next-generation, high throughput, epitaxial deposition and etch processing system designed to increase productivity and cost savings while improving uniformity, performance and yield. With a multi-enaable chamber architecture the Centura NLighten features both a heated substrates and a cool substrates with the option of adding a third for additional applications allowing for maximum chamber utilization. It has a temperature uniformity of ±2°C coupled with an etch uniformity of ±2.5%, this helps to provide a better than ever process stability at different temperatures and helps keep yields consistently high. The NLighten utilizes high performance, robust simultaneous deposition and etch modules to provide the highest level of process uniformity, ultimately enhancing yields and device performance. Equipped with a 22-inch or 25-inch wide-angle view and multi-hydrogen gas distribution it can be used for different processing needs with very precise control over deposition and etch processes. Its CVD cluster components also boasts improved process uniformity with a gasoline oxidation liner and a tailored gas distribution method. For high-temperature applications, the reactor provides exceptional performance with a high temperature stability of ±2°C without high-purity nitrogen needed. This also results in cycle times being greatly reduced. AMAT Centura NLighten NEON reactor is designed to make the most of system throughput, with a capability of up to 200 wafers per hour (WPH), making it the perfect tool for high-volume production with exceptionally low-risk of part damage. It also takes up significantly less footprint than its predecessors, with a maximum footprint of 15 sq.m. APPLIED MATERIALS Centura NLighten NEON reactor is an excellent choice for those looking for an efficient, cost-effective and reliable laboratory reactor for etch and deposition needs. With its multipurpose capabilities, high-temperature stability and the ability to handle large batches, the reactor provides the perfect combination of performance and efficiency needed for the most demanding processing applications.

There are no reviews yet